Easily cleaned ceramic tile

A ceramic tile and easy-to-clean technology, applied in the field of ceramic decoration, can solve the problems of difficult surface cleaning, poor anti-fouling effect, and product blackening, and achieve excellent anti-fouling and easy-cleaning properties, easy to clean, and strong three-dimensional layering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

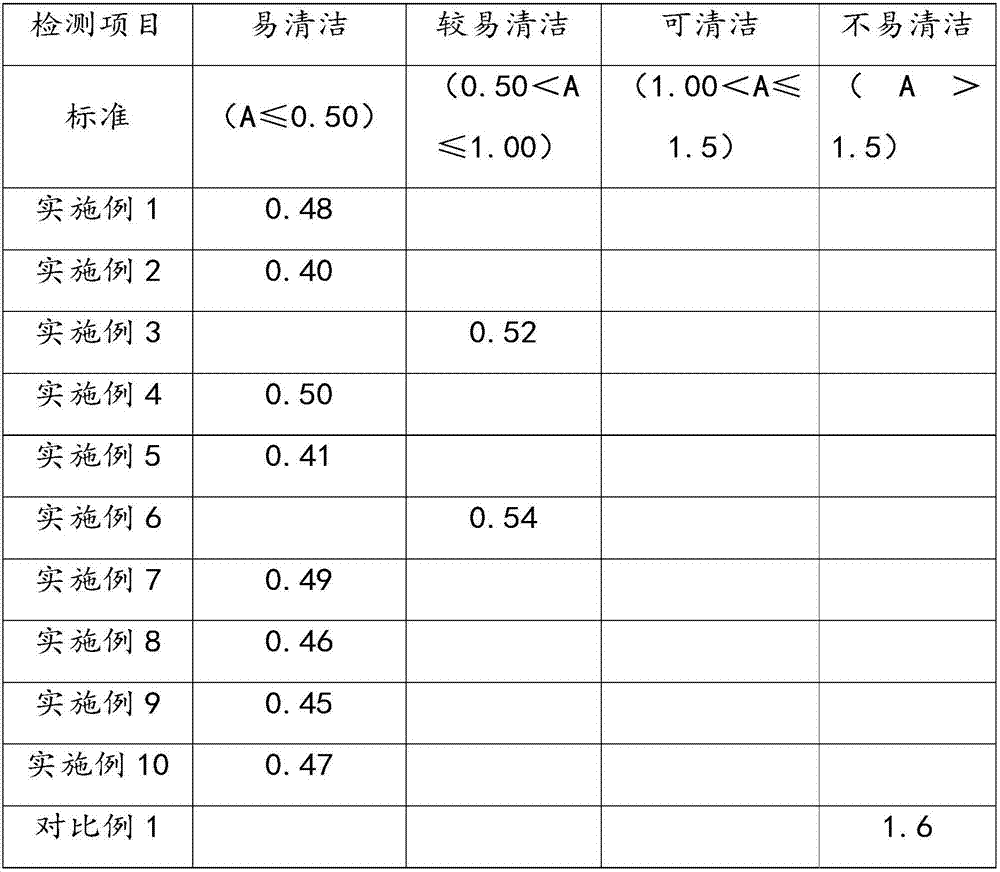

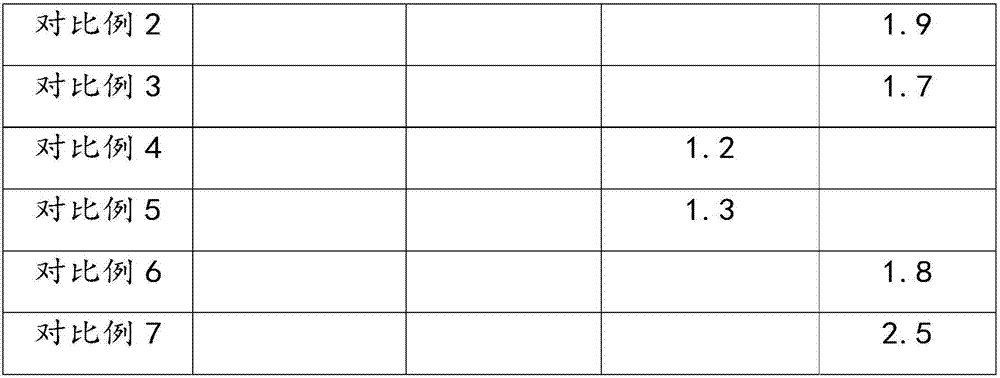

[0082] An easy-to-clean protection brick, which includes a green body layer, a surface glaze layer, a printing layer and an easy-to-clean protection dry grain layer from bottom to top. The ratio of the mass parts of the raw materials shown in Table 1 was prepared.

[0083] Table 1 Example 1-3 Yijie Protective Glaze Raw Material Composition

[0084] raw material

Example 1

Example 2

Example 3

Easy Clean Protective Glaze

90 copies

100 copies

110 copies

230 copies

250 copies

270 copies

transparent glaze

20 copies

30 copies

40 copies

[0085] Among them, Yijie protection particles are mainly composed of the following components in parts by mass: SiO 2 66 copies, Al 2 o 3 21 parts, Fe 2 o 3 0.15 parts, TiO 2 0.06 part, Na 2 O 6 parts, K 2 O 4 parts, MgO 0.15 parts, CaO 1.5 parts and ignition loss 0.15 parts.

[0086] The particle gradation of Yijie Protective Granules is: 60% ...

Embodiment 4-6

[0090] An easy-to-clean protective brick, which includes a green body layer, a surface glaze layer, a printing layer, and an easy-to-clean protective dry granule layer from bottom to top. It is made of the following raw materials in parts by mass: 100 parts of Yijie protective particles, 250 parts of printing oil and 30 parts of transparent glaze. Wherein, the Yijie protection granules are mainly composed of components in parts by mass shown in Table 2.

[0091] Table 2 Example 4-6 Composition of Yijie Protective Granules

[0092] components

[0093] Among them, the particle gradation of the Yijie protective particles, the composition of the printing ink and the transparent glaze are all the same as those in Example 1.

Embodiment 7

[0095] An easy-to-clean protective brick is different from Embodiment 1 in that the components of printing oil and transparent glaze are composed, and the rest are the same as Embodiment 1.

[0096] In this embodiment, the printing oil is mainly composed of the following components in parts by mass: 2 parts of sodium carboxymethyl cellulose, 35 parts of ethylene glycol, 5 parts of bentonite and 80 parts of water.

[0097] The transparent glaze is mainly composed of the following components by mass: 16 parts of albite feldspar, 24 parts of potassium feldspar, 10 parts of kaolin, 14 parts of calcined kaolin, 13 parts of quartz, 17 parts of calcined talc, 10 parts of limestone, and 12 parts of barium carbonate parts and 5 parts of zinc oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com