Concrete construction method and mirror-surface concrete pier column

A construction method and concrete technology, which is applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems that the concrete surface is not easy to achieve mirror effect, the finish is not high, and the color is uneven, so as to improve the appearance aesthetics, uniform color, The effect of color without bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Place the 6mm thick steel formwork horizontally, clean up the sundries and rust stains on the steel formwork, use a roller to evenly paint HD-1 long-term release agent on the inner surface of the steel formwork, let it stand for 24 hours, and wait for HD-1 1 The long-term release agent is completely dry;

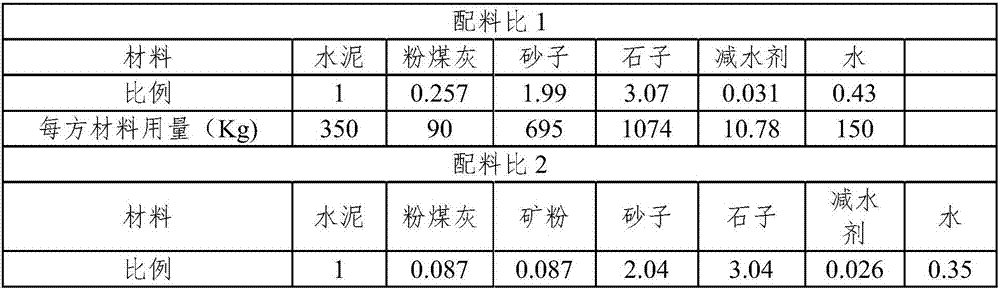

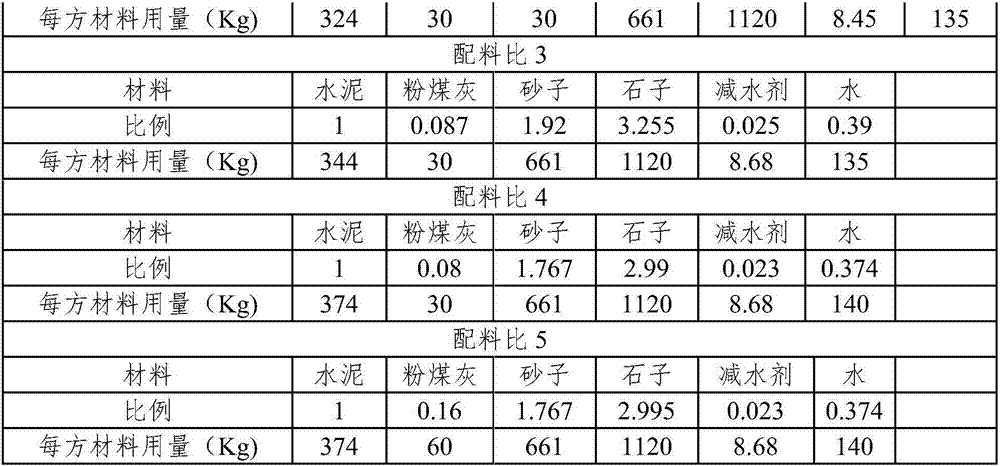

[0049] Mix cement, fly ash, sand, gravel, water reducer and water according to the ratio of 1:0.16:1.767:2.995:0.023:0.374, see the mix ratio 5 in Table 1 for details, and test the concrete after mixing. The slump is 160-200mm;

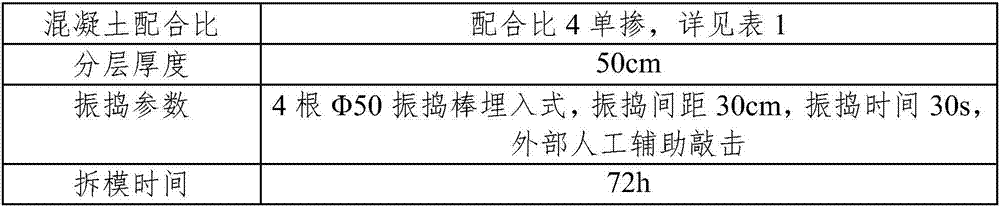

[0050] Build the inner frame of the steel cage model with steel bars, and assemble the dried steel formwork on the periphery of the inner frame of the steel cage to form the outer frame of the model. The outer frame is divided into three layers, and each layer is assembled with four steel formworks. The heights are 2m, 1m, and 0.5m, and the adjacent steel formworks are fixed with bolts, and the joints of the steel formworks are bonded with P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com