Metal pipe section roundness correction method and correction die

A metal pipe, circular section technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as product size out of tolerance, limited precision, long process time, etc., to achieve stable pipe performance, difficult to change, and simple steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

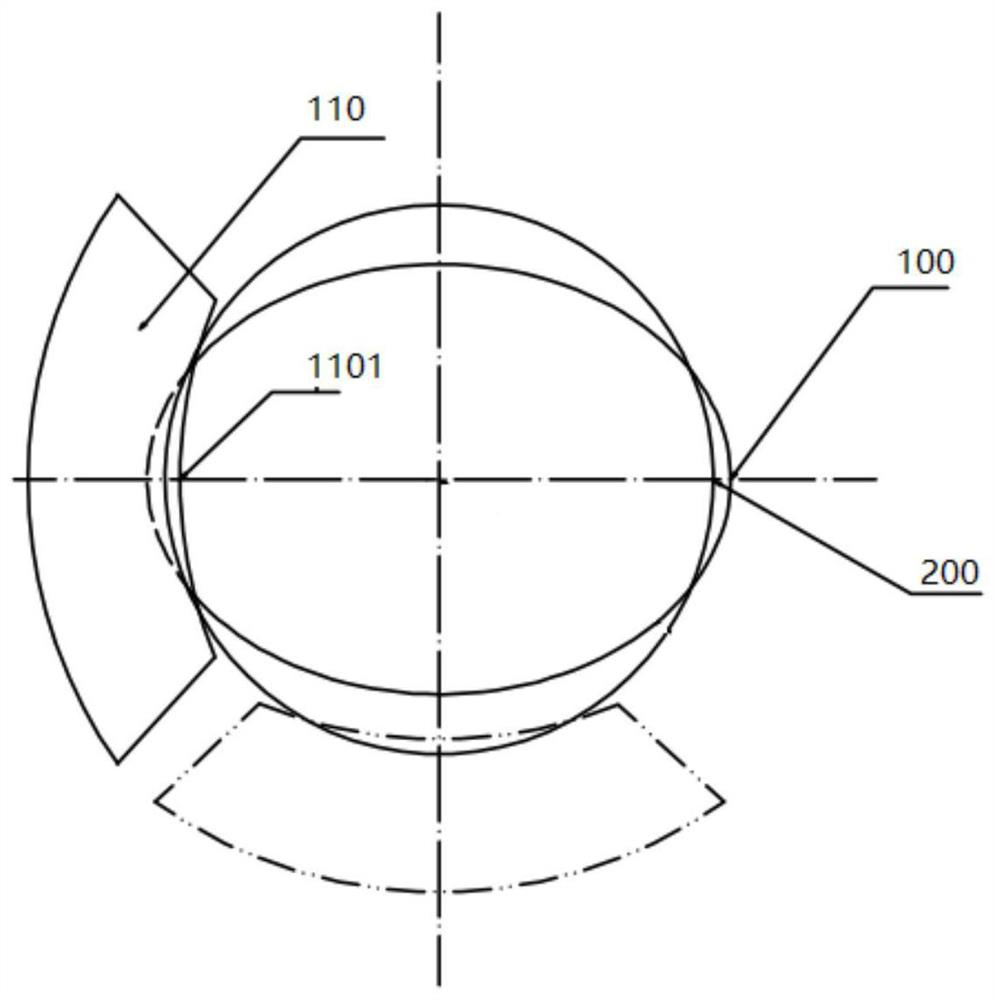

Image

Examples

Embodiment 1

[0034] Take the processing of an aluminum tube with a nominal diameter of 65mm and a wall thickness of 2mm as an example. The specific roundness and accuracy requirements are: the diameter tolerance range in any direction is +0mm to -0.4mm, that is, the diameter is measured along any direction, and the diameter measurement result should be between 65 and 64.6mm. The wall thickness tolerance range is +0.15mm to -0.15mm, that is, the wall thickness is measured at any point, and the measurement result should be between 1.85mm and 2.15mm. At the same time, it is required that the inner and outer surfaces of the pipe shall not have scratches with a depth greater than 0.03mm.

[0035] The manufacturing method is: processing by rolling method, through two-pass processing with a deformation amount of about 35% according to the conventional method, the size of the finished aluminum tube 1 is controlled between 64.62 and 64.98mm in diameter and 1.86-2.14mm in wall thickness, which meets...

Embodiment 2

[0039] Take the processing of an aluminum tube 2 with a nominal diameter of 85 mm and a wall thickness of 2 mm as an example. The specific accuracy requirements are: the diameter tolerance range in any direction is +0mm to -0.5mm, that is, the diameter is measured in any direction along the radial direction, and the diameter measurement result should be between 84.5mm and 85mm. The wall thickness tolerance range is +0.15mm to -0.15mm, that is, the wall thickness is measured at any point, and the measurement result should be between 1.85mm and 2.15mm.

[0040] The manufacturing method is as follows: the production adopts the drawing method, and the size of the primary finished product is controlled at a diameter of 84.53 to 84.92mm, and a wall thickness of 1.89-2.10mm, which meets the precision requirements.

[0041] After heat treatment, the size and performance of the product are all qualified. During the storage process, the pipe was deformed, the roundness of the cross-sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com