Compound foamed aluminum plate

A foamed aluminum board and composite board technology, which is applied in the direction of building components, sound insulation, layered products, etc., can solve the problems of sound absorption, poor sound insulation effect, unsightly appearance, large load impact, etc., and achieve improved sound insulation effect and decorative effect Excellent, weight-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

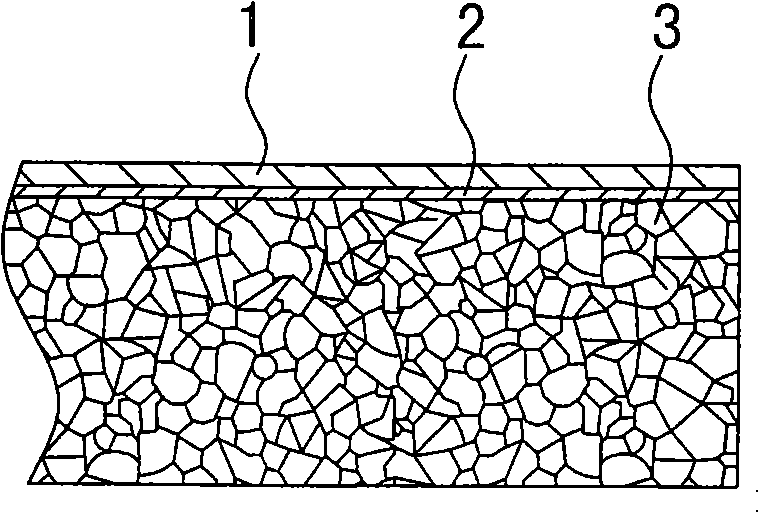

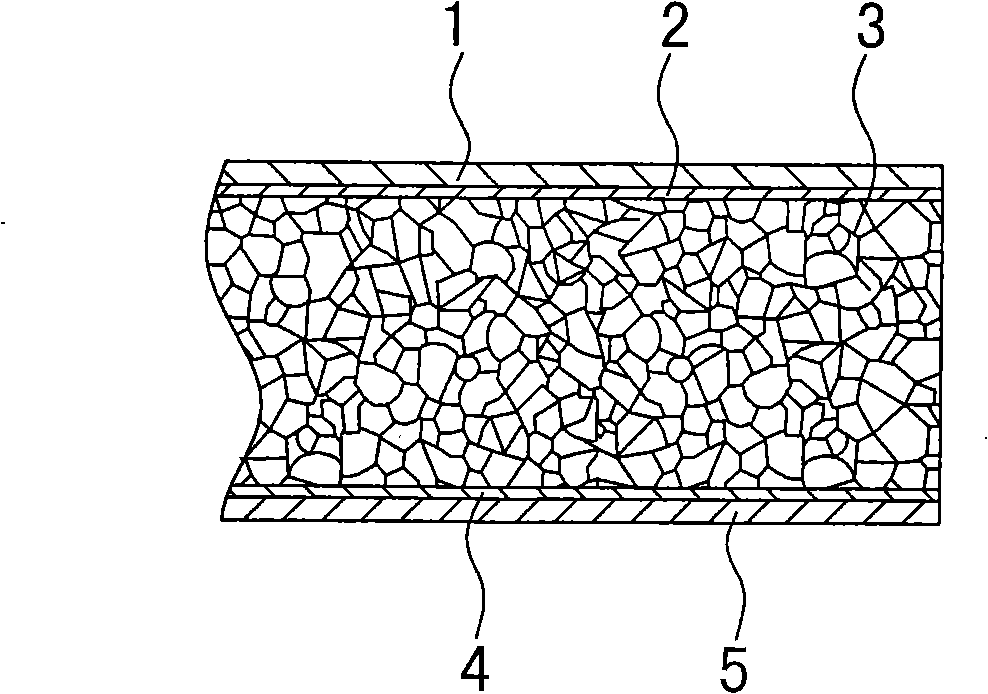

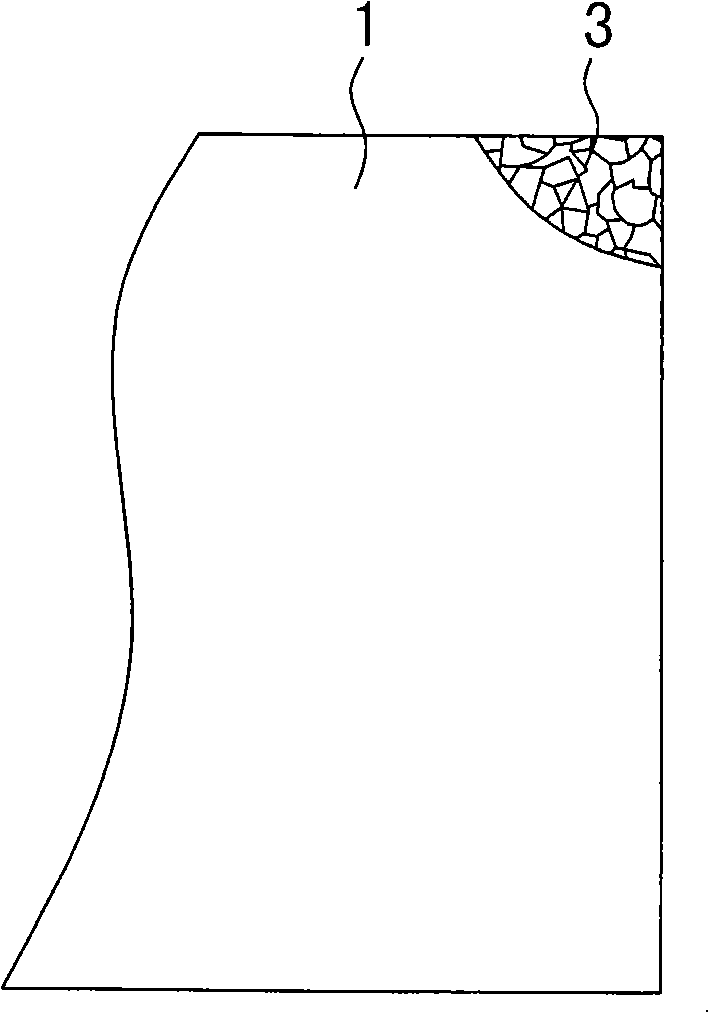

[0010] The invention discloses an aluminum foam composite board, such as Figure 1-Figure 3 Shown is foamed aluminum plate 3. The foamed aluminum plate is an aluminum plate with a wire mesh shape and irregular through holes. Compared with aluminum, its density is greatly reduced. According to needs, it can be made into a lightweight material that is lighter than water. It is more convenient to construct when decorating indoor and outdoor wallboards, floors, and countertops. There are panels outside the foamed aluminum boards. ), the sound insulation effect is significantly improved, eliminating the noise pollution of urban life for people and improving the quality of life, and the rough surface of the aluminum foam board 3 is covered by the smooth marble board 1, which has good decorative properties. The panel is composited on one side of the foamed aluminum plate, and there is an adhesive layer 2 between the marble plate 1 and the foamed aluminum plate 3, such as figure 1 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com