Composite artificial bone material and preparation method thereof

A kind of artificial bone and artificial technology, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problems of short residence time in the defect area, affect the bone healing effect, and the bone wax is not absorbed by the body, so as to promote osteoblasts Mature differentiation, low cost, and the effect of promoting bone healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

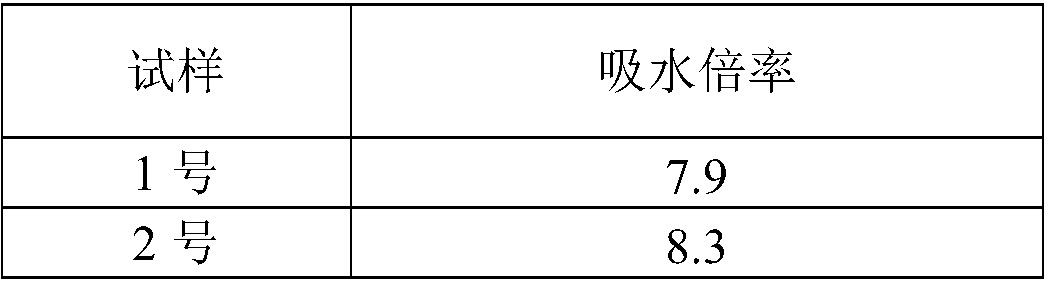

Embodiment 1

[0033] A preparation method of a composite artificial bone material, comprising the steps of: adding 15g PLGA to 100mL 1,4-dioxane, stirring at room temperature for 24h to completely dissolve it, adding 12g nano-hydroxyapatite and 8g of β-tricalcium phosphate, mixed evenly, added to the 3D printing material tank, adjusted the temperature of the low-temperature deposition platform to -30°C for printing and forming; freeze-dried the formed material at -40°C, vacuum degree less than 40Pa for 48 hours, and made porous bone stent, and then pour 5% sodium carboxymethyl starch into the porous bone stent under negative pressure, freeze-dry at -40°C and the vacuum degree is less than 40Pa for 48h, and then sterilize by electron beam irradiation to obtain the finished composite artificial bone (No. 1), the modified starch content is 2.9g, and the irradiation dose is 20kGy. The porous bone scaffold has a pore size of 206 μm and a porosity of 72%.

[0034] A 3D printing ink, the ink is m...

Embodiment 2

[0037]A preparation method of a composite artificial bone material, comprising the steps of: adding 12g PLGA to 100mL 1,4-dioxane, stirring at room temperature for 24h to completely dissolve it, adding 16g nano-hydroxyapatite and 2g of β-tricalcium phosphate, mixed evenly, added to the 3D printing material tank, adjusted the temperature of the low-temperature deposition platform to -30°C for printing and forming; freeze-dried the formed material at -40°C, vacuum degree less than 40Pa for 48 hours, and made porous bone stent, and then pour 6% sodium carboxymethyl starch into the porous bone stent under negative pressure, freeze-dry at -40°C and the vacuum degree is less than 40Pa for 48h, and then sterilize by electron beam irradiation to obtain the finished product of composite artificial bone (No. 2), the modified starch content is 2.6g, and the irradiation dose is 20kGy. The porous bone scaffold has a pore size of 231 μm and a porosity of 80%.

[0038] A 3D printing ink, th...

Embodiment 3

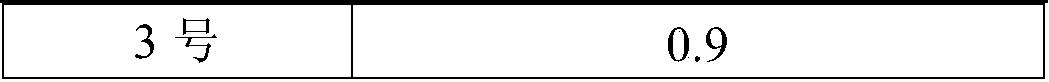

[0041] A preparation method of a composite artificial bone material, comprising the steps of: adding 15g PLGA to 100mL 1,4-dioxane, stirring at room temperature for 24h to completely dissolve it, adding 12g nano-hydroxyapatite and 8g of β-tricalcium phosphate, mixed evenly, added to the 3D printing material tank, adjusted the temperature of the low-temperature deposition platform to -30°C for printing and forming; freeze-dried the formed material at -40°C, vacuum degree less than 40Pa for 48 hours, and made porous bone The bracket is then sterilized by electron beam irradiation to obtain a composite artificial bone product (No. 3), and the irradiation dose is 20 kGy. The porous bone scaffold has a pore size of 201 μm and a porosity of 75%.

[0042] A 3D printing ink, the ink is made of the following raw materials in parts by weight: PLGA 15g, hydroxyapatite 12g, β-tricalcium phosphate 8g.

[0043] A composite artificial bone material, adding the 3D printing ink into a 3D prin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com