Heavy truck hub shell size detection machine

A heavy-duty truck, testing machine technology, applied in measuring devices, instruments, program control in sequence/logic controllers, etc., can solve the problem of inability to guarantee high output, manual testing, insufficient accuracy to improve product failure rates, and low manual testing efficiency. and other problems, to achieve the effect of great practical value, material saving and flanging avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

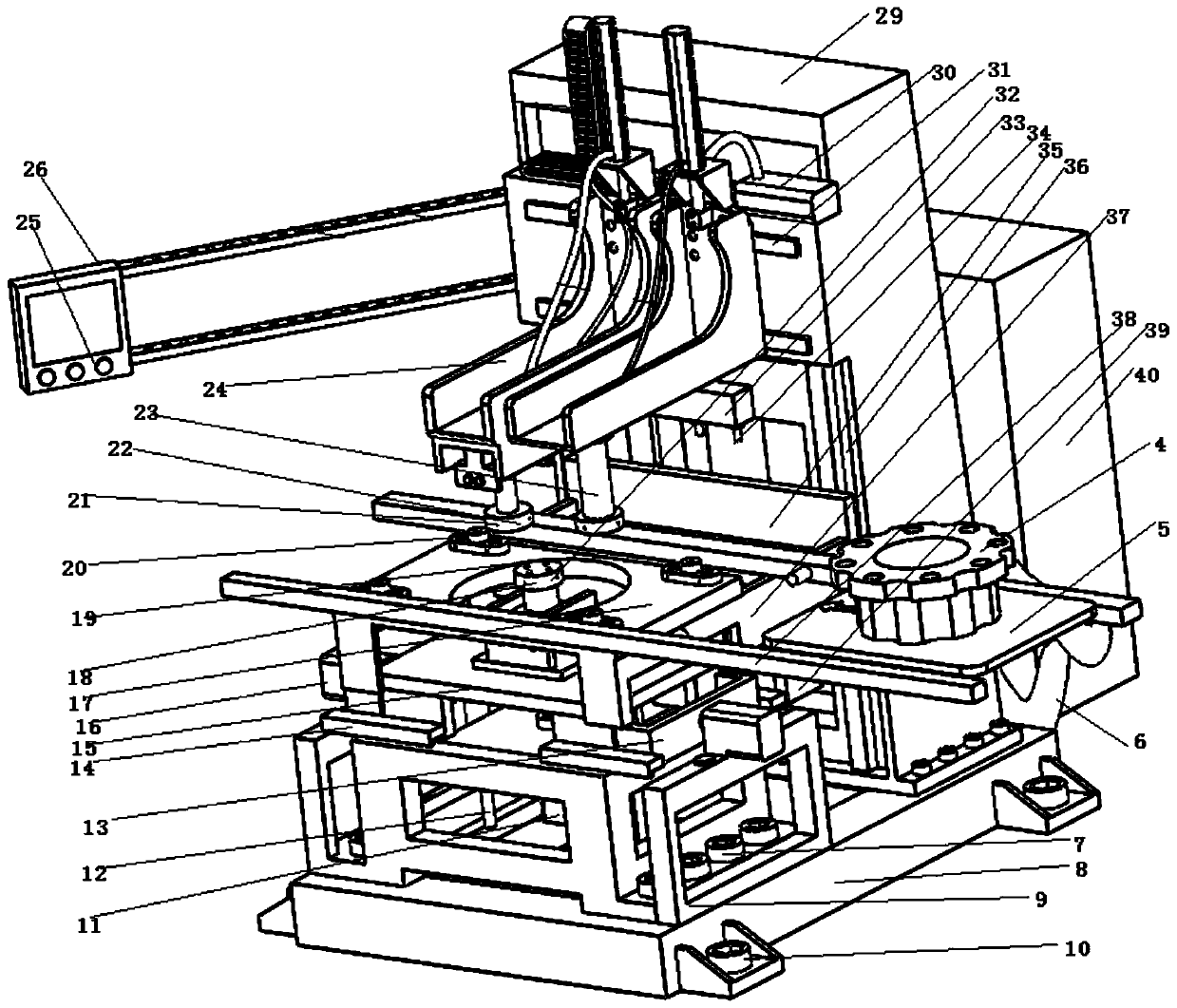

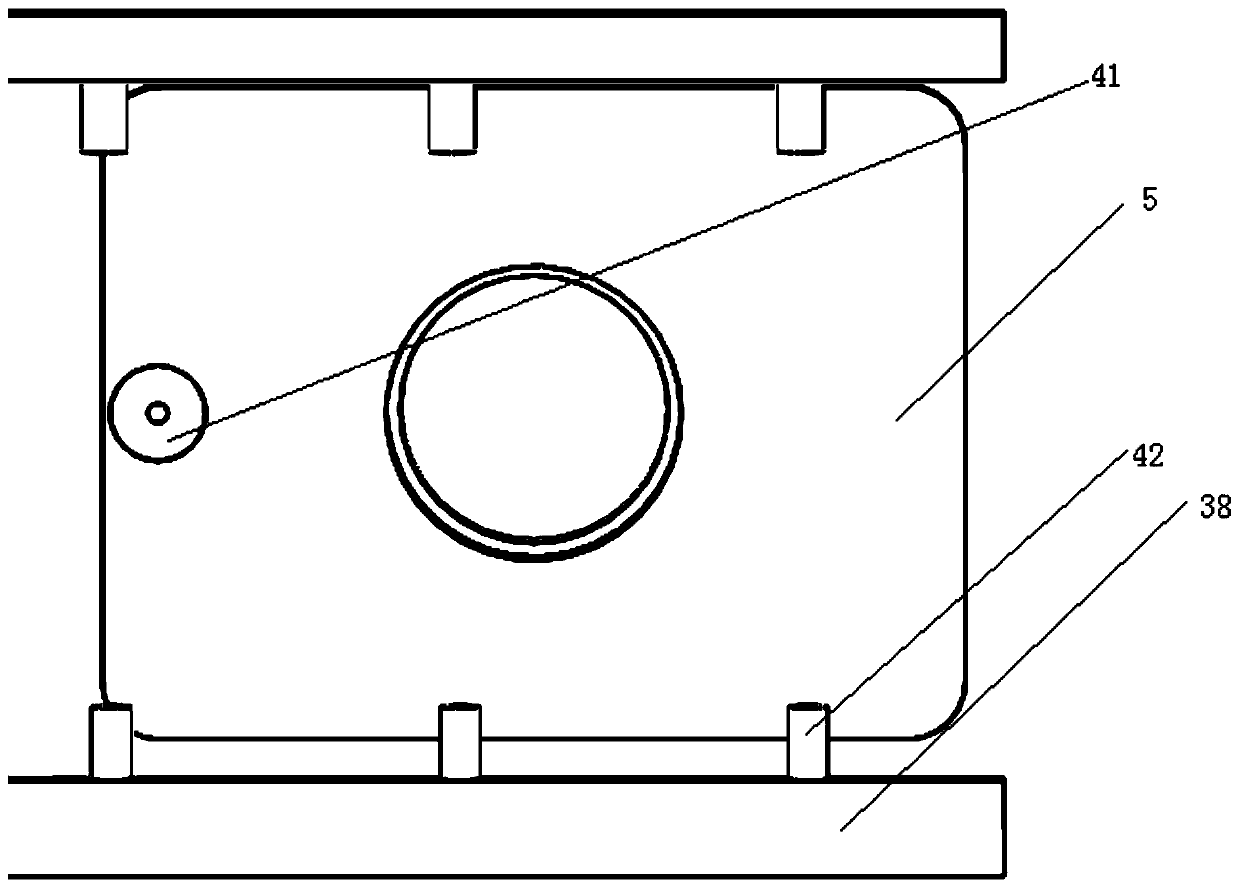

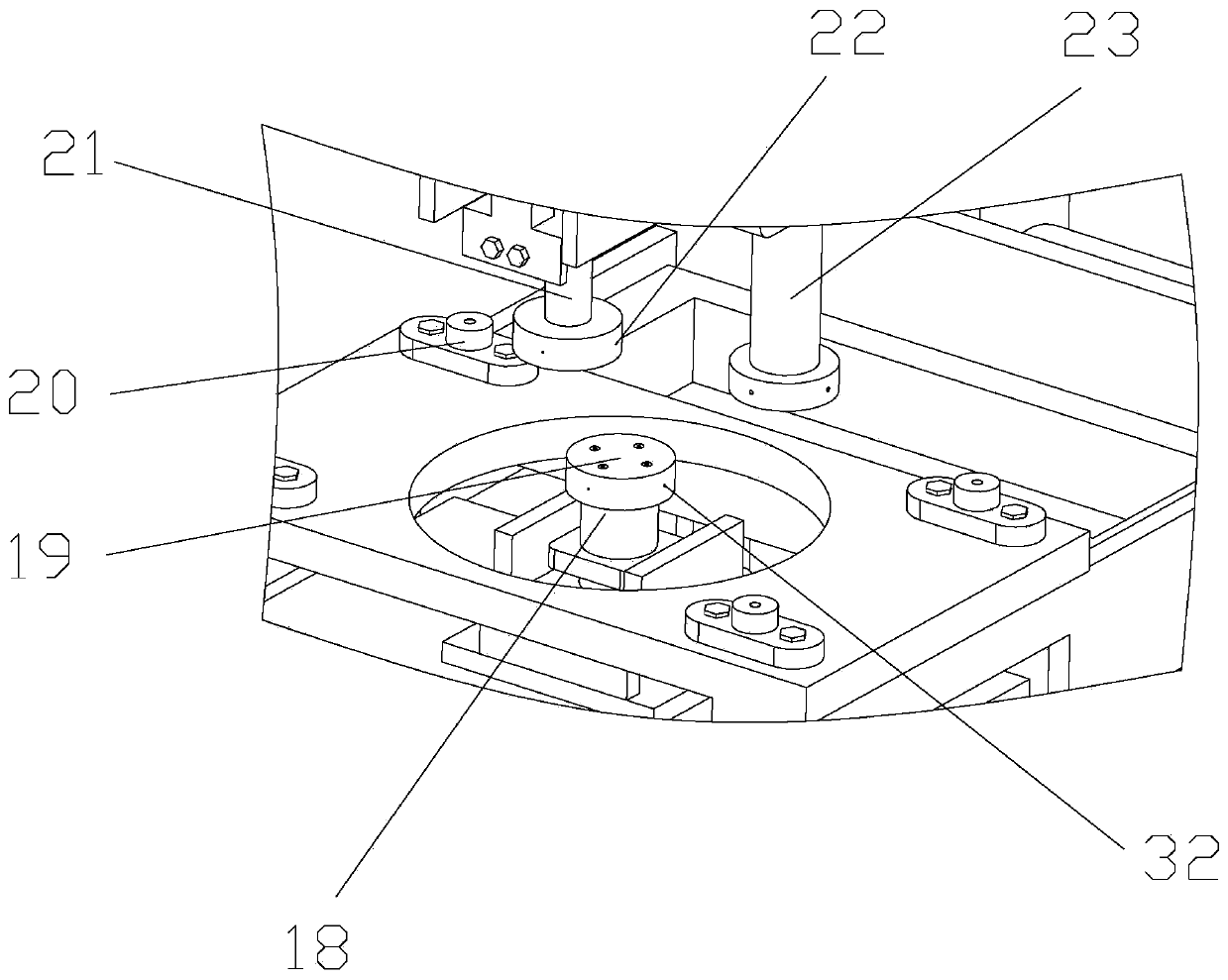

[0025] A heavy-duty truck wheel hub shell size detection machine, as shown in the figure, includes a general equipment frame 8, a workbench frame 9 is arranged on the total equipment frame 8, a workbench master cylinder 11 and a workbench master cylinder 11 are arranged on the workbench frame 9 The total cylinder column 12, the workbench total cylinder 11 and the total cylinder cylinder column 12 are provided with a workbench 15, and the workbench 15 is provided with a lower detection head 18; the total equipment frame 8 is provided with a vertical frame 29, vertical A movable arm mechanism 24 is provided on the frame 29 , and an upper shoulder detection head 21 and an upper detection head 23 are arranged on the movable arm mechanism 24 .

[0026] The upper shoulder detection head 21 is provided with an air tightness detection hole 22 for the upper shoulder detection head, and the lower detection head 18 is provided with an air tightness detection hole 32 for the lower detectio...

Embodiment 2

[0039] A heavy-duty truck wheel hub shell size detection machine, as shown in the figure, includes a general equipment frame 8, a workbench frame 9 is arranged on the total equipment frame 8, a workbench master cylinder 11 and a workbench master cylinder 11 are arranged on the workbench frame 9 The total cylinder column 12, the workbench total cylinder 11 and the total cylinder cylinder column 12 are provided with a workbench 15, and the workbench 15 is provided with a lower detection head 18; the total equipment frame 8 is provided with a vertical frame 29, vertical A movable arm mechanism 24 is provided on the frame 29 , and an upper shoulder detection head 21 and an upper detection head 23 are arranged on the movable arm mechanism 24 .

[0040] On the vertical frame 29, the movable arm mechanism cylinder 30 and the movable arm mechanism slide rail 31, the movable arm mechanism cylinder 30 drives the movable arm mechanism 24 to move on the movable arm mechanism slide rail 31....

Embodiment 3

[0044] A heavy-duty truck wheel hub shell size detection machine, as shown in the figure, includes a general equipment frame 8, a workbench frame 9 is arranged on the total equipment frame 8, a workbench master cylinder 11 and a workbench master cylinder 11 are arranged on the workbench frame 9 The total cylinder column 12, the workbench total cylinder 11 and the total cylinder cylinder column 12 are provided with a workbench 15, and the workbench 15 is provided with a lower detection head 18; the total equipment frame 8 is provided with a vertical frame 29, vertical A movable arm mechanism 24 is provided on the frame 29 , and an upper shoulder detection head 21 and an upper detection head 23 are arranged on the movable arm mechanism 24 .

[0045] The upper shoulder detection head 21 is provided with an air tightness detection hole 22 for the upper shoulder detection head, and the lower detection head 18 is provided with an air tightness detection hole 32 for the lower detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com