Method for preparing 2D/3D organic-inorganic hybrid perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as poor film quality, and achieve the effects of quality improvement, performance improvement, and porosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

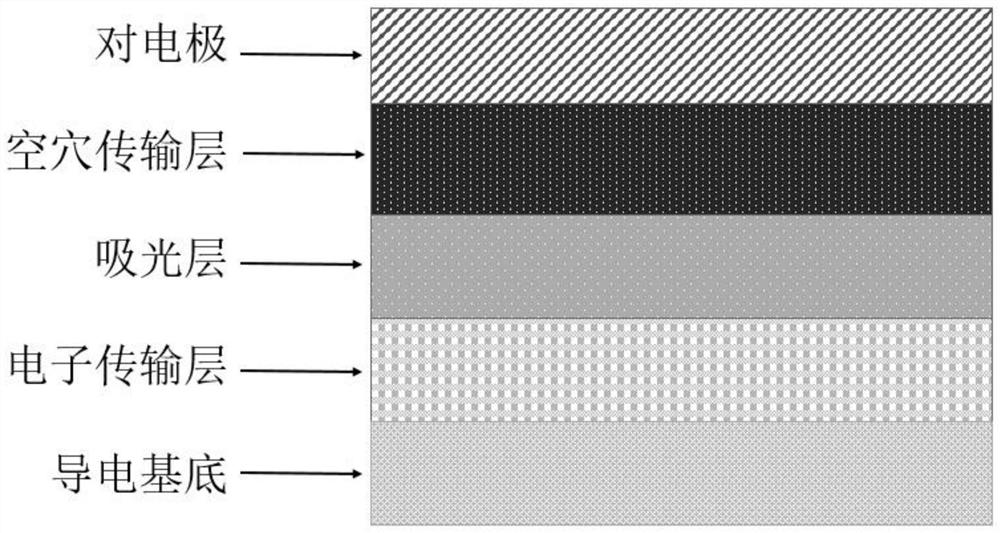

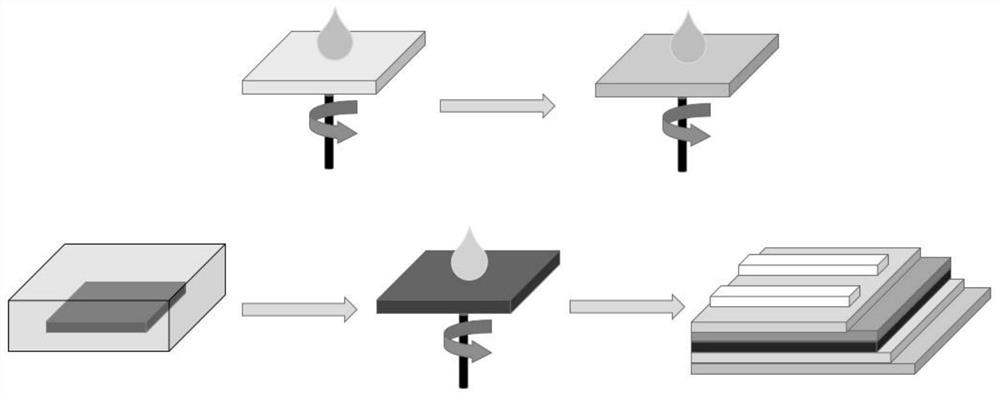

[0020] A preparation method for high-efficiency 2D / 3D perovskite solar cells, using ITO as the conductive substrate, tin dioxide as the electron transport layer, 2D / 3D perovskite light-absorbing layer, Spiro-OMeTAD as the hole transport layer, and silver as the pair electrodes, such as figure 1 and figure 2 As shown, it specifically includes the following steps:

[0021] Step 1: Put the 2cm×2cm ITO glass into the cleaning rack, clean the surface with deionized water, absolute ethanol, acetone, isopropanol and absolute ethanol in sequence, and dry it with nitrogen gas for later use;

[0022] Step 2: Dilute the tin dioxide colloidal solution with a mass fraction of 15wt.% to 2.67wt.% with deionized water, prepare an appropriate amount of tin dioxide solution, and ultrasonically mix it for 30 minutes to obtain a mixed solution A;

[0023] Step 3: Spin-coat mixed solution A on the surface of the ITO glass cleaned in step 1, and anneal at 150°C for 30 minutes to obtain a tin dio...

Embodiment 2

[0029] A preparation method of a 2D / 3D organic-inorganic hybrid perovskite solar cell, using FTO as a conductive substrate, tin dioxide as an electron transport layer, 2D / 3D perovskite light-absorbing layer, and Spiro-OMeTAD as a hole transport layer , gold as the counter electrode, specifically comprising the following steps:

[0030] Step 1: Put the 2cm×2cm FTO glass into the cleaning rack, clean the surface with deionized water, absolute ethanol, acetone, isopropanol and absolute ethanol in sequence, and dry it with nitrogen gas for later use;

[0031] Step 2: Dilute the tin dioxide colloidal solution with a mass fraction of 15wt.% to 2.67wt.% with deionized water, prepare an appropriate amount of tin dioxide solution, and ultrasonically mix it for 30 minutes to obtain a mixed solution A;

[0032] Step 3: Spin-coat the mixed solution A on the surface of the FTO glass cleaned in step 1, and anneal at 150° C. for 30 minutes to obtain a tin dioxide electron transport layer;

...

Embodiment 3

[0038] A preparation method of high-efficiency 2D / 3D organic-inorganic hybrid perovskite solar cells, using ITO as the conductive substrate, tin dioxide as the electron transport layer, 2D / 3D perovskite light-absorbing layer, and Spiro-OMeTAD as the hole transport Layer and carbon are counter electrodes, which specifically include the following steps:

[0039] Step 1: Put the 2cm×2cm ITO glass into the cleaning rack, clean the surface with deionized water, absolute ethanol, acetone, isopropanol and absolute ethanol in sequence, and dry it with nitrogen gas for later use;

[0040] Step 2: Dilute the tin dioxide colloidal solution with a mass fraction of 15wt.% to 2.67wt.% with deionized water, prepare an appropriate amount of tin dioxide solution, and ultrasonically mix it for 30 minutes to obtain a mixed solution A;

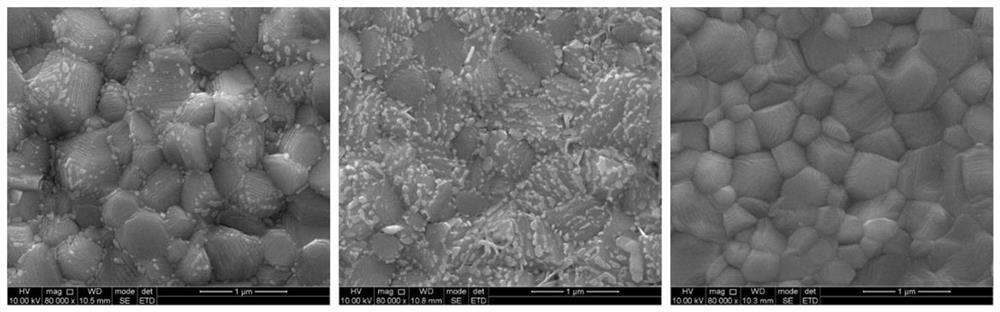

[0041] Step 4: Add 553mg PbI 2 (>99.99%), 198mg MAI (>99.99%) dissolved in 1mL DMF (≥99.9%), heated and stirred at 70°C until completely dissolved to obtain MAP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com