A method of making concrete column formwork

A technology of concrete and columns, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems that cannot meet the requirements of construction, and achieve high turnover rate, high flatness, procurement and transportation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

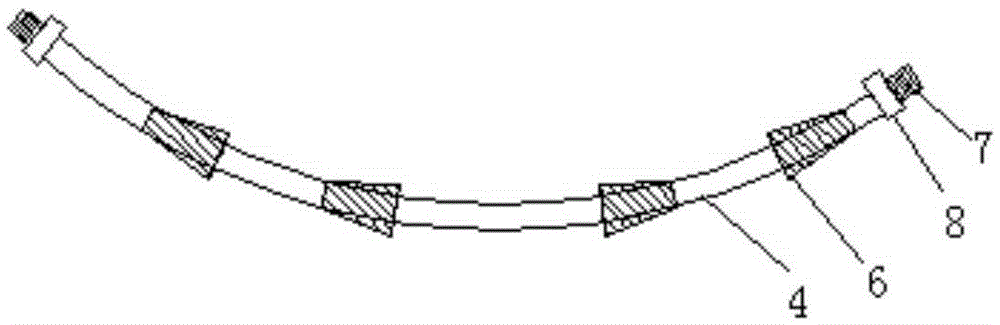

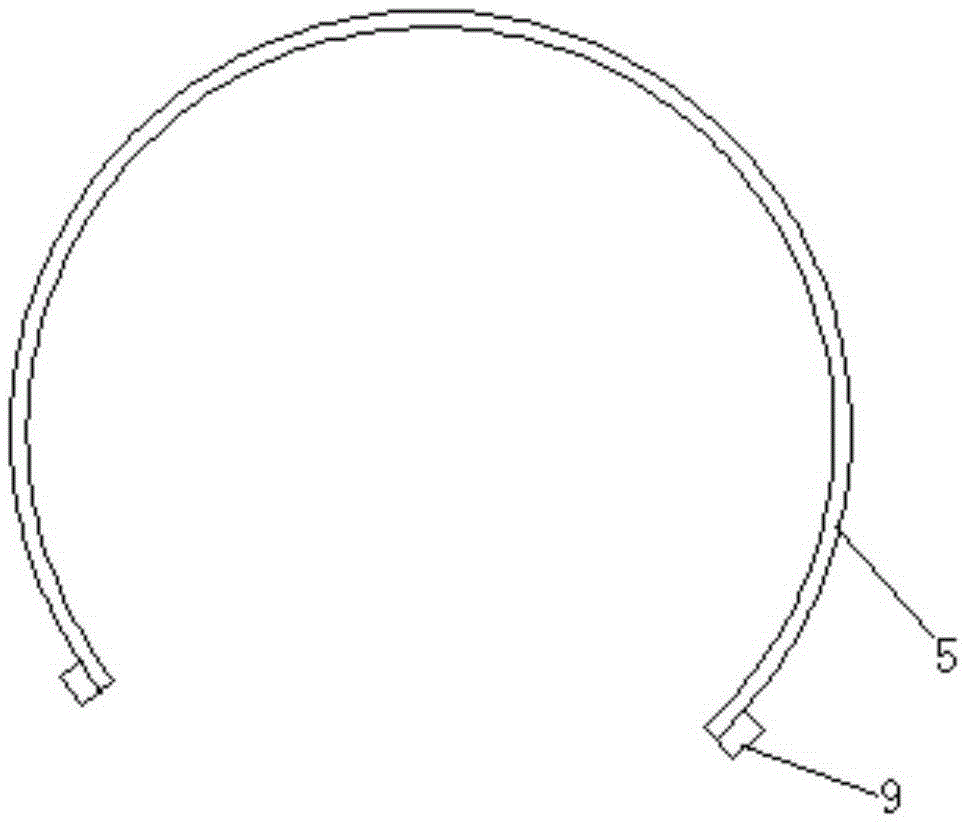

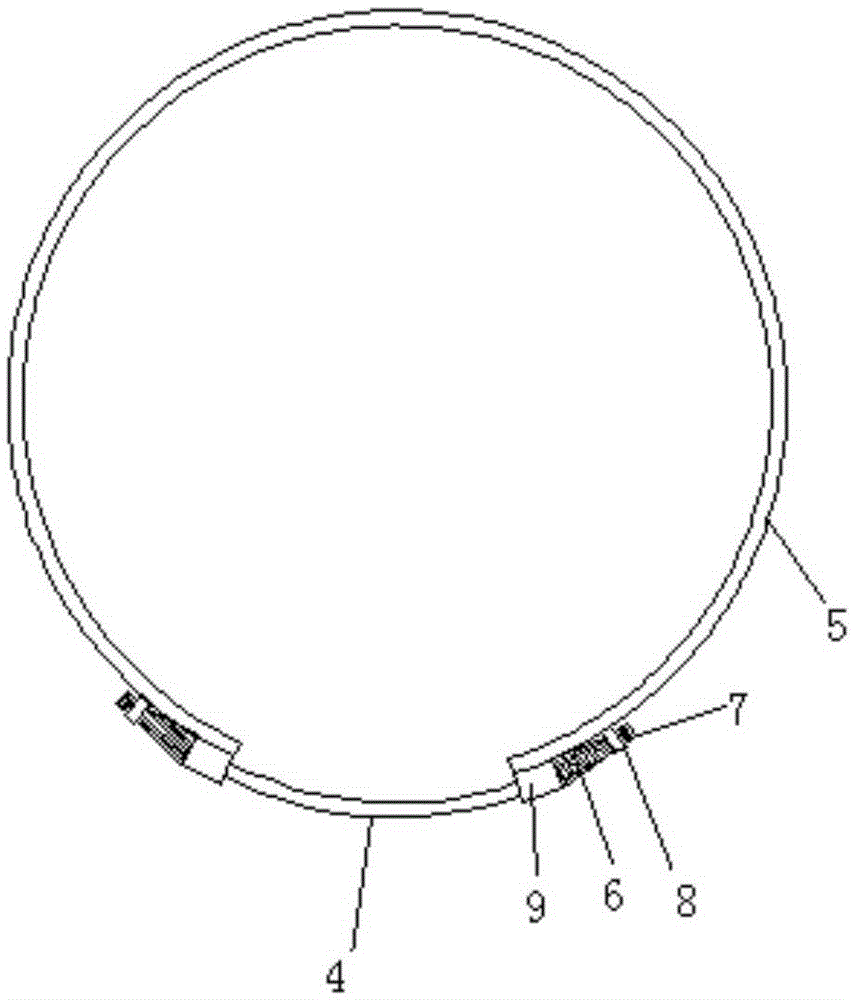

[0014] Such as figure 1 , 2 , 3, 4, a method for making concrete cylindrical formwork, including a corrugated pipe 1, a plurality of horizontal hoops 2 and a plurality of wooden vertical flutes 3, the corrugated pipe 1 is cut into two symmetrical pieces from the middle, so The horizontal hoop 2 includes an arc-shaped steel bar 1 4 and an arc-shaped steel bar 2 5. A plurality of movable sleeves 6 are sleeved on the arc-shaped steel bar 4, and both ends of the arc-shaped steel bar 4 are provided with threads. In section 7, nuts 8 are respectively sleeved on the threaded section 7, and welding sleeves 9 are respectively welded on the outer sides of the two ends of the arc-shaped steel bars 5. The two ends of the welding sleeve 9 have the same diameter, and the movable The two ends of the sleeve 6 have different diameters. The diameter of the thin end is smaller than the diameter of the nut 8, and the diameter of the thick end is larger than the diameter of the welding sleeve 9. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com