Necking mold for thin-wall cylindrical parts

A thin-walled cylinder and necking technology, which is used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to eliminate processing, drum-shaped deformation, and no internal support, and achieve the effect of high surface accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

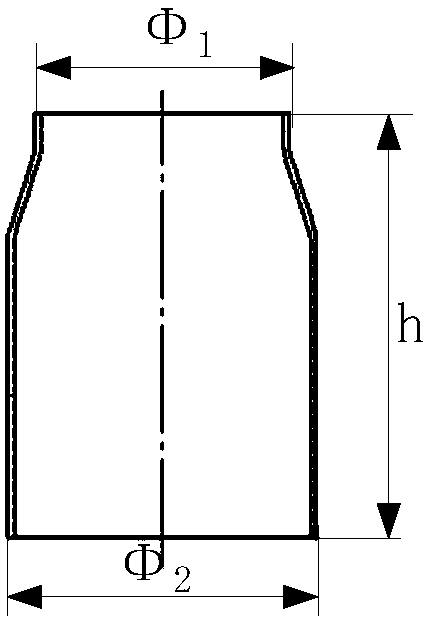

[0035] see figure 1 , the thin-walled cylindrical part 10 is divided into three sections from top to bottom, the first straight line section, the second oblique line section and the third straight line section, the outer circle diameter Φ corresponding to the first straight line section 1 , the outer circle diameter Φ corresponding to the third straight line segment 2 , Φ 1 2 , the diameter of the outer circle corresponding to the second oblique segment is determined by Φ 1 increase to Φ 2 ; The height of the thin-walled cylindrical member 10 is h.

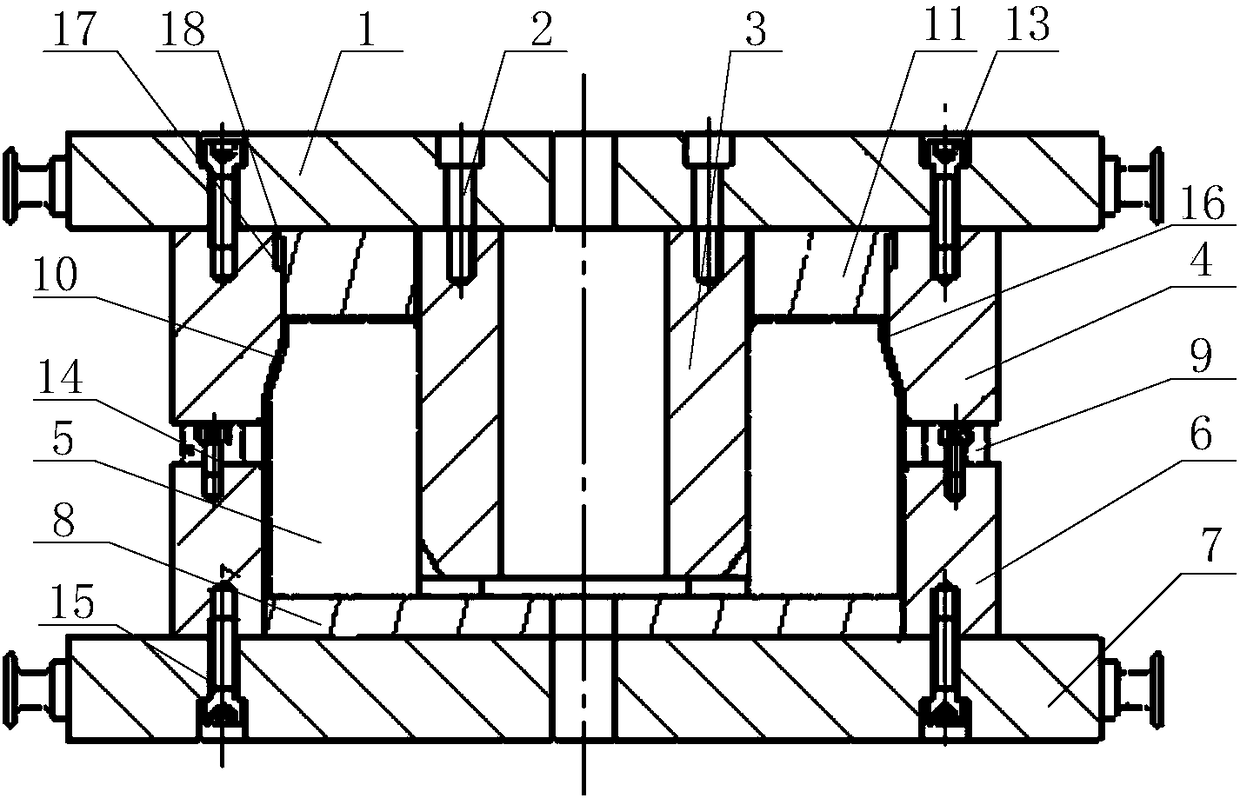

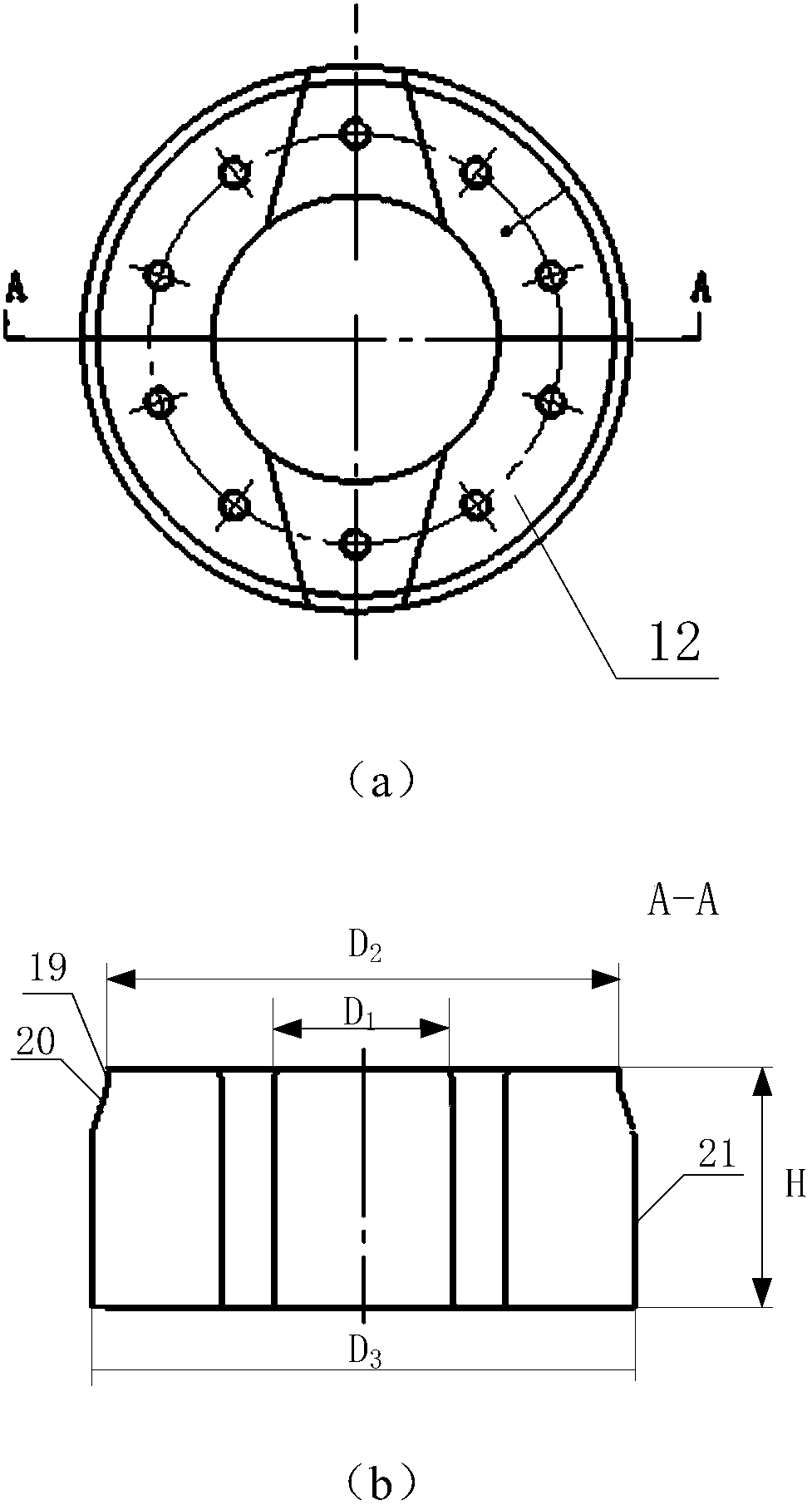

[0036] see figure 2 , The necking mold includes an upper mold and a lower mold, and the upper mold includes an upper template 1, a first fastener 2, a mandrel 3, a die 4, an ejector 11 and a second fastener 13; the lower mold includes a split Punch 5, positioning ring 6, lower template 7, lower top plate 8, pad 9, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com