Method for pouring concrete outside steel pipe columns by using semicircular templates

A technology for concrete and steel pipe columns, which is applied in the processing of building materials, formwork/formwork/working frames, and on-site preparation of building components. It can solve the problems of inconvenient manual movement, heavy weight, and high cost, and achieve easy molding , high turnover times and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

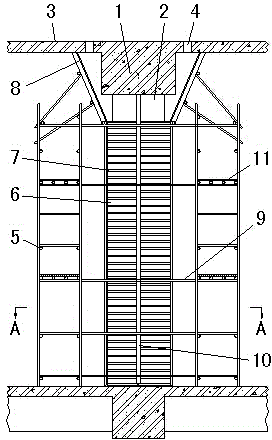

[0025] In this example, the construction is carried out in the following steps:

[0026] 1. Before construction, the required column formwork 6, steel pipes and fixing cards for erecting the scaffold 5, and necessary tools such as adjustable wrench, hammer, pliers, woodworking saw, etc. should be prepared. And complete the preliminary work that meets the construction conditions. For example, the concrete pouring of the beam 1 and the steel pipe column 2 is completed, the strength reaches 1.2MPa, and the binding of the column reinforcement is completed. Clean up the site around the column root, open the pre-buried pouring hole; clean up the site near the pouring hole on the upper floor.

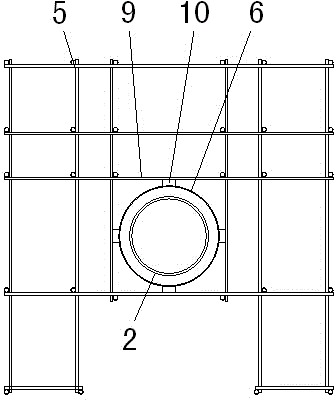

[0027] Second, set up scaffolding. The top view shape of the scaffolding 5 is a door shape, and the scaffolding is erected on three sides of the steel pipe column 2, and the vertical temporary entrance of the column formwork 6 is left on one side of the scaffolding. Bamboo raft slabs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com