Patents

Literature

39results about How to "Accurate roundness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

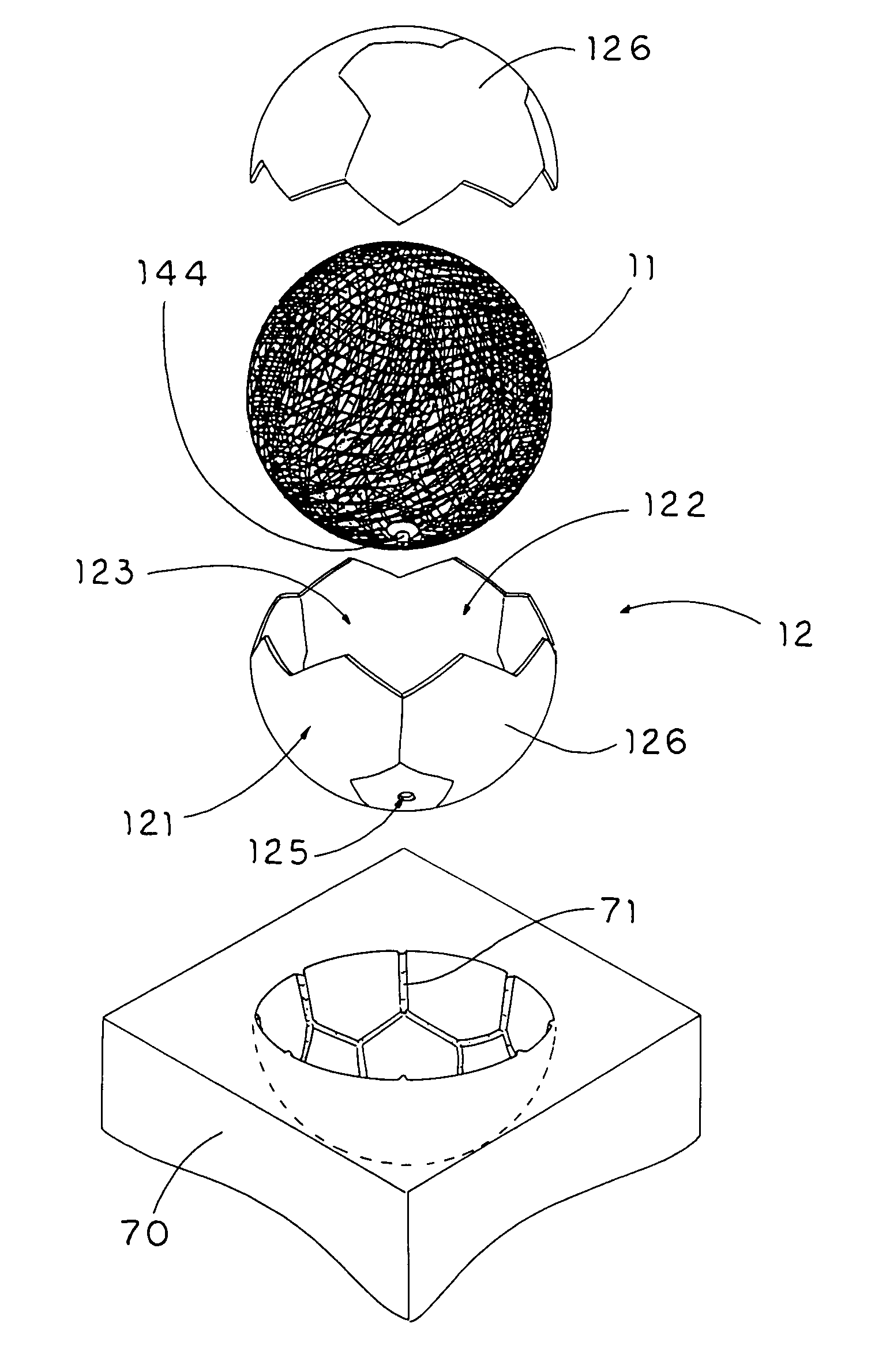

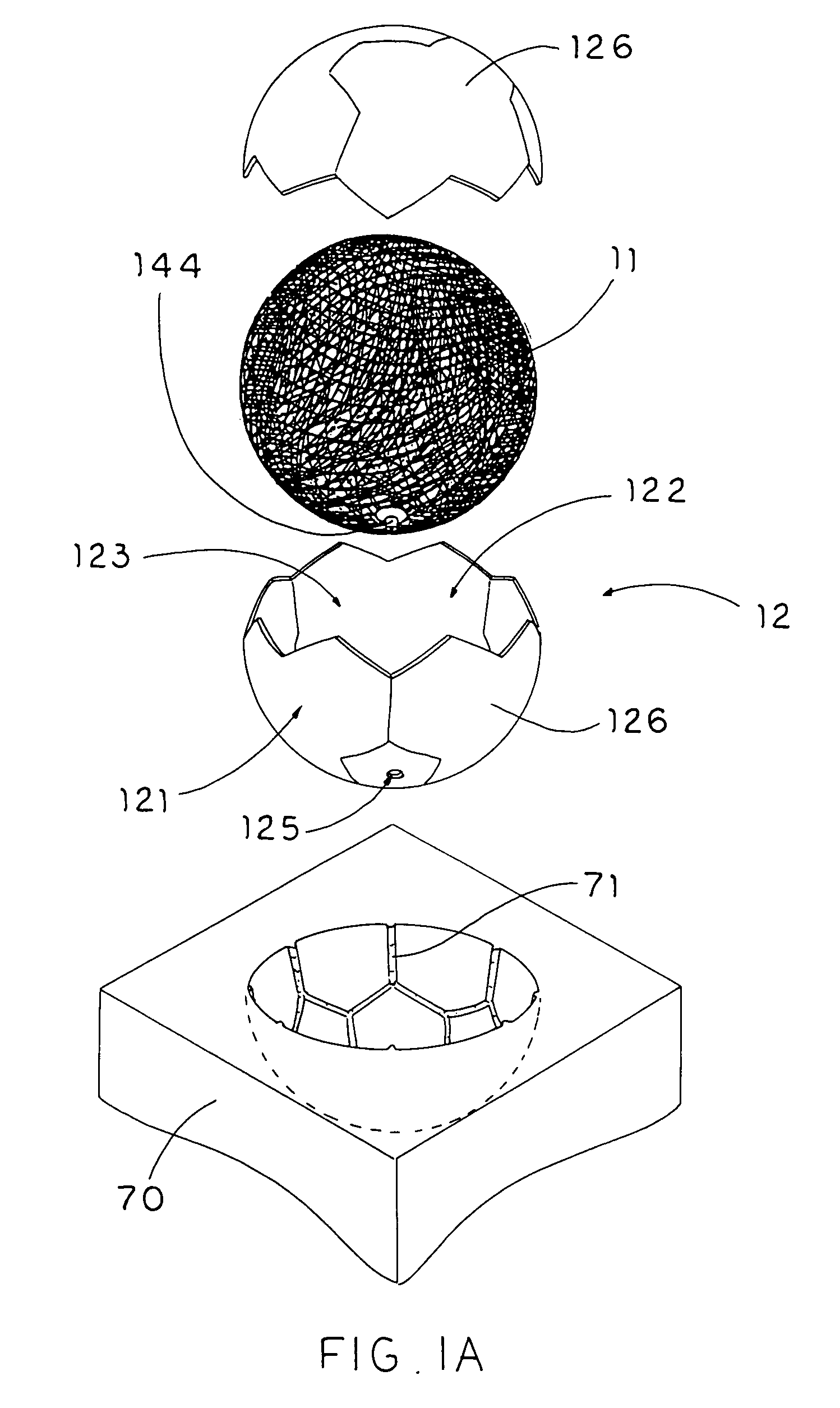

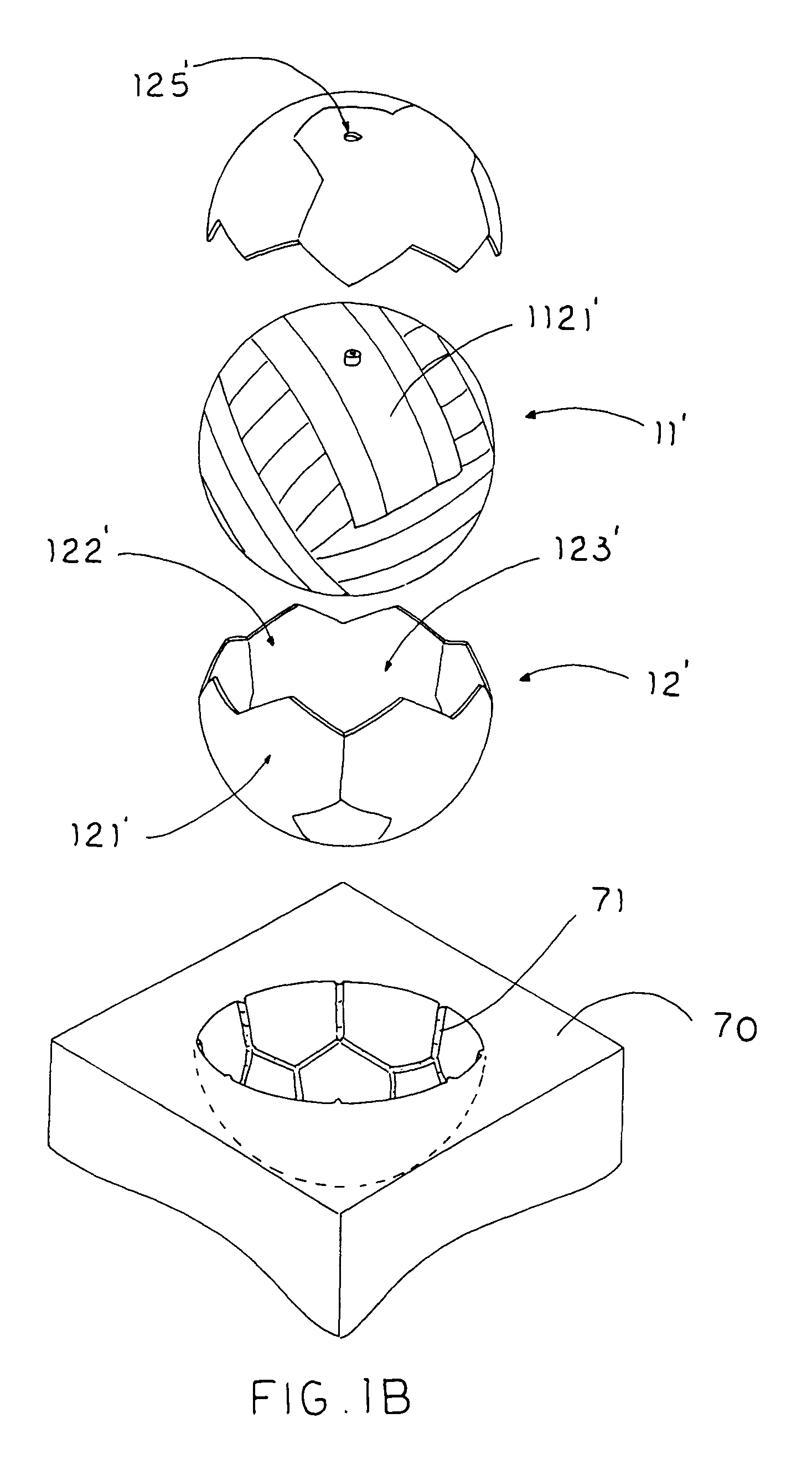

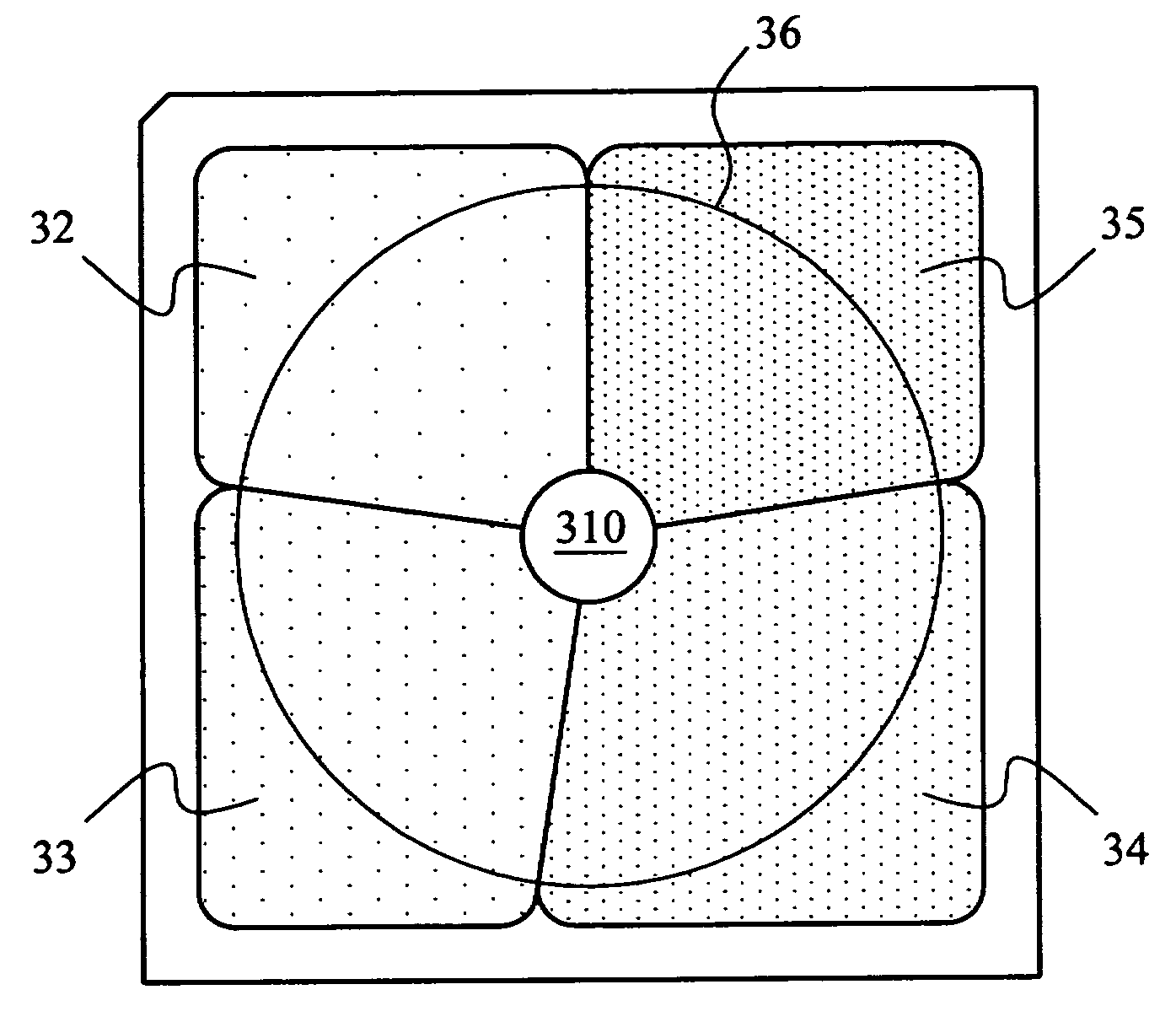

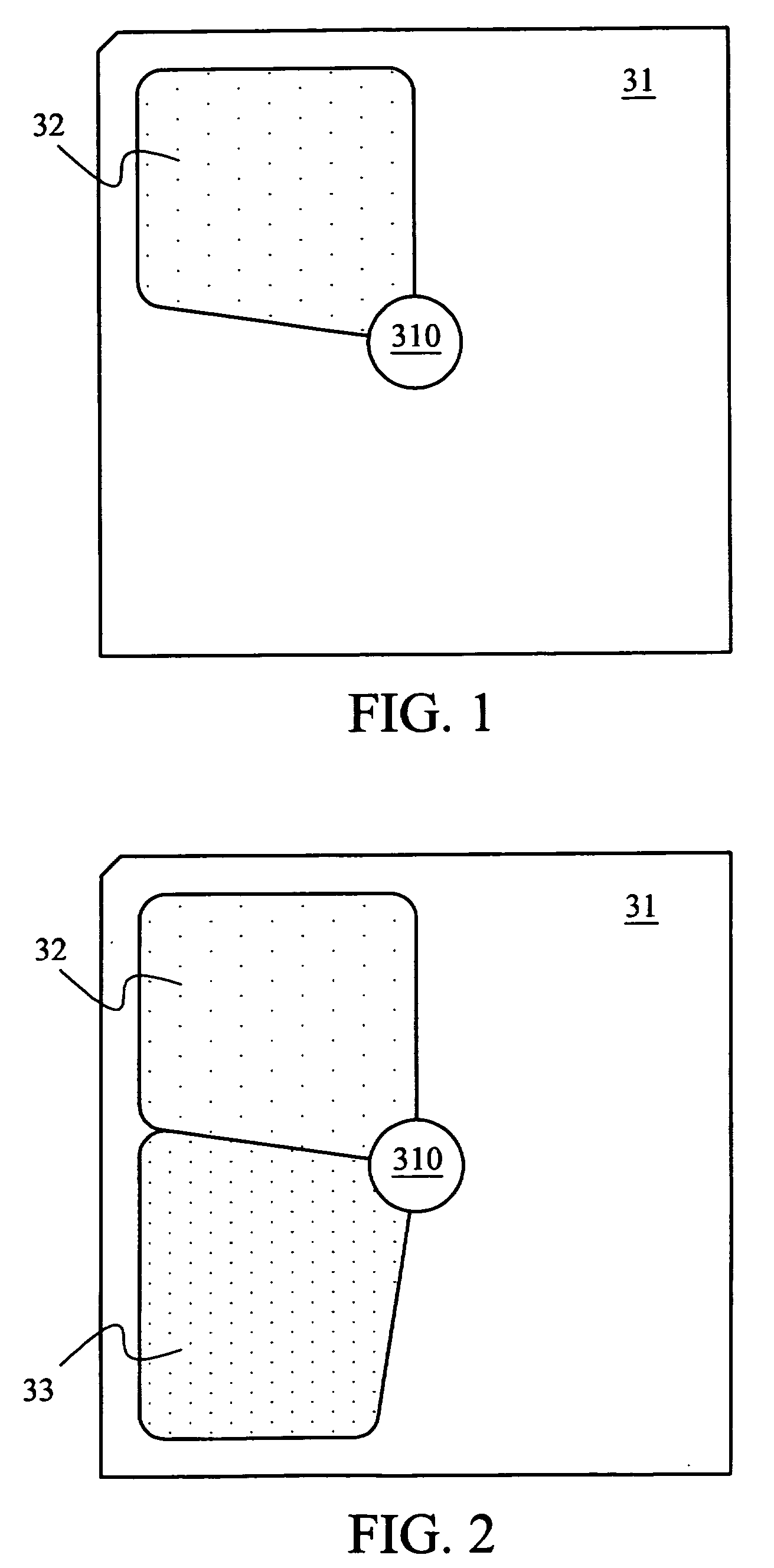

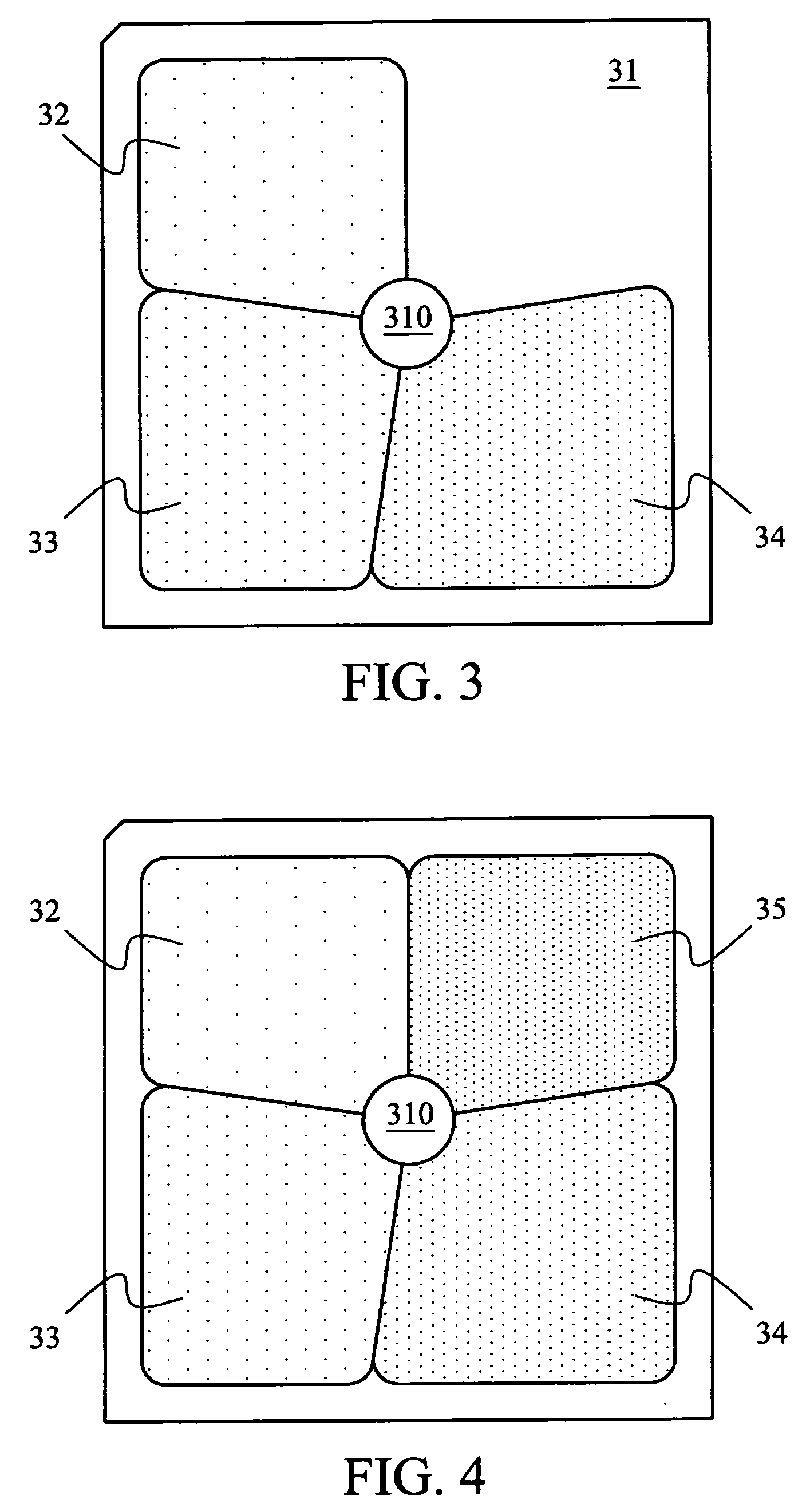

Sportsball with integral ball casing and bladder body

InactiveUS20090209374A1Reduce impactStress minimizationHollow inflatable ballsHollow non-inflatable ballsEngineeringMechanical engineering

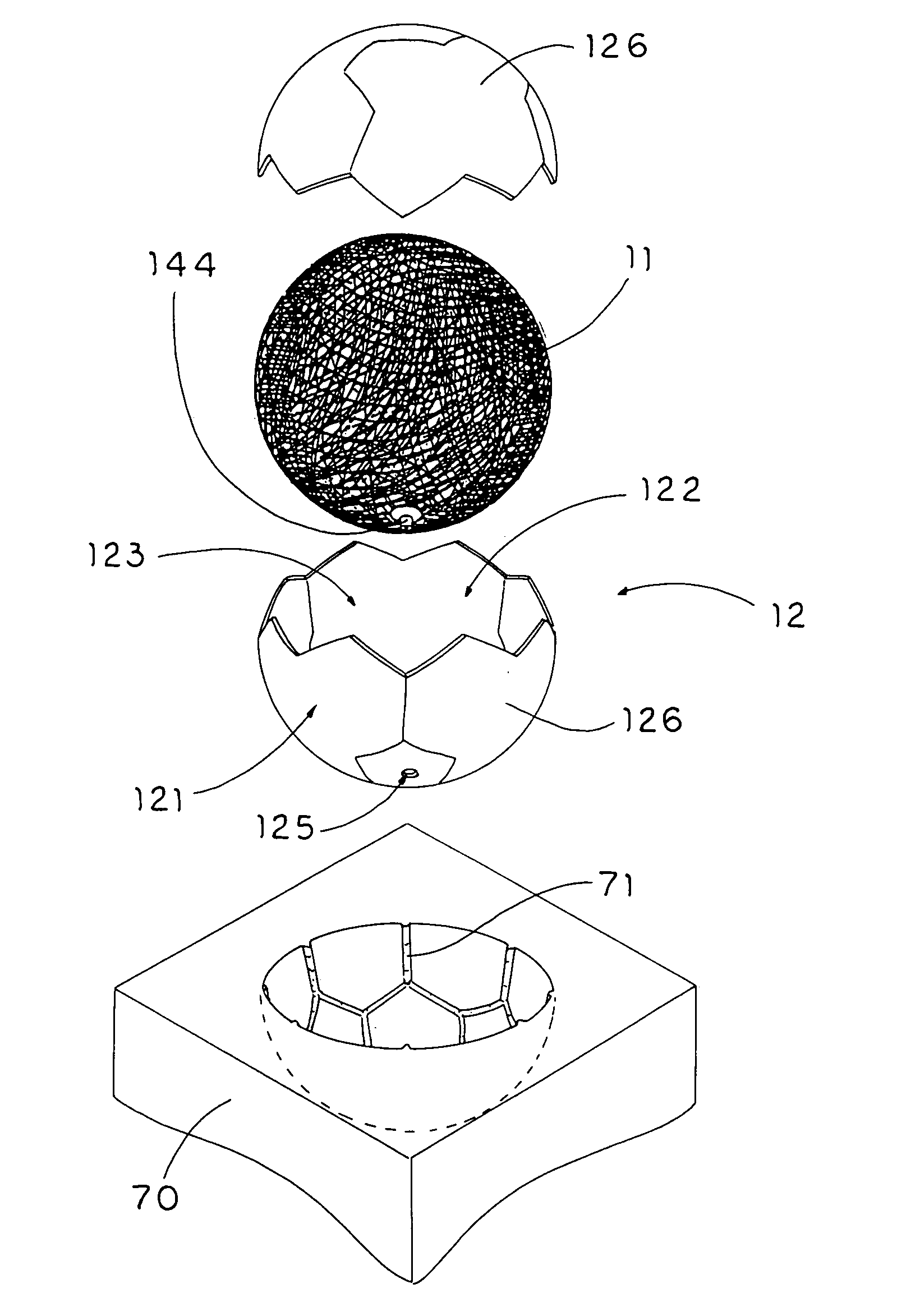

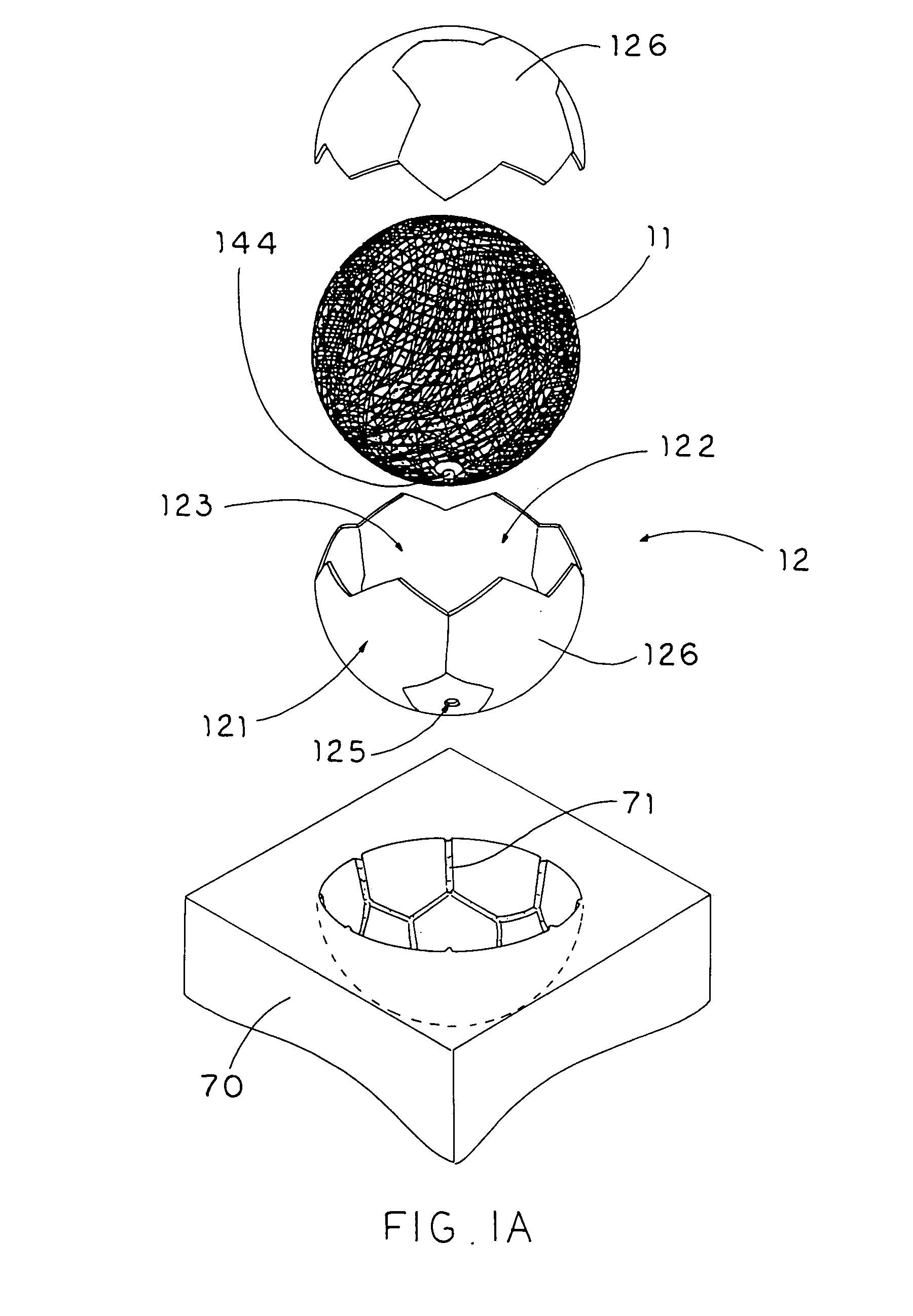

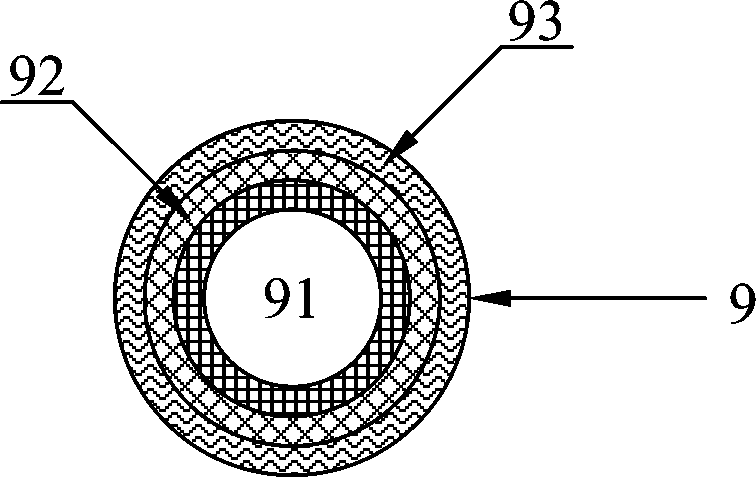

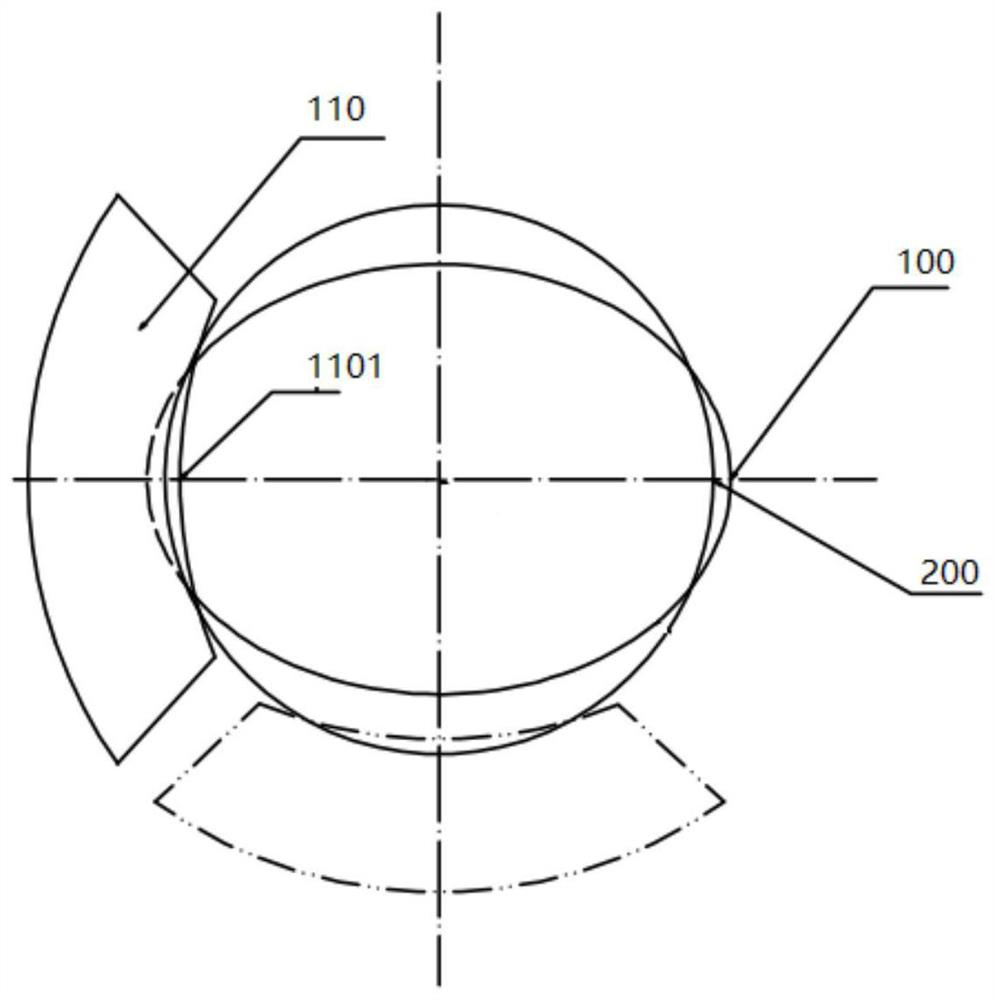

A sportsball includes a barebone ball and an outer ball cover. The barebone ball includes an inflatable bladder body and a ball casing. The ball casing, which is formed in an integrated structure, has an outer circumferential surface, an inner circumferential surface to define an interior cavity to fittingly enclose the bladder body therein, and a plurality of pre-formed channels integrally and indently formed on the outer circumferential surface, such that the ball casing and the bladder body enclosed therewithin form a one piece integrated semi-product of the sportsball. The outer ball cover comprising a plurality of outer cover panels overlapping on the outer circumferential surface of the ball casing at a position that edges of each of the outer cover panels are aligned with the corresponding pre-formed channels respectively.

Owner:TOPBALL SPORTS

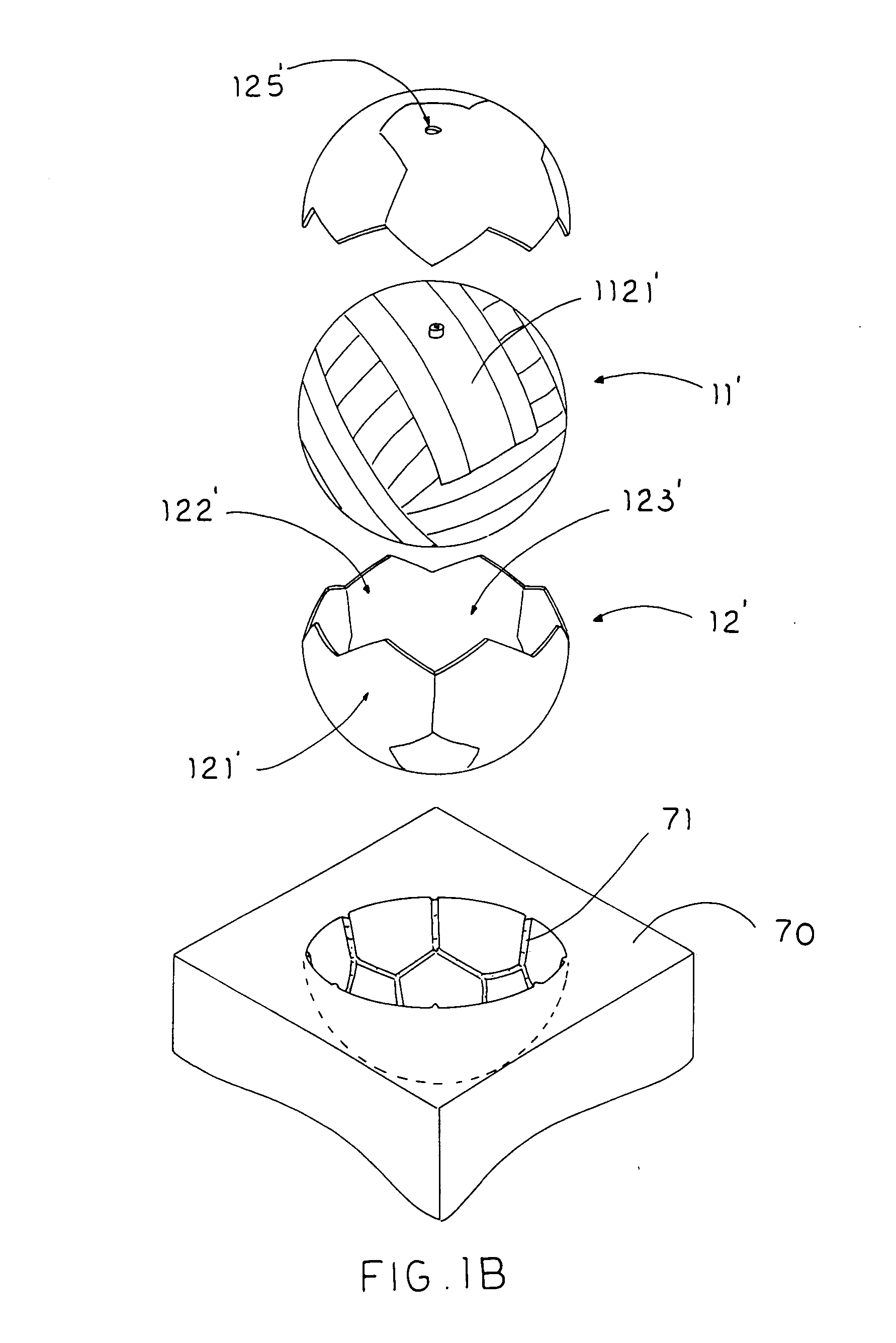

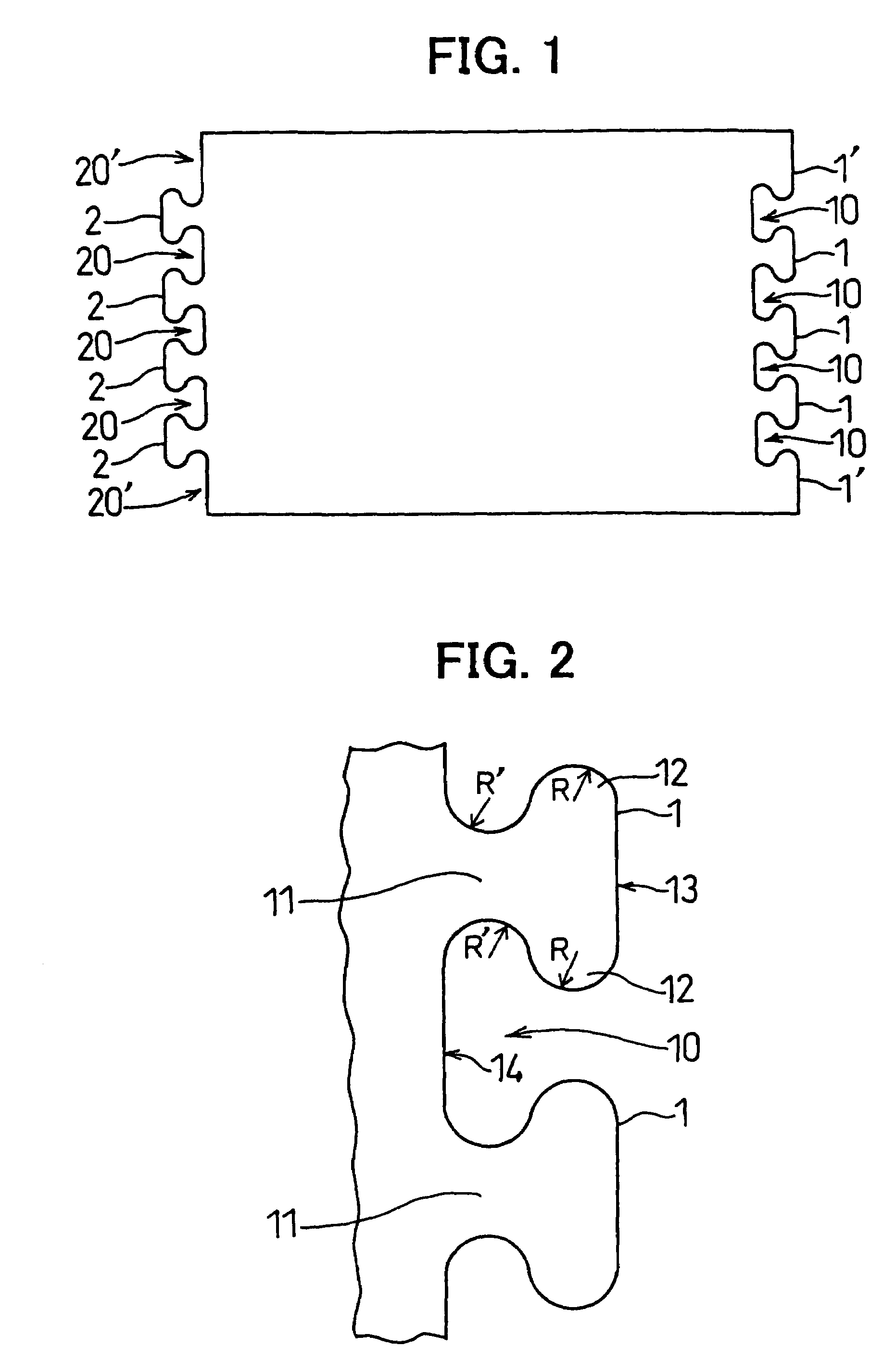

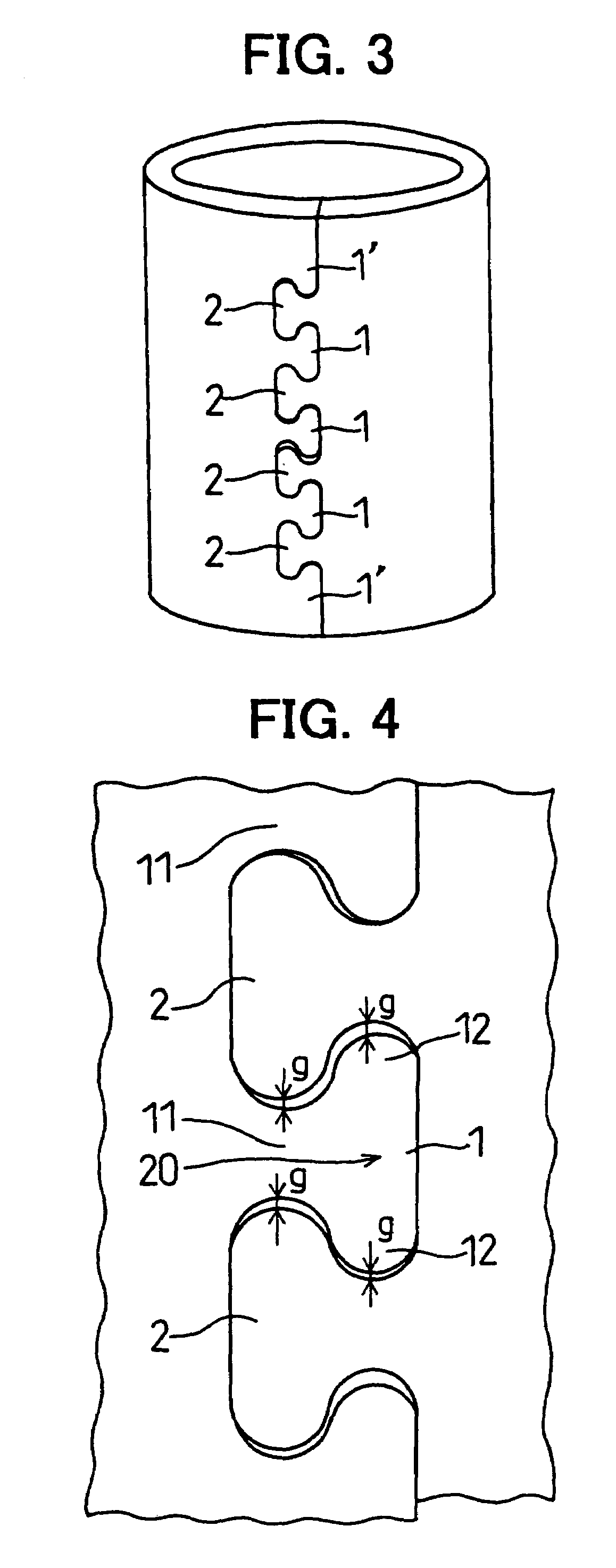

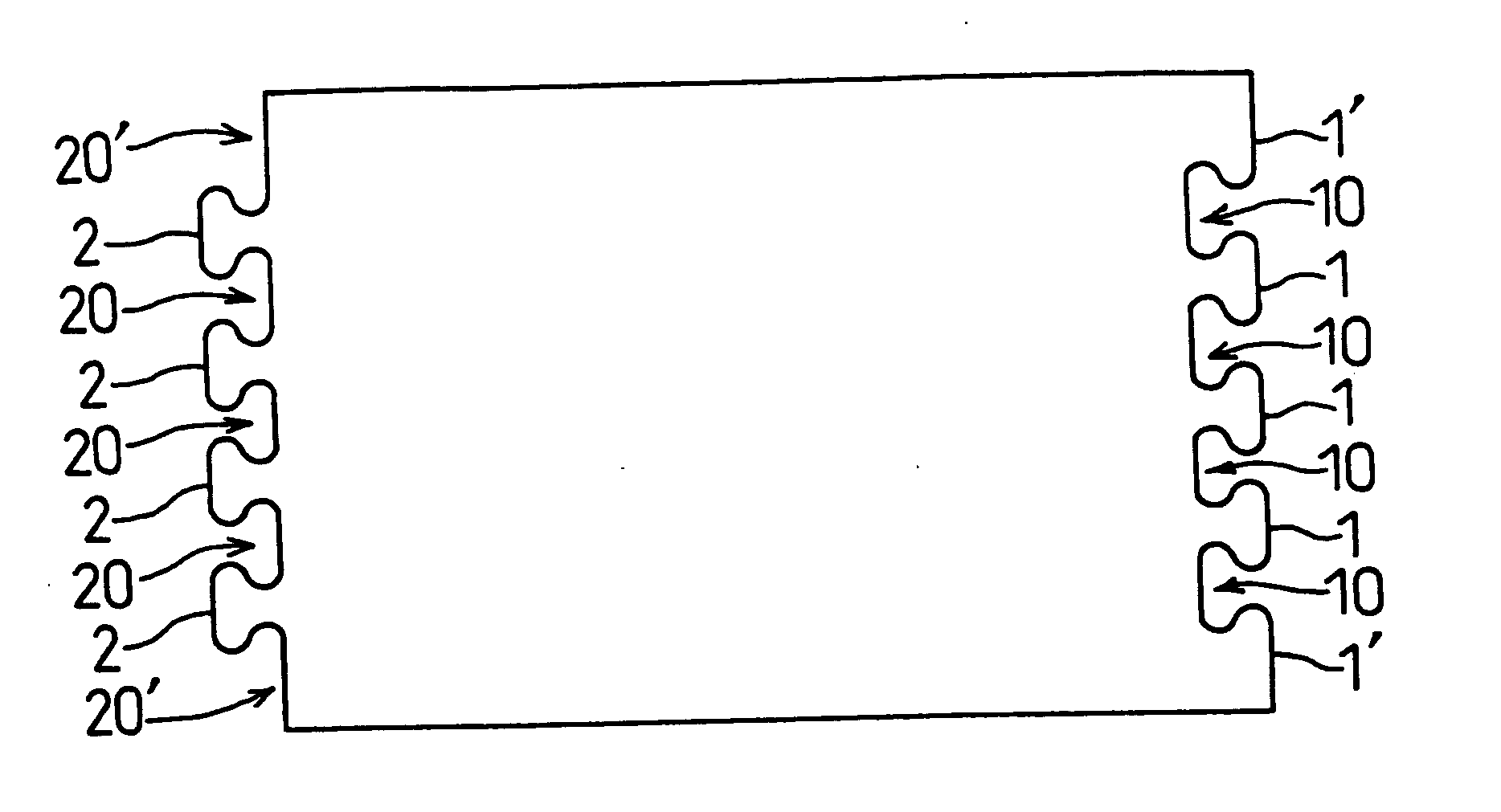

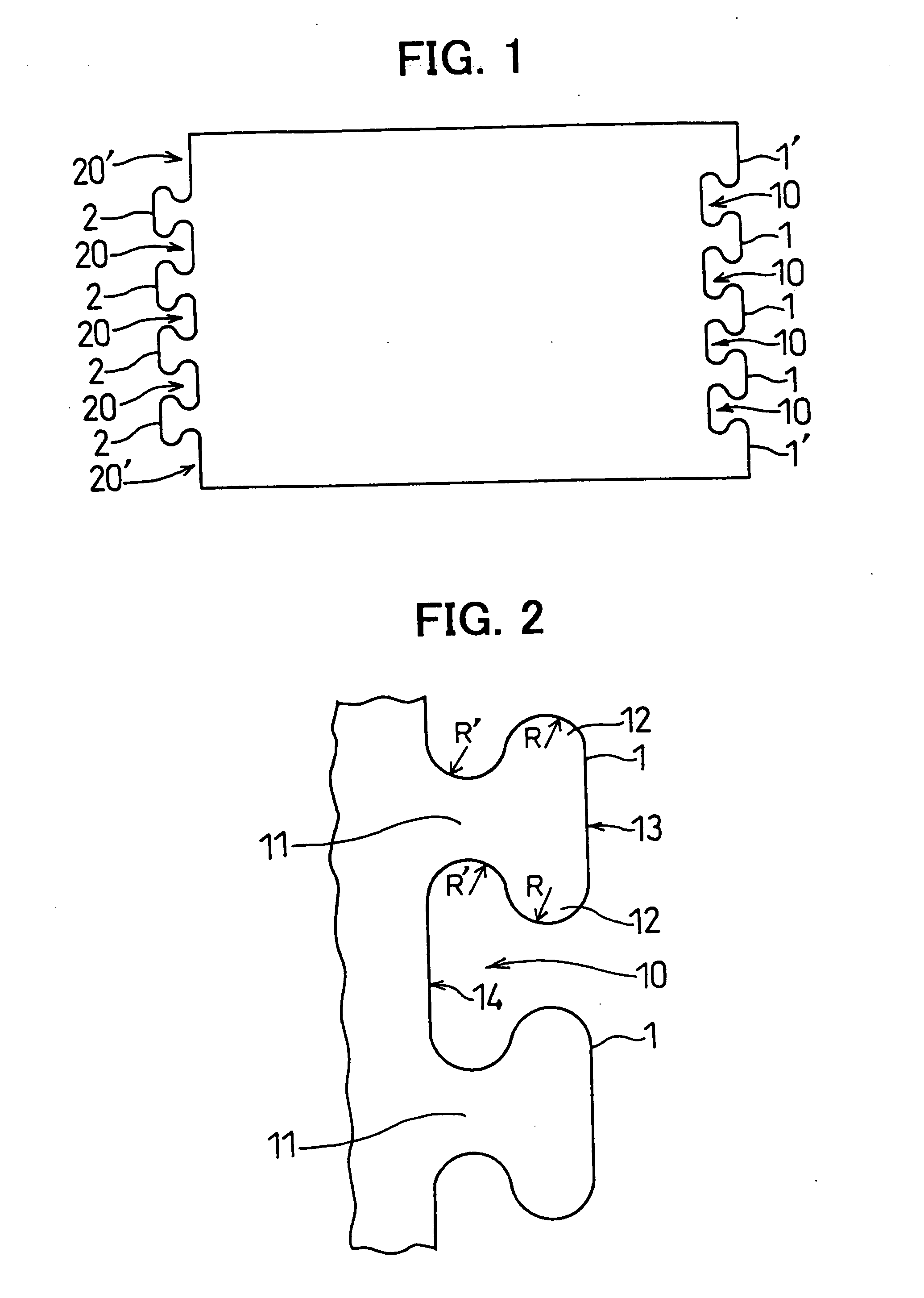

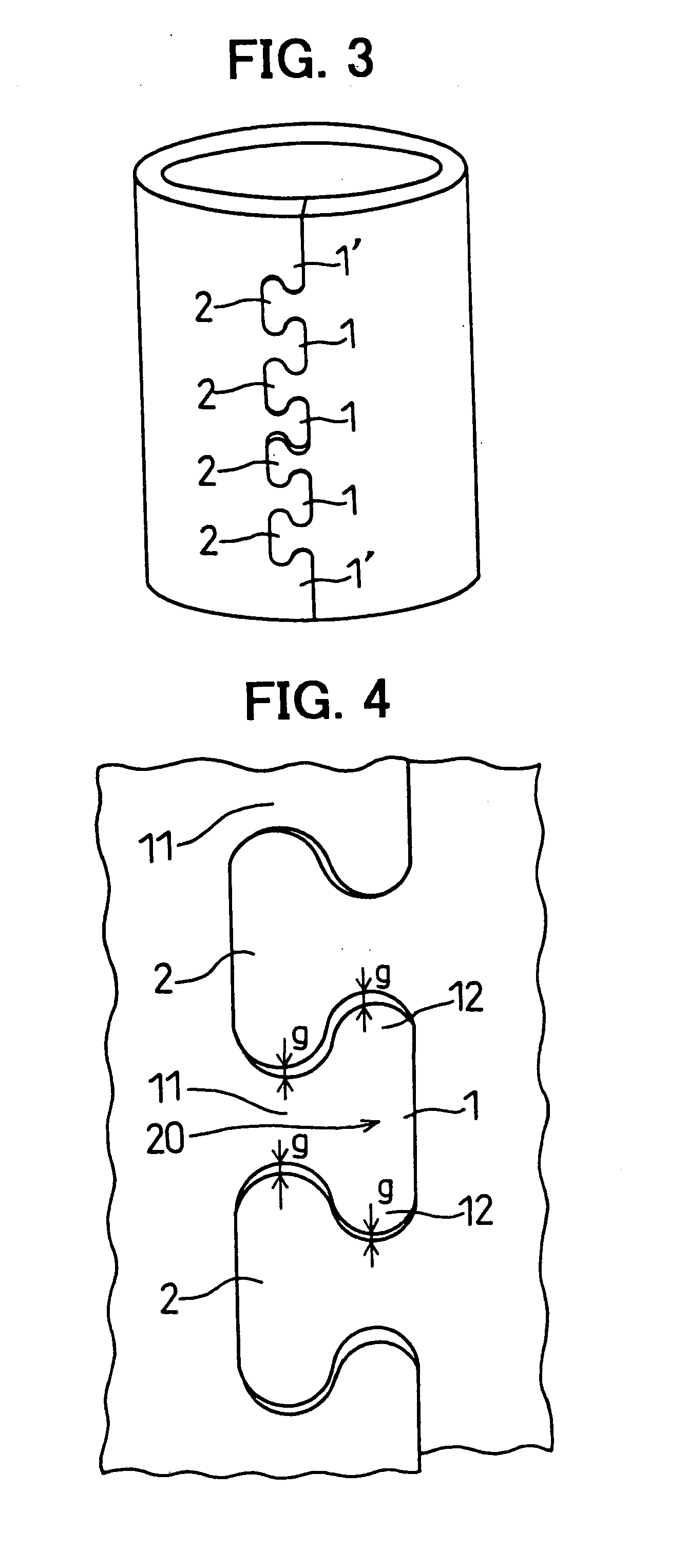

Method of manufacturing yoke of rotary electric machine

InactiveUS7168151B2Accurate roundnessWave amplification devicesMagnetic circuit stationary partsElectric machineEngineering

A method of manufacturing a yoke includes a step of cutting a steel plate into a rectangular sheet having a plurality of first dovetail convexities at one end thereof and a plurality of second dovetail convexities at the other end, a step of rolling the rectangular sheet into a cylinder to fit the first dove tails and the second dove tails to each other and a step of punching border portions of the first dove tails and the second dove tails. The second dovetail convexities are formed to be the same in shape as the first dovetail convexities so that they can fit to the first dovetail convexities. A smooth-faced yoke can be manufacture without using an expensive welder.

Owner:DENSO CORP

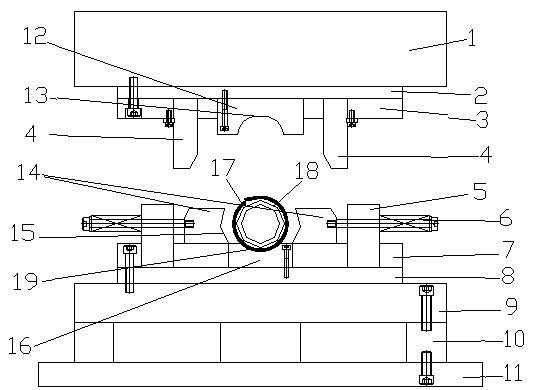

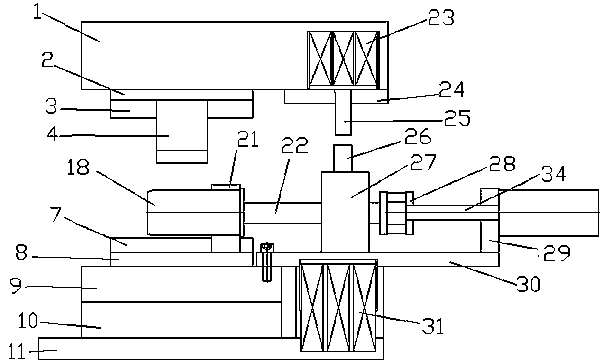

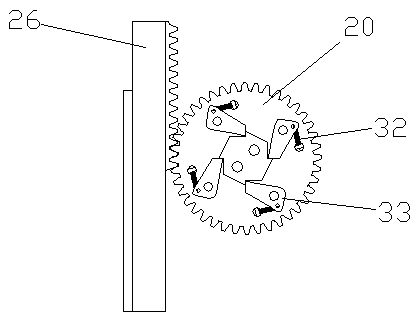

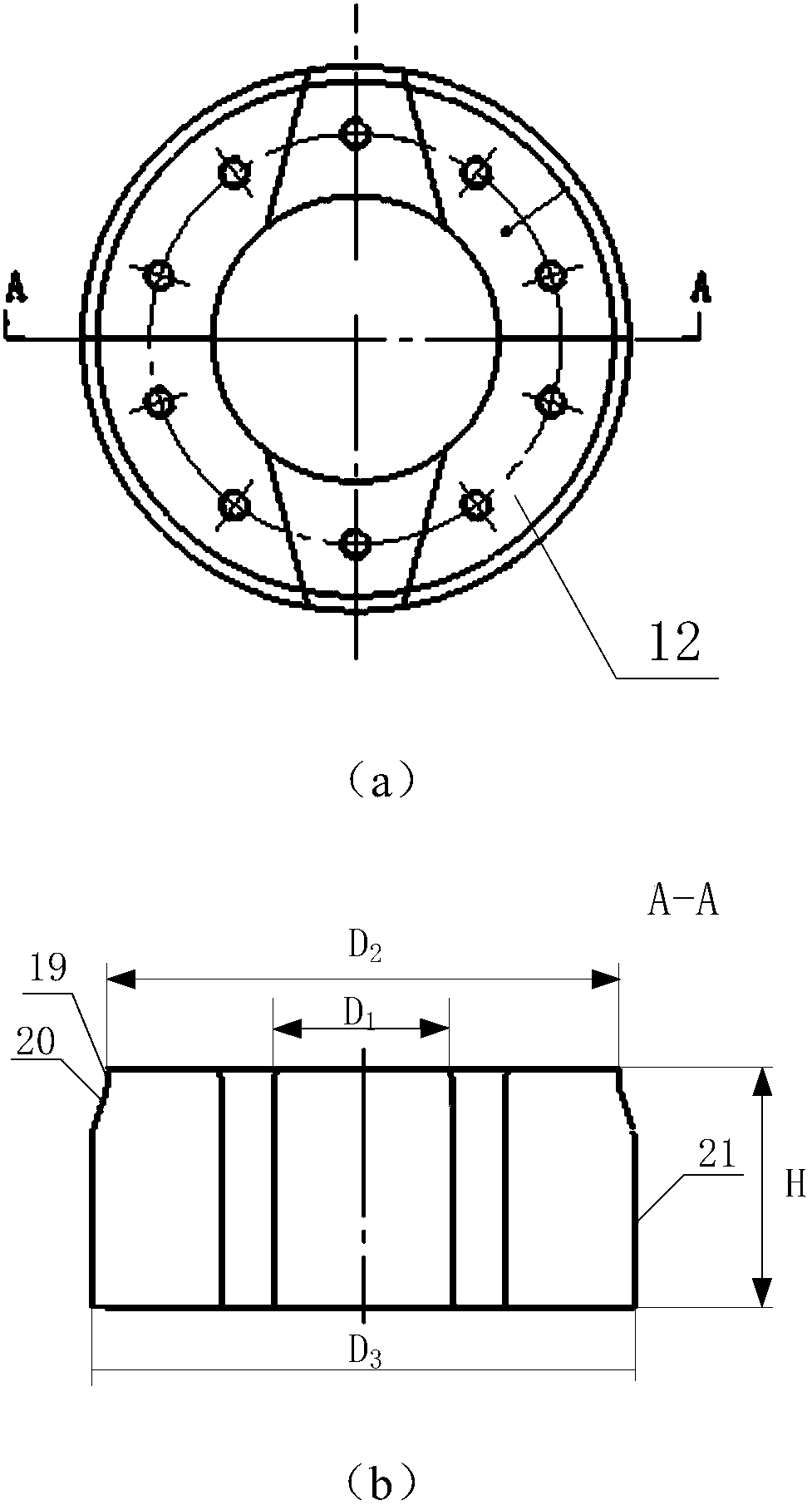

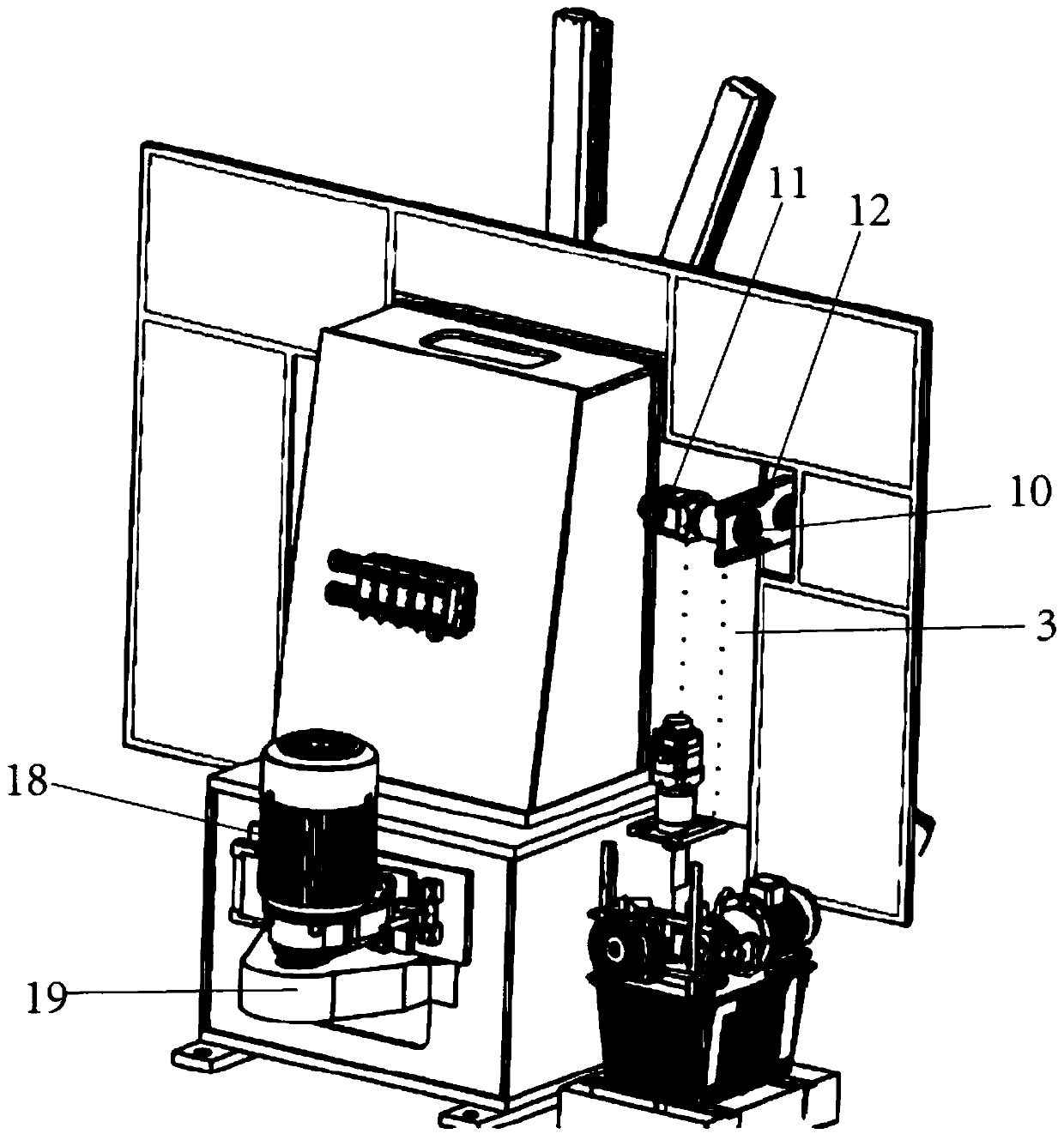

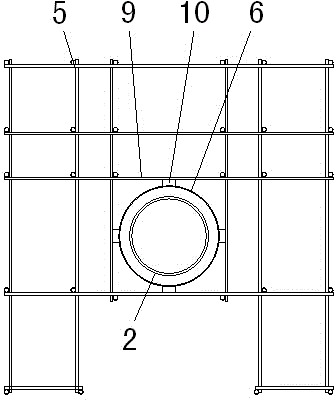

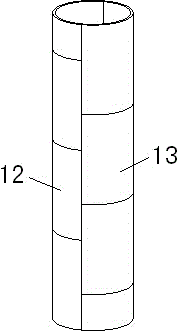

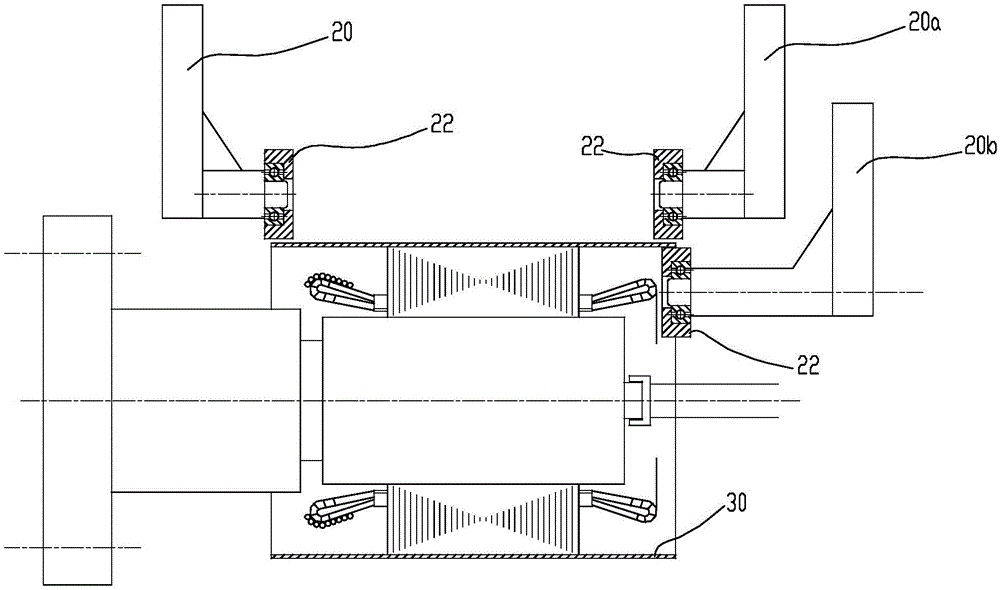

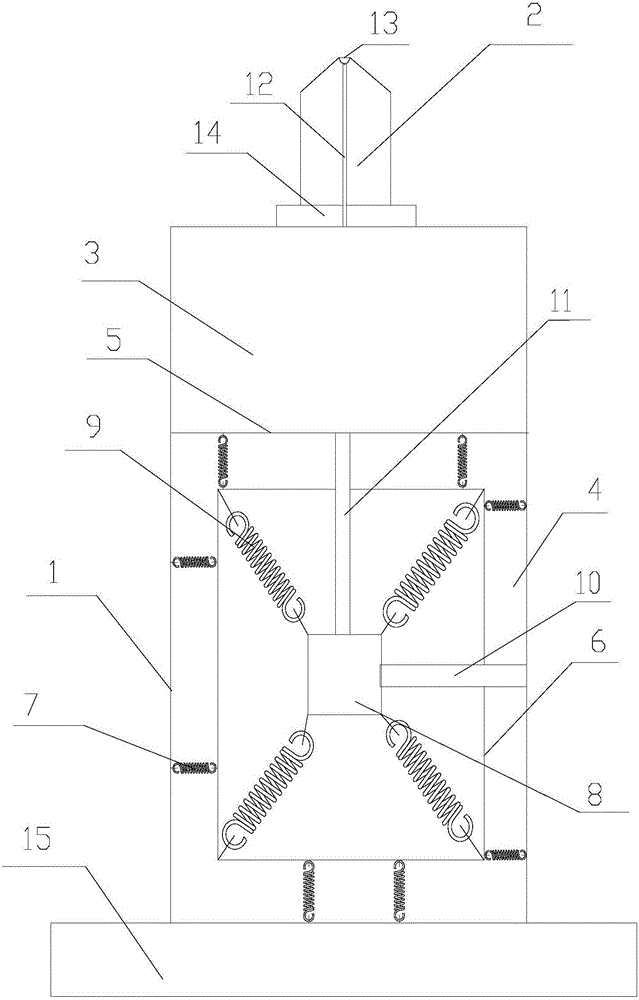

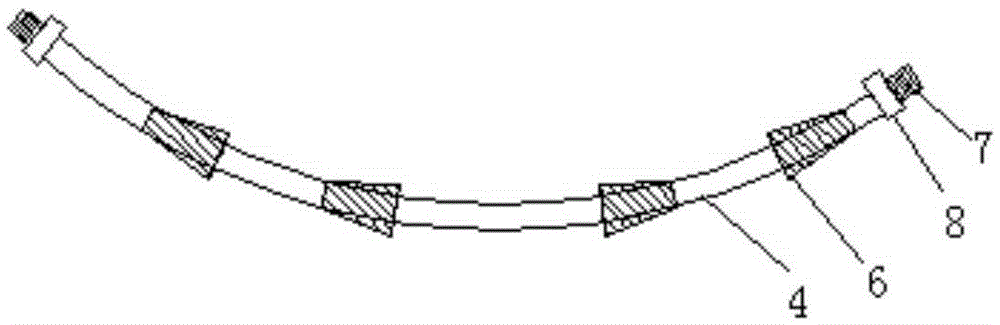

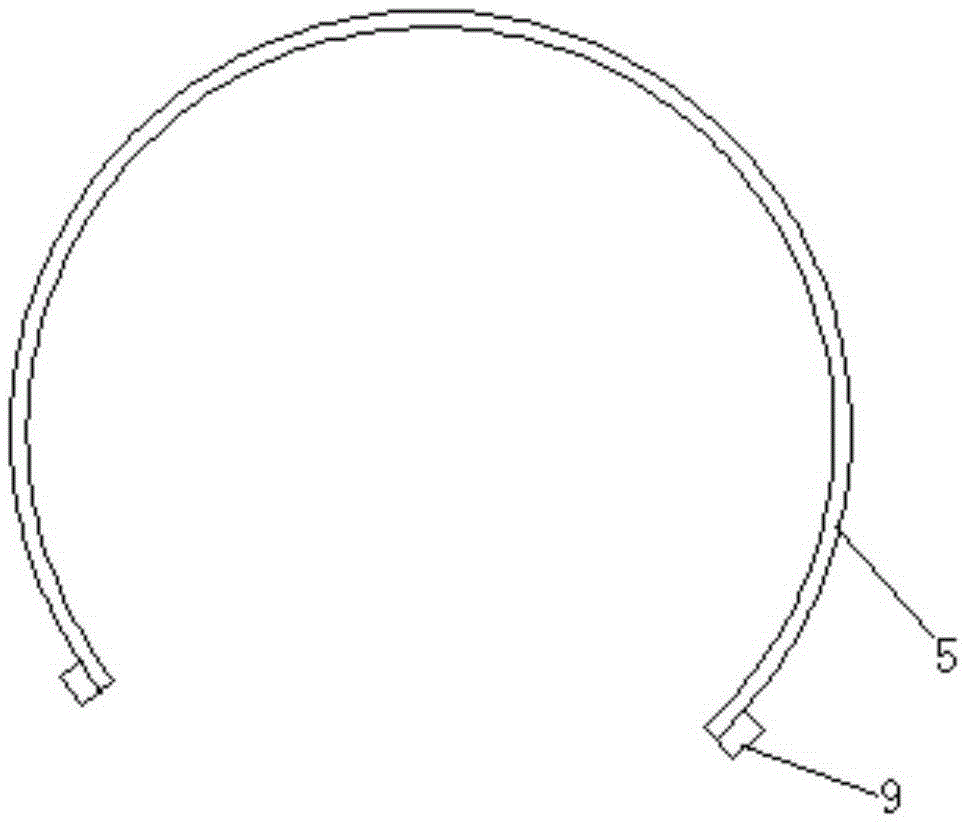

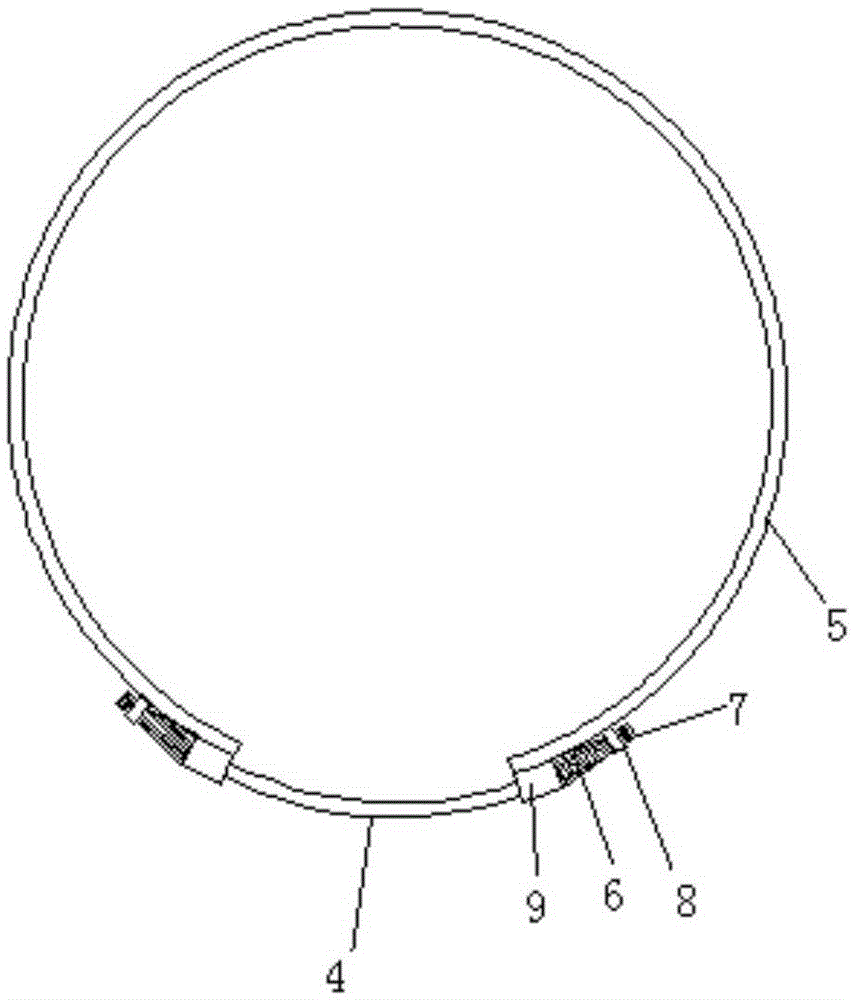

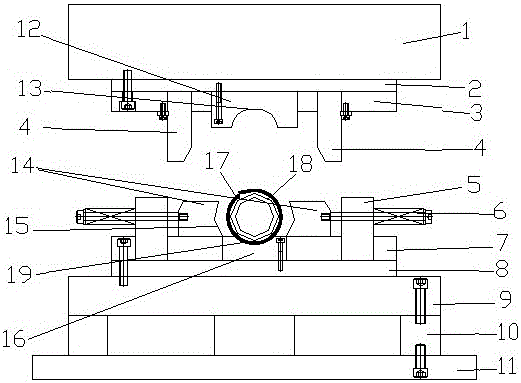

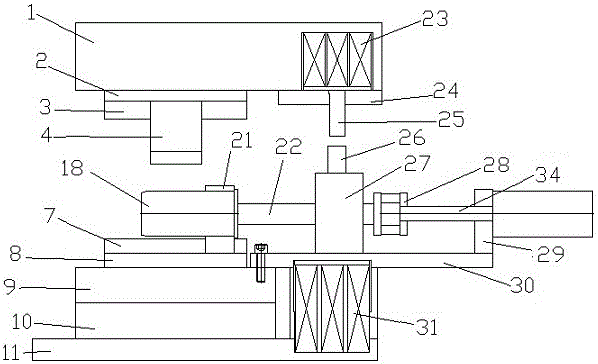

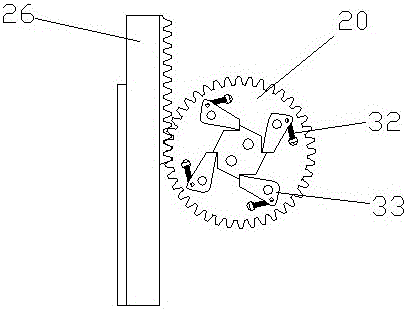

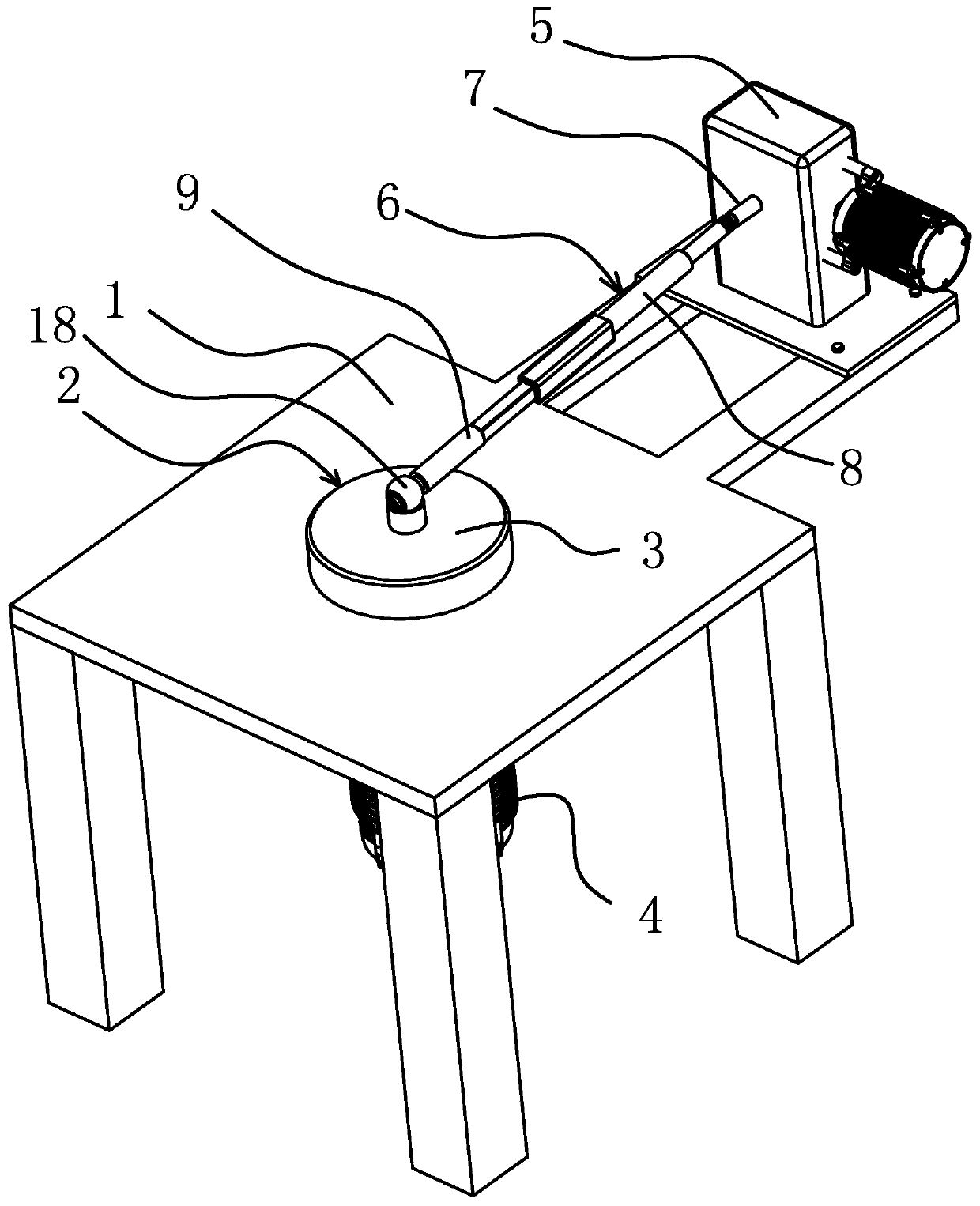

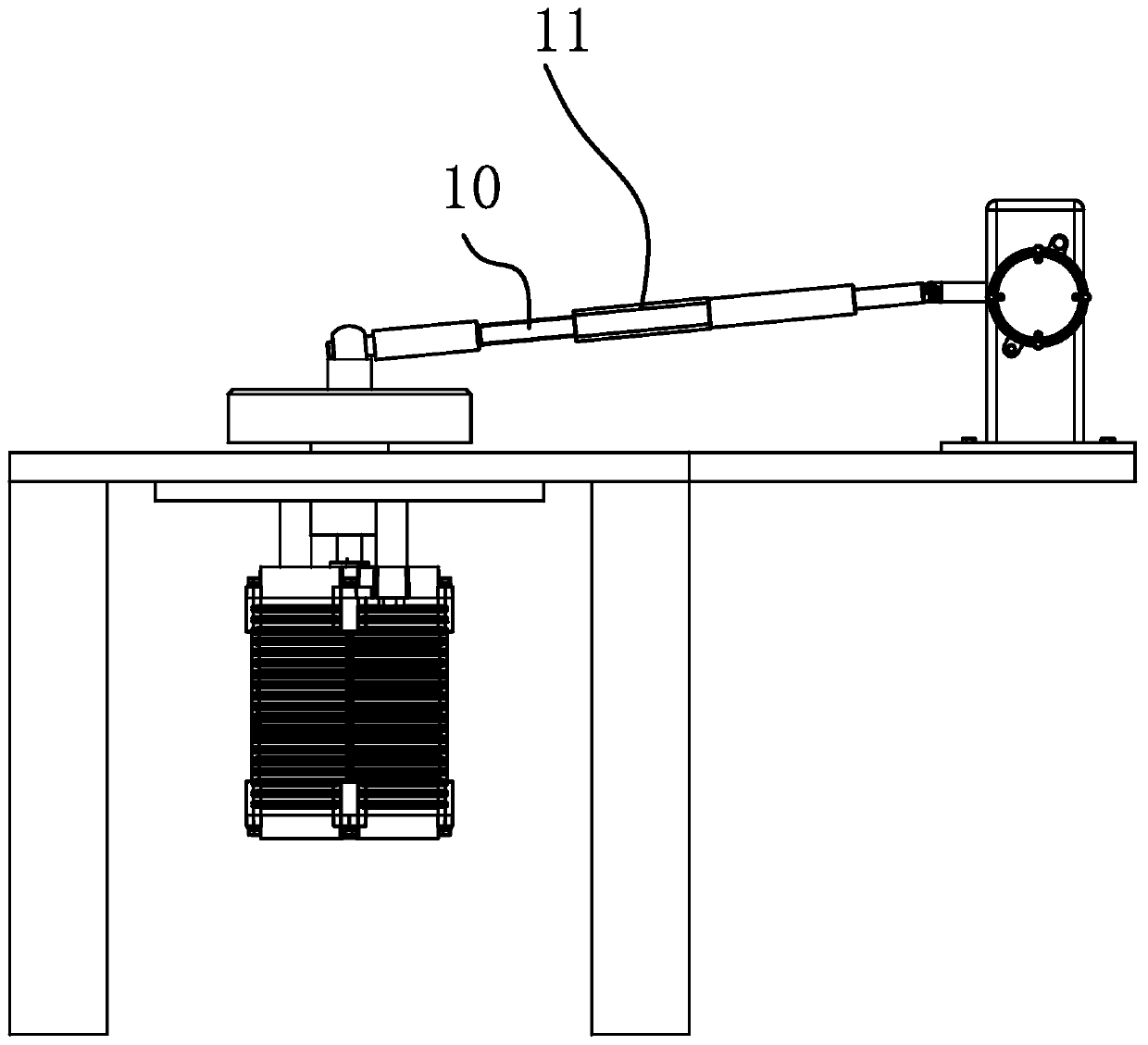

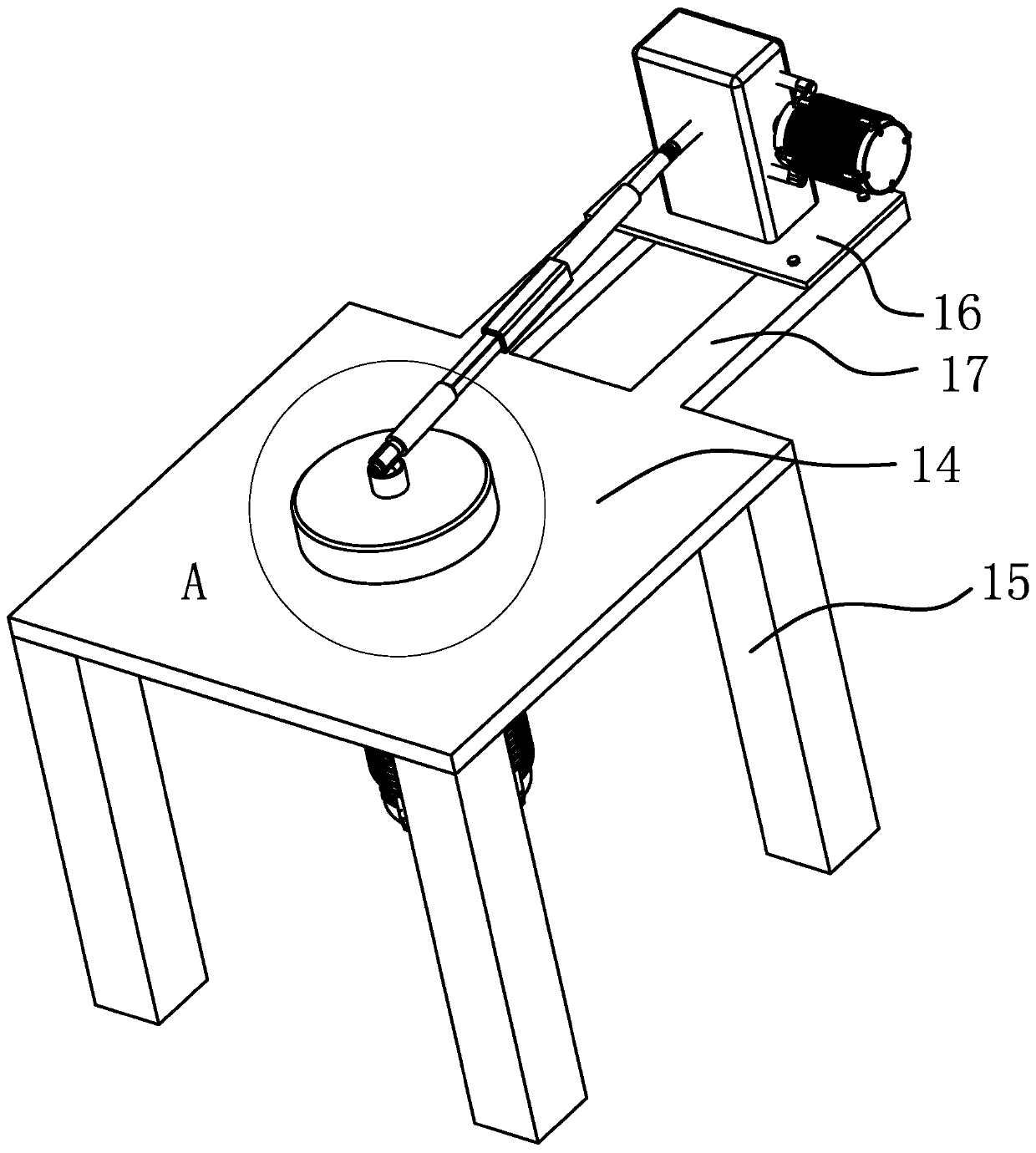

Device for automatically correcting circular degree

The invention provides a device for automatically correcting the circular degree. The device comprises a fixing plate (3) and a cavity die plate (7); the fixing plate (3) is provided with a vertical correction core die (12); the cavity die plate (7) is provided with a core shaft fixing seat (21) which is provided with a rotatable core shaft (18); the core shaft (18) is located under the vertical correction core die (12); rotating positioning mechanisms are arranged on the fixing plate (3) and the cavity die plate (7) and behind the core shaft (18). According to the device for automatically correcting the circular degree, gears and racks which are arranged in the rotating positioning mechanisms are matched with each other to stably control a directional shaft to drive the core shaft to rotate and accordingly the circular degree of a circle tubular component is accurate and accordingly the production process is effectively simplified and the production rate is improved.

Owner:惠州安特科技工业有限公司

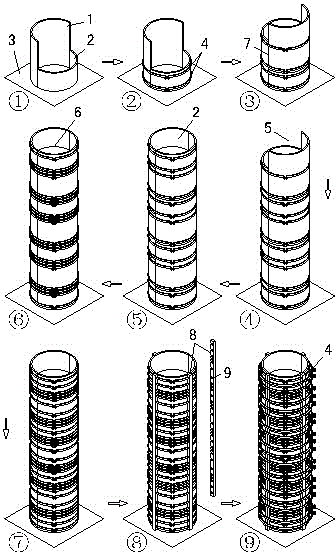

Method of manufacturing yoke of rotary electric machine

InactiveUS20050028350A1Avoid crackingAccurate roundnessMagnetic circuit rotating partsWave amplification devicesSteel platesEngineering

A method of manufacturing a yoke includes a step of cutting a steel plate into a rectangular sheet having a plurality of first dovetail convexities at one end thereof and a plurality of second dovetail convexities at the other end, a step of rolling the rectangular sheet into a cylinder to fit the first dove tails and the second dove tails to each other and a step of punching border portions of the first dove tails and the second dove tails. The second dovetail convexities are formed to be the same in shape as the first dovetail convexities so that they can fit to the first dovetail convexities. A smooth-faced yoke can be manufacture without using an expensive welder.

Owner:DENSO CORP

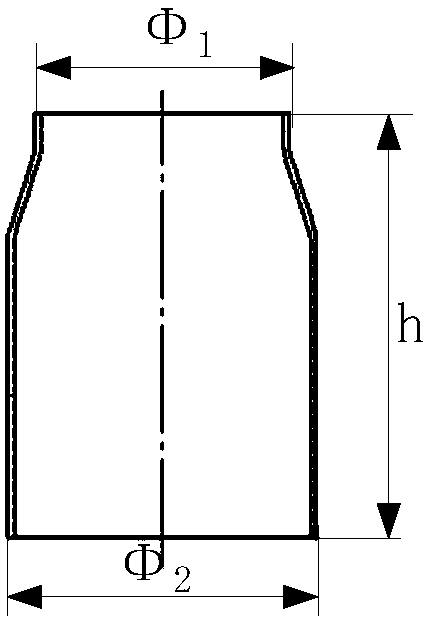

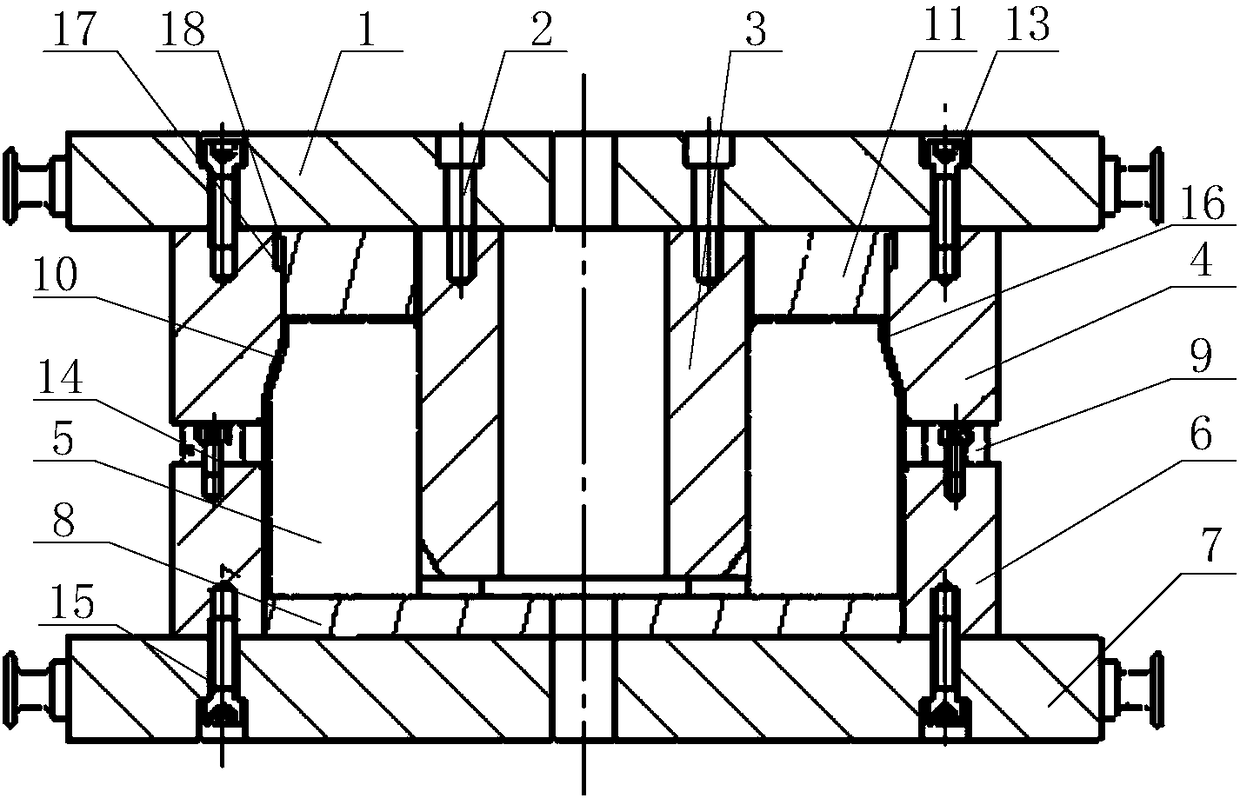

Necking mold for thin-wall cylindrical parts

The invention discloses a necking mold for thin-wall cylindrical parts. An upper die is provided with a mandrel and a female die; a lower die is provided with a positioning ring and a sectioned male die; the thin-wall cylindrical parts are installed in a gap between the sectioned male die and the positioning ring and a gap between the sectioned male die and the female die; the sectioned male die is divided into a plurality of sectioned dies; when the thin-wall cylindrical parts are in a necking process, the upper die is gradually combined with the lower die; the mandrel gradually extends intothe sectioned female die; the mandrel is used for pushing the sectioned male die to radially expand so as to apply pressure stress to the non-necked cylindrical wall of the part and eliminate drum-like formation of the cylindrical wall; after being expanded, the sectioned male die seamlessly clings to the part in the circumferential direction, the roundness of the part can be corrected, no waved edges are generated at the cylindrical wall, the surface quality of the part is obviously improved; and the necking mold is simple in structure, convenient to use, easy to operate and high in machiningefficiency.

Owner:AECC AVIATION POWER CO LTD

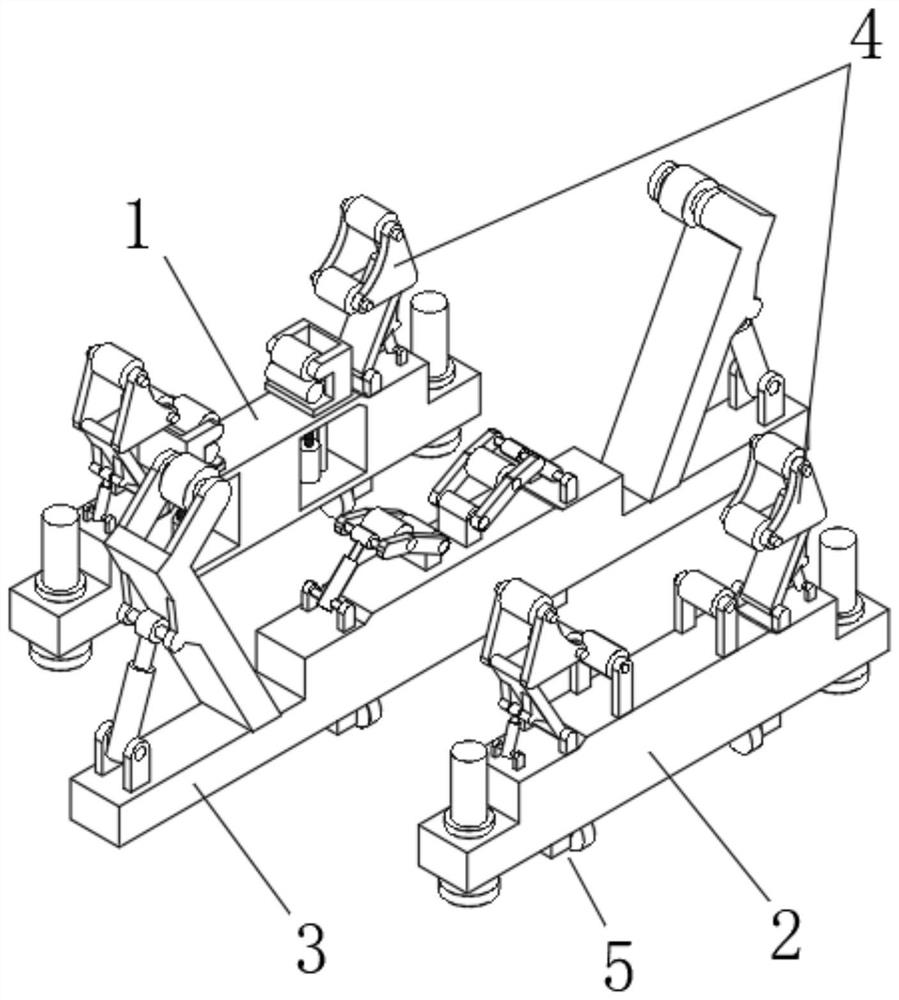

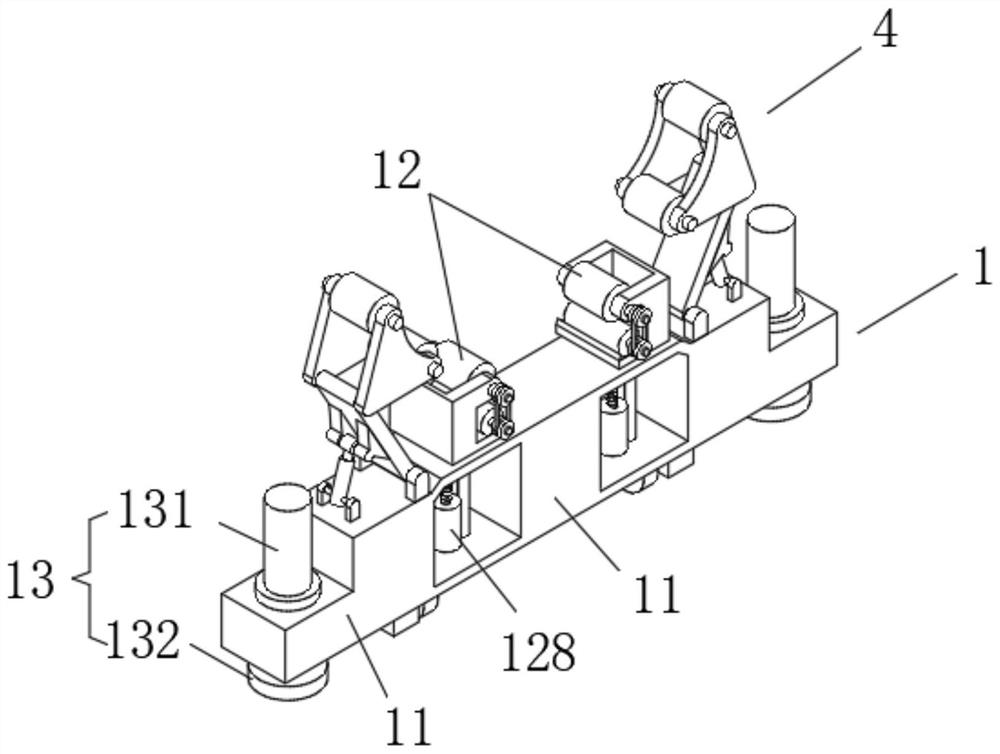

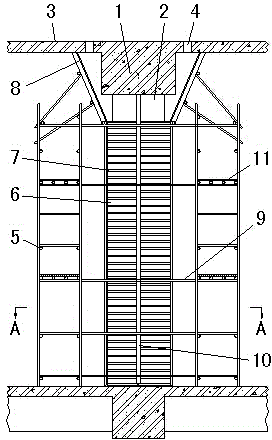

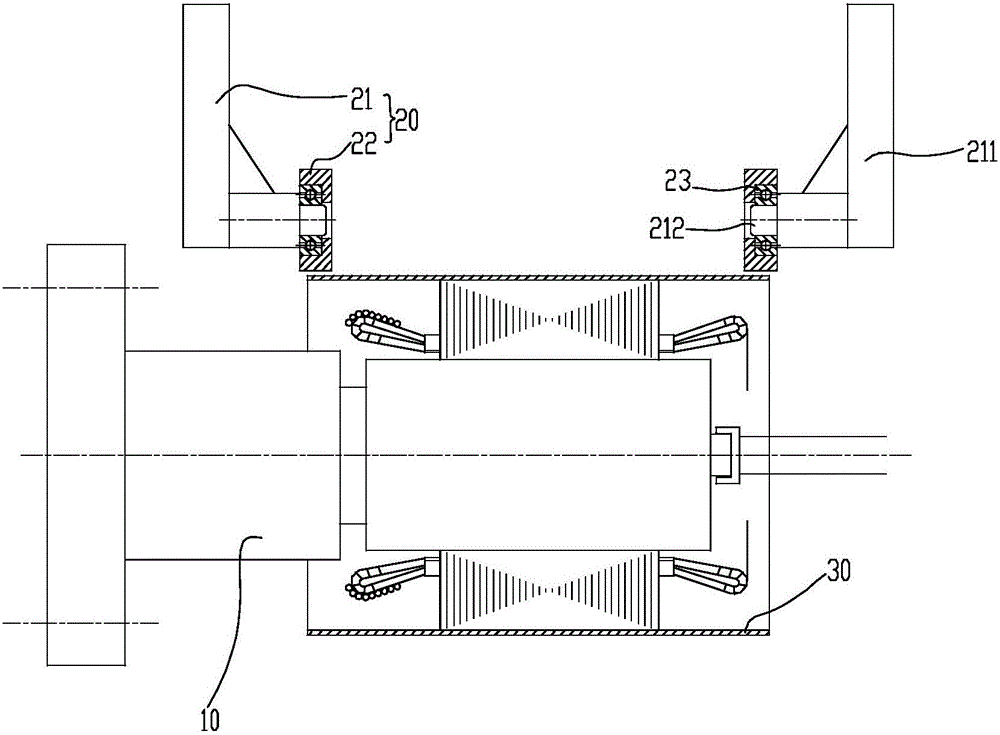

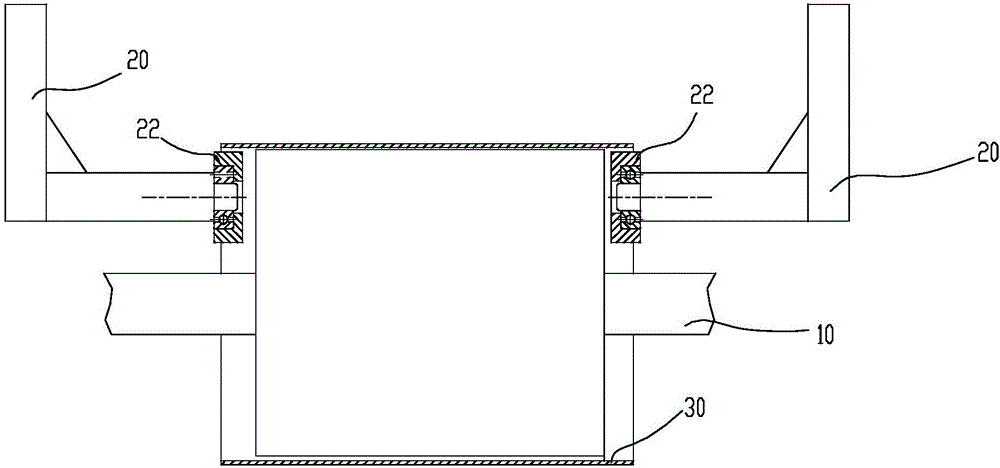

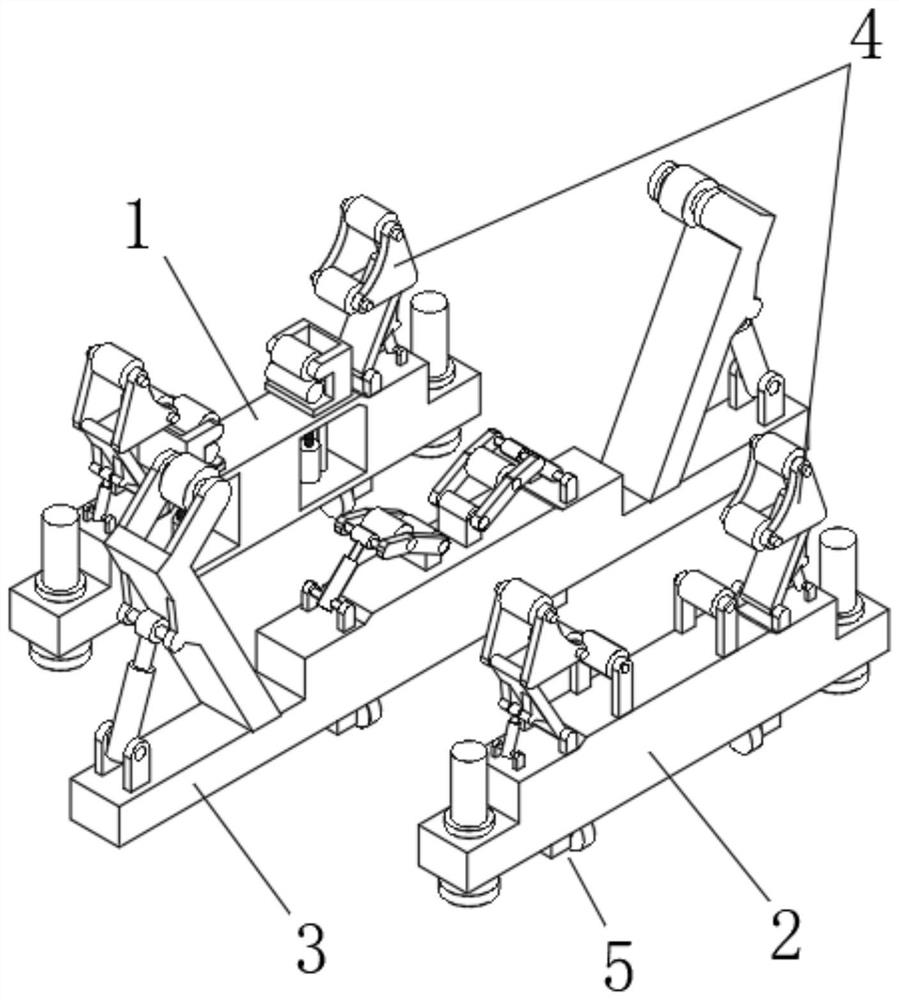

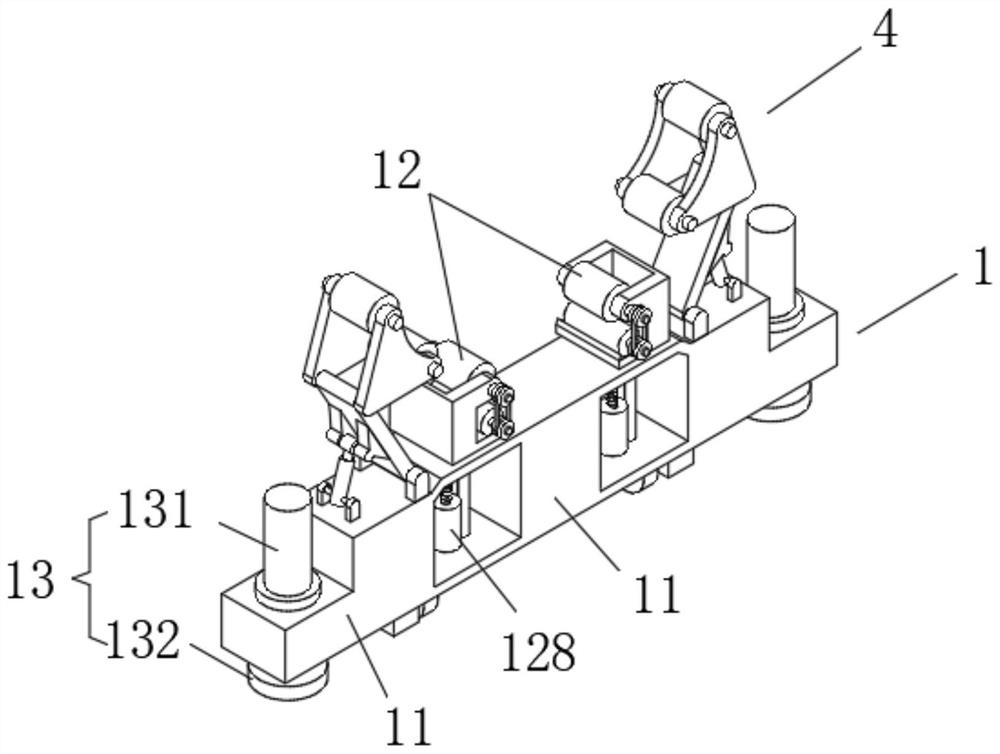

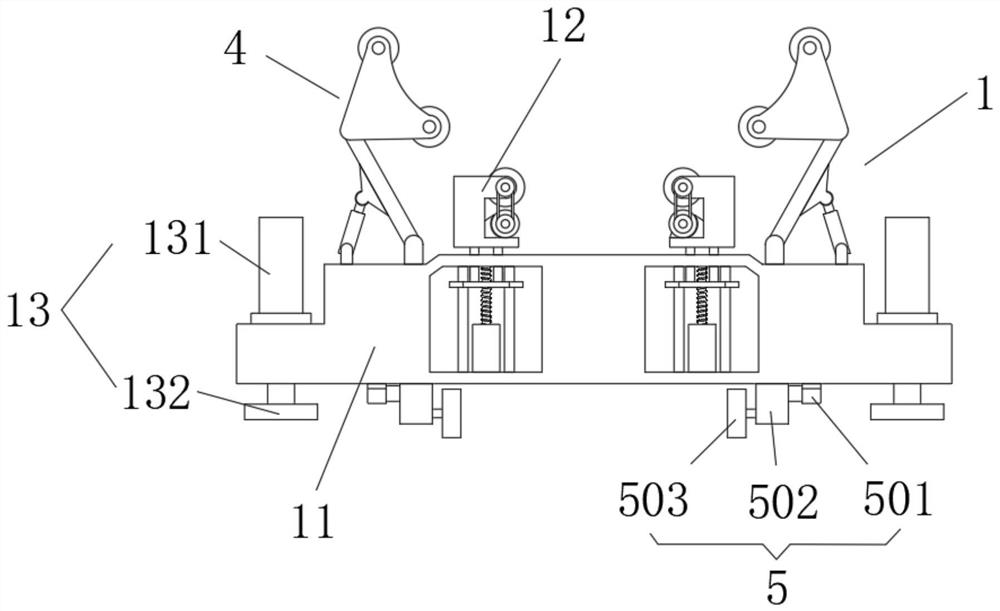

Straight seam welding and grouping welding equipment for large-diameter barrel

PendingCN112935697AImprove welding efficiencyPrevent collapseWelding/cutting auxillary devicesAuxillary welding devicesSeam weldingStructural engineering

The invention provides straight seam welding and grouping welding equipment for a large-diameter barrel, and relates to the technical field of welding equipment. The straight seam welding and grouping welding equipment for the large-diameter barrel comprises a driving welding walking roller carrier, a driven welding walking roller carrier, a hydraulic jacking grouping roller carrier and hydraulic supporting arm mechanisms, wherein the two groups of the hydraulic support arm mechanisms are arranged; the number of each group of hydraulic support arm mechanisms is at least two; one group of hydraulic support arm mechanisms is symmetrically distributed on the driving welding walking roller carrier; and the other group of hydraulic support arm mechanisms is symmetrically distributed on the driven welding walking roller carrier. The hydraulic support arm mechanisms are adjusted to abut against a barrel from the two side faces of the barrel; and the hydraulic support arm mechanisms are used for correcting and lifting a workpiece with the large barrel diameter to prevent the workpiece with the large barrel diameter from collapsing, and the roundness of the workpiece with the large barrel diameter is corrected, so that more time and labor can be saved when workpieces with the large barrel diameter are welded and grouped, and the welding efficiency is improved.

Owner:郑州越达科技装备有限公司

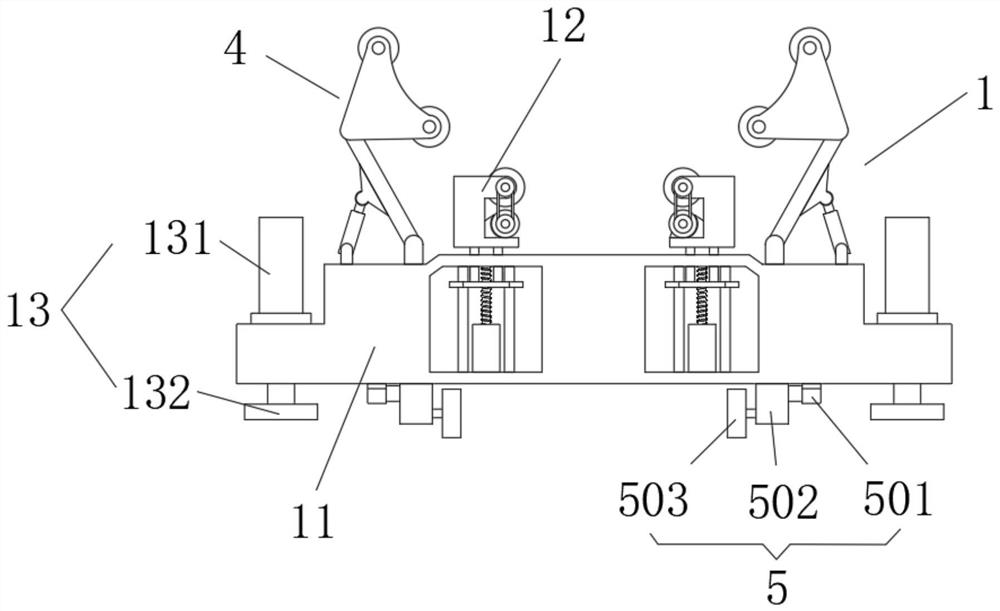

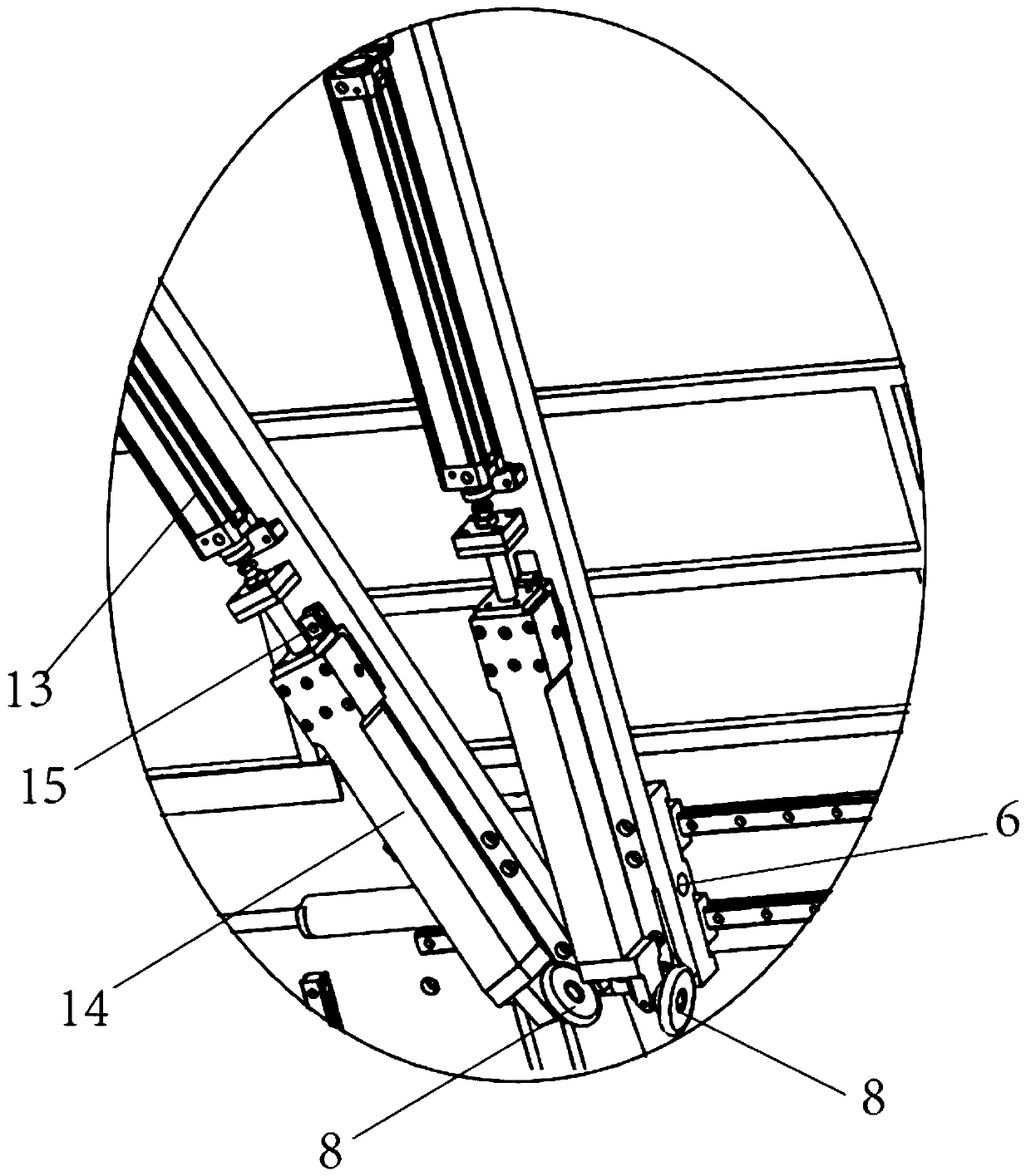

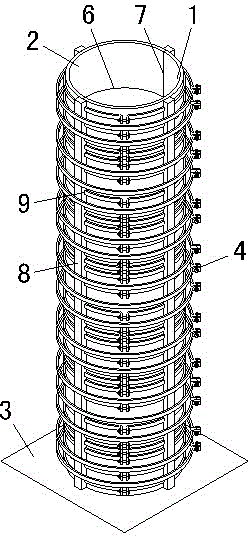

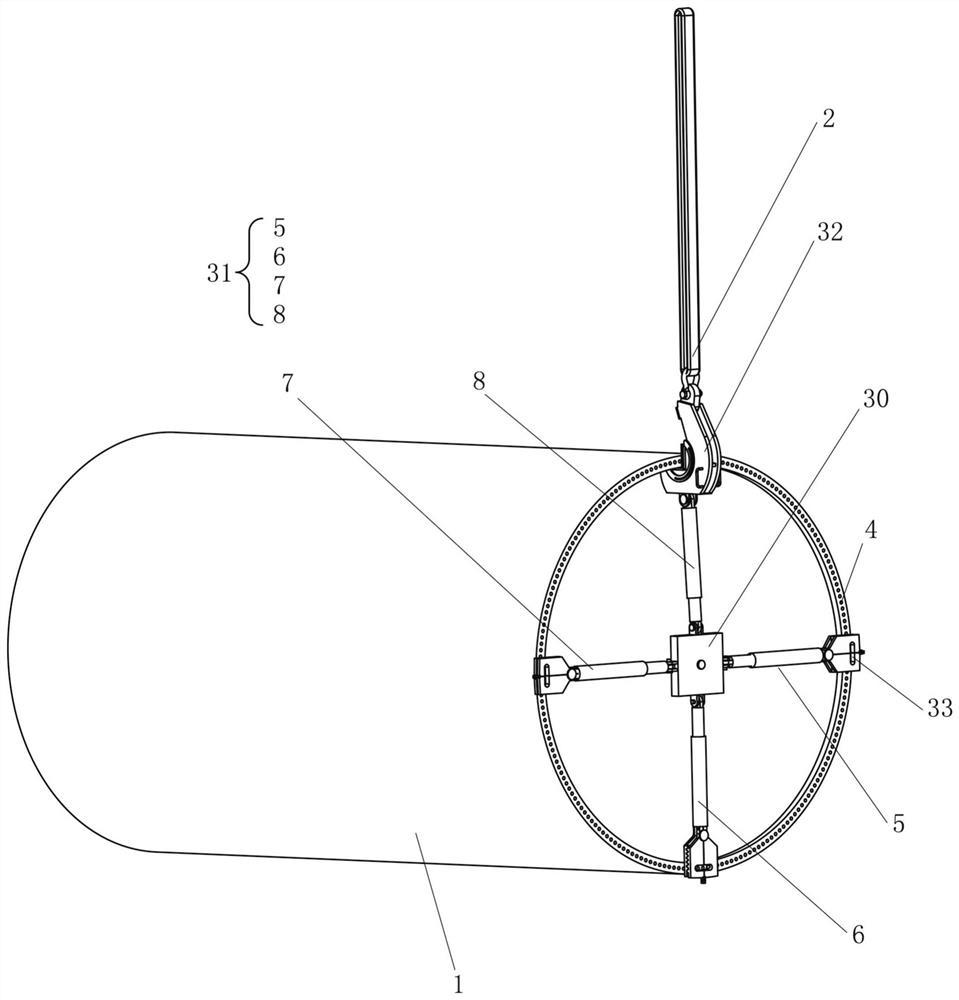

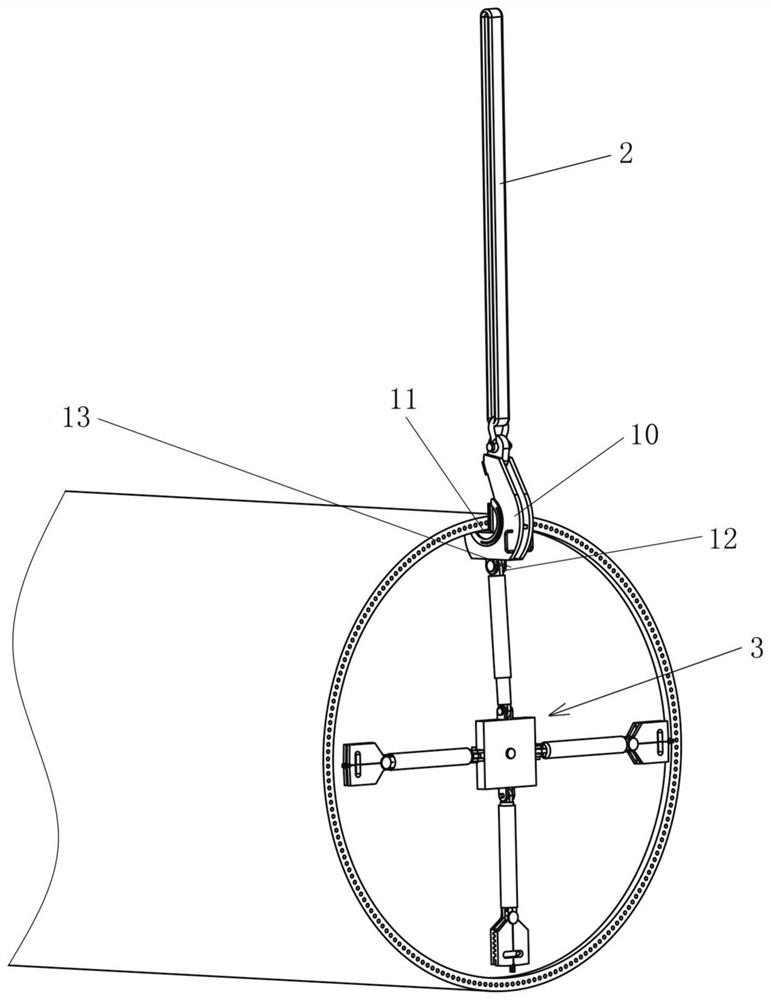

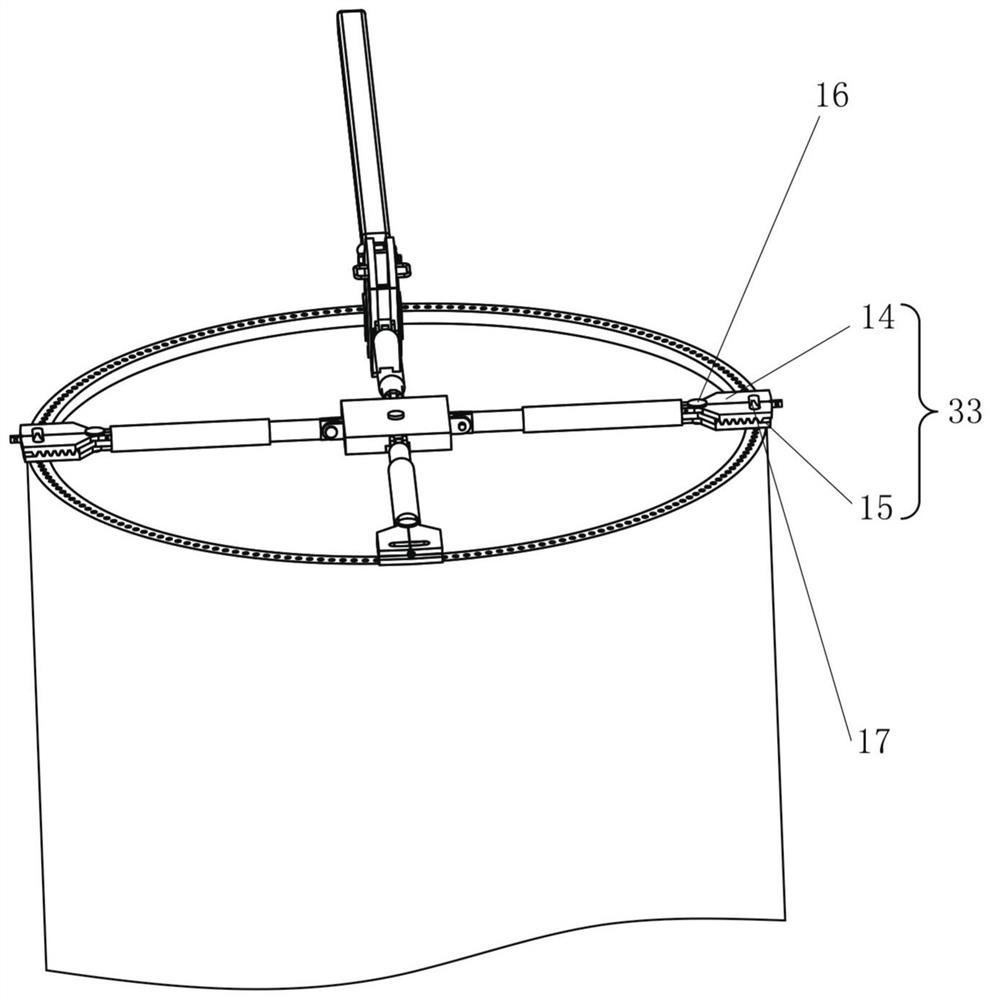

Assembling tire device and method for wind power tower flanges

PendingCN109262195AReduce stress deformationReduced stress residueWelding/cutting auxillary devicesAuxillary welding devicesElectricityJackscrew

The invention relates to the technical field of test instruments, in particular to an assembling tire device and method for wind power tower flanges. The assembling tire device comprises a tire columnand multiple supporting rod assemblies, and the tire column is used for positioning the supporting rod assemblies; the supporting rod assemblies are uniformly distributed on the outer side face of the tire column through radiating, and the distances between the ends, away from the tire column, of the supporting rod assemblies and the center axis of the tire column are equal; the ends, away from the tire column, of the supporting rod assemblies can be driven by a driving part to stretch and retract by an equal length, the tire column is of a cylindrical structure, the supporting rod assembliescomprise sleeves, one end of each sleeve is fixedly arranged on the outer side face of the tire column, the multiple sleeves are arranged through radiating and internally provided with supporting rods, and the supporting rods can conduct reciprocating sliding along the axes of the sleeves and are fixed to set positions. With the assembling tire device and method, the problems can be solved that during production, cylinder segments are not easy to round through correction, and since a jack is adopted for rounding-correcting assembling, the planeness of the welded flanges is poor.

Owner:山东中车同力钢构有限公司

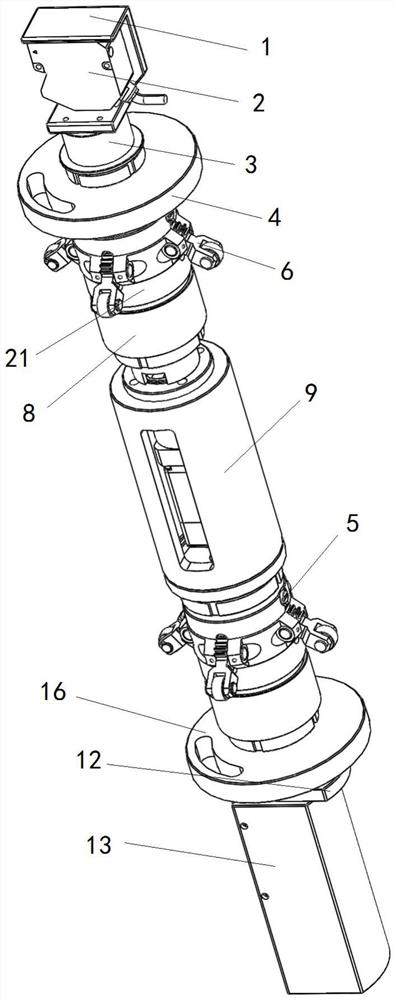

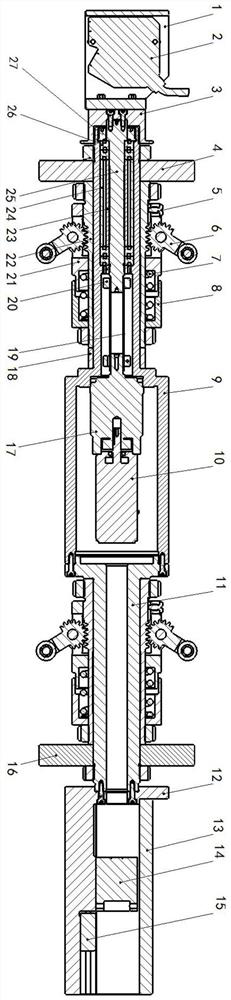

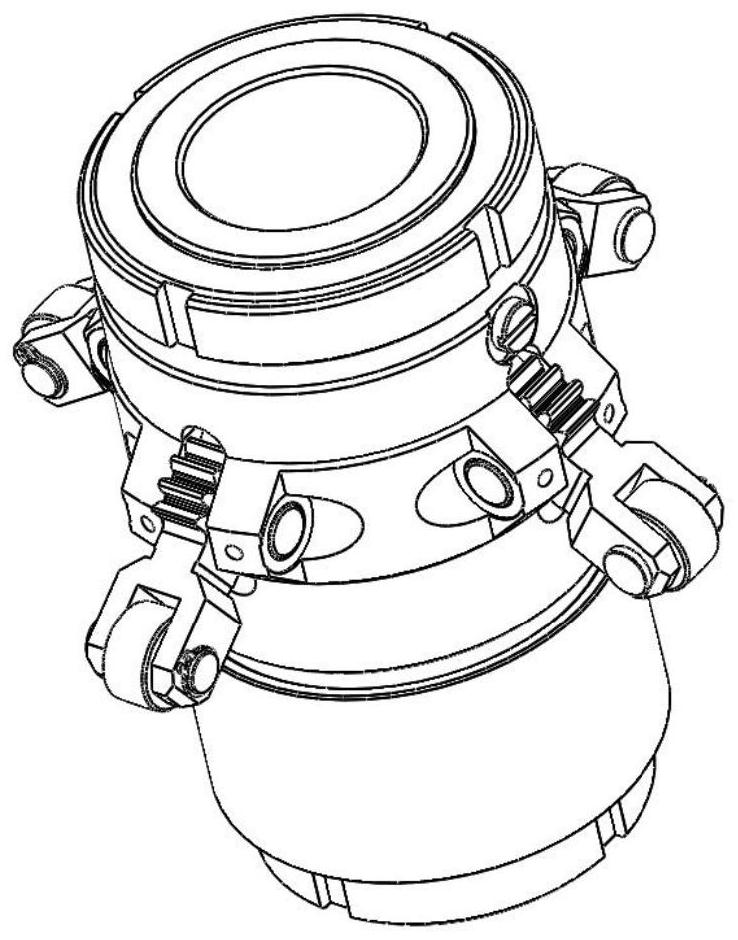

Roundness and straightness error measuring system for deep hole part

The invention discloses a roundness and straightness error measuring system for a deep hole part, and belongs to the technical field of roundness and straightness error measurement of deep hole parts. The system comprises: a supporting unit which comprises a forward bobbin and a backward bobbin which are coaxially arranged; a driving unit comprising a driving device, a sleeve and a driving shaft, wherein the driving device is arranged in a second cavity and fixedly connected with the inner wall of the second cavity, and the driving shaft and the sleeve are arranged in the first cavity; a measuring unit comprising a laser displacement sensor, a two-dimensional position-sensitive sensor, an angle sensor and a laser distance measuring sensor; and centering walking units respectively arranged on the forward bobbin and the backward bobbin. According to the invention, the laser displacement sensor, the two-dimensional position-sensitive sensor and the angle sensor are integrated in a unified manner, positioning is carried out by using the centering walking mechanism, sample point coordinate values in a measurement coordinate system are unified in an absolute coordinate system, and accurate, quantitative and synchronous measurement of roundness and straightness errors of deep hole parts is realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

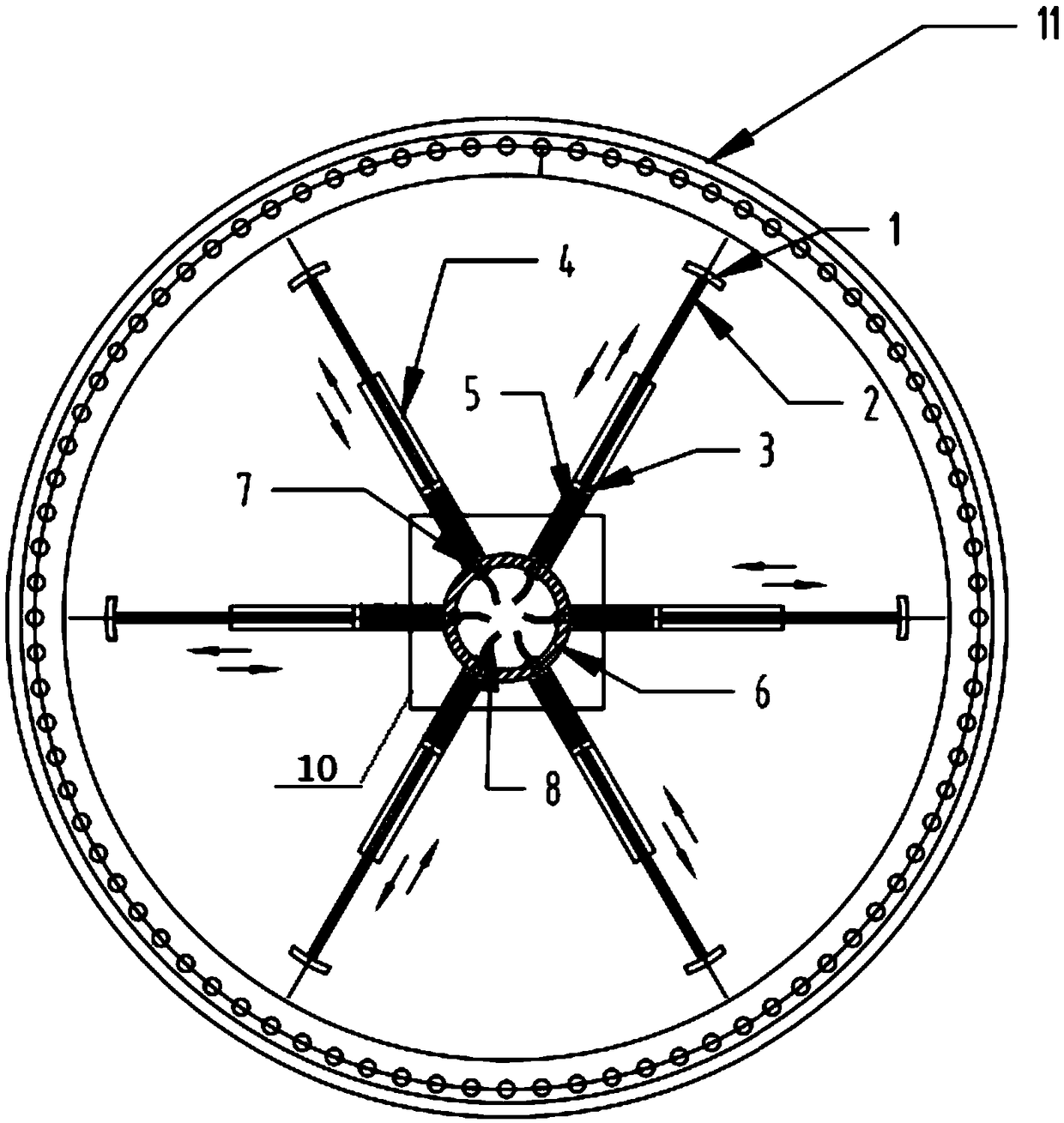

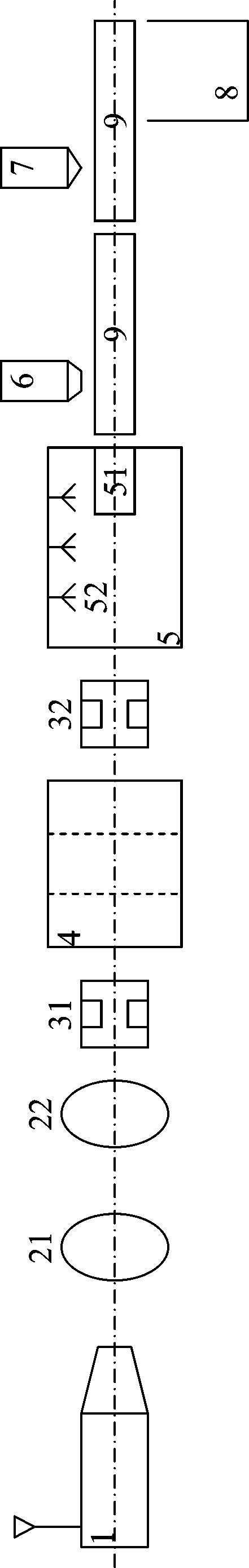

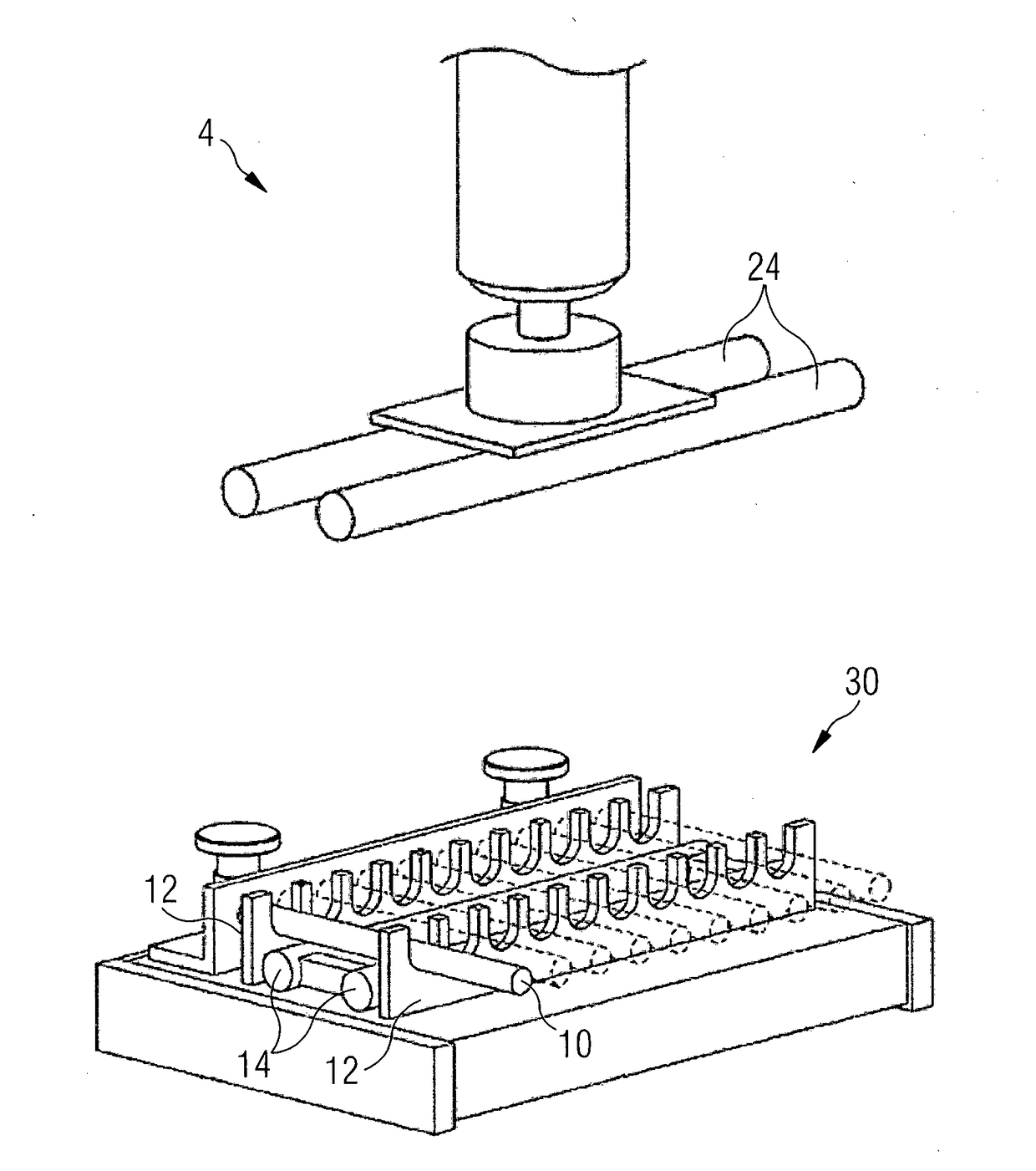

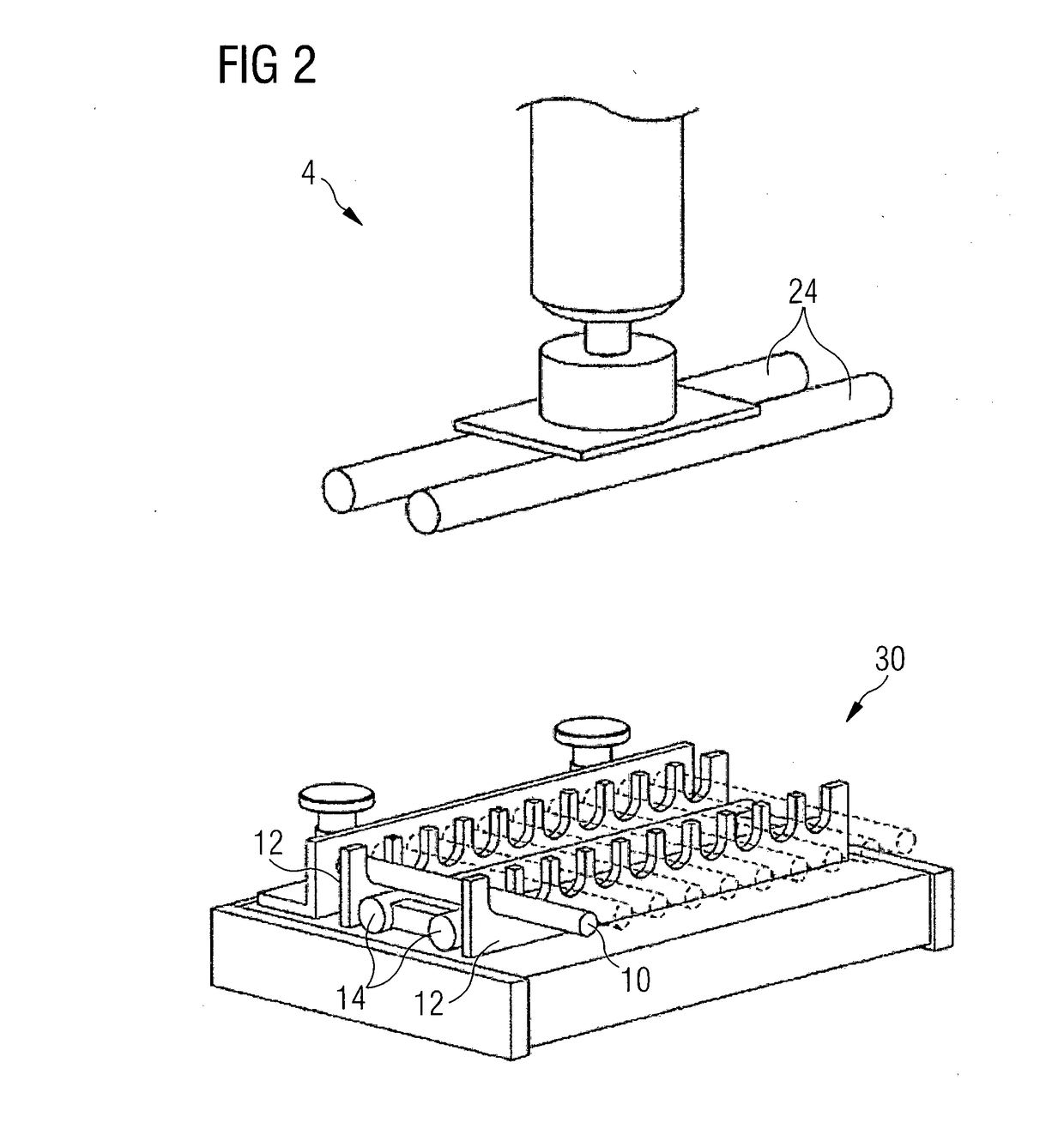

Equipment for thermoplastic continuous fiber pre-impregnated belt pipe production and use method thereof

ActiveCN107775970AEffective correction of roundnessAccurate roundnessTubular articlesWinding machineFiber

The invention relates to the field of a plastic molding composite material containing an enhanced material, in particular to equipment for thermoplastic continuous fiber pre-impregnated belt pipe production and a use method thereof. The equipment for thermoplastic continuous fiber pre-impregnated belt pipe production comprises an extruding machine (1), and is characterized by also comprising a belt winding machine (21), a film winding machine (22), a first traction machine (31), a second traction machine (32), a drying box (4), a vacuum box (5), a marking machine (6), a cutting machine (7) anda material collecting table (8). The use method of the equipment for thermoplastic continuous fiber pre-impregnated belt pipe production is characterized by comprising the following steps for sequential implementation: a, preparation; b, inner layer extrusion; c, pre-impregnated belt winding; d, thermoplastic film winding; e, sizing; f, cooling; g, collection. The pipe quality is high; the raw materials are saved.

Owner:林世平

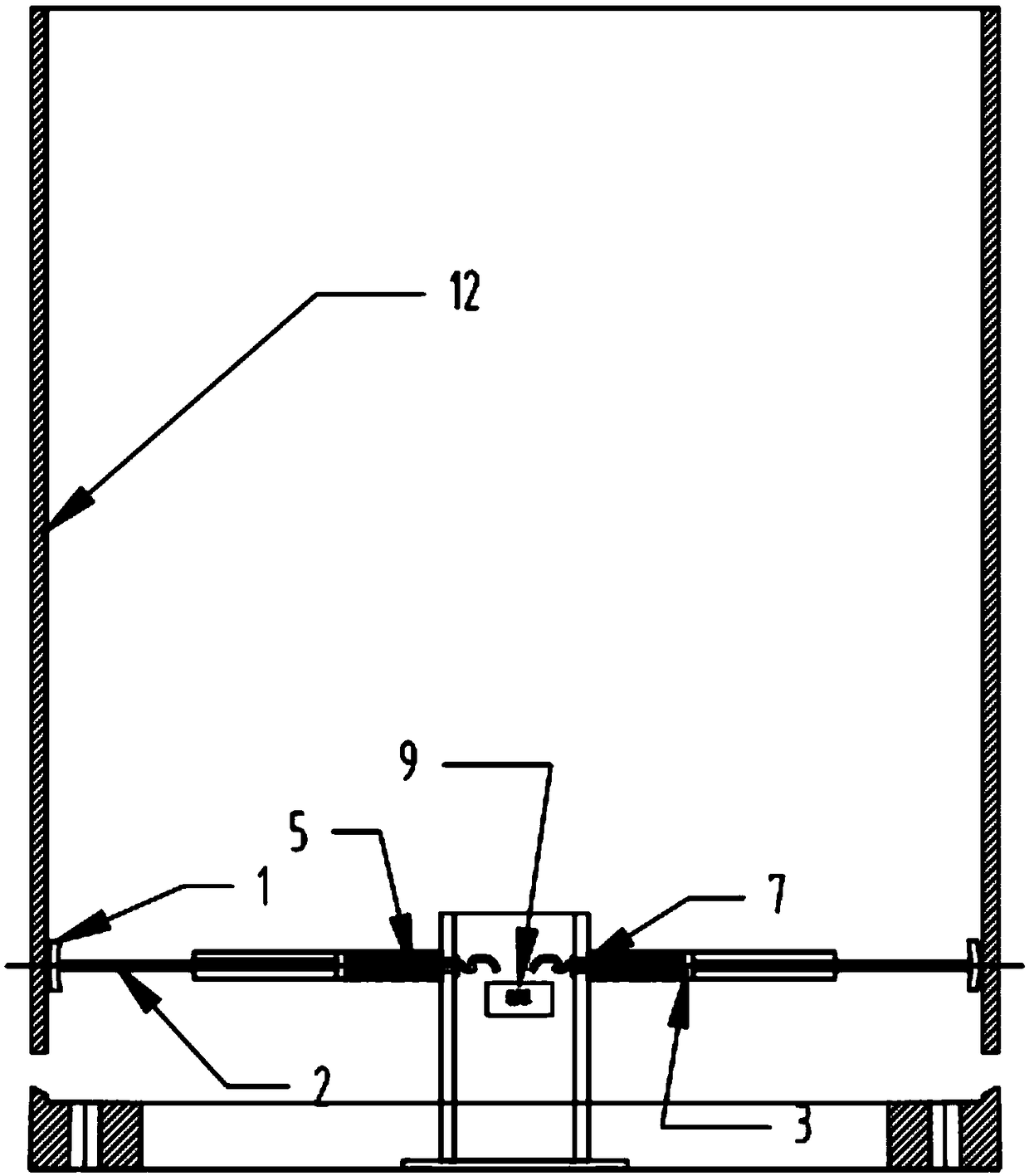

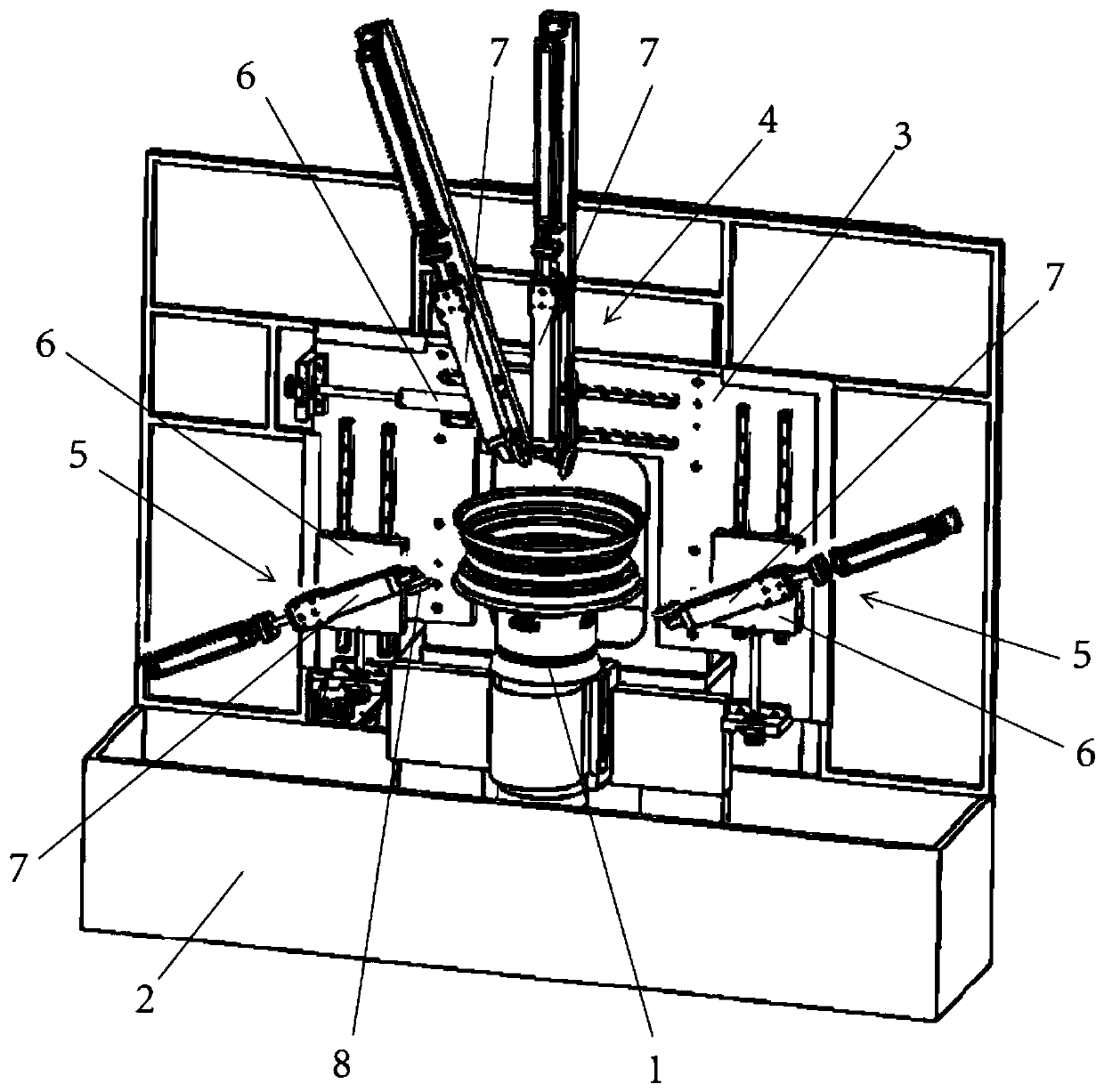

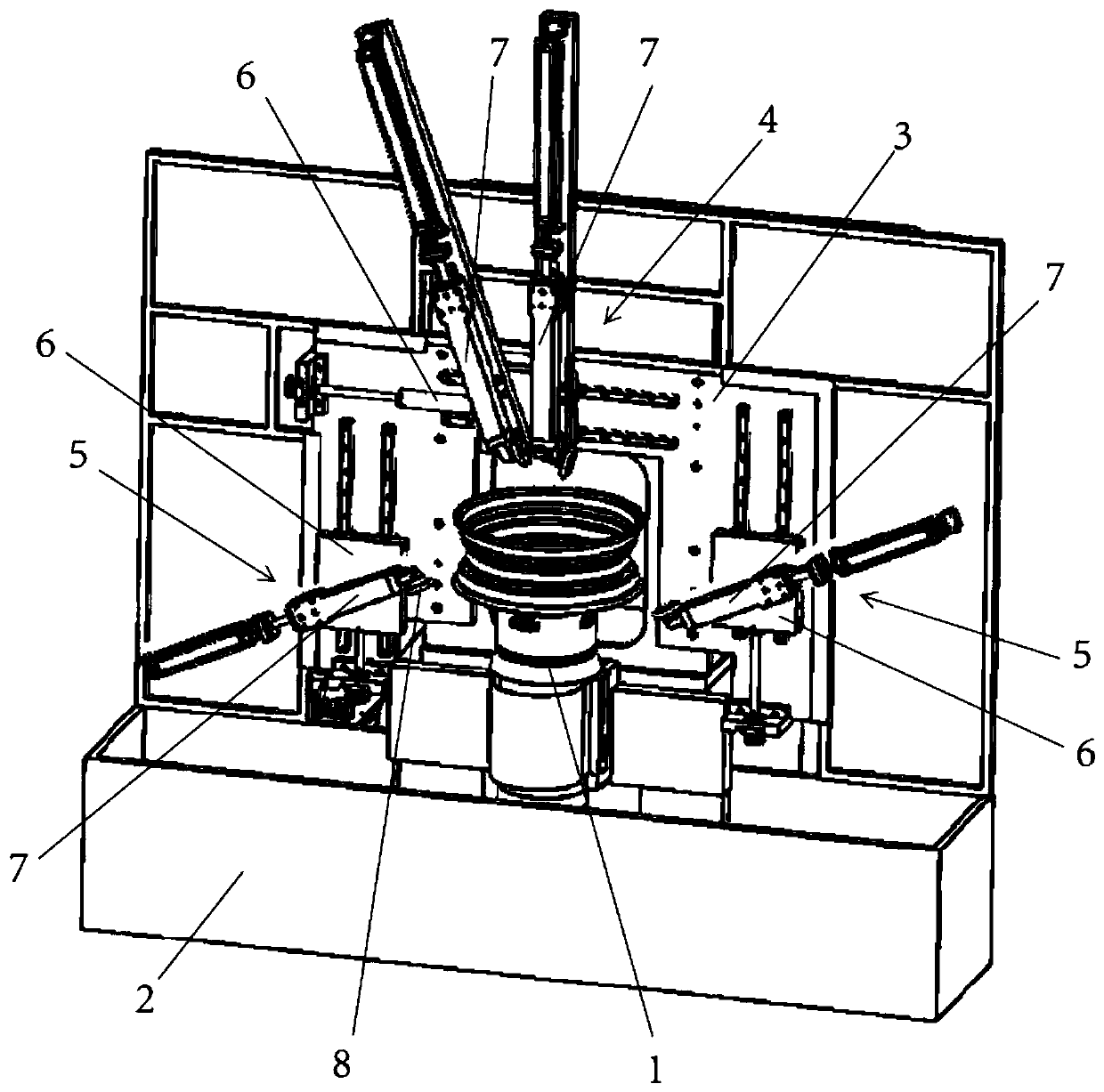

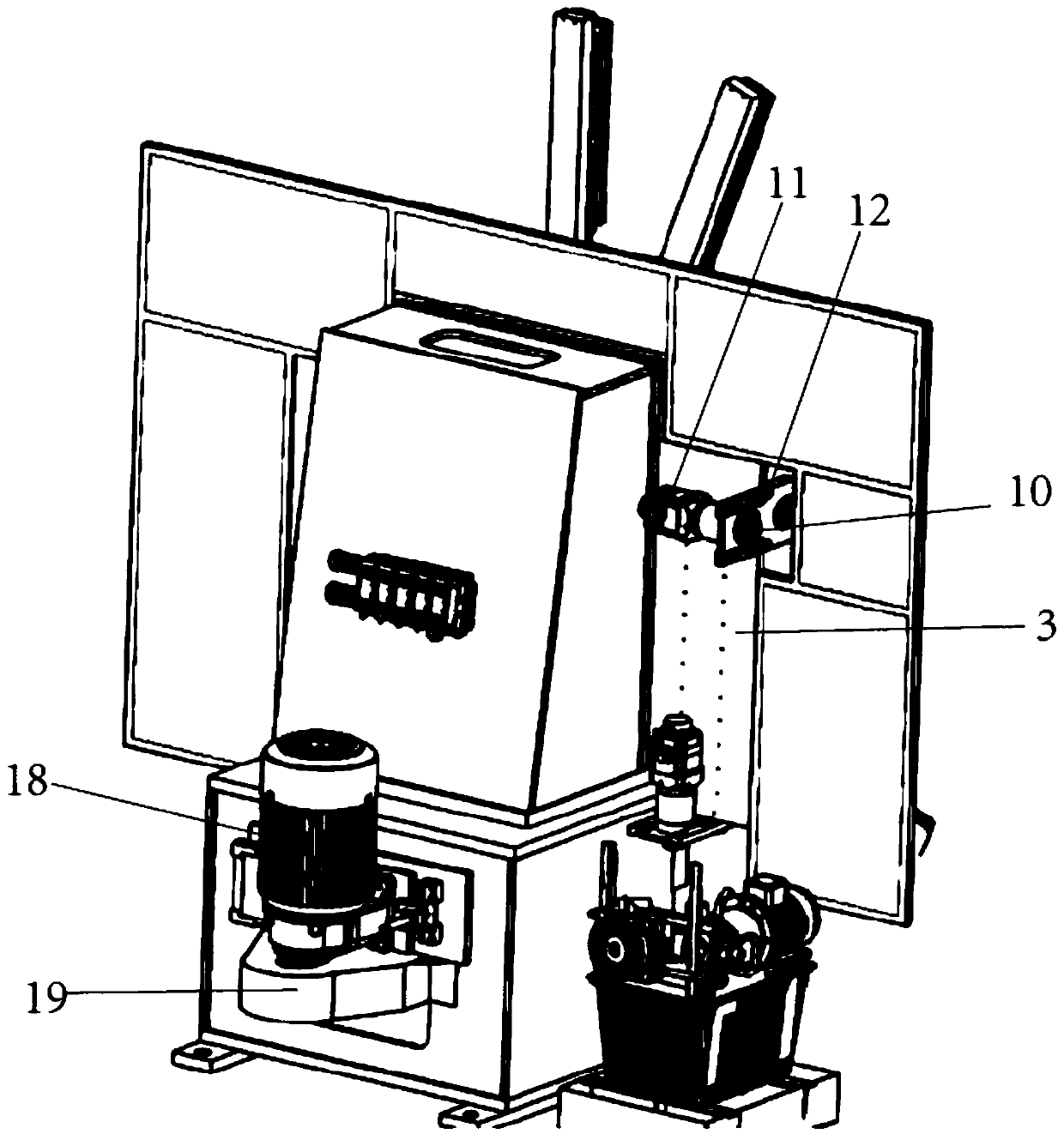

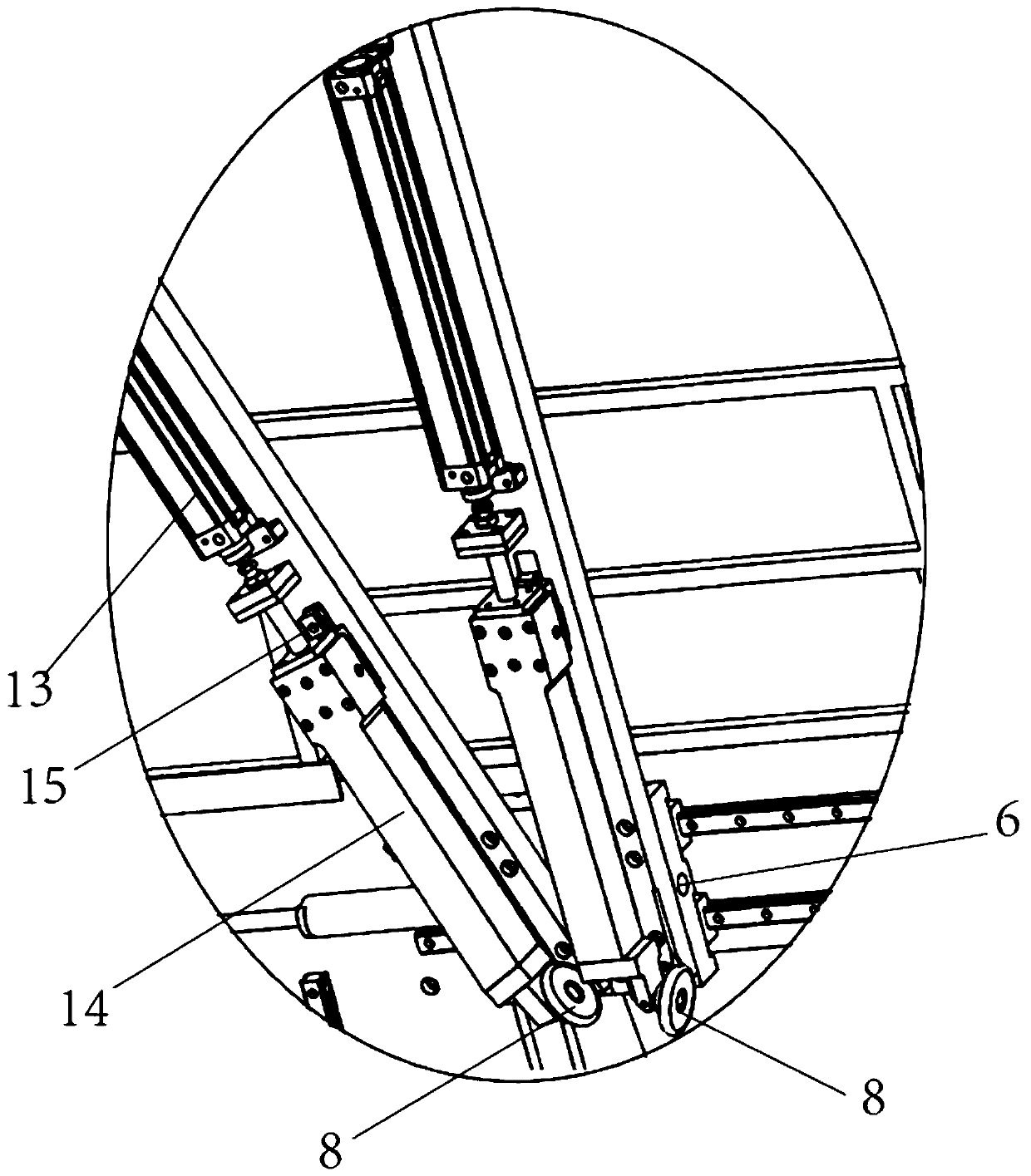

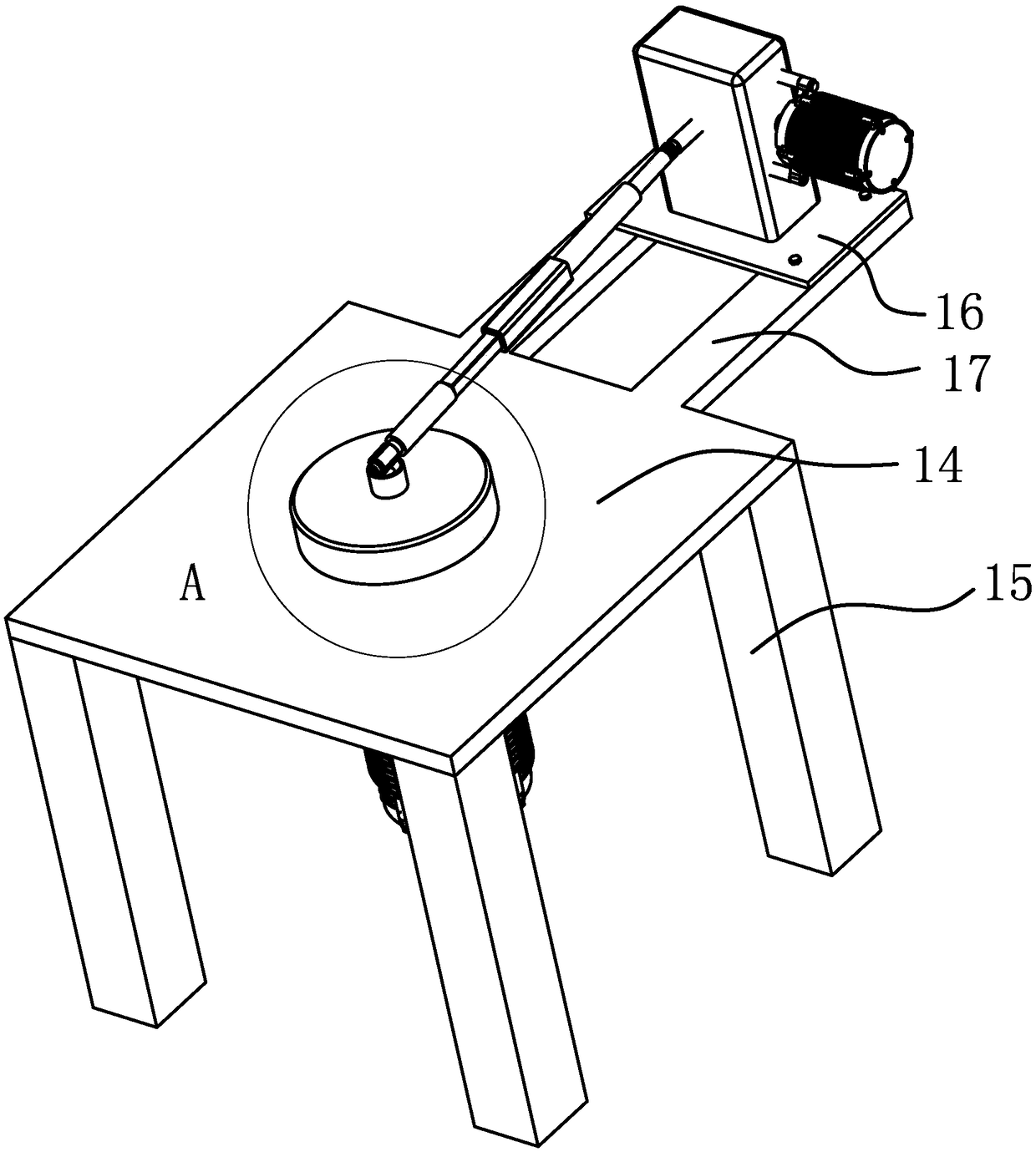

Rolling machine for wheel rim

ActiveCN110238604BImprove physical conditionChemical composition unchangedGrinding machinesStructural engineeringMachine

The invention discloses a rolling machine for a wheel rim. The rolling machine comprises a rotating device for fixing and rotating the wheel rim, the rotating device is arranged on a machine frame, fine machining mounting frames are arranged on the periphery of the rotating device, an end grinding unit and side grinding units are arranged on the finish machining mounting frames, and the end grinding unit, the side grinding units and the rotating device are matched with the outer surface, the inner surface and the end surface of the grinding wheel rim correspondingly; each of the end grinding unit and the side grinding units comprises a sliding table assembly, a telescopic arm is arranged on a sliding platform of each sliding table assembly, and a rolling head is installed on each telescopic arm; and the number of the side grinding units is two and the two side grinding units are arranged on the two sides of the radial direction of the rotating device correspondingly. According to the rolling machine for the wheel rim, the processing precision is high, processing is comprehensive, and the processing efficiency can be effectively improved.

Owner:苏州科匠智能科技有限公司

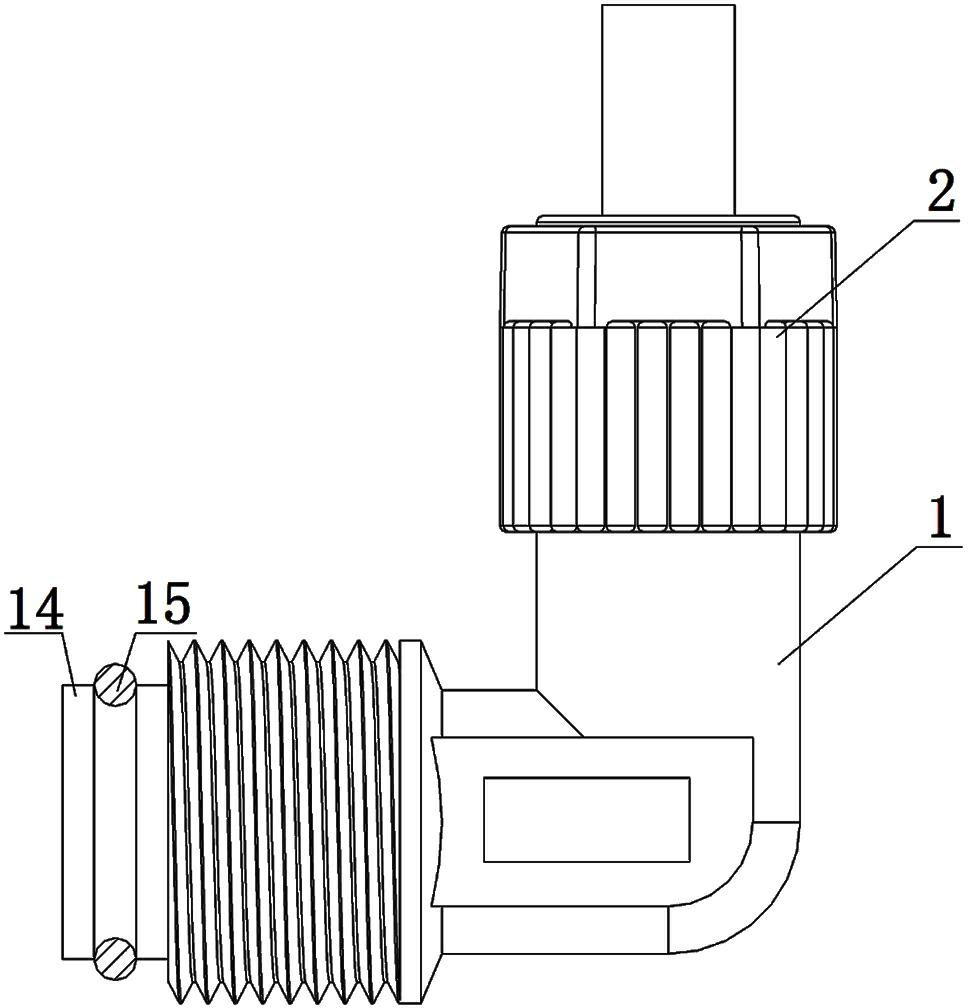

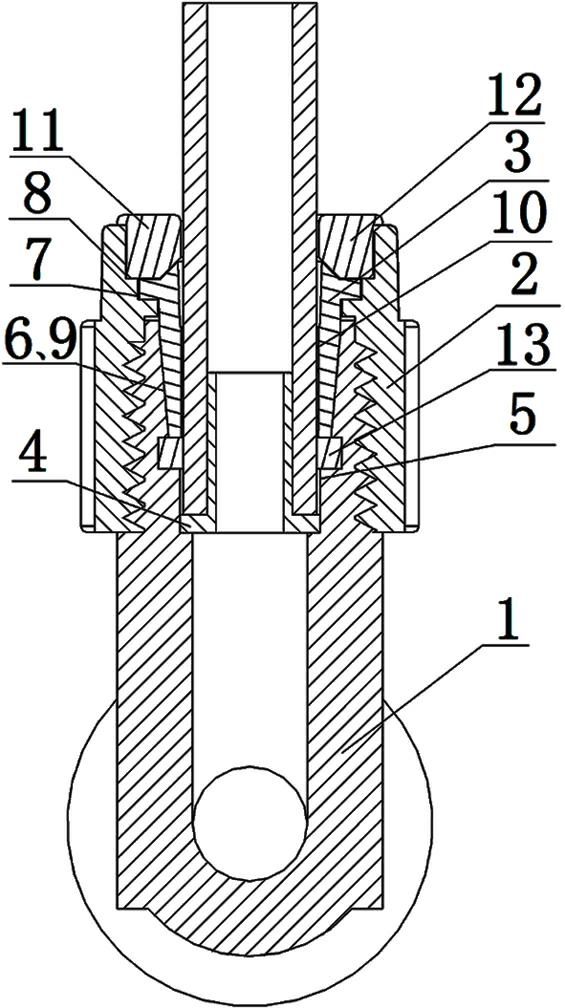

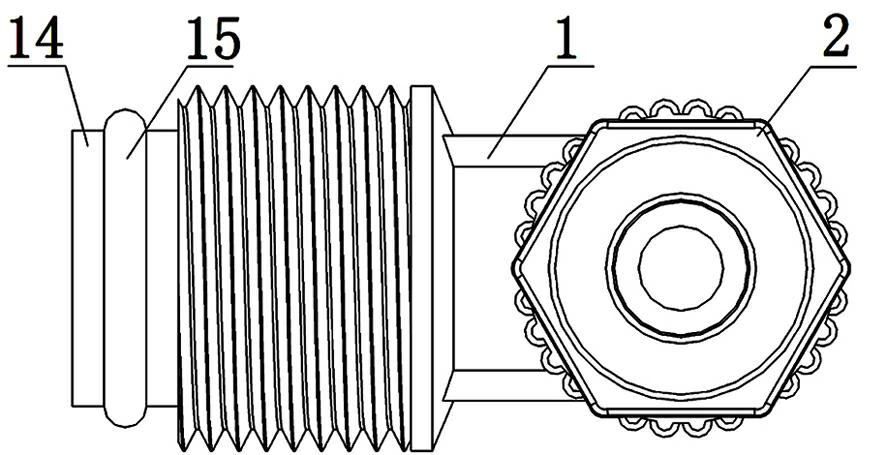

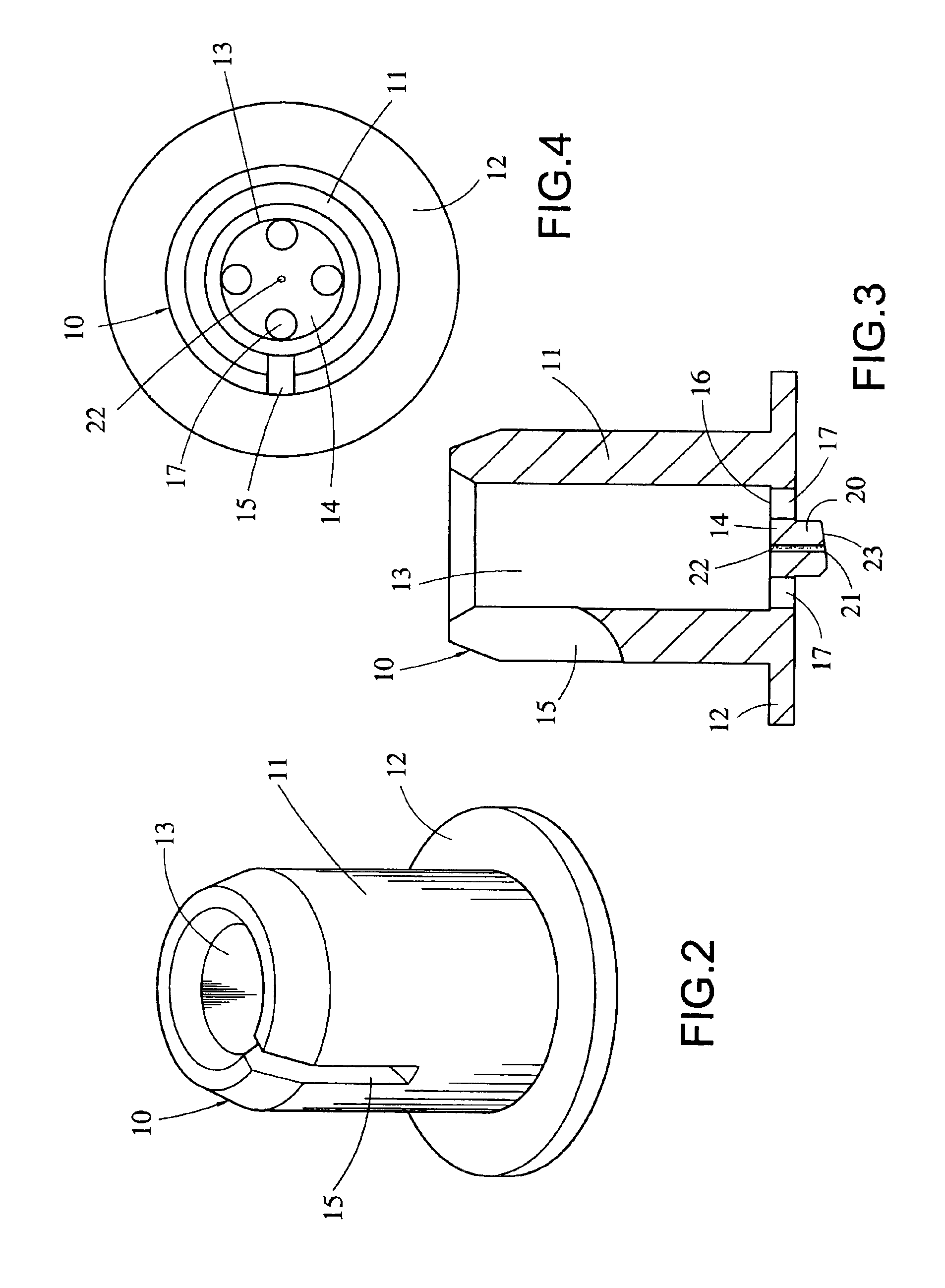

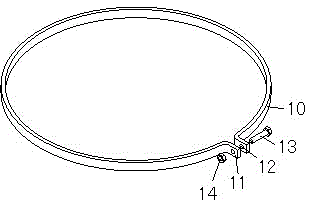

Quickly assembled and disassembled convenient joint

The invention discloses a quickly assembled and disassembled convenient joint. The convenient joint comprises a joint (1), a locking screw cap (2), a movable pawl (3) and a pipe clamp (4); one end of the joint (1) is provided with a pipe body connecting port (5); the locking screw cap (2) is arranged outside the pipe body connecting port (5); the locking screw cap (2) is provided with a groove A (7) and a groove B (8); the movable pawl (3) is arranged in the groove B (8); the movable pawl (3) is provided with an annular skirt edge (11); an end cover (12) is arranged in the groove A (7); the skirt edge (11) is movably positioned in the groove B (8) by the end cover (12); and an O-shaped silica gel sealing ring B (15) is arranged at the other end of the joint (1). The convenient joint has the advantages that: because the movable pawl and the locking screw cap form an integrated structure, the convenient joint is convenient for installation, has a better sealing effect and does not affect the sealing quality when being repeatedly assembled and disassembled; and the locking screw cap is a double-purpose screw cap and is convenient for installation.

Owner:胡高中

Method for pouring concrete outside steel pipe columns by using semicircular templates

InactiveCN105649327AAvoid damageWith strengthForms/shuttering/falseworksBuilding material handlingGlass fiberFloor slab

The invention discloses a method for pouring concrete outside steel pipe columns by using semicircular templates. The method comprises the following steps: constructing after concrete is poured in beams and the steel pipe columns of a building, the strength reaches 1.2 MPa, and column reinforcements are bound; reserving pouring holes in an upper floor when the beam and steel pipe column concrete is poured; when concrete outside the steel pipe columns is poured, firstly erecting a scaffold outside the to-be-poured steel pipe columns, assembling column templates by using the scaffold, wherein the column templates are semicircular wood templates or glass fiber reinforced plastics templates of which the lengths are different, fixing the column templates with steel strip hoops, forming pouring grooves between the tops of the column templates and the pouring holes reserved in the upper floor, and fixing and positioning the column templates through steel pipes connected to the scaffold; then pouring concrete outside the steel pipe columns by using self compact concrete; and finally, finishing pouring construction of the concrete outside the steel pipe columns through mould release and maintenance. The method disclosed by the invention mainly has the characteristics of smooth inner surfaces, precise roundness, high strength, easiness in moulding and convenience in assembly and disassembly.

Owner:CHINA CONSTR FOURTH ENG DIV

Shaping device of thin-walled rotary piece

The invention relates to the field of rotary body thin-walled workpiece machining, in particular to a shaping device of a thin-walled rotary piece. The shaping device comprises a rotary shaft used for fixing the thin-walled rotary piece and driving the thin-walled rotary piece to rotate. The rotation central line of the thin-walled rotary piece coincides with the axis of the rotary shaft. A shaping unit is arranged beside the rotary shaft. The shaping unit comprises a support and a shaping ring fixed to the support. The axis of the shaping ring is parallel to the axis of the rotary shaft. The distance between the shaping ring and the axis of the rotary shaft is equal to the sum or difference of the theoretical rotation radius of the thin-walled rotary piece and the radius of the shaping ring. In the process that the rotary shaft drives the thin-walled rotary piece to rotate, the shaping ring continuously squeezes the pipe wall, with too large or too small rotation radius, of the thin-walled rotary piece, so that the outer wall of the part contracts inwards or expands outwards, the oval section of the thin-walled rotary piece is trimmed to be circular, the roundness of the thin-walled rotary piece is corrected rapidly and effectively, and the quality of the thin-walled rotary piece is improved.

Owner:ANHUI WANNAN ELECTRIC MACHINE

Sportsball with integral ball casing and bladder body

InactiveUS8900077B2Reduce impactStress minimizationHollow inflatable ballsHollow non-inflatable ballsEngineeringMechanical engineering

A sportsball includes a barebone ball and an outer ball cover. The barebone ball includes an inflatable bladder body and a ball casing. The ball casing, which is formed in an integrated structure, has an outer circumferential surface, an inner circumferential surface to define an interior cavity to fittingly enclose the bladder body therein, and a plurality of pre-formed channels integrally and indently formed on the outer circumferential surface, such that the ball casing and the bladder body enclosed therewithin form a one piece integrated semi-product of the sportsball. The outer ball cover comprising a plurality of outer cover panels overlapping on the outer circumferential surface of the ball casing at a position that edges of each of the outer cover panels are aligned with the corresponding pre-formed channels respectively.

Owner:TOPBALL SPORTS

Monolithic color wheel and process for fabrication of the same

InactiveUS20060227441A1Accurate concentricityAccurate roundnessProjectorsColor photographyColor gelEngineering

A method for fabricating a monolithic color wheel. The method includes (a) preparing a square transparent substrate; (b) forming a plurality of color filters on the square transparent substrate; and (c) cutting the square transparent substrate and the color filters together along a circular path, to form a color filter disk. Through these steps, a color filter disk of color wheel can be produced with better dynamic equilibrium quality, and will run more quietly and smoothly.

Owner:HON HAI PRECISION IND CO LTD

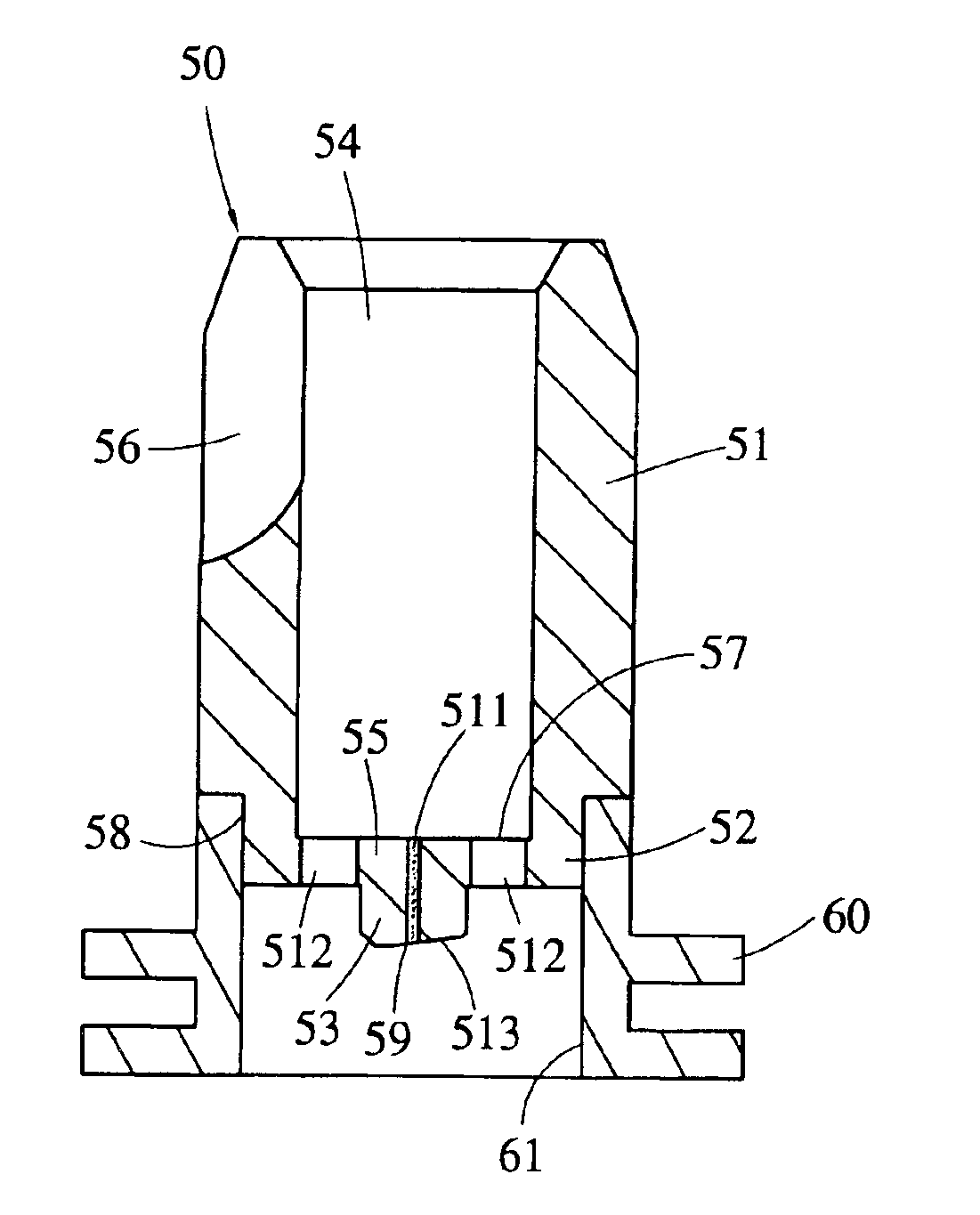

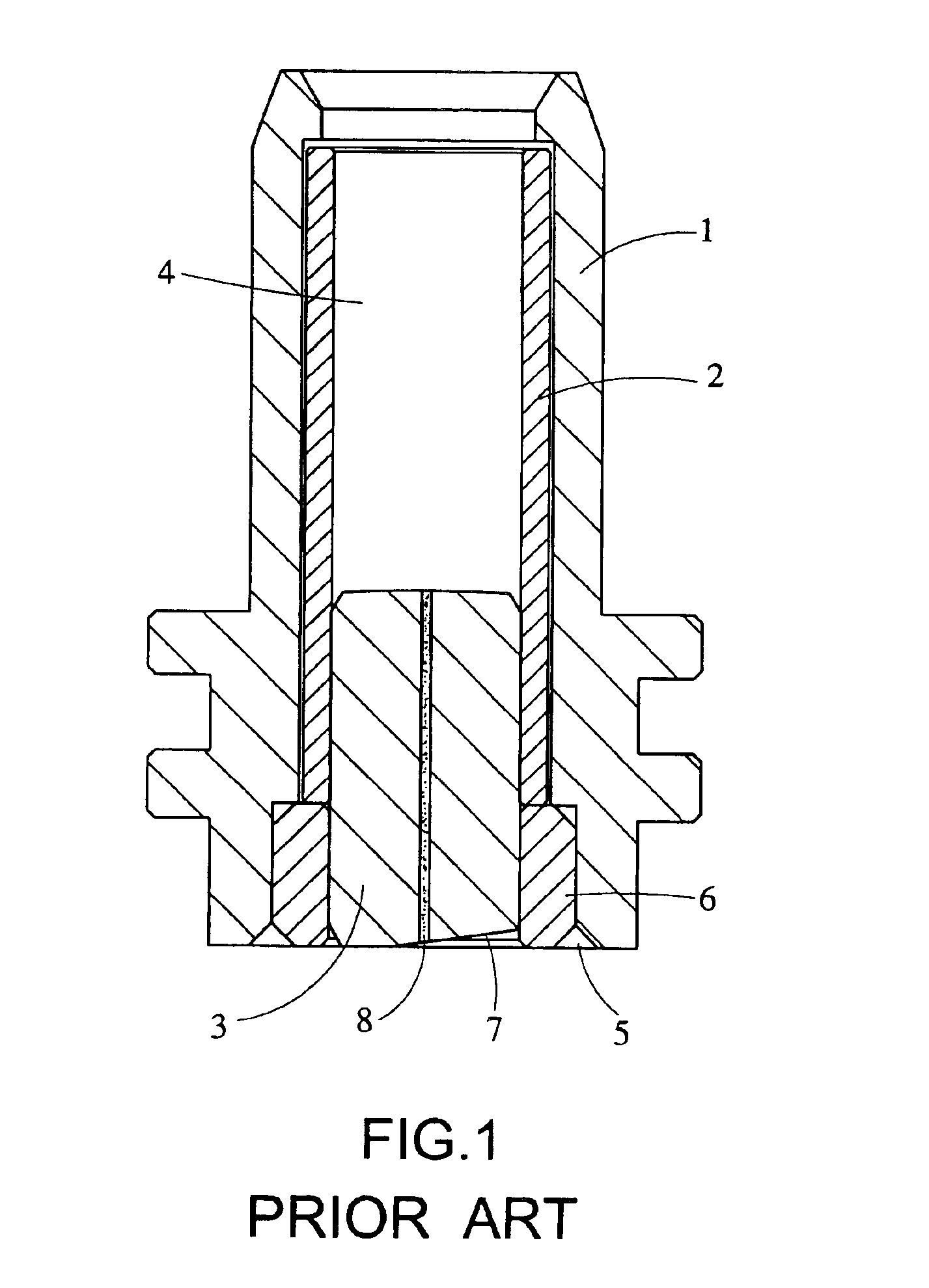

Optical connector

InactiveUS6926450B2Shorten the lengthAccurate roundnessCoupling light guidesEngineeringInjection moulding

An optical connector including a hollow, cylindrical shroud having a section, a bore defined within the section, the bore being adapted to fit an optical fiber connector therein and allow the same to plug or unplug a predetermined number of times, the bore being terminated at a bottom opening of the section; a cylinder axially extended a predetermined distance from a center of the bottom of the section, the cylinder having a longitudinal hole with an optical fiber fitted therein wherein a precise circularity in each of the bore and the hole and coaxial characteristics of the same are obtained by forming the shroud and the cylinder by electrical casting; and an annular flange formed integrally in a bottom of the shroud by electrical casting or injection molding, the flange being adapted to fasten a laser diode element or light detection element.

Owner:HUNG CHEN HUNG

Smoking article

InactiveUS20180325166A1Easy to processReduce the cost of the whole machineCigar manufactureCigarette manufactureFiltrationEngineering

The present invention relates to a smoking article comprising a tobacco rod, a filter comprising at least one plug of filtration material wrapped with one or more filter wrappers, and a tipping material attaching the tobacco rod and the filter, wherein the tipping material has a basis weight of at least 50 grams per square metre, and a thickness of between about 40 and about 55 microns.

Owner:JT INT SA

Fixing method and structure for columnar mould

InactiveCN105649328ASmooth inner surfaceAccurate roundnessForms/shuttering/falseworksEngineeringSteel belt

The invention discloses a fixing method and structure for a columnar mould. The columnar mould is erected by semicircular templates of which the lengths are different, wherein horizontal joints (6) among the templates are arranged in a staggered manner; the horizontal joints (6) are plugged through steel strip hoops (4) and the templates are fixed; and vertical joints (7) are plugged through battens (8) that are fixed through the steel strip hoops (4). The columnar mould disclosed by the invention is combined by the semicircular templates, has a smooth inner surface, is precise in roundness and has certain hardness. The columnar mould has few joints and is high in flatness, and the vertical joints are compact so that mortar does not leak. The columnar mould is easy to form, convenient to disassemble and assemble, high in effect and good in insulating property, so that construction in winter is facilitated. The columnar mould is good in workability. According to the fixing method disclosed by the invention, buckling deformation is hardly generated, and the columnar mould cannot crack, and is good in water resistance performance, high in turnover frequency, long in service life and easy to release. A release agent coats the columnar mould during use, and the reinforcing hoops loose to be automatically peeled off, so that damage on the template is reduced.

Owner:CHINA CONSTR FOURTH ENG DIV

Rolling machine for wheel rim

ActiveCN110238604AImprove physical conditionChemical composition unchangedGrinding machinesEngineeringGrinding wheel

The invention discloses a rolling machine for a wheel rim. The rolling machine comprises a rotating device for fixing and rotating the wheel rim, the rotating device is arranged on a machine frame, fine machining mounting frames are arranged on the periphery of the rotating device, an end grinding unit and side grinding units are arranged on the finish machining mounting frames, and the end grinding unit, the side grinding units and the rotating device are matched with the outer surface, the inner surface and the end surface of the grinding wheel rim correspondingly; each of the end grinding unit and the side grinding units comprises a sliding table assembly, a telescopic arm is arranged on a sliding platform of each sliding table assembly, and a rolling head is installed on each telescopic arm; and the number of the side grinding units is two and the two side grinding units are arranged on the two sides of the radial direction of the rotating device correspondingly. According to the rolling machine for the wheel rim, the processing precision is high, processing is comprehensive, and the processing efficiency can be effectively improved.

Owner:苏州科匠智能科技有限公司

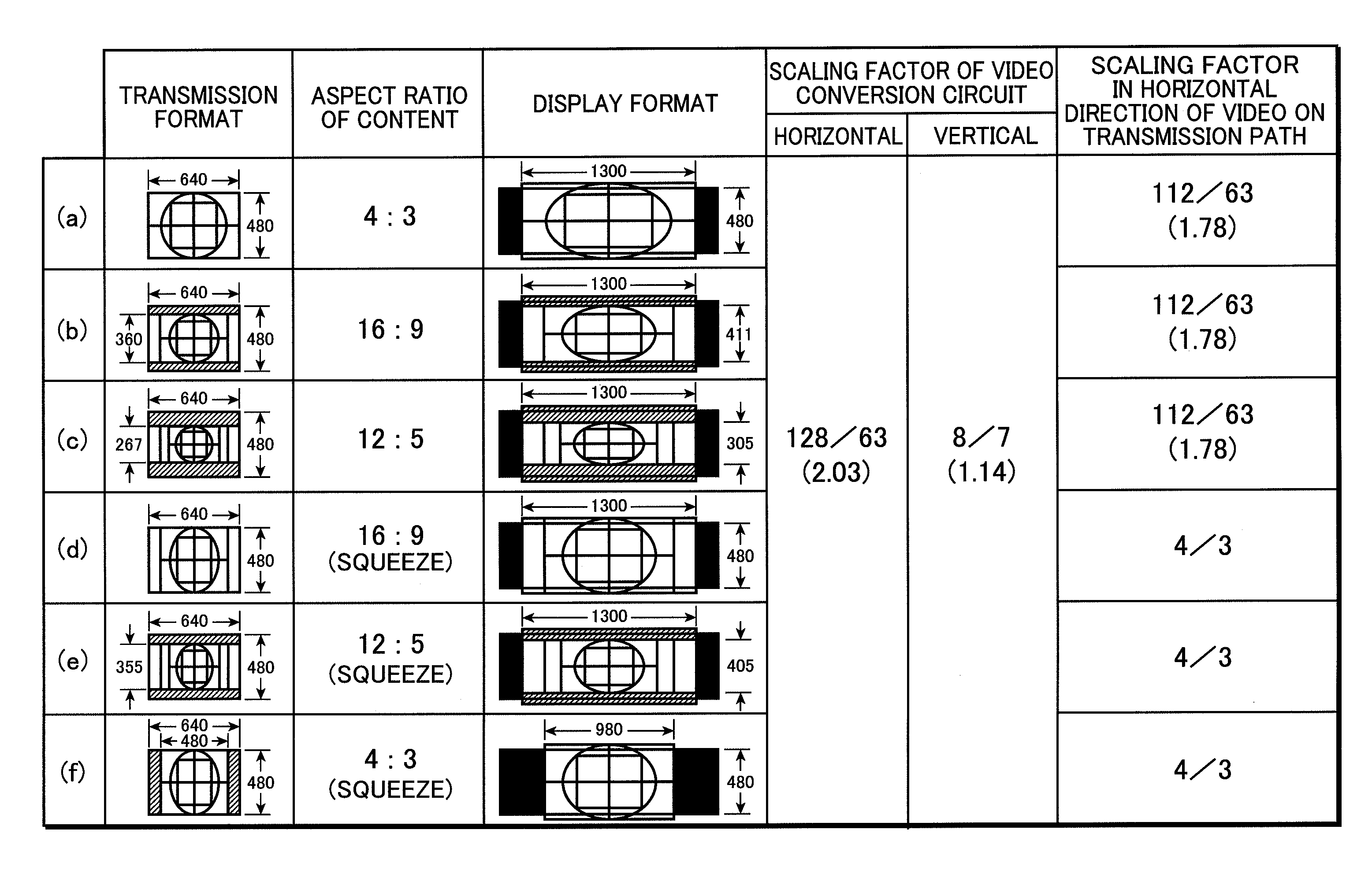

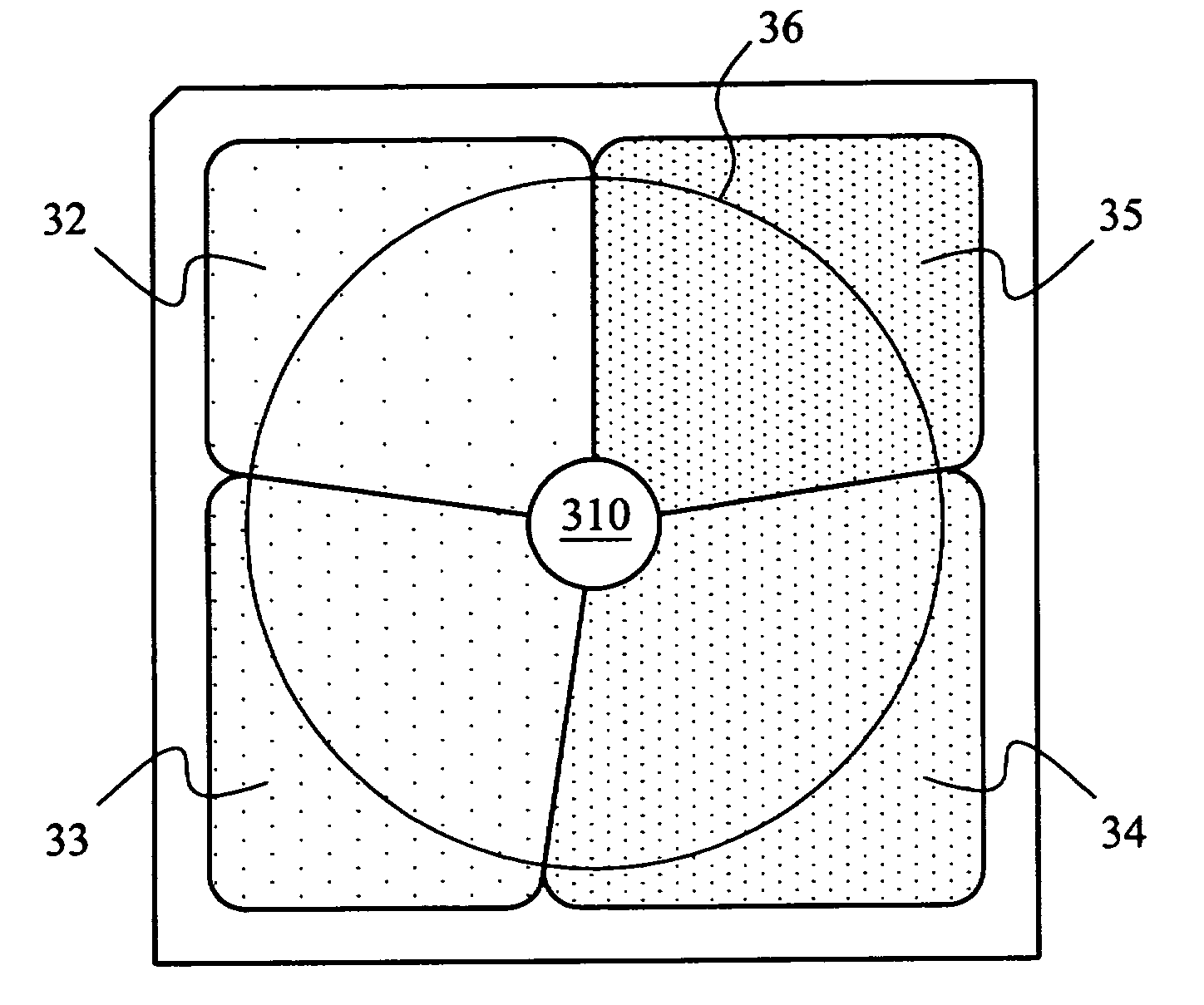

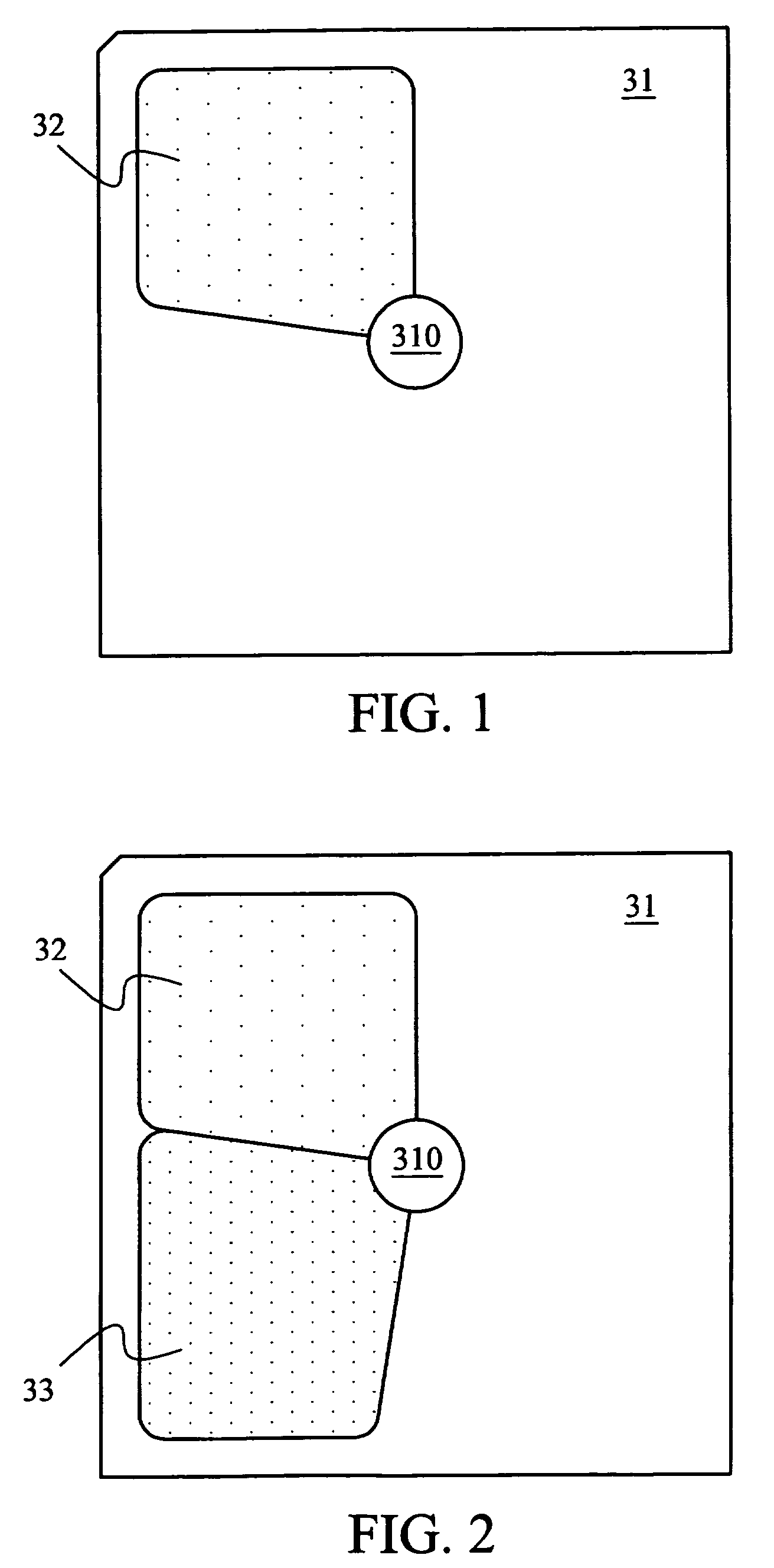

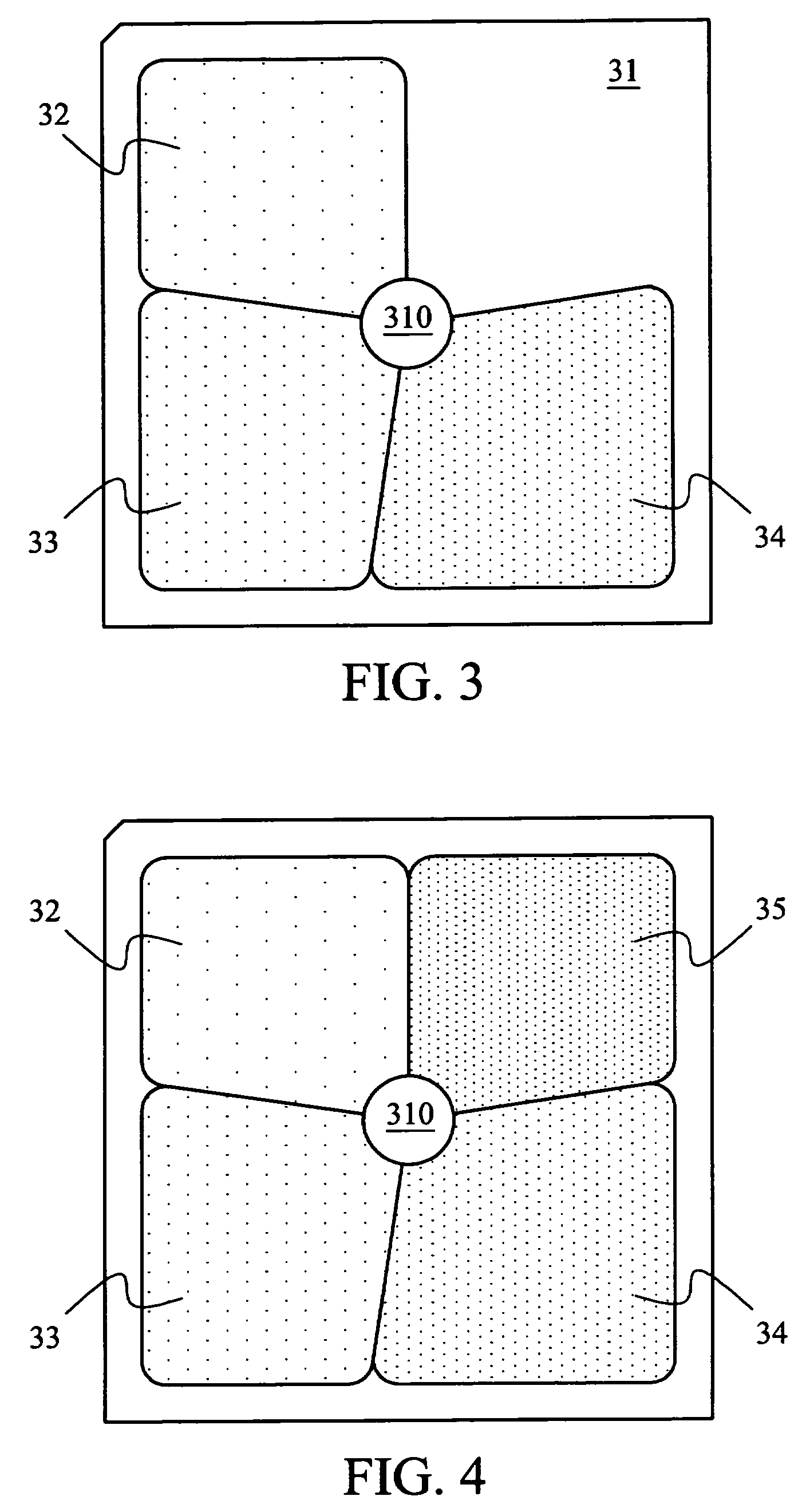

Video display device displaying input videos in various screen modes and/or aspect ratios

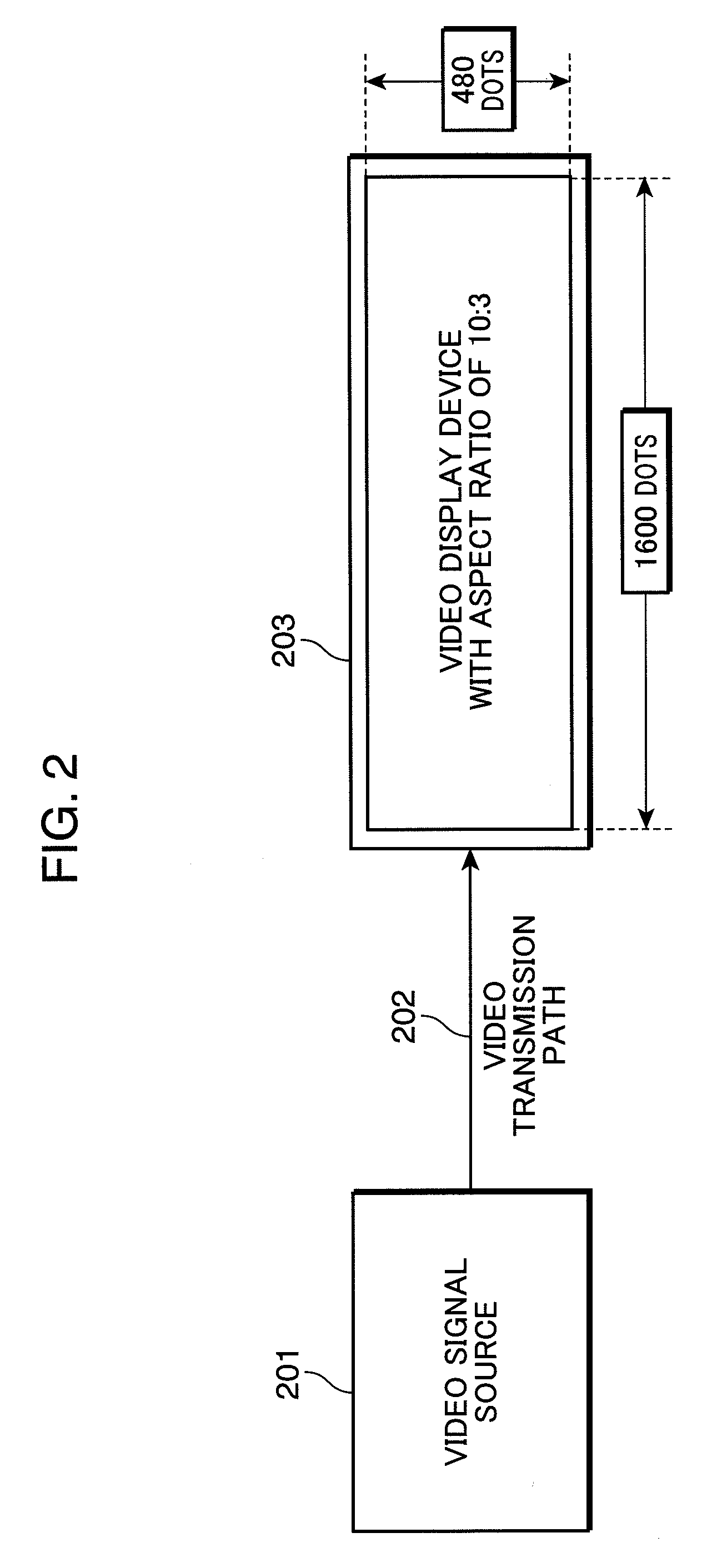

ActiveUS8319891B2Growth inhibitionAccurate roundnessPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningComputer graphics (images)Display device

A video display device is provided with a video conversion circuit for extending an inputted video signal in horizontal and / or vertical directions, and a display unit including a display screen whose aspect ratio is longer in the horizontal direction than 16:9 and adapted to display the video extended by the video conversion circuit. The video conversion circuit includes a mode for extending the inputted video at a scaling factor of A, which is equal to or larger than 1, in the horizontal direction and at a scaling factor of B, which is equal to or larger than 1, in the vertical direction, so that videos effectively utilizing the aspect ratio of the video display device can be displayed while reducing incongruous feeling caused by the extension in the horizontal direction. Thus, an increase in the number of screen modes can be minimized, and modes capable of giving a remarkable sense of presence and modes capable of displaying right circles can be provided in the video display device with an aspect ratio of, e.g. 10:3.

Owner:PANASONIC CORP

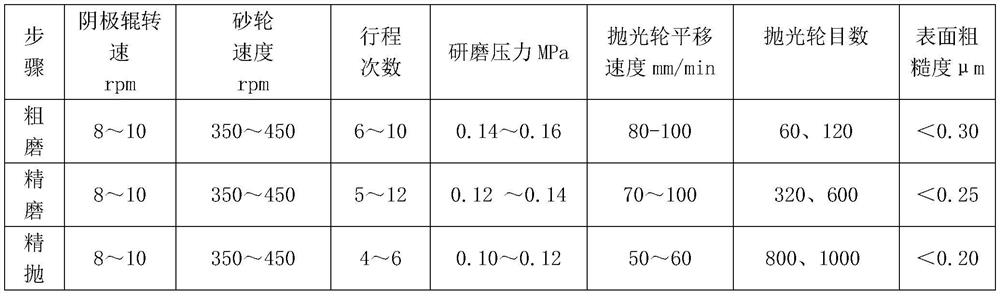

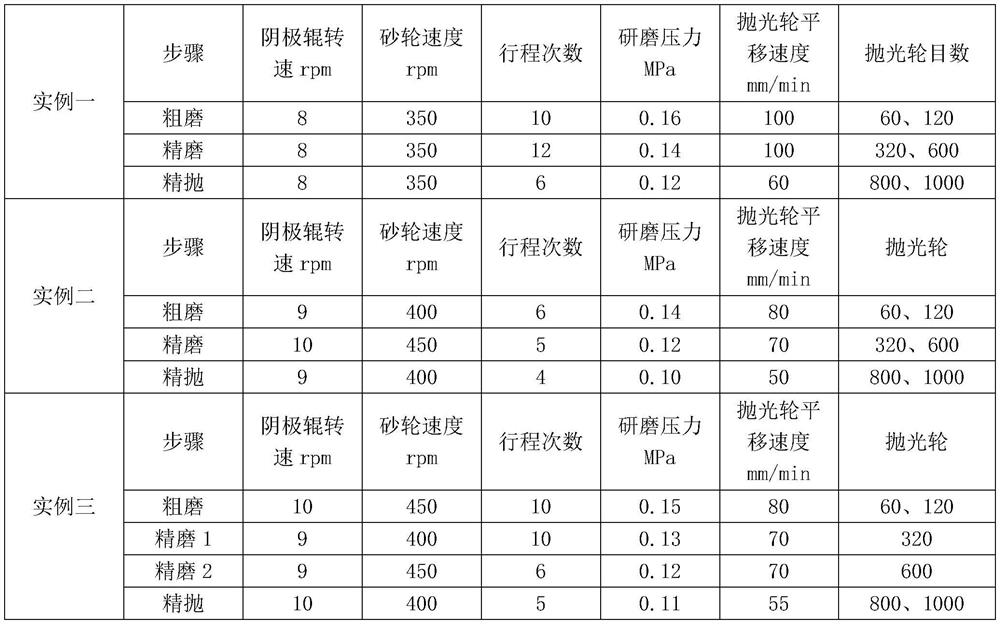

Precise grinding and polishing method for cathode roller

InactiveCN111761418AAvoid the impact of grinding and polishing qualityEfficient removalPolishingSurface roughness

The invention discloses a precise grinding and polishing method for a cathode roller. The method comprises the following steps of soaking a polishing wheel in pure water in a closed and dust-free grinding environment; sequentially carrying out surface rough grinding by adopting a polishing wheel with the particle size of 60 meshes and a polishing wheel with the particle size of 120 meshes; sequentially carrying out surface fine grinding by adopting a polishing wheel with the particle size of 320 meshes and a polishing wheel with the particle size of 600 meshes; cleaning the surface of the finely ground cathode roller; sequentially carrying out surface fine polishing on the cathode roller by adopting a polishing wheel with the particle size of 800 meshes and a polishing wheel with the particle size of 1000 meshes; and cleaning the surface of the cathode roller. The surface roughness of the cathode roller formed by the process is 0.2 <mu> m or below, the cathode roller has a certain mirror surface effect, the production operation period is long, and product crystals are compact.

Owner:JINCHUAN GROUP LIMITED

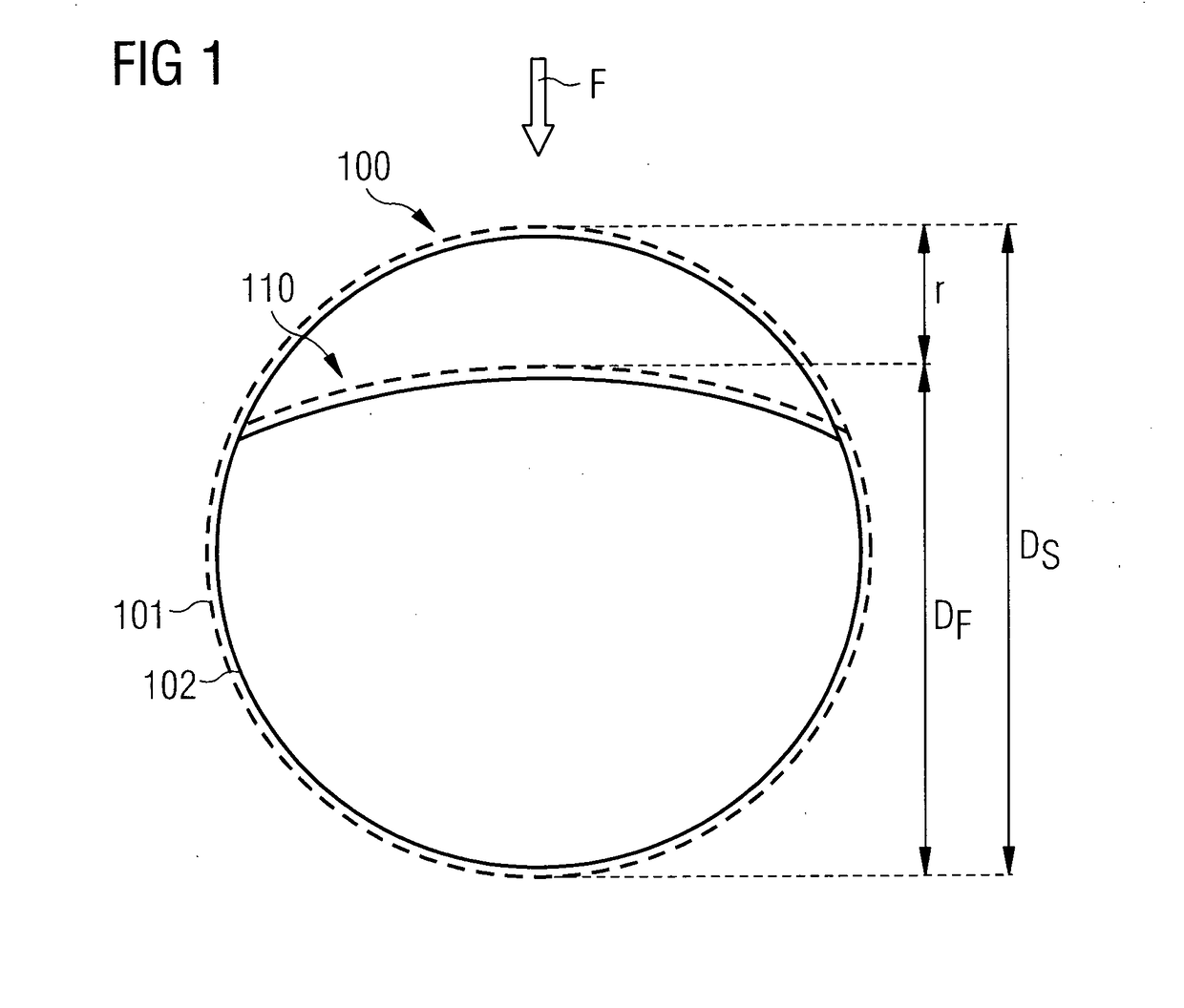

Metal pipe section roundness correction method and correction die

InactiveCN112605179AAccurate roundnessImprove performanceShaping toolsStructural engineeringMechanical engineering

The invention relates to a metal pipe section roundness correction method and a correction die. The correction method comprises the steps of forcing a pipe to be corrected to pass through a convex polygonal die in a drawing manner, and enabling the cross section of the pipe to be locally bent and deformed in order to adapt to a polygon, so that the roundness of the pipe is improved. The correction die comprises a die body and at least three movable die sections, wherein the die sections are provided with working faces; the working faces of the die sections are arranged around the center of the die and form a convex polygon; the distance from the corner of the polygon to the center of the die is larger than the radius of the pipe; and the radial distance from the die sections to the center of the die is adjustable. According to the correction method and the correction die provided by the invention, the roundness of the pipe can be improved under the condition that the diameter, the wall thickness nominal size and the performance of the metal pipe are not changed.

Owner:有研金属复材技术有限公司

Straight seam welding and grouping welding method for large-diameter cylinder

ActiveCN113070632APrevent collapseImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSeam welding

The invention provides a straight seam welding and grouping welding method for a large-diameter cylinder, and relates to the technical field of welding equipment. The straight seam welding and grouping welding method for the large-diameter cylinder comprises the following steps that firstly, rolling wheels on a driving welding walking rolling wheel frame, a driven welding walking rolling wheel frame and at least two hydraulic jacking grouping rolling wheel frames are placed on two parallel rails which are arranged on the ground in advance, wherein the hydraulic jacking grouping rolling wheel frames are located between the driving welding walking rolling wheel frame and the driven welding walking rolling wheel frame; and the driving welding walking rolling wheel frame is placed close to the end, needing to be welded, of the cylinder. A hydraulic supporting arm mechanism is adjusted, the cylinder can be jacked from the two side faces of the cylinder, the hydraulic supporting arm mechanism is used for correcting and lifting a workpiece with the large cylinder diameter to prevent the workpiece with the large cylinder diameter from collapsing, the roundness of the workpiece with the large cylinder diameter is corrected, more time and labor can be saved when the workpiece with a large cylinder diameter is welded and assembled, and the welding efficiency is improved.

Owner:郑州越达科技装备有限公司

Ultra-precise rapid circularity measuring tool

The invention relates to an ultra-precise rapid circularity measuring tool which comprises a tool body and a ball fixing device. The tool body is of a hollow structure, the upper portion of the tool body includes a vacumm chamber, the lower portion of the tool body includes a buffering chamber, and the vacuum chamber is separated from the buffering chamber via a separator plate; the vacumm chamber is internally provided with a vacuum pump accommodating cavity which is fixed in the vacuum chamber via damping springs; and the vacuum pump accommodating cavity is internally provided with a vacuum pump which is fixed in the vacuum pump accommodating cavity via extension springs. The ultra-precise rapid circularity measuring tool reduces vibration of a circularity test during motion greatly via dual damping, the ball to be tested is fixed in a vacuum absorption manner instead of using an external binder, the balls of different materials can be tested, and the circularity of the ball can be determined rapidly and accurately.

Owner:CHANGZHOU RUNCHANG PHOTOELECTRIC TECH

A method of making concrete column formwork

InactiveCN103726649BHigh strengthImprove turnover rateForms/shuttering/falseworksSupporting systemKeel

The invention discloses a method for manufacturing a concrete cylindrical template. The method relates to corrugated pipes, a plurality of horizontal hoops and a plurality of vertical wooded keels. The two symmetrical corrugated pipes are well arranged in a cylindrical mode, the middle of each corrugated pipe is sleeved with the corresponding horizontal hoop, the vertical wooden keels are placed between the horizontal hoops in parallel to wrap the corrugated pipes, and the vertical wooden keels are sleeved with a plurality of horizontal hoops from top to bottom. According to the method, the cylindrical template is made from high-density polyethylene and has the advantages that the weight is low, the strength is high, the rotating rate is high, the inner surface is smooth, tenacity is good, and purchase transportation is convenient. The number of construction joints is small, flatness is high, contact between vertical joints is tight, and leakage is avoided. The template can be free of joint in the horizontal direction besides the two symmetrical joints in the vertical direction, the surface of poured concrete is smooth, color is consistent, roundness is accurate, and the vertical error is small. Forming is easy to achieve, assembly and disassembly are convenient, and work efficiency is high. Complicated external supporting systems are not needed, and maintenance and clearing are convenient to achieve after disassembly.

Owner:中建四局第六建设有限公司淮南分公司

Tower lifting appliance

ActiveCN112279078AStable forceAppropriate structureWind energy generationLoad-engaging elementsMechanical engineeringIndustrial engineering

The invention provides a tower lifting appliance. The tower lifting appliance comprises a connecting support and multiple telescopic parts. The multiple telescopic parts are radially arranged at intervals with equal angles, one end of each of the multiple telescopic parts is connected to the connecting support, the other end of one of the multiple telescopic parts hooks a tower flange through a lifting hook, and the other end of each of the rest telescopic parts is fixed to the tower flange. By the adoption of the tower lifting appliance, the roundness of the tower flange can be corrected in the transportation, reshipment and lifting processes, and therefore it is guaranteed that a tower is smoothly installed.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

A roundness automatic correction device

Owner:惠州安特科技工业有限公司

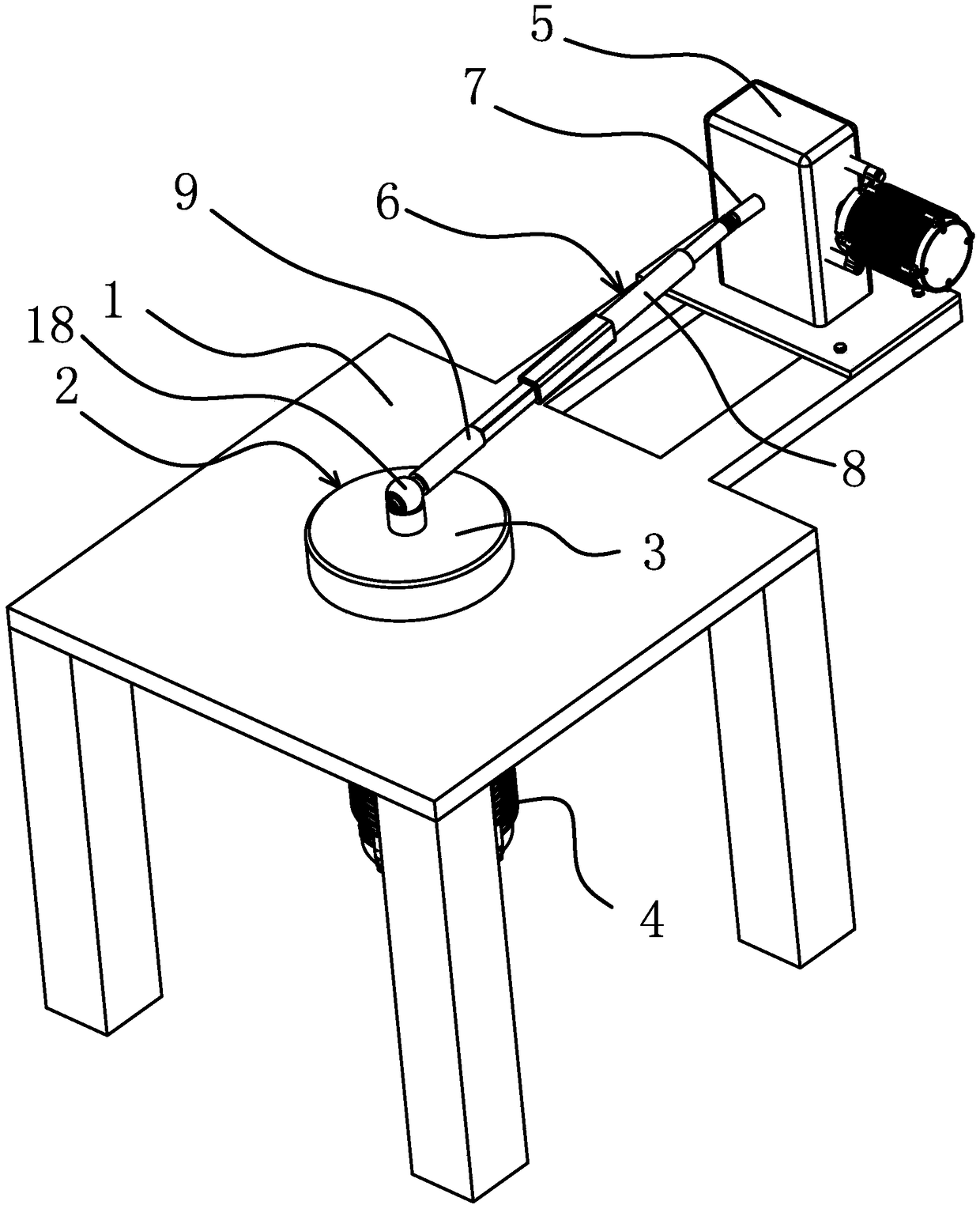

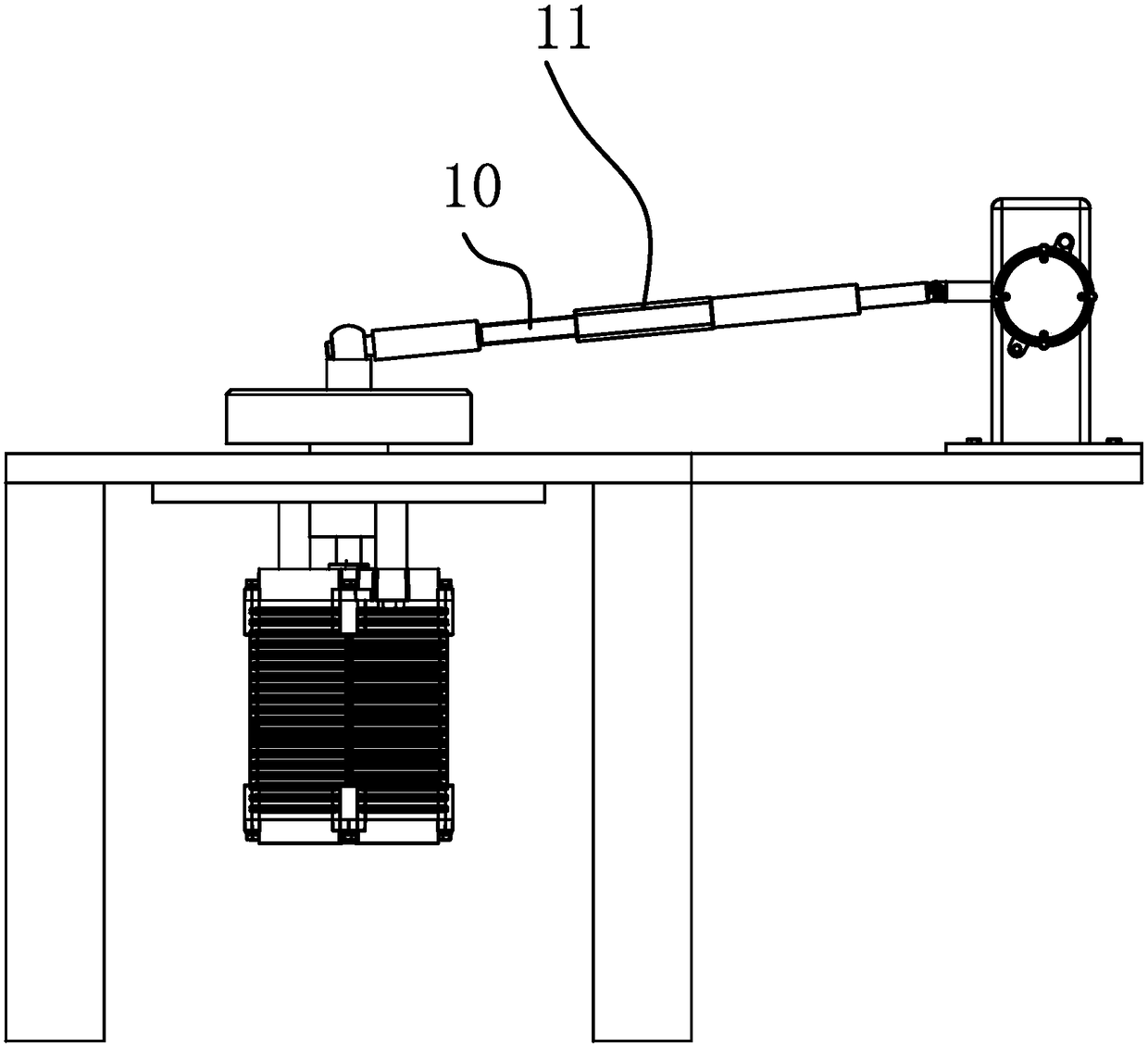

Sphere and machining method thereof

The invention provides a sphere and a machining method thereof, and belongs to the technical field of machines. According to the sphere and the machining method thereof, the technical problems that inthe prior art, the grinding precision of the sphere is not high, and deviation of roundness exists are solved. According to the technical scheme, the sphere comprises a sphere body made of metal, a central hole is formed in the sphere body along any axis, and the two ends of the central hole penetrate through the sphere body. The machining method of the sphere comprises the steps that the lower end of a grinding sleeve is fixed to a mounting disc, the inner end of a supporting rod is inserted in the central hole of the sphere body, and the supporting rod and the sphere body are detachably fixed; and the sphere body is placed on the grinding sleeve, a first driving source is started to drive the grinding sleeve to rotate in the direction of the vertical axis, a second driving source is driven to drive the supporting rod to rotate in the direction of the horizontal axis, the supporting rod drives the sphere body to rotate synchronously, thus grinding movement with the perpendicularly staggered movement track is generated between the sphere body and the grinding sleeve, grinding is conducted till the outer spherical surface of the sphere body reaches the preset precision requirement,then grinding is stopped, and the sphere body is taken out and discharged.

Owner:杨陈彬

Monolithic color wheel and process for fabrication of the same

InactiveUS7253977B2Accurate concentricityAccurate roundnessProjectorsColor photographyEngineeringColor wheel

Owner:HON HAI PRECISION IND CO LTD

A ball grinder

ActiveCN107745329BGrind evenlyAccurate roundnessGrinding carriagesSeat surface grinding machinesGrinding millMachine

The invention provides a ball grinding machine, belongs to the mechanical technical field and solves the technical problems that in the prior art, the ball grinding precision is not high, deviation isgenerated on roundness and the like. According to the technical scheme, the ball grinding machine comprises a rack. The rack is rotatably connected to a grinding head for grinding a target ball or amounting disc for fixing an external grinding cover; a supporting rod is also arranged above the rack; the outer end of the supporting end is fixedly connected to an output shaft of a driving source II and the driving source II can drive the supporting rod to rotate. The ball grinding machine provided by the invention can grind the outer spherical surface of the ball all around without dead angles. The ball and the grinding equipment are more easily aligned during processing, and the position needs not to be adjusted precisely.

Owner:杨陈彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com