Elastic seal ring

An elastic sealing and sealing ring technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as leakage, affecting railway transportation safety, leakage and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above subject of the present invention is limited to the following embodiments.

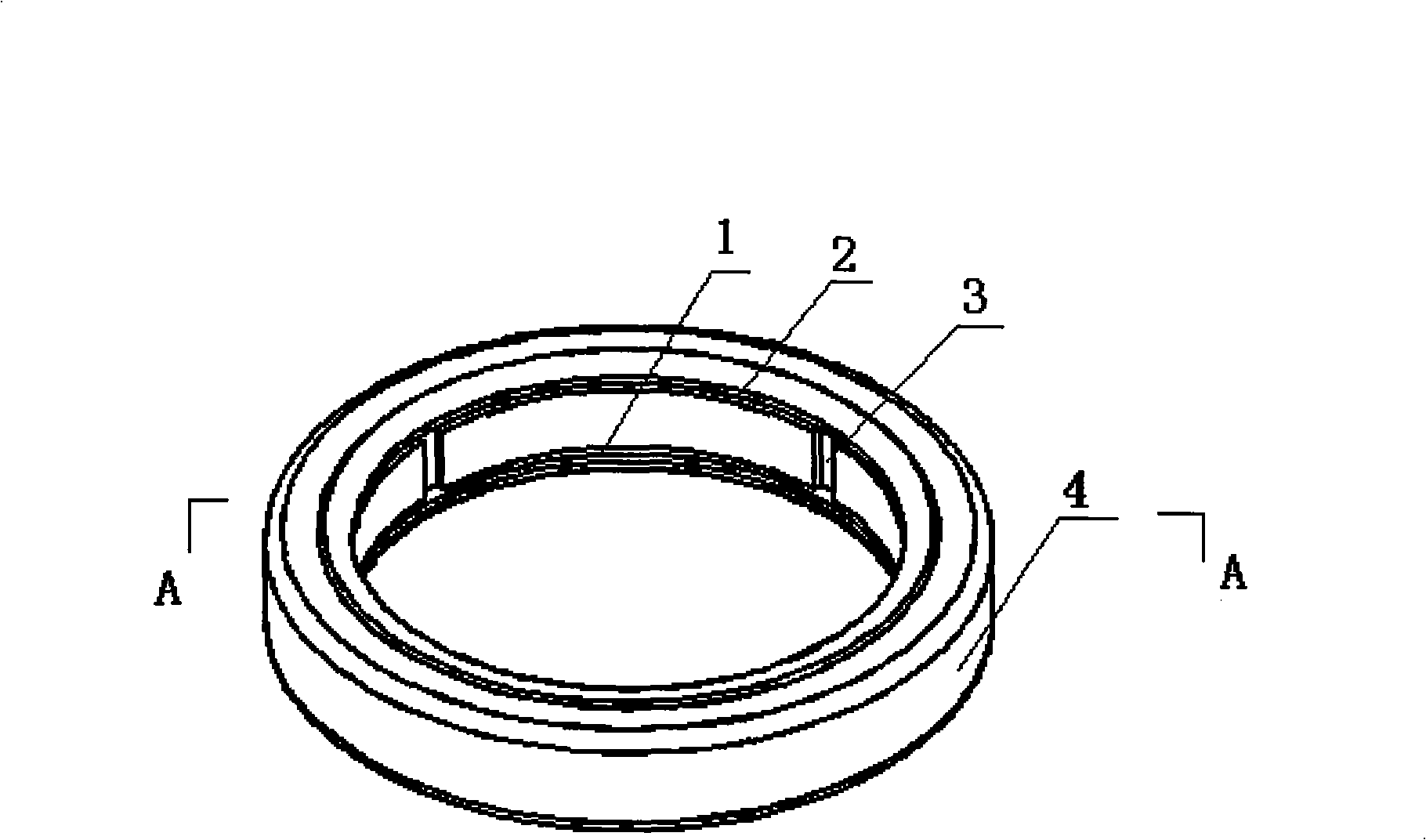

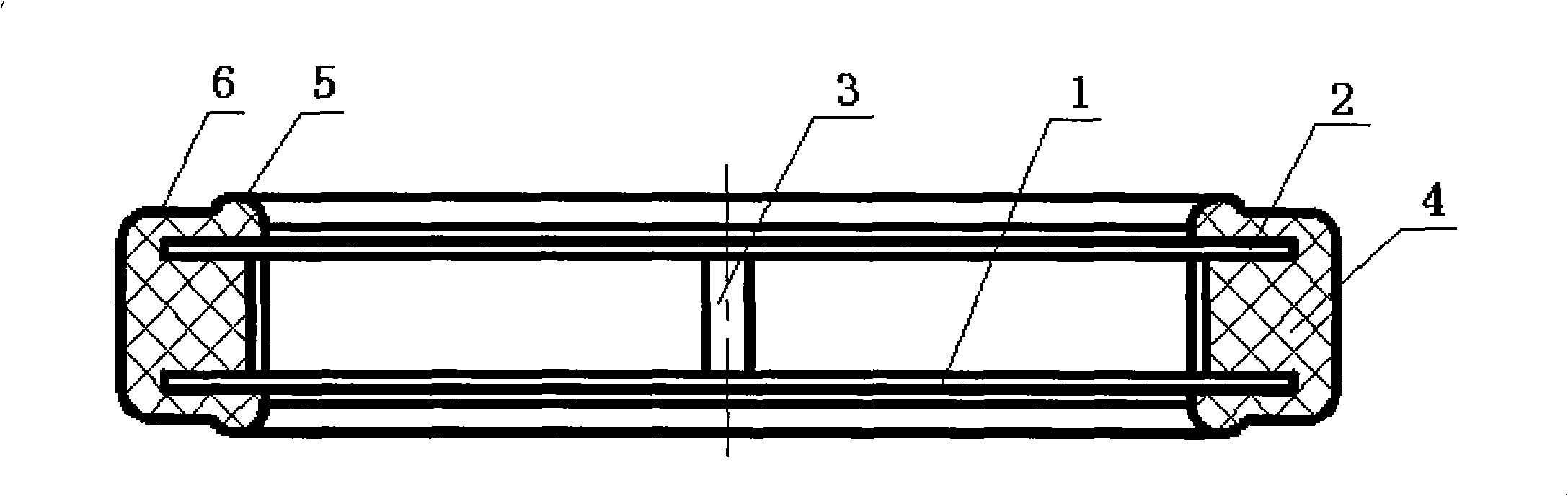

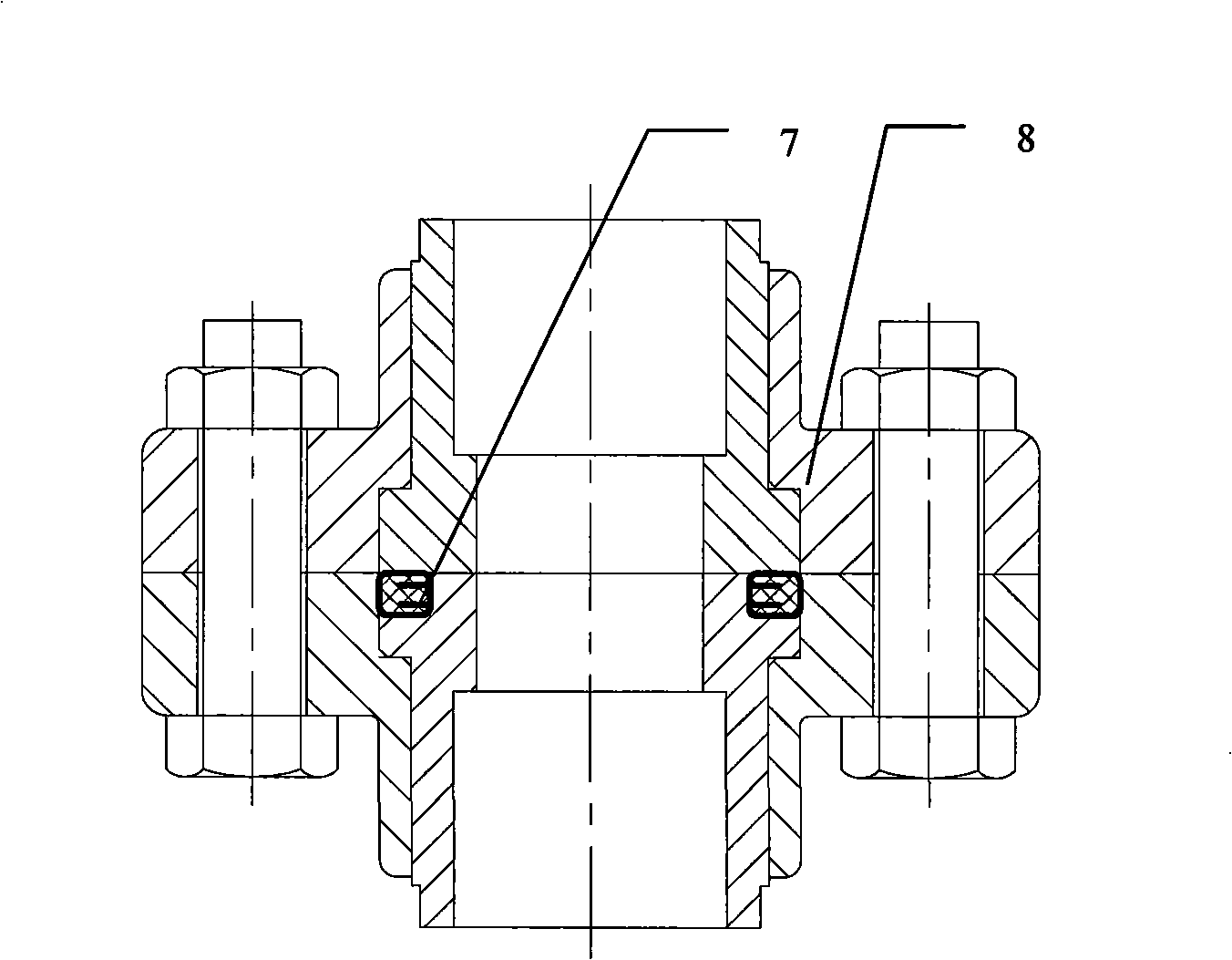

[0022] like figure 1 , 2 As shown: the elastic sealing ring is an O-shaped rubber sealing ring. There is a gap extending along the circumferential direction on the inner ring surface of the sealing ring body 4. The distance between the gap and the outer ring surface of the ring is 1.8mm, and the width is 0.5mm. To ensure sufficient strength of the elastic sealing ring, the gap forms two upper and lower lip-shaped sealing layers (1, 2), and its cross-sectional shape is an "E"-shaped cross-section. The air guide groove 3 provided between the upper and lower gaps will penetrate the upper and lower gaps to ensure that the air entering the upper lip seal layer can enter the lip seal layer at the bottom of the ring body. The size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com