Application and coating method of water-based wood coating on the surface of electric guitar

A wood coating, water-based technology, applied to the surface coating liquid device, special surface, pre-treated surface, etc., can solve the problems of non-environmental protection, high content of organic volatiles, strong odor, etc., to achieve a strong sense of three-dimensional layering, Good adhesion, natural and clear color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

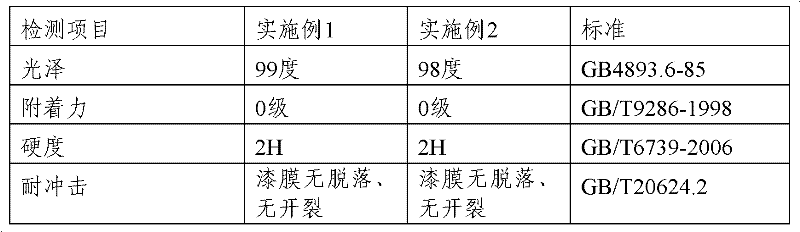

Examples

Embodiment 1

[0039] Example 1: Glossy mahogany effect

[0040] 1. Material selection: choose basswood material with no knots, cracks, clear and beautiful wood grain;

[0041] 2. Material treatment: Use 240# sandpaper to sand along the wood grain of basswood to remove burrs and sand marks on the surface of basswood;

[0042] 3. Material color correction: Add ZW71100 water-based red color essence with water to correct the greenish part of the material to be consistent with other parts;

[0043] 4. Sealing primer: adjust the ZW40266 water-based clear primer with water to a viscosity of 11 seconds, spray a "ten" evenly, and dry for 2 hours;

[0044] 5. Sanding: Use 320# sandpaper to sand along the wood grain, remove burrs, and do not sand through;

[0045] 6. Bottom coloring: add the prepared water-based mahogany color essence to ZW72000 water-based wood bottom coloring base material, stir evenly, wipe it evenly, then wipe it clean, and dry it for 1.5 hours to highlight the wood grain textur...

Embodiment 2

[0056] Example 2: Bright olive green transparent color effect

[0057] 1. Material selection: choose maple wood material without scars, cracks, and clear and beautiful wood grain;

[0058] 2. Material processing: Use 240# sandpaper to sand along the maple wood grain to remove surface burrs and sand marks on the maple material;

[0059] 3. Material color correction: Add ZW71500 water-based green color essence with water to correct the reddish part of the material to be consistent with other parts;

[0060] 4. Sealing primer: adjust the ZW40266 water-based clear primer with water to a viscosity of 10 seconds, spray a "ten" evenly, and dry for 1.5 hours;

[0061] 5. Sanding: Use 400# sandpaper to sand along the wood grain, remove burrs, and do not sand through;

[0062] 6. Bottom coloring: Add the prepared water-based olive green essence into the ZW72000 water-based wood bottom coloring base material, stir evenly, wipe it evenly, then wipe it clean, and dry it for 1.0 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com