Semi-reflective and semi-transparent glass and preparation method thereof

A semi-reflective, semi-transparent and glass technology, applied in chemical instruments and methods, glass/slag layered products, lamination devices, etc., can solve problems such as easy scratches, air bubbles, and damage to the optical effects of semi-reflective and semi-transparent optical films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of above-mentioned transflective and translucent glass, comprises the steps:

[0058] S10 , providing a glass substrate 10 .

[0059] The glass substrate 10 can be selected from float glass or other conventional glass in the field.

[0060] Preferably, the thickness of the glass substrate 10 is 0.3-3.0 mm, more preferably 0.55-1.1 mm.

[0061] Preferably, the refractive index of the glass substrate 10 is 1.52.

[0062] Preferably, the glass substrate 10 is cleaned and dried first.

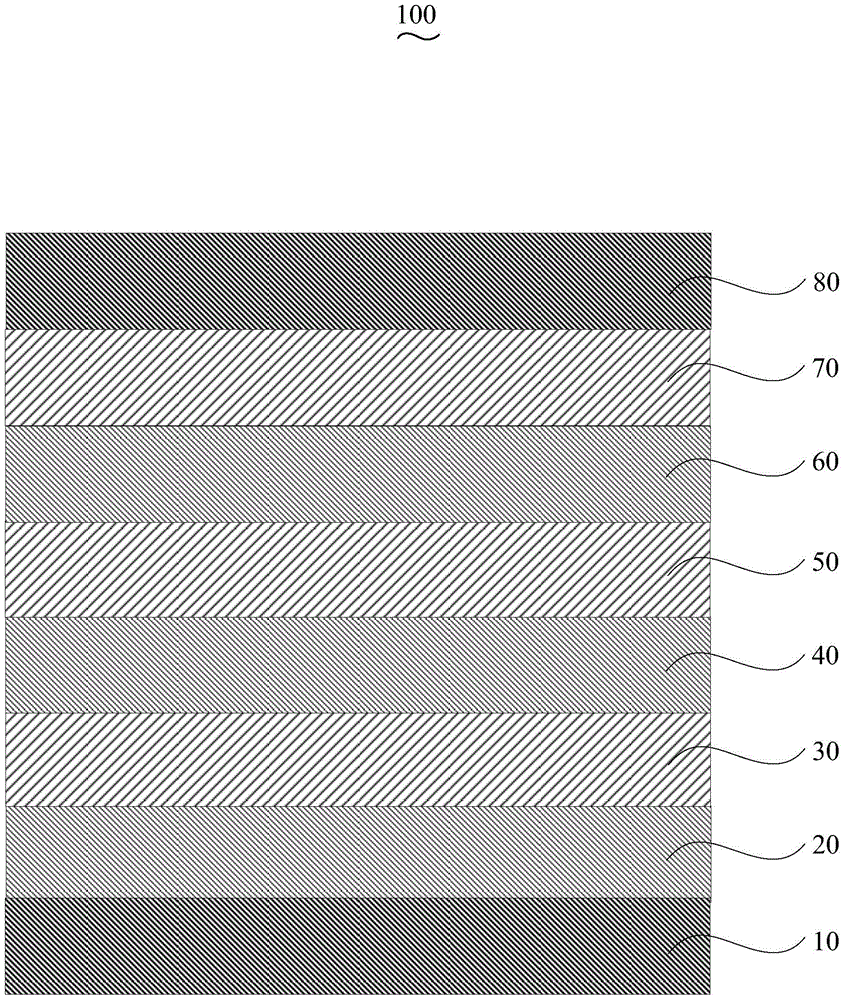

[0063] S20, deposit the first low refractive index layer 20, the first high refractive index layer 30, the second low refractive index layer 40, the second high refractive index layer 50, the third The low-refractive-index layer 60, the third high-refractive-index layer 70, and the fourth high-hardness refractive-index layer 80 form a semi-reflective and semi-transparent glass.

[0064] The material of the first low refractive index layer 20 is SiO 2 . SiO 2 The...

Embodiment 1

[0089] The structure of the semi-reflective and semi-transparent glass of embodiment 1 is a glass substrate Wherein, " / " represents a stacked structure, and the values in brackets represent thicknesses, which are the same in the following embodiments.

[0090] The material of the glass substrate in Example 1 is soda lime glass with a thickness of 0.7 mm.

[0091] The semi-reflective and semi-transparent glass of Example 1 is tested for light with a wavelength range of 380-780 nm by using Nippon Denshoku SD-6000, and the reflectance at 550 nm is 20%.

[0092] The hardness of the semi-reflective and semi-transparent optical film layer was tested with a pencil hardness tester, and the hardness was 7H.

[0093] Take a certain amount of semi-reflective and semi-transparent optical film glass with a reflectivity of 20%, soak it in NaOH solution with a concentration of 10wt% and a temperature of 40°C for 2H. After testing the spectrum of the sample after immersion, compared wi...

Embodiment 2

[0097] The structure of the semi-reflective and semi-transparent glass of embodiment 2 is a glass substrate

[0098] The material of the glass substrate in Example 2 is soda lime glass with a thickness of 1.1 mm.

[0099] The semi-reflective and semi-transparent glass of Example 2 was tested for light with a wavelength range of 380-780 nm by using Nippon Denshoku SD-6000, and the test result showed that the reflectance at 550 nm was 30%. The hardness of the semi-reflective and semi-transparent optical film layer was tested with a pencil hardness tester, and the hardness was 7H.

[0100] Take a certain amount of semi-reflective and semi-transparent optical film glass with a reflectivity of 30%, soak it in NaOH solution with a concentration of 10wt% and a temperature of 40°C for 2H. After testing the spectrum of the sample after immersion, compared with the spectrum before immersion, the coincidence is very good; the adhesion is still 5B after testing 100 grids.

[0101] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com