Method for manufacturing InP monolithic microwave integrated circuit

A microwave integrated circuit and indium phosphide single-chip technology, which is applied in the field of indium phosphide materials, can solve problems such as fragmentation and damage in the production process, and achieve the effects of improving the processing yield, no surface scratches, and avoiding corrosion defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

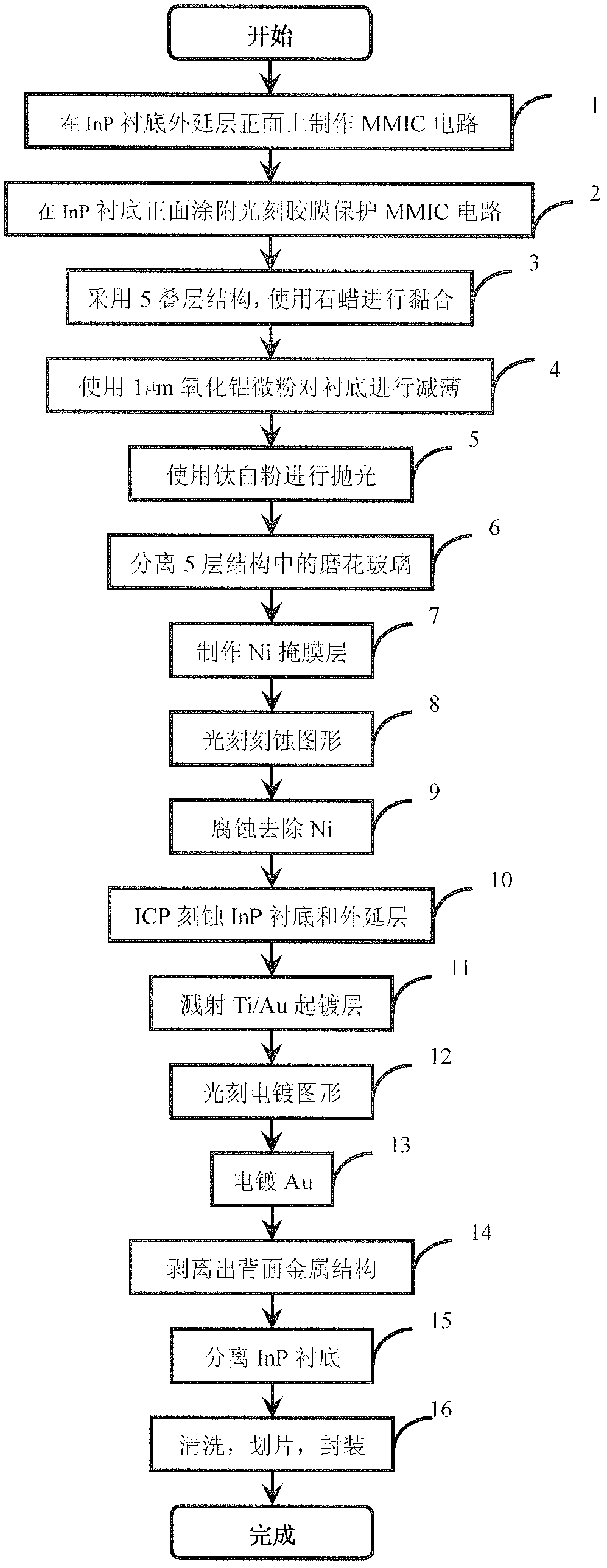

[0039] Such as figure 1 as shown, figure 1 It is a flowchart of a method for making an InP MMIC according to an embodiment of the present invention, including the following steps:

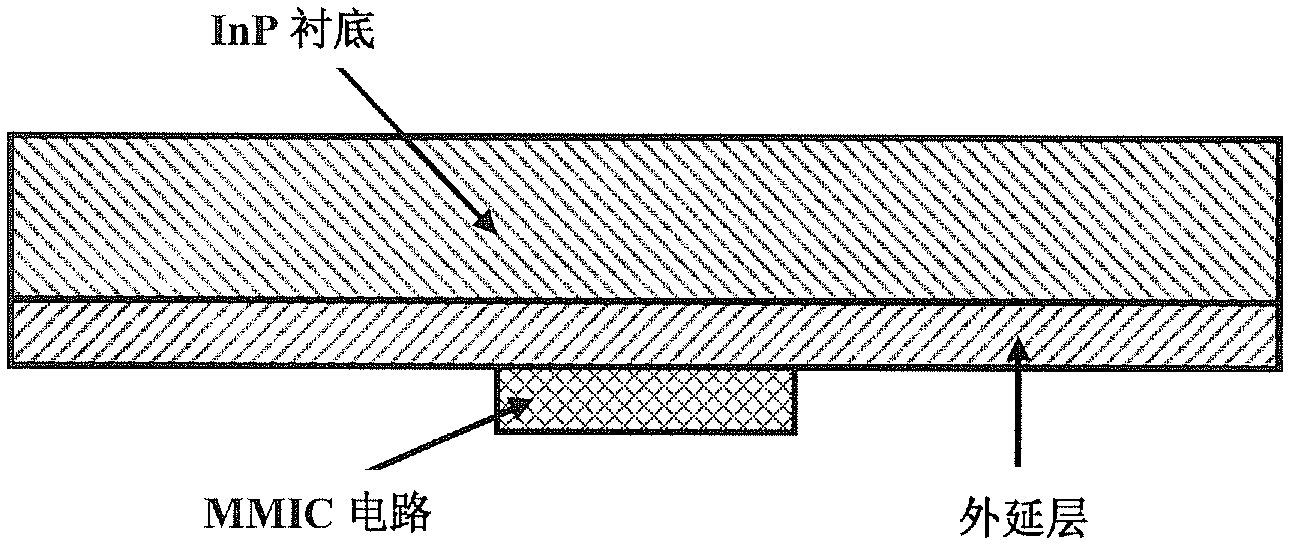

[0040] Step 1: Fabricate MMIC circuits on the epitaxial layer on the front side of the InP substrate, including: front-side die unit structure, wiring, air bridge structure, capacitors, resistance matching networks, etc.

[0041] Step 2: Coating a photoresist layer on the epitaxial layer on the front surface of the InP substrate and the MMIC circuit to protect the MMIC circuit to form an InP substrate.

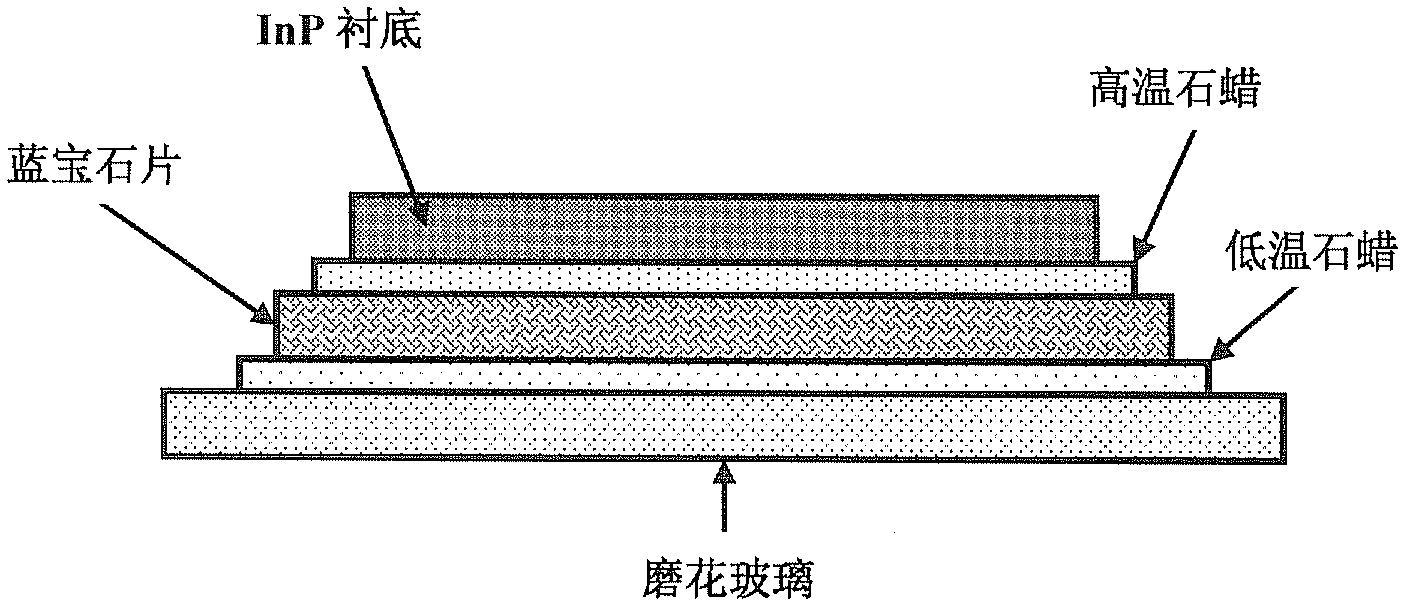

[0042] Step 3: Use paraffins with different melting points and different flexibility to bond the InP substrate, sapphire double-sided polis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Etching depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com