Energy-saving furnace body of polycrystalline silicon reduction furnace

A reduction furnace, polysilicon technology, applied in silicon compounds, sustainable manufacturing/processing, inorganic chemistry, etc., can solve the problems of difficult polishing of the inner wall of the furnace, poor polishing effect, etc., to achieve safe production, good mirror effect, improve The effect of the energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

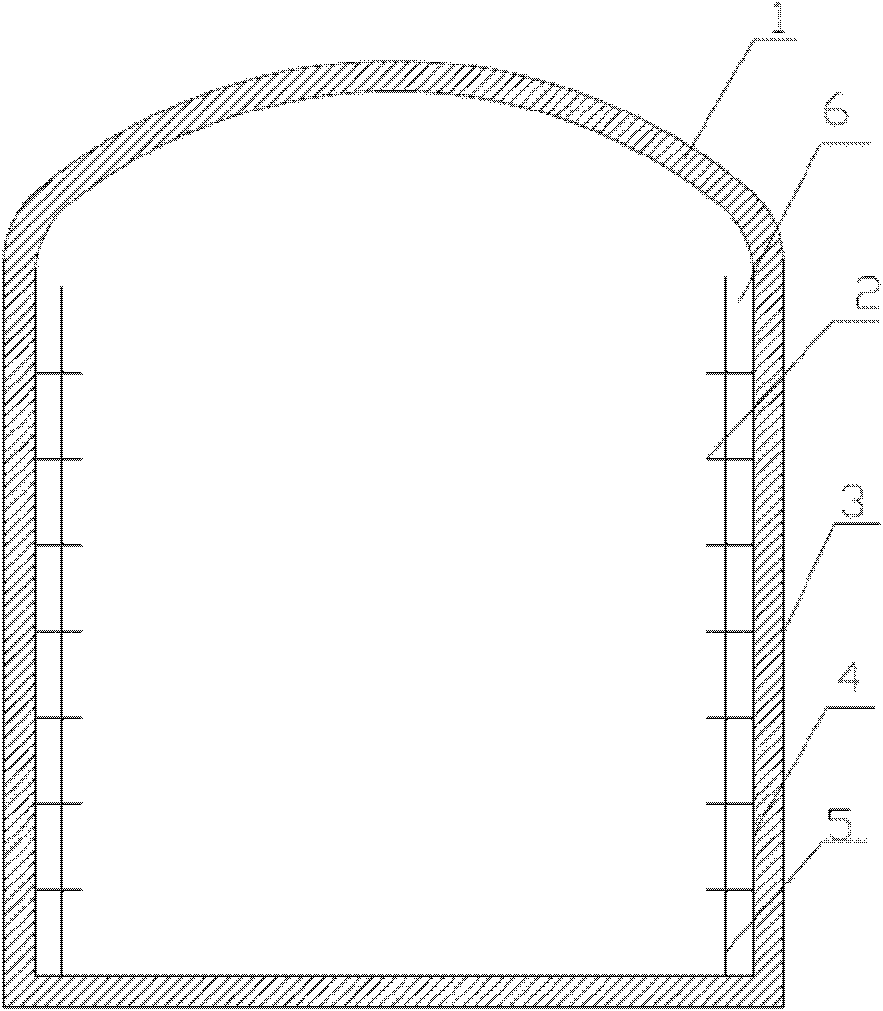

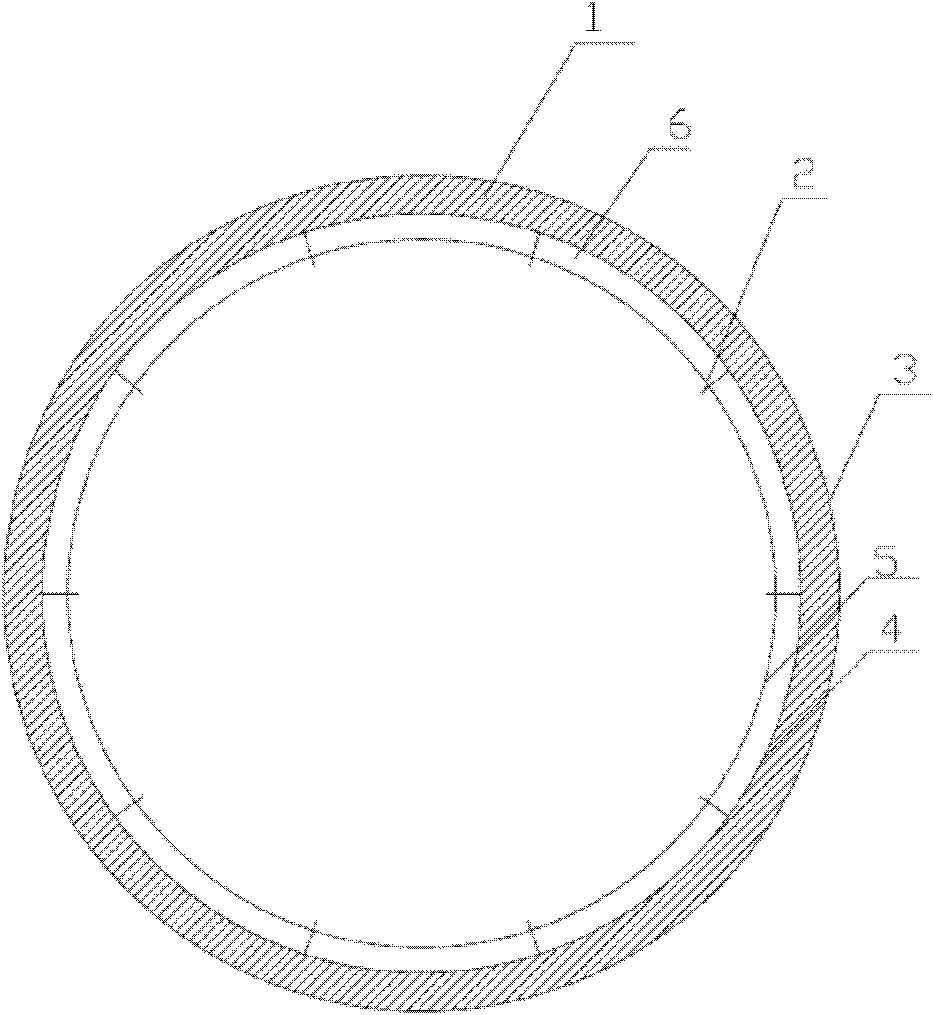

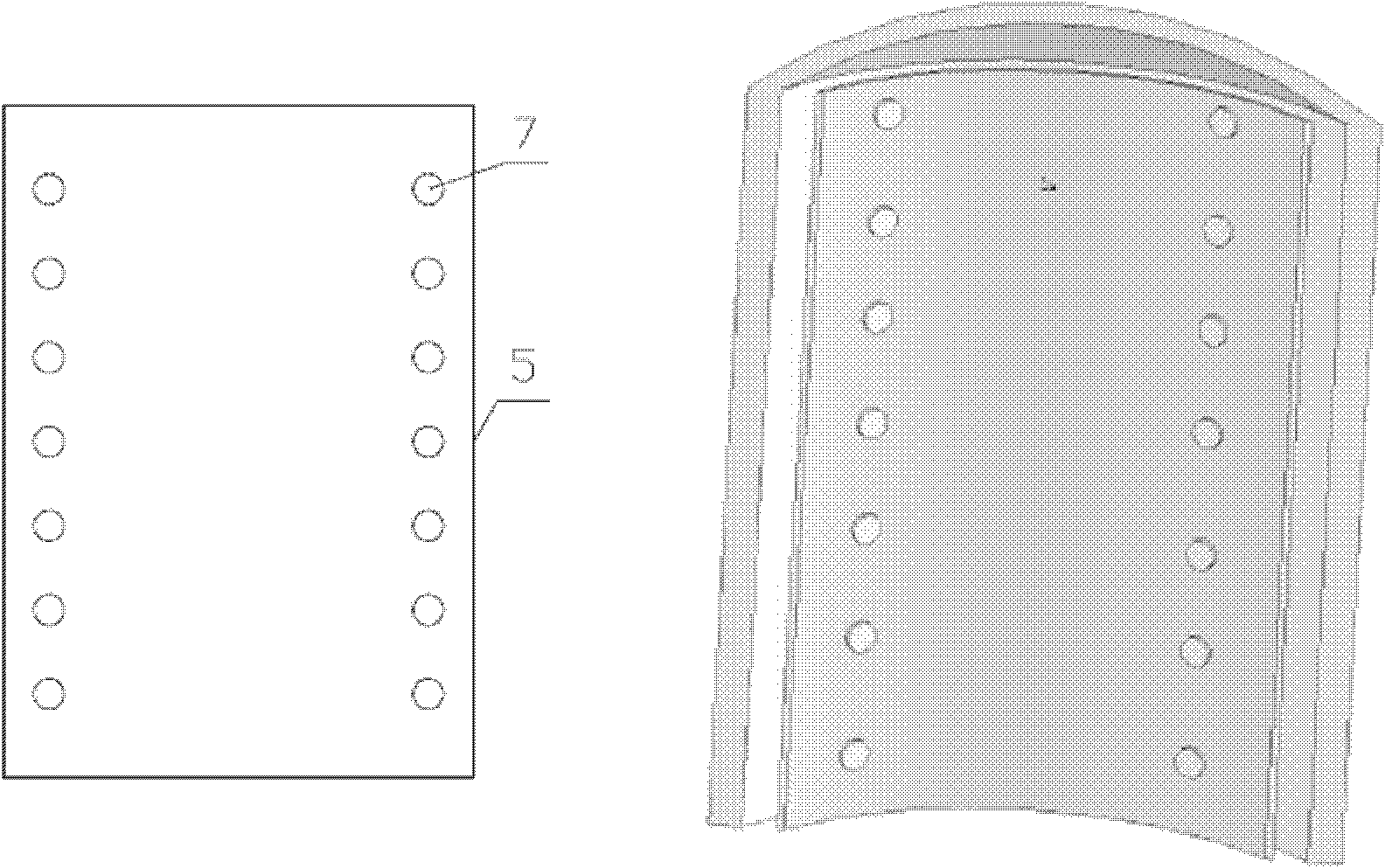

[0017] Implementation mode 1: if figure 1 , 2 As shown, the polysilicon reduction furnace body includes: 1-furnace body insulation cylinder, 2-stainless steel bolts, 3-furnace body wall, 4-furnace body wall, 5-new inner wall, 6-insulation layer, 7-bolts hole. Wherein, newly-increased inner wall 5 selects the stainless steel sheet that thickness is 0.2mm for use, and its overall shape is identical with furnace body, can be divided into rectangle ( image 3 ), the area of each rectangular stainless steel sheet is 0.1 square meters (2m high, 0.05m wide), and 8 bolt holes are opened on the sheet, and the hole size is 10mm, which is mainly used for fixing needs and heat transfer control Need, the stainless steel sheet is polished by the machine tool, the polishing process is convenient and the polishing effect is good, and the polished mirror surface roughness can achieve Ra0.008μm. The stainless steel bolt 2 used is M8 in type and has a length of 60mm. By adjusting the positi...

Embodiment approach 2

[0018] Implementation mode 2: if image 3 As shown, the polysilicon reduction furnace body includes: 1-furnace body insulation cylinder, 2-stainless steel bolts, 3-furnace body wall, 4-furnace body wall, 5-new inner wall, 6-insulation layer, 7-bolts hole. Wherein, newly added inner wall 5 selects the stainless steel sheet that thickness is 2mm for use, and its overall shape is identical with body of furnace, can be divided into rectangle during preparation, and the area of every rectangular stainless steel sheet is 2 square meters (height is 2m, and width is 1m), There are 8 bolt holes on the sheet, and the size of the hole is 12mm, which is mainly used for the needs of fixing and heat transfer control. The stainless steel sheet is polished by the machine tool. The polishing process is convenient and the polishing effect is good. The polished mirror surface The roughness can achieve Ra0.008μm. The stainless steel bolt 2 used is M10, the length is 60mm, and the thickness of...

Embodiment approach 3

[0019] Implementation mode 3: if image 3 As shown, the polysilicon reduction furnace body includes: 1-furnace body insulation cylinder, 2-stainless steel bolts, 3-furnace body wall, 4-furnace body wall, 5-new inner wall, 6-insulation layer, 7-bolts hole. Wherein, newly-increased inner wall 5 selects the stainless steel sheet that thickness is 1mm for use, and its overall shape is identical with furnace body, can be divided into rectangle ( image 3 ), the area of each rectangular stainless steel sheet is 1 square meter (height is 2m, width 0.5m), bolt holes 8 are opened on the sheet, and the size of the hole is 12mm, which is mainly used for fixing needs and heat transfer control Need, the stainless steel sheet is polished by the machine tool, the polishing process is convenient and the polishing effect is good, and the polished mirror surface roughness can achieve Ra0.008μm. The stainless steel bolt 2 used is M10, the length is 60mm, and the thickness of the heat insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com