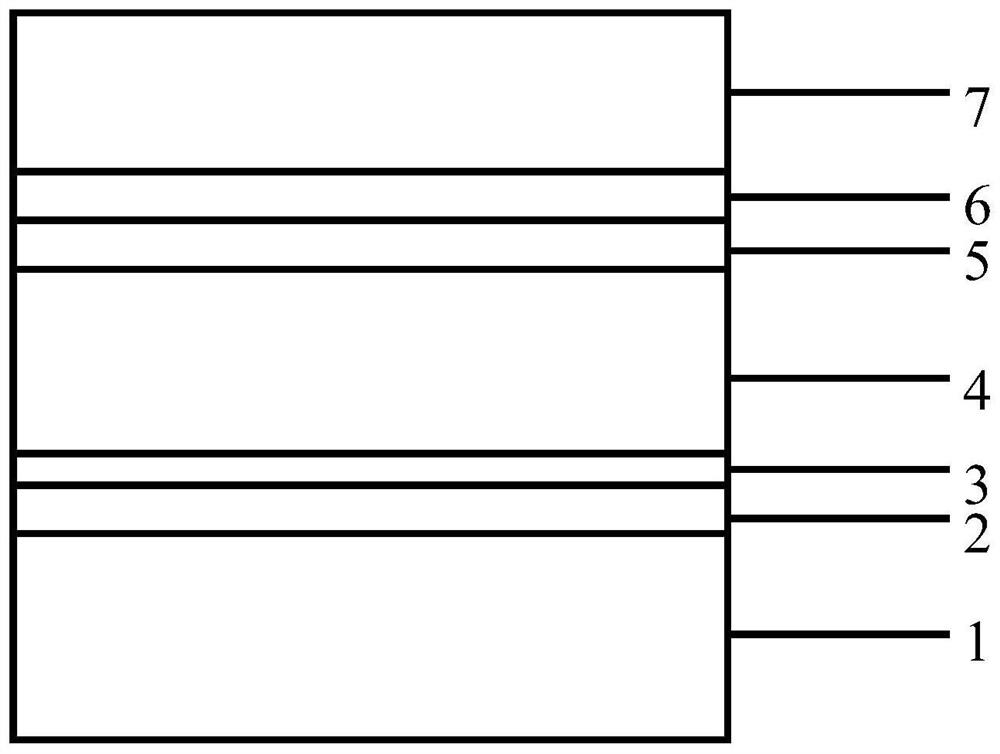

Trans-plane structure perovskite solar cell and preparation method thereof

A technology of solar cells and planar structures, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of insufficient coating of perovskite films, high surface roughness of nickel oxide, poor conductivity, etc., and achieve dense films, Effect of smooth surface and increased transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The trans planar structure perovskite solar cells were fabricated according to the following steps:

[0035] Step 1: Put the 2cm×2cm FTO conductive glass into the cleaning rack, use detergent, deionized water, acetone, isopropanone and absolute ethanol to clean it ultrasonically, and then blow it dry with nitrogen.

[0036] Dissolve 0.1g of nickel acetate in 4mL of ethanol solution, add 24uL of ethanolamine, and stir in a water bath at 60°C for 6-10h. After filtering, a nickel oxide precursor solution is obtained. Next, 50 ul of tributyl phosphate tBP solution was added to 4 mL of nickel oxide solution to obtain a hole transport layer precursor solution. The hole transport layer precursor solution was spin-coated on the pretreated FTO glass surface. Spin coating at a speed of 4000 rpm for 40 s, and then anneal at 280° C. for 60 min to obtain a nickel oxide hole transport layer.

[0037] Step 2: Dissolve 2 mg of LiF in 1 mL of deionized water, and stir for 12-36 hours...

Embodiment 2

[0043] The trans planar structure perovskite solar cells were fabricated according to the following steps:

[0044] Step 2 is not included in this embodiment, and other steps are the same as the preparation method of the embodiment.

Embodiment 3

[0046] The trans planar structure perovskite solar cells were fabricated according to the following steps:

[0047] Step 2, step 3, step 4, step 5, step 6 preparation process is identical with embodiment.

[0048] Step 1: Put the 2cm×2cm FTO conductive glass into the cleaning rack, use detergent, deionized water, acetone, isopropanone and absolute ethanol to clean it ultrasonically, and then blow it dry with nitrogen.

[0049] Dissolve 0.1g of nickel acetate in 4mL of ethanol solution, add 24uL of ethanolamine, and stir in a water bath at 60°C for 6-10h. After filtering, a nickel oxide precursor solution is obtained. The nickel oxide precursor solution was spin-coated on the pretreated FTO glass surface. Spin coating at a speed of 4000 rpm for 40 s, and then anneal at 280° C. for 60 min to obtain a nickel oxide hole transport layer.

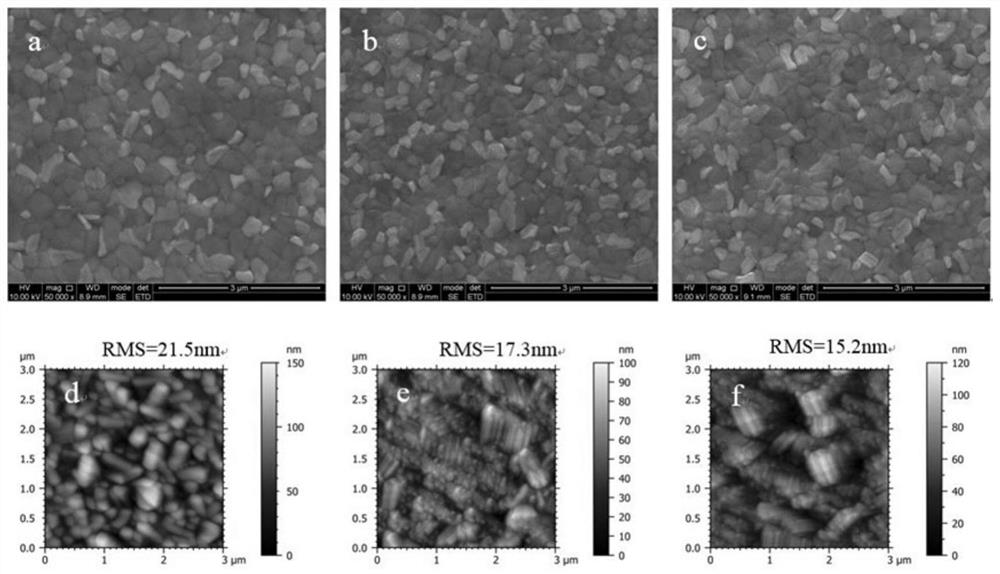

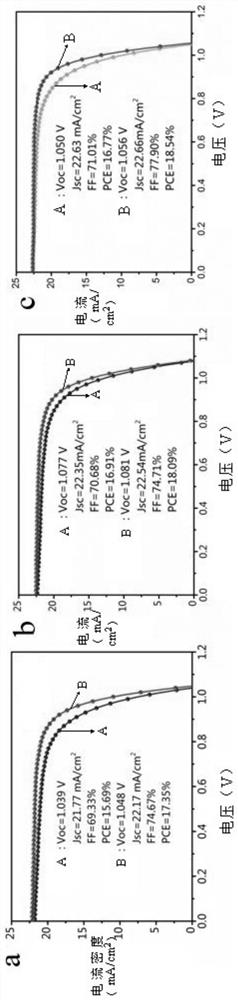

[0050] The surface morphology and surface roughness of the obtained perovskite light-absorbing layer films were observed by scanning electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com