Precise grinding and polishing method for cathode roller

A cathode roll, precise technology, applied in the field of grinding and polishing, can solve the problems of raw foil solution system pollution, short operating life, coarse copper foil crystals, etc., and achieve the effect of long production operating cycle, precise geometric shape, and dense product crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

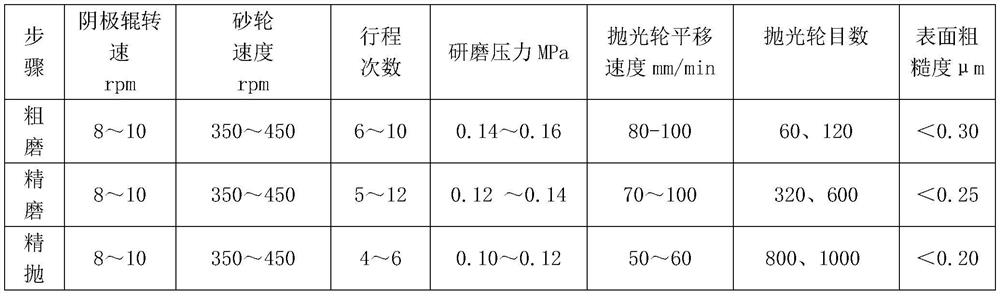

Method used

Image

Examples

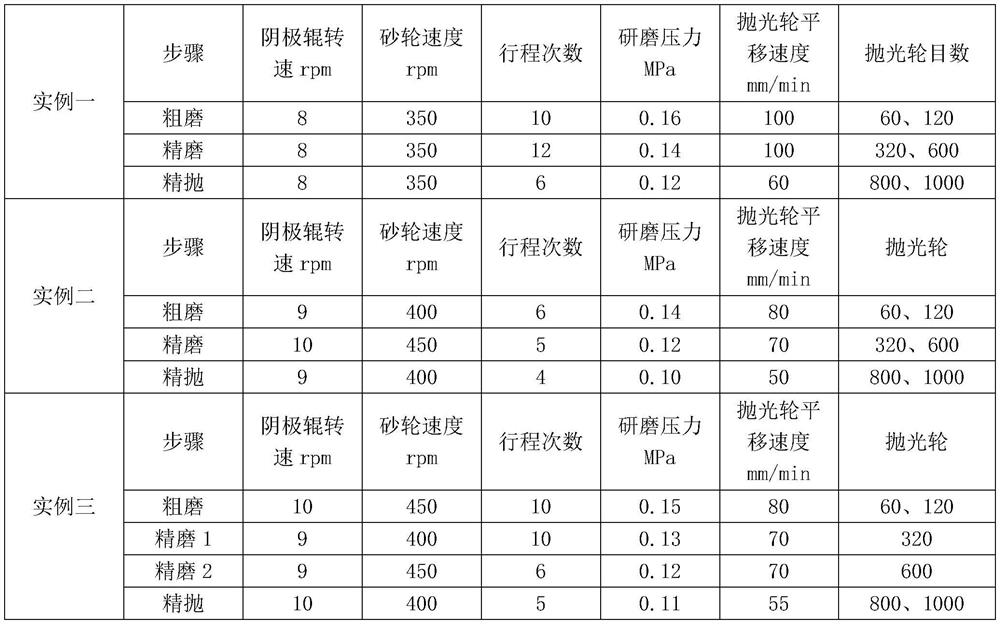

Embodiment 1

[0037] Place the cathode roller to be treated on the cathode roller turret, soak each polishing wheel with pure water, install the polishing wheel and lock the protective cover, and run it without load for 3 minutes to confirm that the polishing wheel is operating normally;

[0038] Roughly grind the surface of the cathode roller with a polishing wheel with a particle size of 60 mesh and 120 mesh in turn, set the rotation speed of the cathode roller to 8r / min, the rotation speed of the polishing wheel to 350r / min, and the translational speed of the polishing wheel to 100mm / min; the grinding pressure is 0.16MPa , the number of strokes is 10 times, the pure water spray position is adjusted to the tangent between the polishing wheel and the cathode roller, the spraying direction is consistent with the feeding direction of the polishing wheel, and the water flow rate is 0.2m 3 / h;

[0039] The surface of the cathode roller is finely ground with a polishing wheel with a particle si...

Embodiment 2

[0044] Place the cathode roll to be treated on the cathode roll turret, soak each polishing wheel with pure water, install the polishing wheel and lock the protective cover, and run it without load for 5 minutes to confirm that the polishing wheel is operating normally;

[0045] Roughly grind the surface of the cathode roll with a polishing wheel with a particle size of 60 mesh and 120 mesh in turn, set the rotation speed of the cathode roll to 9r / min, the rotation speed of the polishing wheel to 400r / min, and the translational speed of the polishing wheel to 80mm / min; the grinding pressure is 0.14MPa , 6 strokes, adjust the pure water spraying position to the tangent between the polishing wheel and the cathode roller, the spraying direction is consistent with the feeding direction of the polishing wheel, and the water flow rate is 0.4m 3 / h;

[0046] The surface of the cathode roller is finely ground with a polishing wheel with a particle size of 320 mesh and 600 mesh in turn...

Embodiment 3

[0051] Place the cathode roll to be treated on the cathode roll turret, soak each polishing wheel with pure water, install the polishing wheel and lock the protective cover, and run it without load for 4 minutes to confirm that the polishing wheel is operating normally;

[0052] Roughly grind the surface of the cathode roller with a polishing wheel with a particle size of 60 mesh and 120 mesh in turn, set the rotation speed of the cathode roller to 10r / min, the rotation speed of the polishing wheel to 450r / min, and the translational speed of the polishing wheel to 80mm / min; the grinding pressure is 0.15MPa , the number of strokes is 10 times, the pure water spray position is adjusted to the tangent between the polishing wheel and the cathode roller, the spraying direction is consistent with the feeding direction of the polishing wheel, and the water flow rate is 0.3m 3 / h,

[0053] The surface of the cathode roller is finely ground with the polishing wheel of 320 mesh and 600 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com