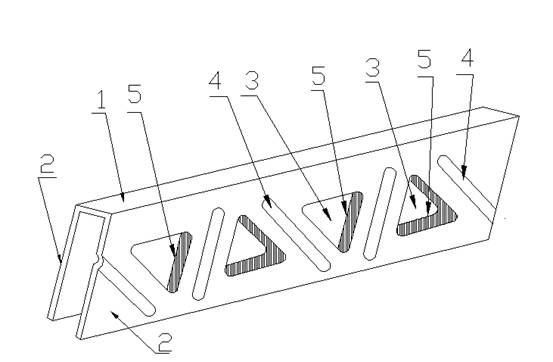

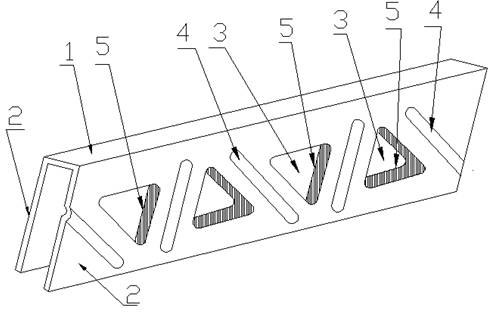

Lightweight U-shaped steel beam structure

A profiled steel, lightweight technology, applied in truss-type structures, joists, girders, etc., can solve problems such as the impact of building safety performance, increase the weight of buildings, and be unfavorable for cost savings, so as to reduce construction costs, reduce weight, and reduce costs. Overall weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The sides of the U-shaped steel beam bottom plate 1 are symmetrically formed with U-shaped steel beam side plate edges 2; a row of equilateral triangle through holes 3 are punched out in the middle of the U-shaped steel beam side plate edges 2; The regular triangular through holes 3 are alternately arranged in positive and negative directions, and the mouth of each regular triangular through hole 3 has a folded edge 5 folded to the same side. Elongated ribs 4 in opposite directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com