Patents

Literature

30results about How to "Strong sense of three-dimensional layering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

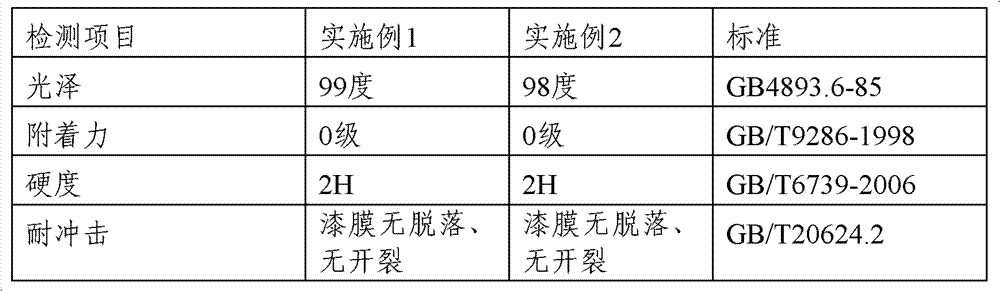

Application and coating method of water-based wood coating on the surface of electric guitar

ActiveCN102266845AAltered high volatile organic contentChange the smell bigPretreated surfacesSpecial surfacesWater basedElectric guitar

The invention relates to application of an aqueous wood coating to the surface of an electric guitar and a coating method thereof. Polyurethane modified acrylic resin, the hardness of which is required to reach the hardness H or scratch of a Chung Hwa pencil, is taken as the principal film-forming substance. The hardness of the aqueous wood coating is required to reach the hardness H of the Chung Hwa pencil. The coating method provided by the invention can be used for acquiring a film-coating effect with excellent fullness, high hardness and excellent mirror surface effect. An aqueous wood coating system is adopted in the invention and the defects of a solvent based coating that the content of organic volatile matter is high, the odor is thick and the environment is polluted are avoided, thereby meeting the demands of customers to a musical instrument for safety, environmental protection and nature.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

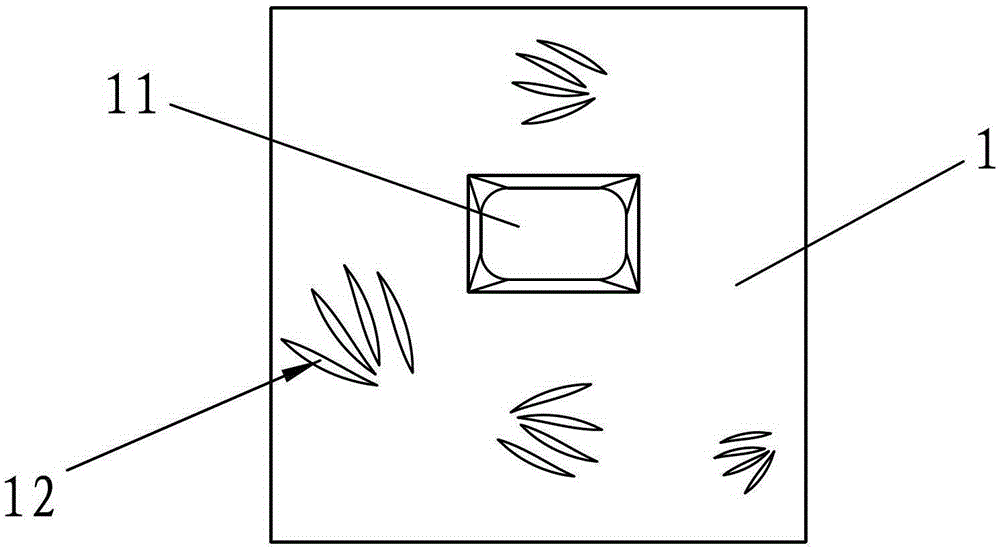

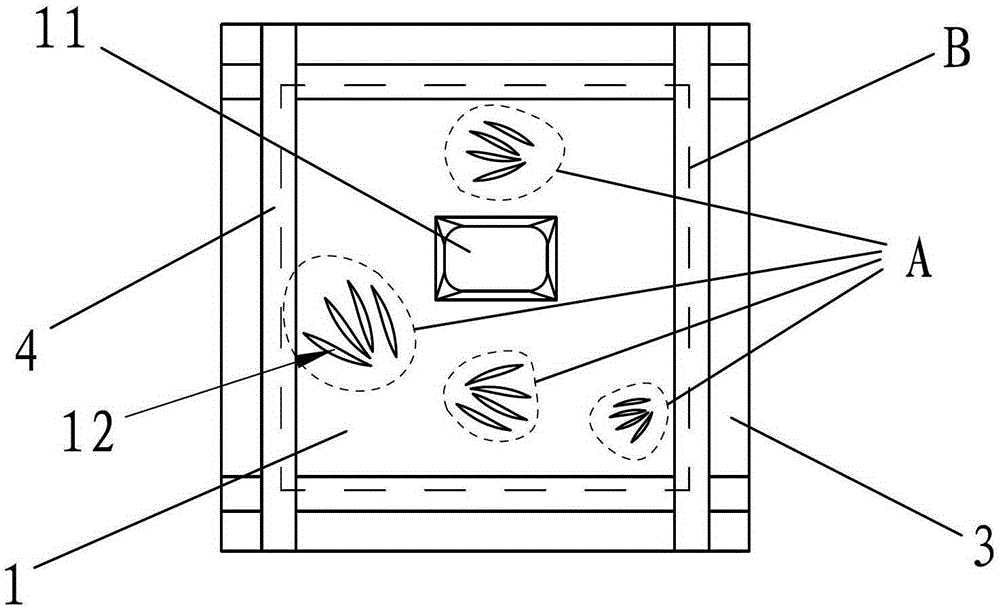

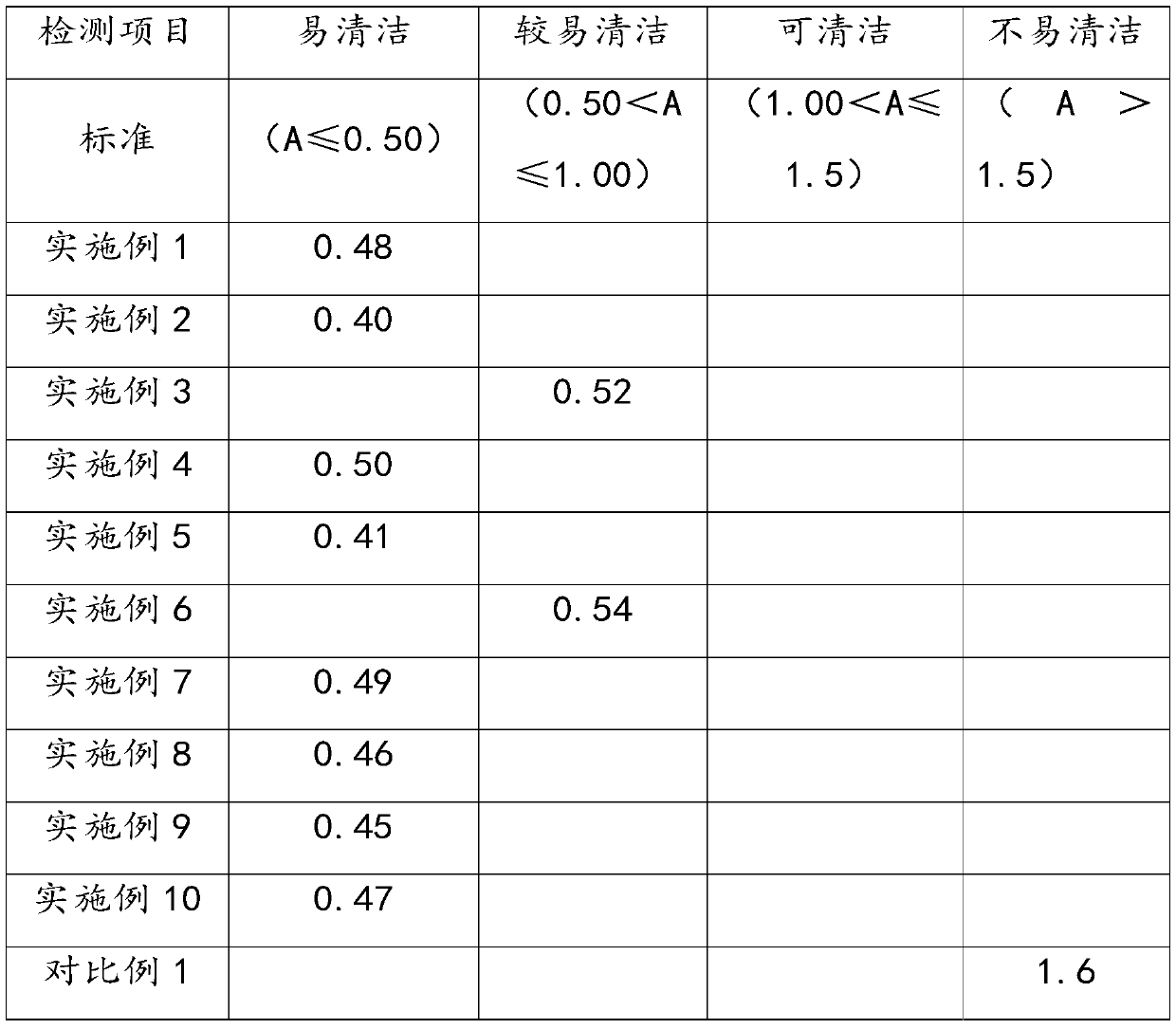

Easily cleaned ceramic tile

ActiveCN107285812AExcellent stain resistance and easy cleaningGood pollution resistanceBrickContamination

The invention belongs to the technical field of ceramic, and relates to an easily cleaned ceramic tile. The provided ceramic tile comprises a blank layer, a cover glaze layer, a printed layer, and an easily cleaned protective dry particle layer. The easily cleaned protective dry particle layer is formed by paving easily cleaned protective glaze, which comprises the following components in parts by weight: 90 to 110 parts of easily cleaned protective particles, 230 to 270 parts of stamp-pad ink, and 20 to 40 parts of transparent glaze. The provided ceramic tile has the advantages that the ceramic tile can be cleaned easily, has a good performance on resisting contamination, can be easily maintained and managed every day, and solves the problems that dirt is easily hidden in conventional tiles and the conventional tiles are difficult to clean.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

Granulated ceramic and production technology thereof

The invention discloses granulated ceramic and a production technology thereof. The granulated ceramic is characterized by comprising the following formula compositions in percentage by weight: 30%-75% of SiO2, 1%-20% of CaO, 0-17% of MgO, 1%-21% of Al2O, 1%-7% of Na2O+K2O, 0%-6% of B2O3, 0%-10% of BaO, 0%-7% of ZnO, 0%-5% of Sb2O3, 0%-2% of Cl, 0%-10% of F, 0%-10% of P2O5 and 0-10% of ZrO2, and a coloring material is added as required. The production technology comprises the following steps: firstly, laying a layer of blocky (flaky) glass blocks made of special compositions, or crude glass granules with mesh of more than 2 on a ceramic blank or a die, sintering and polishing. The prepared granulated ceramic bricks or glass ceramic crystals are strong in three-dimensional layering of color, and glittering and translucent.

Owner:冯翠兰

Preparation method of easy cleaning ceramic tile

ActiveCN107382377AGood pollution resistanceEasy to cleanDecorative surface effectsNanotechnologyCeramic tiles

Belonging to the technical field of ceramics, the invention relates to a preparation method of an easy cleaning ceramic tile. The preparation method of the easy cleaning ceramic tile comprises the steps of: (a) preparing a blank layer; (b) applying overglaze on the blank layer to form an overglaze layer; (c) conducting printing on the overglaze layer to form a printing layer; and (d) applying easy cleaning protective glaze on the printing layer to form an easy cleaning protective dry granular layer. The easy cleaning protective glaze comprises the following components by mass: 90-110 parts of easy cleaning protective glaze, 230-270 parts of stamp-pad ink, and 20-40 parts of transparent glaze. The preparation method provided by the invention has the advantages of simple operation, easy implementation and low cost. The ceramic tile prepared by the method has excellent antifouling and easy cleaning properties, i.e. good antifouling performance and easy cleaning.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

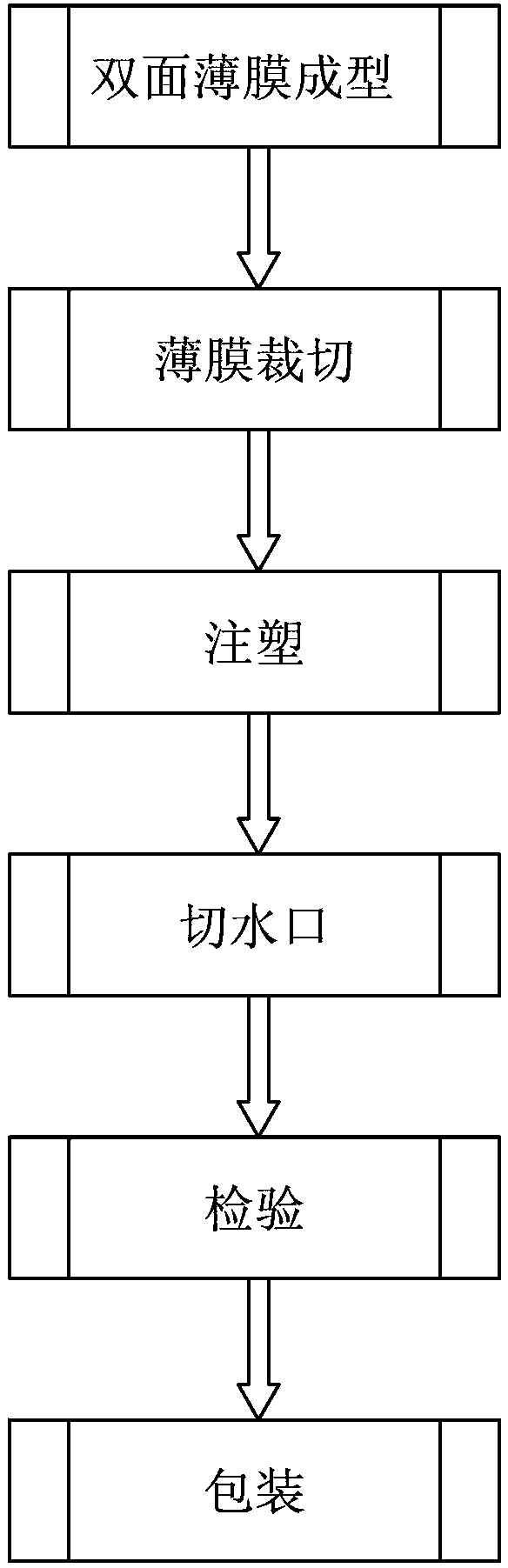

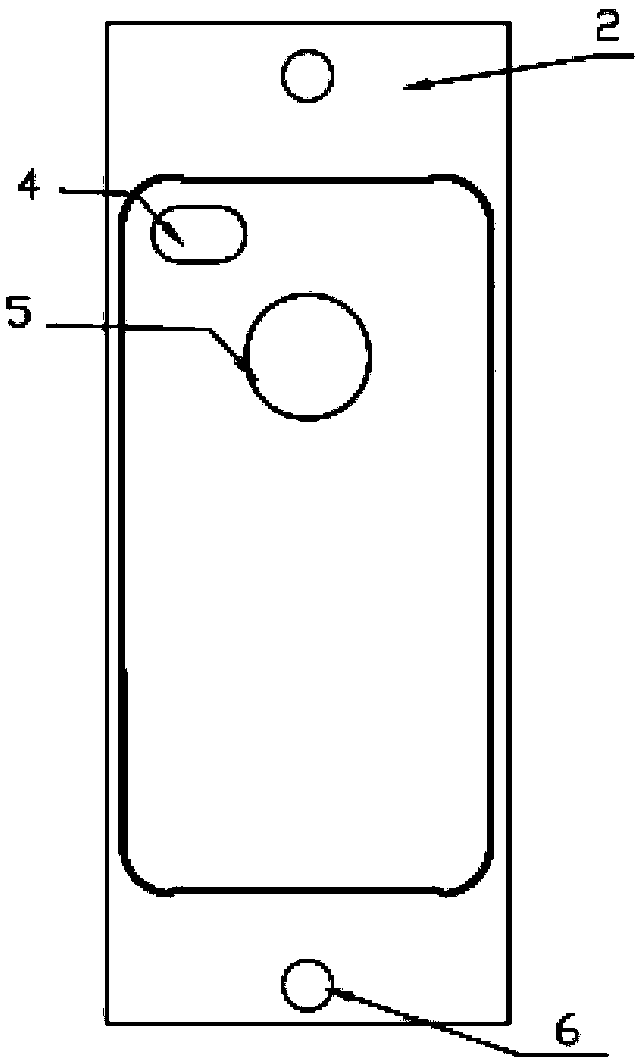

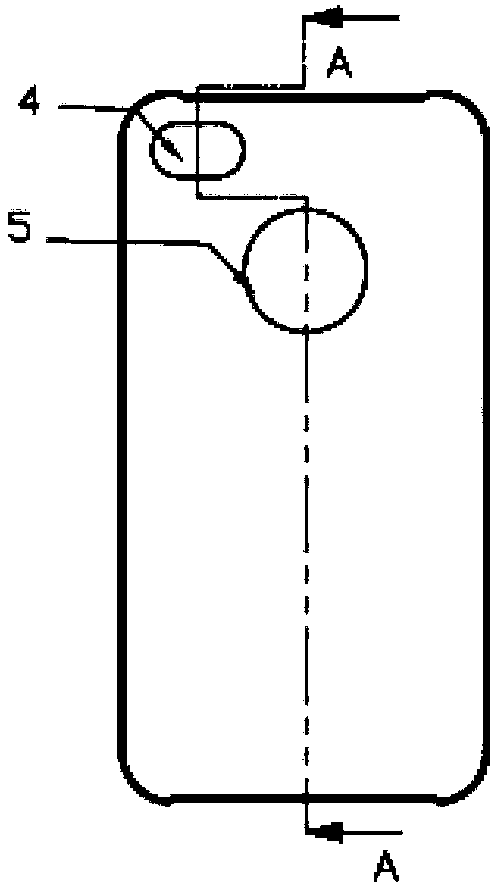

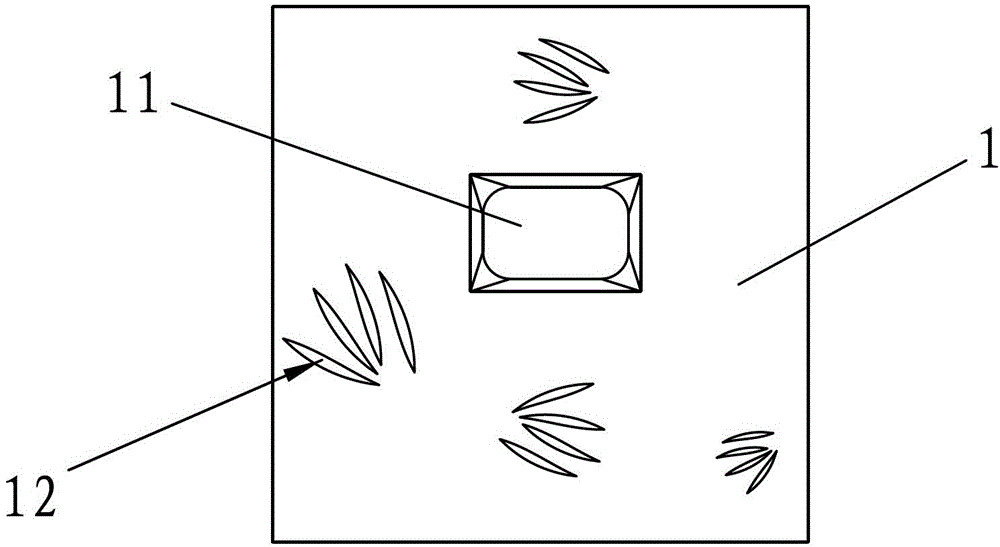

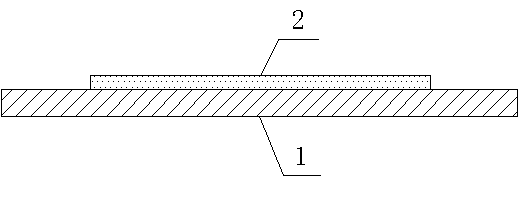

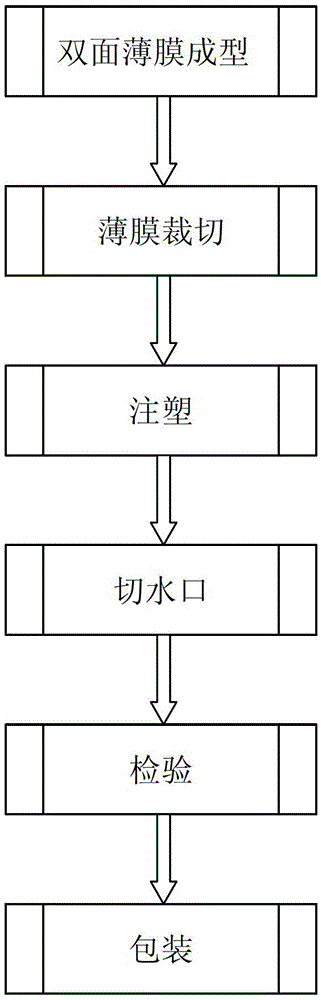

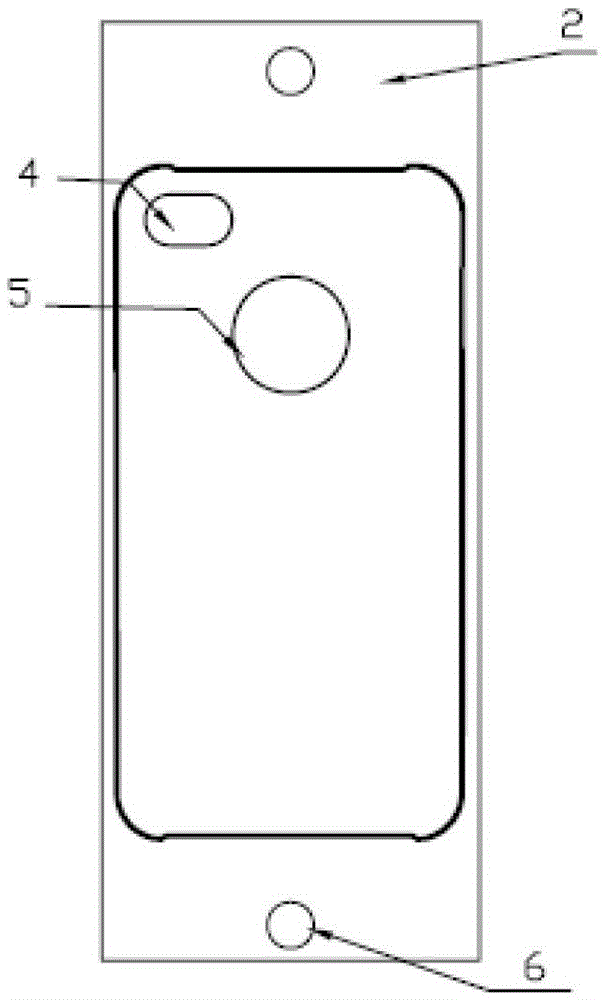

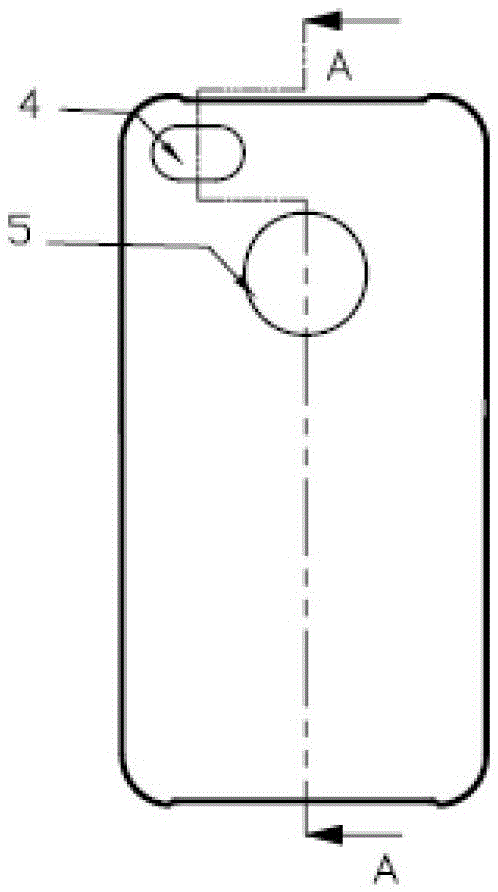

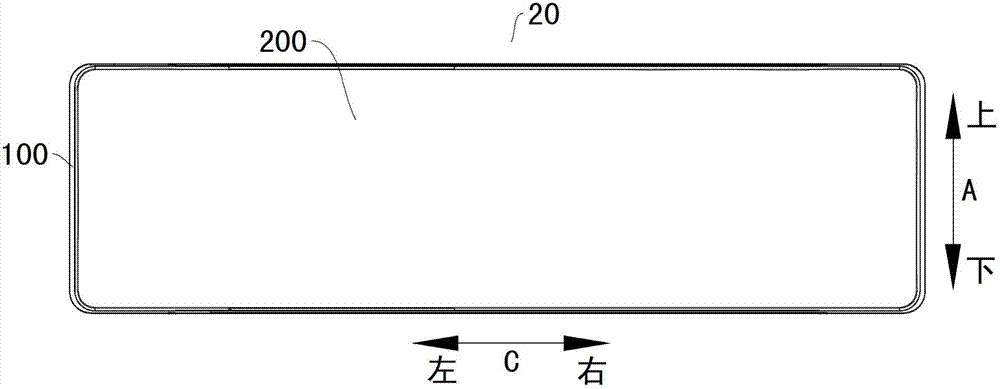

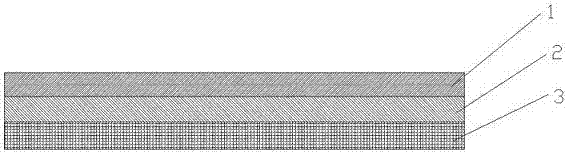

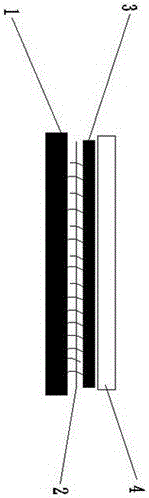

Double-surface die inner injection moulding product and production method thereof

ActiveCN104339600AReduce the difficulty of productionImprove yieldOther printing apparatusTelephone set constructionsColor printingEngineering plastic

The invention relates to a double-surface die inner injection moulding product and a production method thereof. The production method comprises the following steps: employing four-color printing to obtain a right side film (2) and employing Keshi color printing to obtain a back side film (3), forming a required shape through film moulding and cutting, respectively placing the right side film (2) and the back side film (3) in an injection moulding transparent engineering material (1) corresponding to an injection mould, performing nozzle cutting on an injection member after moulding, examining and packaging to obtain the right side film (2) and the back side film (3), and the transparent engineering plastics product capable of performing injection moulding of the right side film (2) and the back side film (3). The production method has the beneficial effect that pattern three-dimensional layering is stronger, no warping is generated on the products, the adhesive force between the film and the transparent plastic is large; product yield rate is increased by 20%, product deformation degree is decreased by 50%; and the production efficiency is increased.

Owner:QUNDA PLASTIC ELECTRONICS SHENZHEN

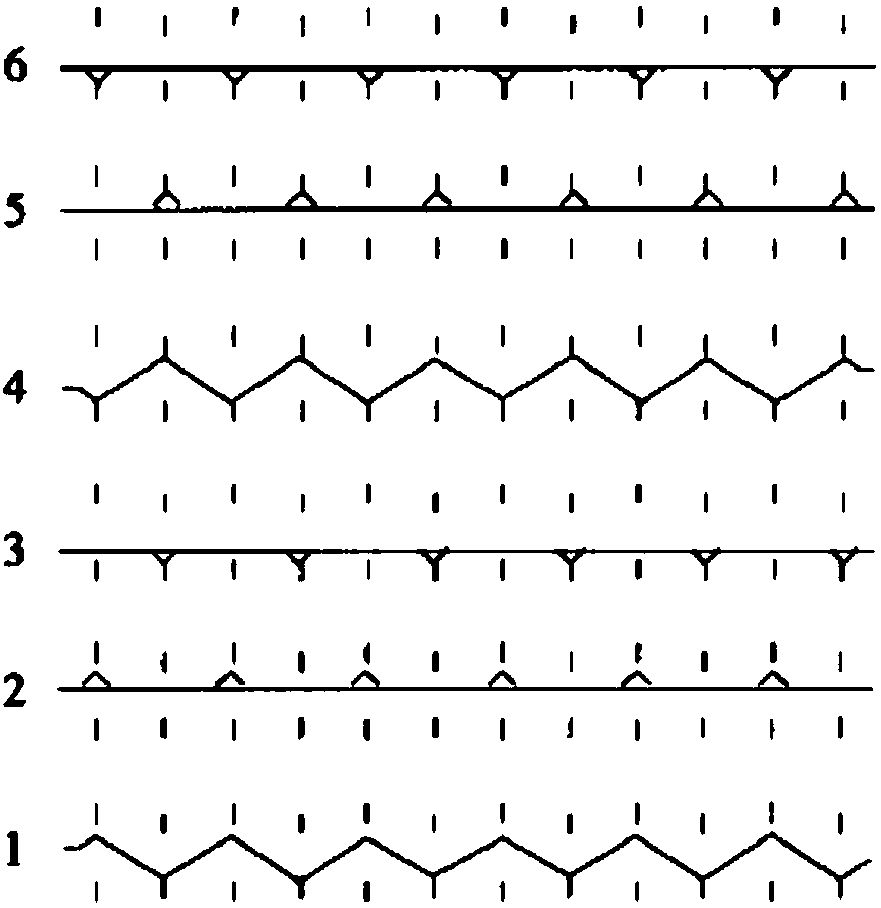

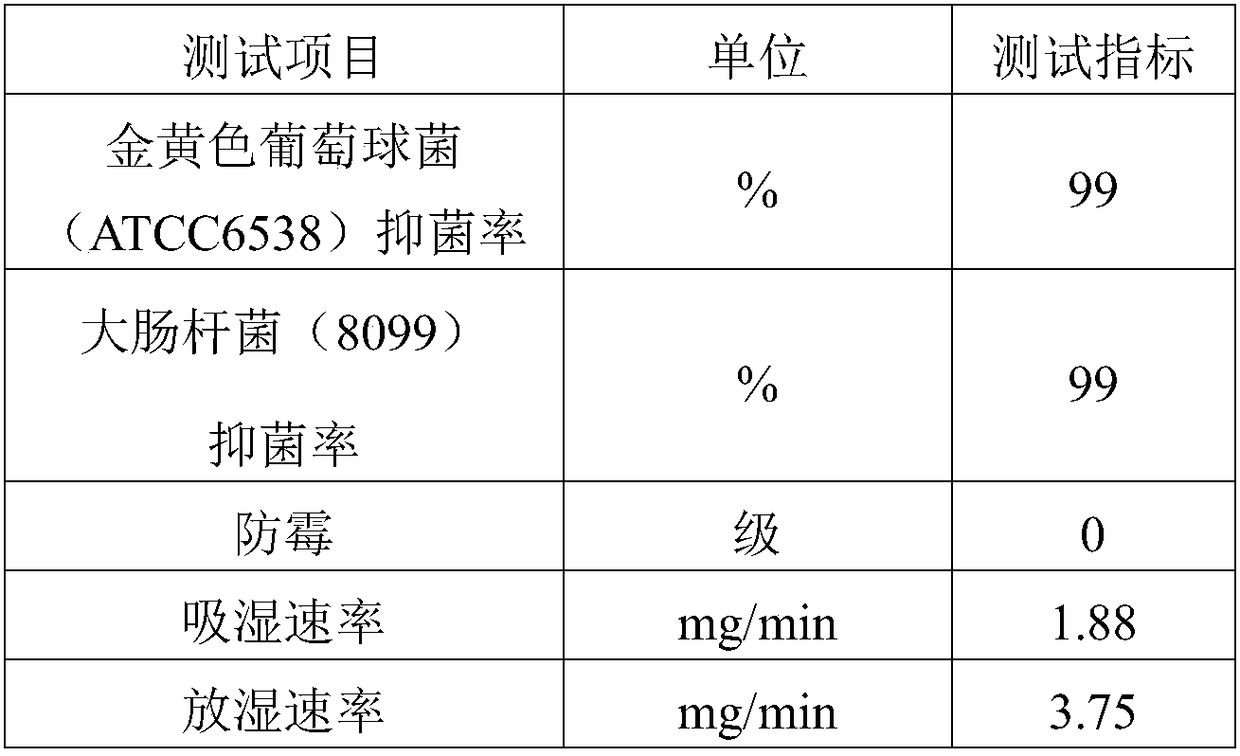

Production method for linen-cotton slubbed sofa fabric

InactiveCN104562375AStatic freeFast moisture absorption and heat dissipationWoven fabricsYarnFiberMoisture absorption

The invention relates to the technical field of textile fabrics, in particular to a production method for a linen-cotton slubbed sofa fabric. According to the production method, due to the addition of natural linen fibers, the fabric is cool, air-permeable, antistatic, high in moisture absorption and radiation speed, soft and comfortable, and does not stick to the skin; the linen fibers have the effect of inhibiting the growth of bacteria, and are lethal to insects, so that human skin can be effectively prevented from being damaged by bacteria and mites; the fabric produced by the method is produced by interweaving high-strength warp and weft twines, so that the fabric is high in strength and wear resistance; a plain structure production mode is adopted, so that warp and weft yarns can be most closely intertwined, most firm texture and most appearance flatness of the fabric are achieved, and the strength and the wear resistance of the fabric are further enhanced; slubbed twines with extremely high thickness contrast are adopted as the weft yarns, so that the fabric is highly layered, and unique visual effects and texture effects are achieved.

Owner:HUNAN GUANGYUAN HEMP IND CO LTD

Environment-friendly comfortable bamboo fiber fabric

InactiveCN110760976AFeel goodSoft and smoothWet spinning methodsWoven fabricsPolymer scienceSpinning

The invention relates to the technical field of clothes fabrics and discloses an environment-friendly comfortable bamboo fiber fabric. The environment-friendly comfortable bamboo fiber fabric is madefrom warps and wefts by interweaving and is characterized in that polyester filament yarns serve as the warps, and bamboo pulp fibers serve as the wefts and are made by compounding bamboo pulp and sodium alginate base solution through wet spinning. The fabric is great in hand feeling, and due to adding of the polyester fibers, elasticity of the fabric is greatly improved, and softness and smoothness in hand feeling are improved.

Owner:安徽竞秀纺织有限公司

Three-dimensional and multi-directional hemp fiber blended fabric

The invention discloses three-dimensional and multi-directional hemp fiber blended fabric. The three-dimensional and multi-directional hemp fiber blended fabric is prepared from weft yarn, vertical yarn and warp yarn by multi-directional weaving, wherein the weft yarn is blended yarn prepared from hemp fiber and at least one of cotton fiber, polyester fiber, polyamide fabric and viscose fiber; thevertical fiber is polyester monofilament, nylon monofilament or multifilament; the warp yarn is synthetic filament yarn or blended composite yarn of the synthetic filament yarn and staple hemp fiber.The three-dimensional and multi-directional hemp fiber blended fabric not only has silk luster and good crease resistance, but also has the characteristics of being antibacterial, deodorant, breathable, moisture-absorbent, quick-drying and the like and is high in three-dimensional layering sense.

Owner:中国人民解放军62023部队 +2

Single-width positioned silk patterned fabric and production method thereof

ActiveCN108085842AStrong sense of three-dimensional layeringIncrease added valueSwivel-woven fabricsLappet-woven fabricsEngineeringDesign pattern

The invention discloses single-width positioned silk patterned fabric which is 150 cm in pattern width and 220-240 cm in pattern height; fine brushwork rose flowers are a main material for patterns; the fabric is interwoven of Tencel and silk. A production method comprises the steps: designing pattern and specification of the fabric, designing a pattern weaving process, drafting with a jacquard machine, weaving, and dyeing and finishing the fabric. The single-width positioned silk patterned fabric herein has different colors on warps and wefts; flowers on 'single pattern' fabric cover are highly stereoscopic and vivid, great fashion is presented, the situation that traditional fabric cover presents various flower patterns is fully broken through, and great visual impact is created. The single-width positioned silk patterned fabric has high added value, may be made into high-grade wedding beddings and has a promising market prospect.

Owner:JIANGSU YUEDA HOME TEXTILE

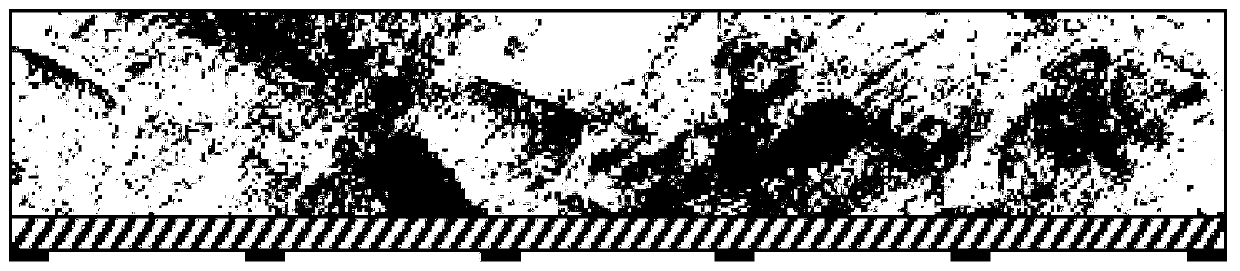

Flaky frit microcrystallite glass ceramic composite plate and preparation method thereof

The invention discloses a flaky frit microcrystallite glass ceramic composite plate and a preparation method thereof. The preparation method comprises the following steps: distributing materials, namely, distributing not less than two layers of frits having different shapes on green brick and spraying a fixing agent for fixation, wherein at least one layer of frits is formed by irregular flaky frits; sintering; and polishing. The flaky frits are introduced to a colored microcrystallite glass decoration layer, tape casting is generated when the flaky frit is fused, control of sintering temperature and other process control are further combined, and thus the defects that particle border cannot be broken through when the particle frit glass crystallizes, pattern is single, change is less and layering is bad are overcome, and the obtained product is peculiar in figure, daedal in color effect, cloud-covered, strong in three-dimensional layering and lifelike in stone texture.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +3

Production method for microcrystalline-glass large crystallization stone

A disclosed production method for microcrystalline-glass large crystallization stone is characterized by comprising spreading a plurality of glass blocks or sheets or distributing in a layered manner, then putting in a crystallization kiln for crystallization, and sintering and polishing. The prepared microcrystalline-glass crystallization stone is extremely strong in pattern stereo hierarchy sense, and is glittering and translucent.

Owner:廖为民

Three-dimensional oil painting and method and assembly for making same

InactiveCN102975561AStrong sense of three-dimensional layeringLow costDecorative surface effectsSpecial ornamental structuresPigmentPetroleum engineering

The invention provides a three-dimensional oil painting and a method and assembly for making the same, belonging to the technical field of decorative paintings and solving the problems that the conventional oil painting is low in three-dimensional sense and is difficult to draw. The assembly used for making the three-dimensional oil painting comprises a base, blank bodies, an oil painting pen and pigments, wherein the blank bodies are classified into two types, namely a bottom layer blank body and a three-dimensional blank body. The method for making the three-dimensional oil painting comprises the following steps of: (1) fixing the bottom layer blank body, namely fixing the bottom layer blank body on the base; (2) drawing patterns, namely respectively drawing patterns on the bottom layer blank body and the three-dimensional blank body with the oil painting pen by using special techniques with different pigment coverage rates; and (3) sticking the three-dimensional blank body drawn in the step (2) at the corresponding part of the bottom layer blank body. The manufactured three-dimensional oil painting is high in layering feeling, is vivid and is low in cost and has high enjoyment value and good decorative effect; the drawing process is simple and is easy to learn; the possibility of do it yourself (DIY) oil paintings is guaranteed; and the market prospect is wide.

Owner:金圣

A kind of preparation method of three-dimensional antique oil painting

InactiveCN102275456AStrong three-dimensional senseFashionable and diverseDecorative surface effectsThree-dimensional effectsCardboardLight irradiation

The invention relates to a preparation method of a three-dimensional antique oil painting. It is characterized in that it consists of the following steps: (1) cutting the medium density board or thin cardboard into the same size as the decorative painting, (2) bonding the decorative painting and the medium density board or thin cardboard together with glue, (3) Apply a layer of gel-like transparent glue evenly on the surface of the decorative painting, and then use a roller to roll the glue surface to produce accumulation or texture effects. (4) Put the processed decorative painting into the empty frame. The antique oil painting produced by the present invention has the advantages of simple process, various styles, high transparency, low transport breakage rate, non-toxic and harmless, high safety, certain waterproof ability, no reflection under light irradiation, not easy to change color after long-term use, and overall After the painting is finished, the surface effect is realistic and the three-dimensional effect is strong. It can improve the grade of oil painting and other advantages, and it is a new product in the picture frame.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

Decorating plate brick producing process

The production process of a decoration board brick sprays a layer of epoxide resin varnish evenly on the surface, then a layer of laser powder fleck on the surface, sweeping and pressing the surface with the laser powder evenly attached on the glass brick, resting until drying of the varnish, spraying bottom paint on the laser powder fleck and baking in 150 degree for 30-60 minutes, cooling, net printing the bottom color paint with plastic rubber till its natural drying or baking it to dryness. It is cheap in cost, good in luster, straightness, transparency and intensity with strong cubic effect, free from erosion with long durability.

Owner:潘文建

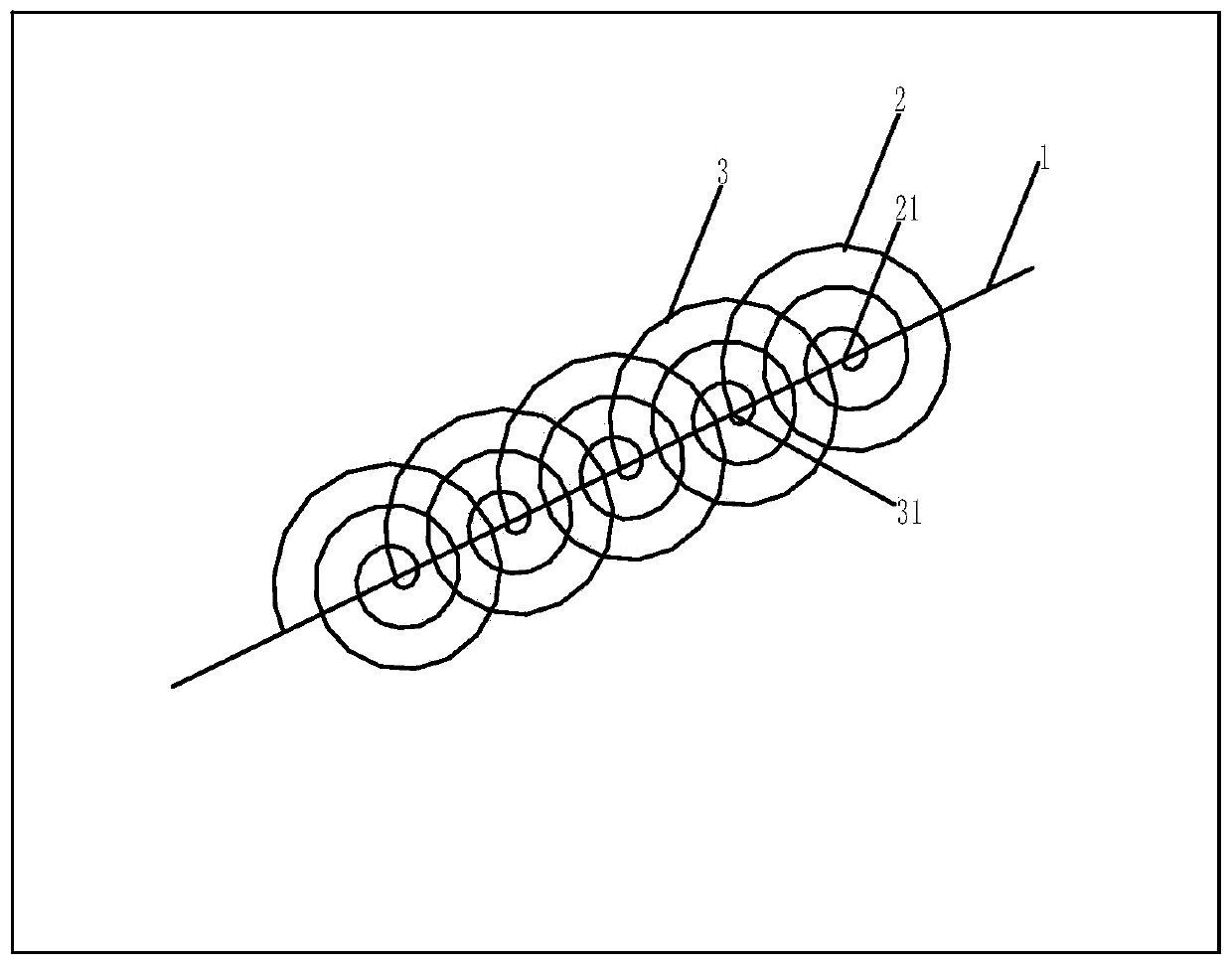

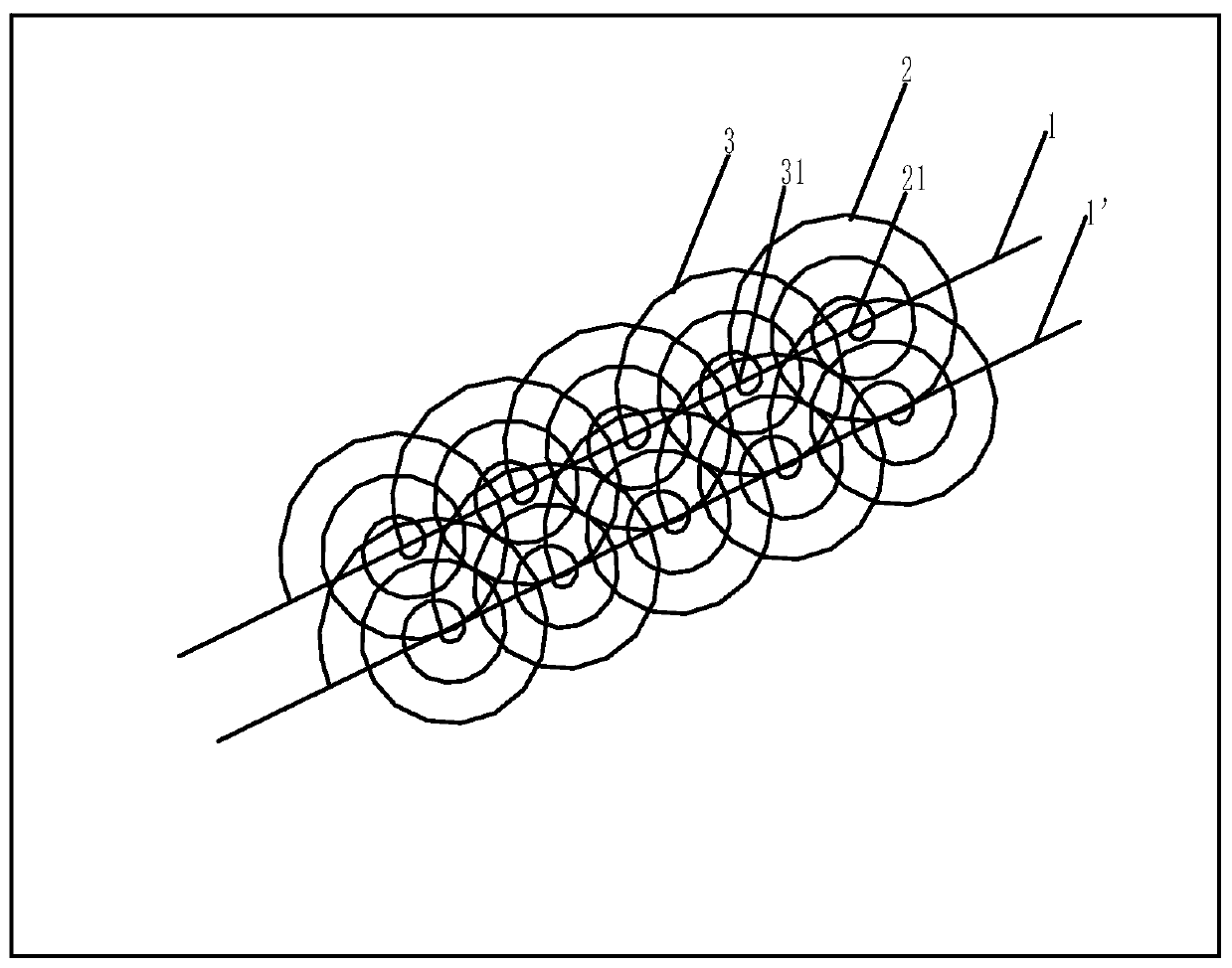

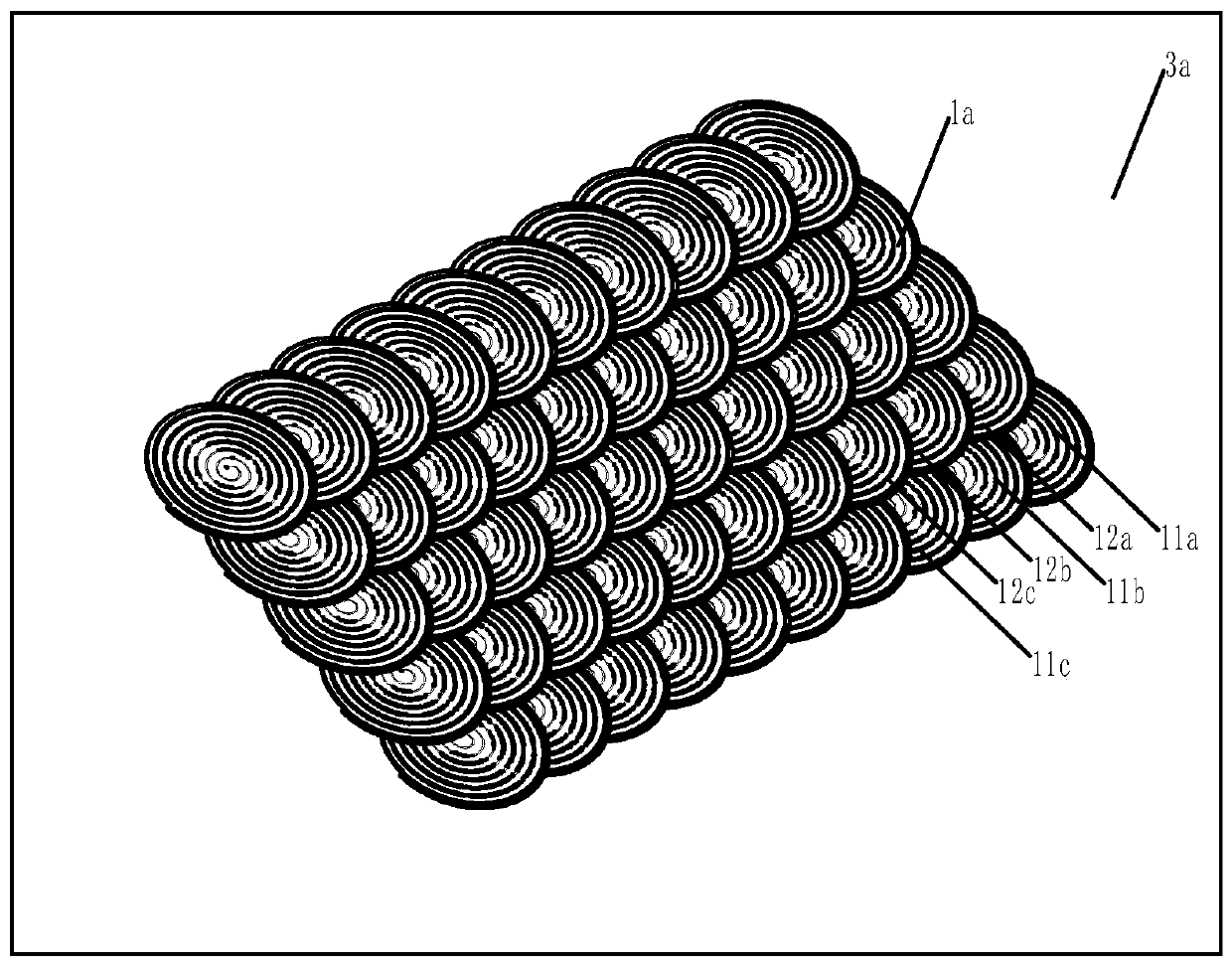

Computer embroidery disk ring close-packed stacking three-dimensional embroidery method and embroidery product

InactiveCN110004611AHigh degree of reductionVariety of aestheticsAutomatic machinesAdditional valuesEngineering

The invention belongs to the technical field of embroidery, and particularly relates to a computer embroidery disk ring close-packed stacking three-dimensional embroidery method and an embroidery product. The method includes the steps: making a plate by a computer, and designing a reference line on a fabric to be embroidered; making disk-shaped embroidery tracks with a plurality of spirals round the reference line from inside to outside or from outside to inside by taking the reference line as an axis to form a second disk shape; forming disk-shaped embroidery tracks of a plurality of three-dimensional stacking layers taking a first reference line as an axis, and so on. According to the computer embroidery method, three-dimensional effects are achieved by making the plate by the computer,the embroidery product has high reduction degree of hand embroidery, rich in hand feeling, high in three-dimensional layer sense and rich, beautiful and diverse in pattern, and a mechanized and large-scale embroidery process with an improved additional value is achieved.

Owner:林淳爽

A kind of three-dimensional oil painting and its manufacturing method and manufacturing components

InactiveCN102975561BStrong sense of three-dimensional layeringLow costDecorative surface effectsSpecial ornamental structuresPigmentPetroleum engineering

Owner:金圣

Unique positioning silk pattern fabric and production method thereof

ActiveCN108085842BStrong sense of three-dimensional layeringIncrease added valueSwivel-woven fabricsLappet-woven fabricsPolymer scienceJacquard loom

The invention discloses a single-width positioning silk pattern fabric, the fabric has a flower width of 150cm and a flower height of 220-240cm, and the flower pattern uses fine brushwork roses as the main material, and tencel and real silk are selected for interweaving. The production method includes the steps of designing the pattern and specification of the fabric, designing the weaving process, drawing in the jacquard loom, and weaving, dyeing and finishing the fabric. The patterned fabric of the present invention can realize the effect of warp and weft different colors, and the "single flower" cloth surface has a strong sense of three-dimensional layering of flowers, lifelike, and presents a strong fashion, completely breaking the traditional situation of multiple flower patterns on the cloth surface, forming a relatively strong pattern visual impact effect. The finished fabric has high added value, can be made into high-end wedding bedding, and has a broad market prospect.

Owner:JIANGSU YUEDA HOME TEXTILE

Easy clean ceramic tile

ActiveCN107285812BExcellent stain resistance and easy cleaningGood pollution resistanceBrickContamination

The invention belongs to the technical field of ceramic, and relates to an easily cleaned ceramic tile. The provided ceramic tile comprises a blank layer, a cover glaze layer, a printed layer, and an easily cleaned protective dry particle layer. The easily cleaned protective dry particle layer is formed by paving easily cleaned protective glaze, which comprises the following components in parts by weight: 90 to 110 parts of easily cleaned protective particles, 230 to 270 parts of stamp-pad ink, and 20 to 40 parts of transparent glaze. The provided ceramic tile has the advantages that the ceramic tile can be cleaned easily, has a good performance on resisting contamination, can be easily maintained and managed every day, and solves the problems that dirt is easily hidden in conventional tiles and the conventional tiles are difficult to clean.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

New-generation AF coating equipment capable of preventing fingerprint interference for notebook computer shell

PendingCN114381697AStrong sense of three-dimensional layeringCoating reliability is highVacuum evaporation coatingSputtering coatingLaptopTriangular prism

The invention relates to the technical field of film coating, and discloses a new-generation AF film coating device capable of preventing fingerprint interference for a notebook computer shell, the new-generation AF film coating device comprises a device main body, a fastening mechanism and a film coating mechanism, the film coating mechanism comprises a stress support and a bearing seat connected to the stress support, and rotating shafts are arranged below the two sets of fixed vertical frames correspondingly, and a film coating block is connected between the two sets of rotating shafts in a penetrating mode. According to the new-generation AF coating equipment capable of preventing fingerprint interference for the notebook computer shell, through rotation of a rotating fan, it is guaranteed that a coating film is rapidly air-dried and formed, meanwhile, dust or waste generated in the coating period is prevented from being accumulated together, a coating block is arranged to be in a triangular prism shape, coating can be achieved through three planes, and through rotation of the coating block, the coating film can be rapidly formed. The coating plane can be controlled, the three-dimensional layering sense of the surface of the notebook computer shell obtained after coating is higher, the situation that the coating surface is single is avoided, and meanwhile coating reliability is higher.

Owner:KUNSHAN JER ELECTRONICS TECH

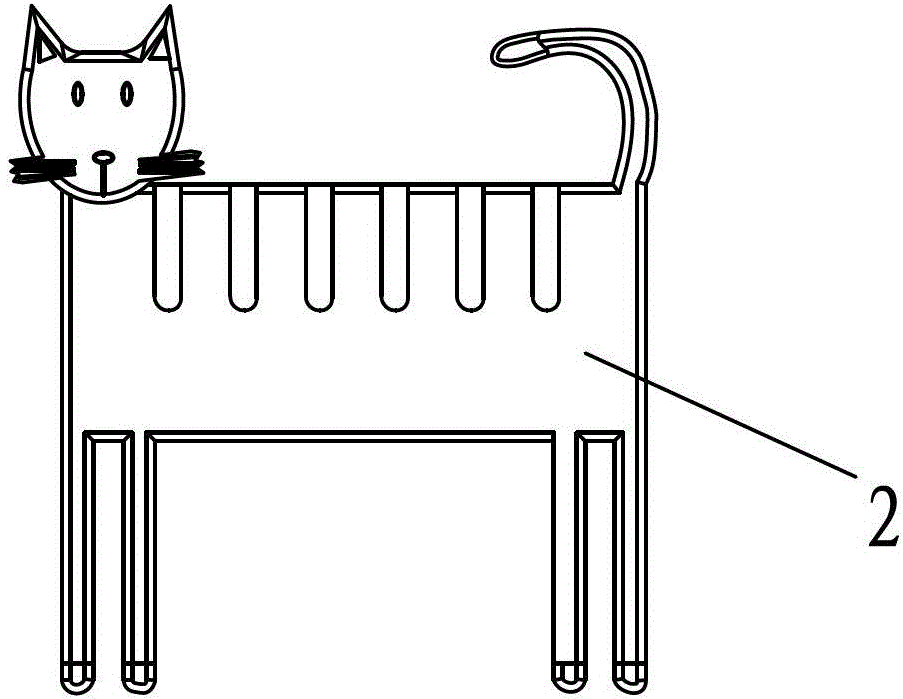

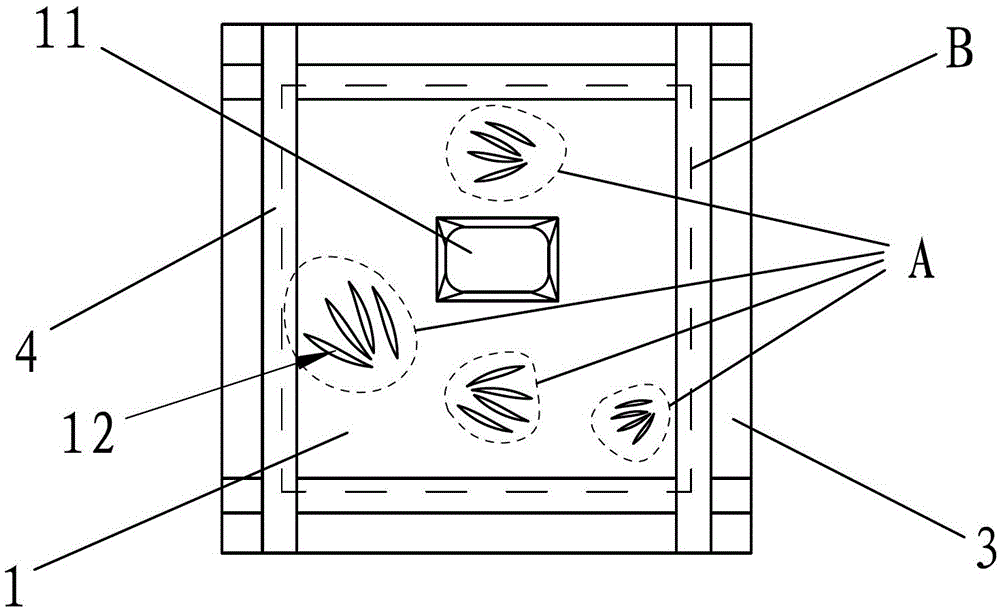

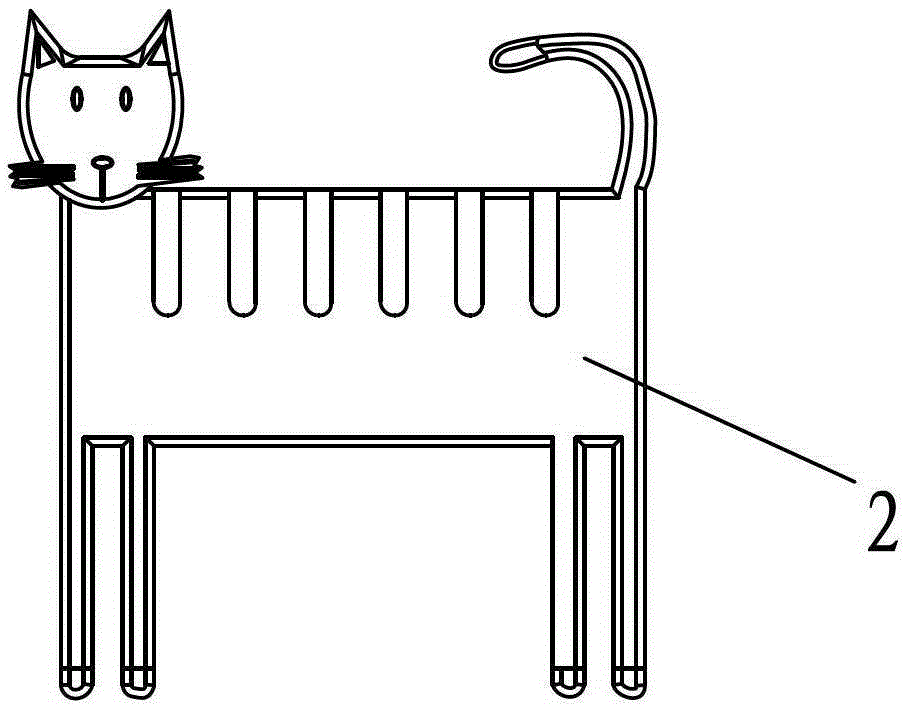

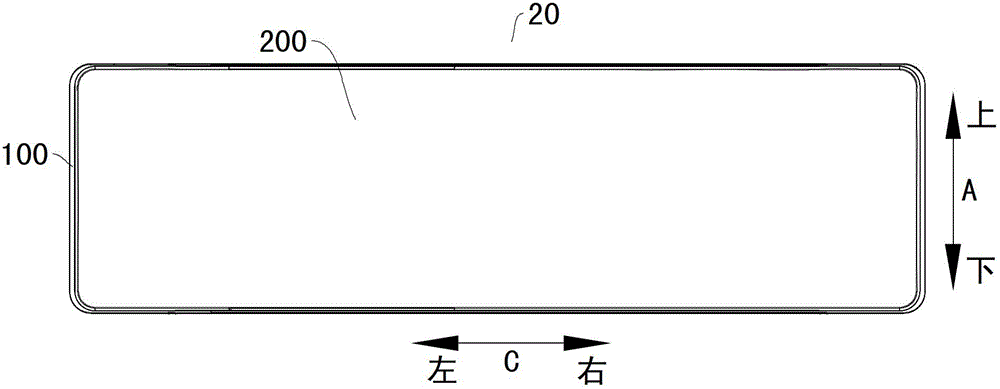

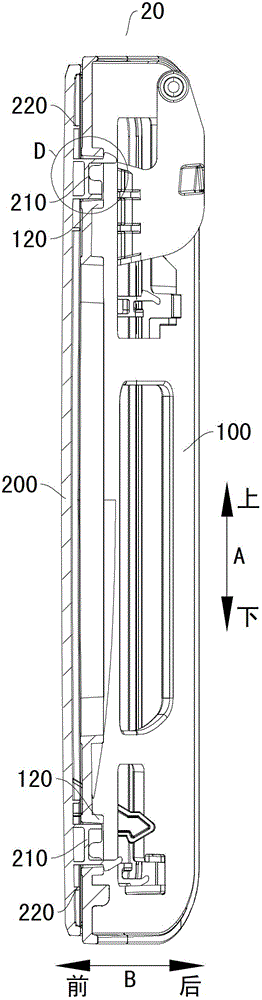

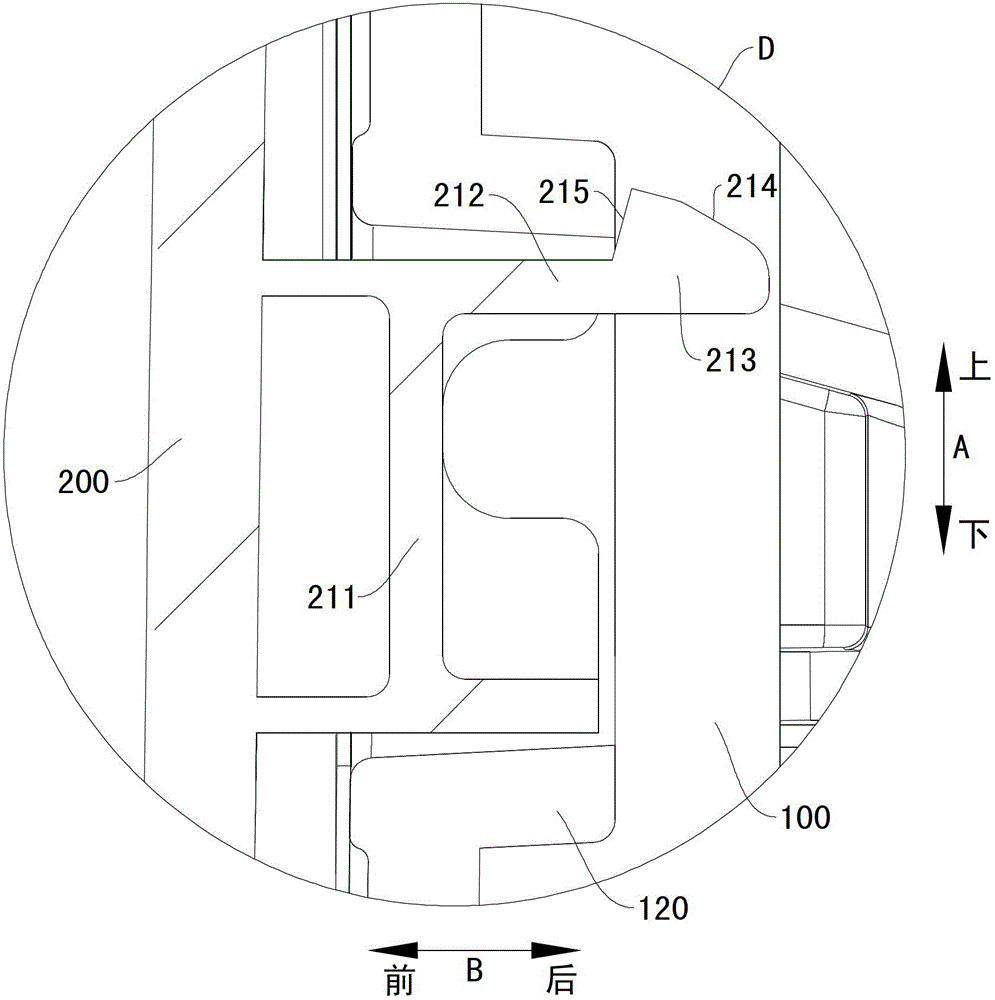

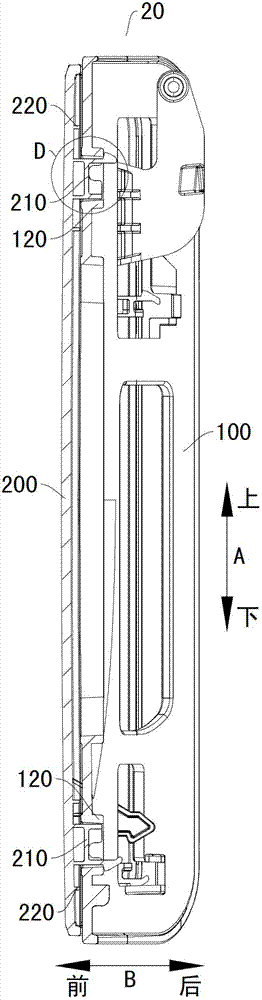

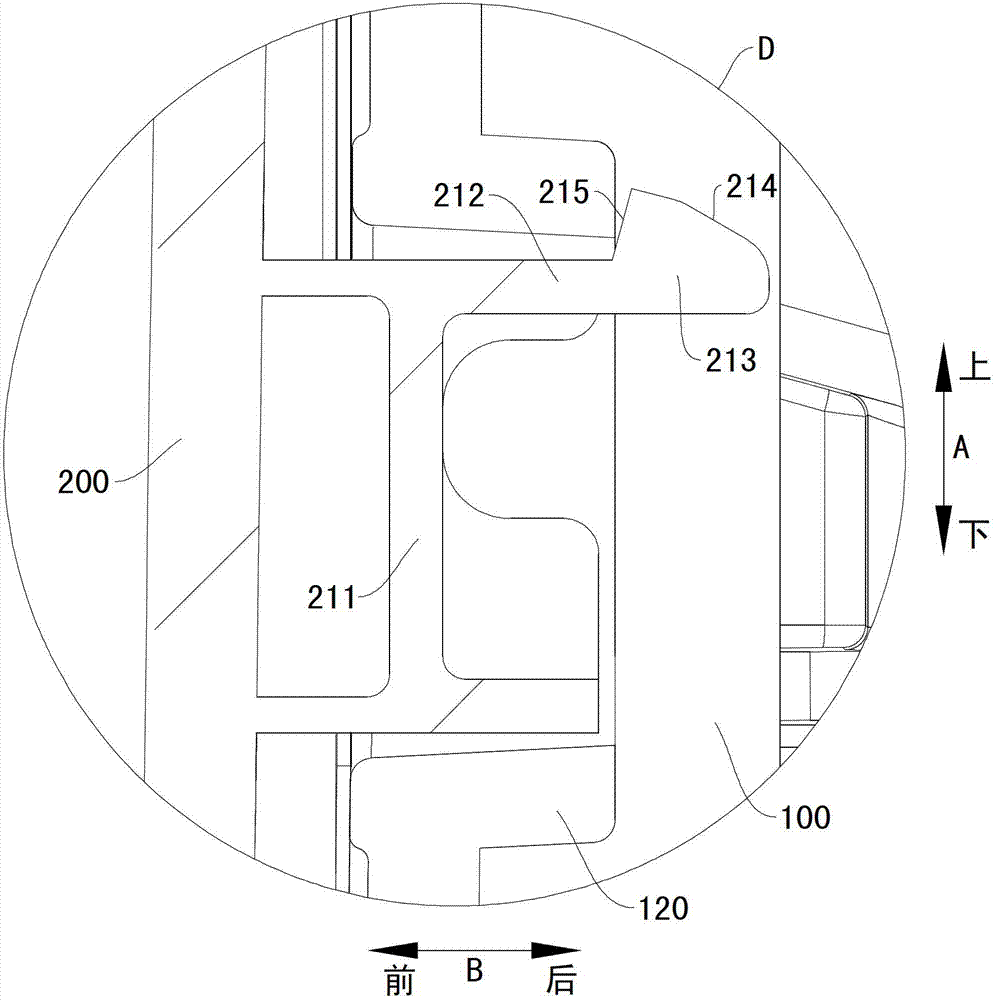

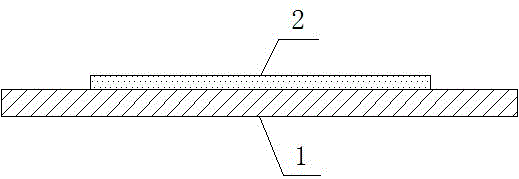

Panel assembly of air conditioner and air conditioner having same

ActiveCN103925688BIncrease the three-dimensional layered beautyVariety of colorsHeating and ventilation casings/coversEngineering

Owner:HANDAN MIDEA REFRIGERATION EQUIP +1

Three-dimensional dynamic logo packaging product and manufacturing process thereof

ActiveCN103129831AImprove visual effectsStrong sense of three-dimensional layeringFlexible coversWrappersLaser holographyDimensional modeling

The invention discloses a three-dimensional dynamic logo packaging product and a manufacturing process of the three-dimensional dynamic logo packaging product. The three-dimensional dynamic logo packaging product comprises a nickel plate layer and a dynamic logo layer arranged on the nickel plate layer. The three-dimensional dynamic logo packaging product and the manufacturing process of the three-dimensional dynamic logo packaging product adopt the three-dimensional laser holography, a hologram is built by one or more real physical three-dimensional models, or manufactured by three-dimensional images directly generated on a computer, a ratio really reappears the designed model, the three-dimensional layering feeling is quite strong, and a stepless dynamic effect of a vector is achieved. When the three-dimensional dynamic logo packaging product and the manufacturing process of the three-dimensional dynamic logo packaging product are applied to graphic packaging, the visual effect of the packaging is largely strengthened.

Owner:云南清甜香科技发展有限公司 +1

A double-sided in-mold injection molding product and its manufacturing method

ActiveCN104339600BStrong sense of three-dimensional layeringLong holding timeOther printing apparatusTelephone set constructionsColor printingEngineering plastic

The invention relates to a double-surface die inner injection moulding product and a production method thereof. The production method comprises the following steps: employing four-color printing to obtain a right side film (2) and employing Keshi color printing to obtain a back side film (3), forming a required shape through film moulding and cutting, respectively placing the right side film (2) and the back side film (3) in an injection moulding transparent engineering material (1) corresponding to an injection mould, performing nozzle cutting on an injection member after moulding, examining and packaging to obtain the right side film (2) and the back side film (3), and the transparent engineering plastics product capable of performing injection moulding of the right side film (2) and the back side film (3). The production method has the beneficial effect that pattern three-dimensional layering is stronger, no warping is generated on the products, the adhesive force between the film and the transparent plastic is large; product yield rate is increased by 20%, product deformation degree is decreased by 50%; and the production efficiency is increased.

Owner:QUNDA PLASTIC ELECTRONICS SHENZHEN

Preparation method of easy-to-clean ceramic tile

ActiveCN107382377BGood pollution resistanceEasy to cleanDecorative surface effectsTextile printerGlaze

The invention belongs to the technical field of ceramics, and relates to a preparation method of an easy-to-clean ceramic tile. The preparation method of the easy-to-clean ceramic tile provided by the present invention comprises the following steps: (a) preparing a green body layer; (b) applying top glaze on the green body layer to form a top glaze layer; (c) printing on the top glaze layer , forming a printing layer; (d) applying Yijie protection glaze on the printing layer to form an Yijie protection dry particle layer; the Yijie protection glaze includes the following components in parts by mass: 90 to 110 parts of Yijie protection particles, printing ink 230-270 parts and 20-40 parts of transparent glaze. The preparation method provided by the invention is simple to operate, easy to implement, and low in cost, and the ceramic tiles prepared by the method have excellent anti-pollution and easy-to-clean properties, that is, good anti-pollution performance and easy to clean.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

Air-conditioner panel assembly and air-conditioner with same

ActiveCN103925688AIncrease the three-dimensional layered beautyVariety of colorsHeating and ventilation casings/coversEngineering

The invention discloses an air-conditioner panel assembly and an air-conditioner with the same. The air-conditioner panel assembly comprises a base board and a panel, wherein the panel is arranged on the base board, the shape of the panel is matched with that of the base board, and the periphery of the base board is exposed out of the periphery of the panel. The air-conditioner panel assembly has the advantages that the panel assembly is colorful, the three-dimensional layering sense is high, the air-conditioner is attractive, and the like.

Owner:HANDAN MIDEA REFRIGERATION EQUIP +1

Application of aqueous wood coating to surface of electric guitar and coating method thereof

ActiveCN102266845BImprove fullnessGood mirror effectPretreated surfacesCoatingsElectric guitarAcrylic resin

The invention relates to application of an aqueous wood coating to the surface of an electric guitar and a coating method thereof. Polyurethane modified acrylic resin, the hardness of which is required to reach the hardness H or scratch of a Chung Hwa pencil, is taken as the principal film-forming substance. The hardness of the aqueous wood coating is required to reach the hardness H of the Chung Hwa pencil. The coating method provided by the invention can be used for acquiring a film-coating effect with excellent fullness, high hardness and excellent mirror surface effect. An aqueous wood coating system is adopted in the invention and the defects of a solvent based coating that the content of organic volatile matter is high, the odor is thick and the environment is polluted are avoided, thereby meeting the demands of customers to a musical instrument for safety, environmental protection and nature.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

Processing method of novel worsted composite scarf

InactiveCN107974746AAvoid deformationDoes not affect appearanceMulti-ply fabricsTextile shapingWorstedEngineering

The invention discloses a processing method of a novel worsted composite scarf. The novel worsted composite scarf comprises a scarf body. The scarf body comprises a terylene layer, a cashmere layer and a pure cotton layer. The terylene layer is arranged on the outer portion of the scarf body. The pure cotton layer is arranged at the bottom of the terylene layer. The cashmere layer is arranged at the bottom of the pure cotton layer. The overall weight ratios of the pure cotton layer, the terylene layer and the cashmere layer account for 25-45%, 5-25% and 10-30% respectively. The processing method has the advantages that three layers of fabric textures, serving as the surface, the middle and the lining, are adopted, so that advantages of fineness, softness, heat insulation and elasticity ofsuperfine wool as well as advantages of lightness, thinness, softness and natural luster of terylene yarns can be displayed, and lightness, thinness and heat insulation effects of pure cotton are achieved; the processing method is simple, and suitable for mass production.

Owner:德清昊昊服饰有限公司

Phantom automobile shell and production process

InactiveCN106347248AImprove artistic aestheticsImprove adhesionVehicle componentsWear resistantWood grain

The invention relates to the field of automobile manufacturing, and refers to a phantom automobile shell and a production process thereof. The veneer is pasted on the car shell, and the veneer of different tree species presents different patterns and effects. The veneer is sliced from roots, forks, sickly twisted and odd-shaped tree trunks, gall wood, and shadow wood. Select those veneers with strange natural wood grain textures, wet the surface with water, and irradiate them with light. It can be decorated with veneer that can have strong reflection, and the wood grain can show a strong sense of three-dimensional layering. After the veneer is designed and cut, the veneer is pasted and spliced with glue. After the veneer is polished and repaired, the surface is coated with four to five layers. The left and right are transparent, wear-resistant, aging-resistant, acid-base resistant, and high-hardness paint coating. Under the reflective background of the transparent oil paint layer, the thin wood grain can produce the effect of moving shadows and strong three-dimensional effect. The effect seen by the car at every angle and different light is different, and it can really achieve the effect of phantom Be more personal.

Owner:陈跃平

Three-dimensional dynamic logo packaging products and its manufacturing process

ActiveCN103129831BStrong sense of three-dimensional layeringWith stepless dynamic effectFlexible coversWrappersLaser holographyDimensional modeling

The invention discloses a three-dimensional dynamic logo packaging product and a manufacturing process of the three-dimensional dynamic logo packaging product. The three-dimensional dynamic logo packaging product comprises a nickel plate layer and a dynamic logo layer arranged on the nickel plate layer. The three-dimensional dynamic logo packaging product and the manufacturing process of the three-dimensional dynamic logo packaging product adopt the three-dimensional laser holography, a hologram is built by one or more real physical three-dimensional models, or manufactured by three-dimensional images directly generated on a computer, a ratio really reappears the designed model, the three-dimensional layering feeling is quite strong, and a stepless dynamic effect of a vector is achieved. When the three-dimensional dynamic logo packaging product and the manufacturing process of the three-dimensional dynamic logo packaging product are applied to graphic packaging, the visual effect of the packaging is largely strengthened.

Owner:云南清甜香科技发展有限公司 +1

Polishing brick and its preparing process

A polishing brick and method for preparing same is characterized in that, the brick is composed of SiO2, Al2O3, CaO, MgO, K2O, Na2O and rare substances, wherein SiO2 is 65-70 in mass percentage, CaO is 2-7 in mass percentage, MgO is 2-7 in mass percentage, Al2O3 is 17-20 in mass percentage, K2O is 5-7 in mass percentage and rare substances are 3-4 in mass percentage. Compared with the present techniques, the product prepared in the invention has the advantages of strong stereoscopic feeling, plentiful patterns, nice quality and much like the effect in the polar glacier.

Owner:广东博华陶瓷有限公司

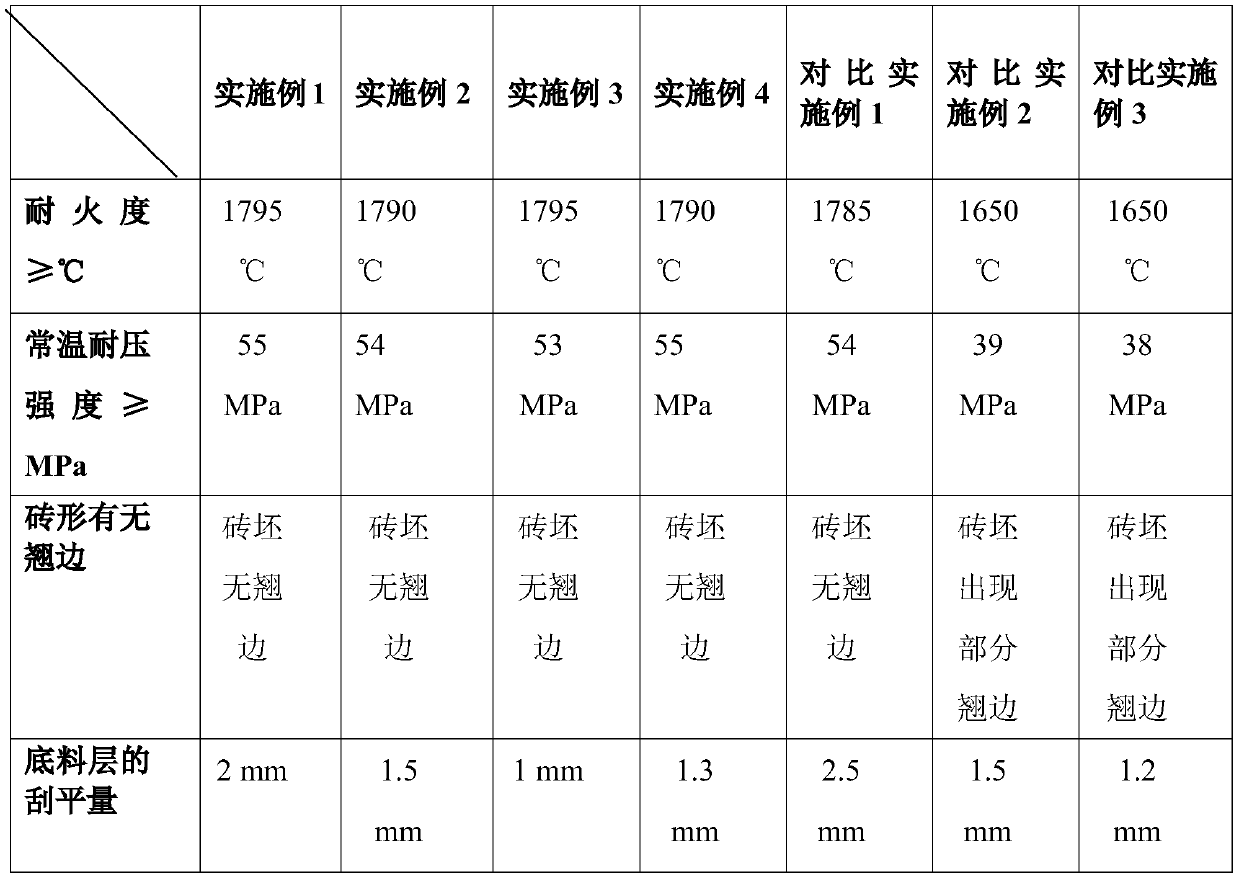

A kind of preparation technology of whole body brick with single fabric layer and its whole body brick

ActiveCN108582420BReduce manufacturing costEnhance natural texture effectFeeding arrangmentsClaywaresBrickEngineering

The invention discloses a preparing technology of a whole-body brick of a single surface layer and a whole-body brick. The preparing technology includes the following steps that (1), green brick bottom material of high alumina pug with 25%-40% weight fraction is adopted and arranged in a pressing machine model cavity to form a bottom material layer; (2), figured surface is arranged on the green brick bed charge layer to form a surface material layer; (3), the green brick is formed by pressing, and the thickness of the bottom material layer is 10%-20% of the thickness of the green brick; and (4), after fired in a kiln, the bottom material is striken off and the whole-body brick with the single surface layer is achieved. Through the design of a two-times material arranging technology combining thin-layer bottom material arranging with bottom material layer polishing, the whole-body brick of the single surface layer with coincident surface and bottom is obtained, the surface layer is closer to pattern texture of stone, three-dimensional sense is high, cost of production is low and application is wide.

Owner:FOSHAN DONGPENG CERAMIC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com