Temperature-sensitive color-changeable material, preparation method thereof and one-way perspective temperature-sensitive type glass

A technology of temperature-sensitive discoloration and glass, which is applied in the field of glass product production, can solve the problems of glass opacity, low repeatability, and high energy consumption, and achieve the effect of avoiding difficult layout, avoiding easy leakage, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

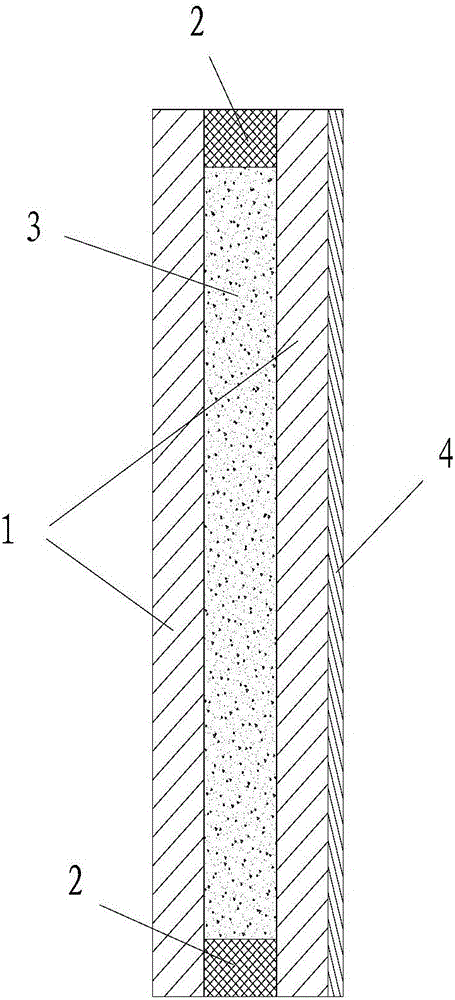

Image

Examples

Embodiment 1

[0034] This embodiment relates to a temperature-sensitive color-changing material, and its raw material composition includes a temperature-sensitive polymer, a film-forming monomer, a thickener, a dispersant and a cross-linking agent. Among them, the temperature-sensitive polymer is N_isopropylacrylamide, polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer, polyoxyethylene-polyoxybutylene-polyoxyethylene block copolymer or polyoxyethylene At least one of ethylene-polyoxypentene-polyoxyethylene block copolymers; film-forming monomers are acrylamide, polyvinyl alcohol, 2-acrylamide-2-methylpropanesulfonic acid, dimethylacrylamide At least one of the above; the thickener is at least one of glycerin, polyethylene glycol, gelatin, agar, methylcellulose, sodium alginate, carrageenan, and hydroxypropyl methylcellulose; the dispersant is chlorinated At least one of sodium, sodium lauryl sulfate, sodium dodecylbenzenesulfonate, sodium glycocholate, the cross-linking agent ...

Embodiment approach 2

[0043] Weigh 6-12g (such as 10g) N_isopropylacrylamide, 0.02-0.1g (such as 0.05g) N,N'-methylenebisacrylamide, 0.02-0.06g (such as 0.04g) ammonium persulfate , Add 0.2-0.5g (such as 0.3g) sodium lauryl sulfate, 0.3g benzophenone into 100ml deionized water, stir evenly, pour it into a transparent container after vacuum defoaming, and cure it by ultraviolet exposure.

Embodiment approach 3

[0045] Weigh 0.8-1g (such as 0.9g) polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer, 0.02-0.1g (such as 0.05g) N,N'-methylenebisacrylamide, 10-30ml (12.6-37.8g, such as 25.2g) glycerin, 1-6g (such as 4g) sodium alginate, 0.02-0.06g (such as 0.04g) ammonium persulfate, 0.1-0.3g (0.2g) sodium lauryl sulfate , add 0.01-0.03g (such as 0.02g) N,N,N',N'-tetramethylethylenediamine into 100ml deionized water, stir evenly, pour it into the container after vacuum defoaming, and store it at 30-60°C ( Such as 45 ℃) thermal curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com