Shaping device of thin-walled rotary piece

A thin-walled rotary and shaping device technology, which is applied in the field of thin-walled workpiece processing of rotary bodies, can solve the problems of insufficient cutting, easy spring back to original shape, and many auxiliary man-hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

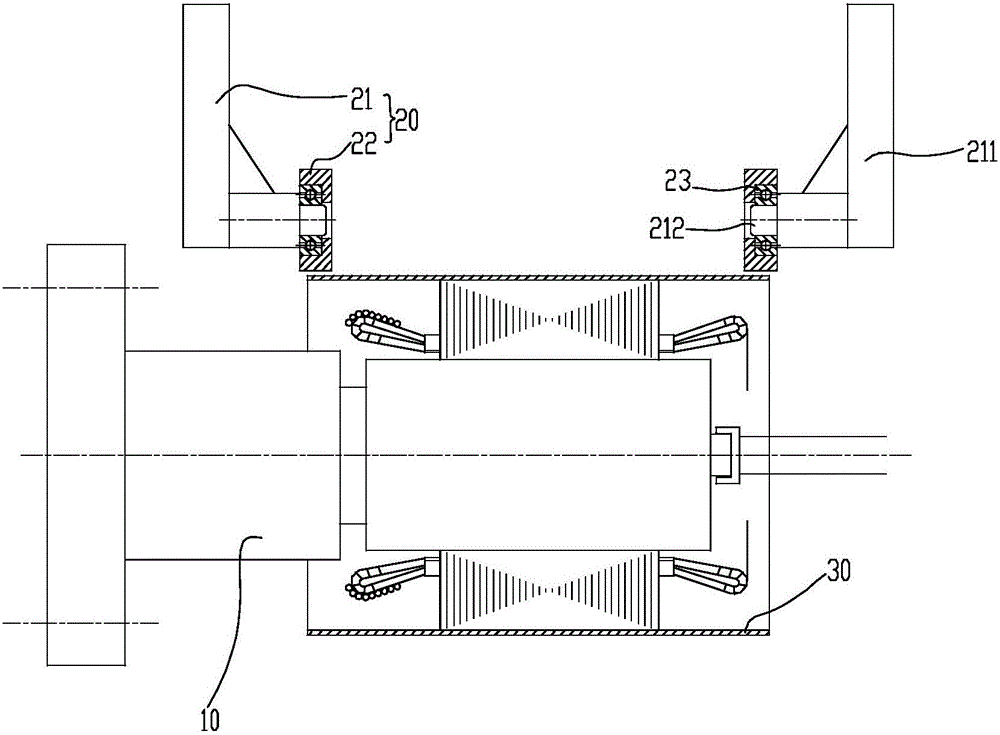

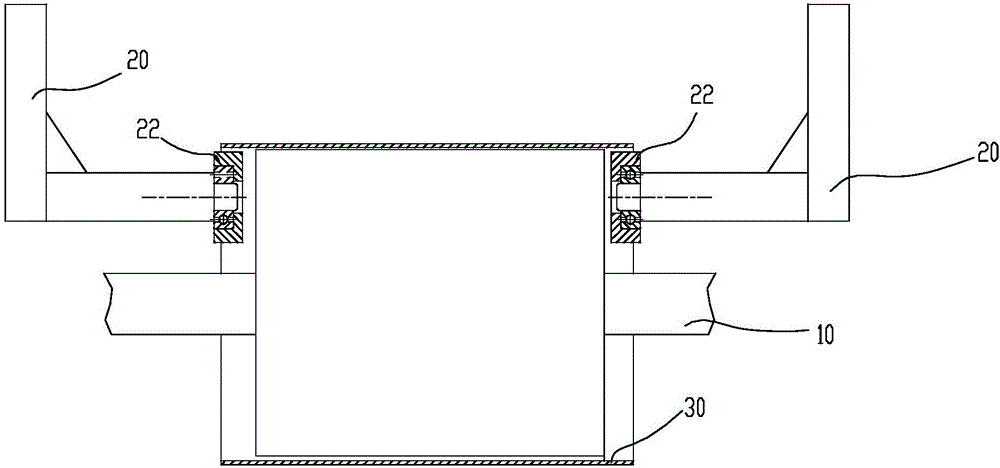

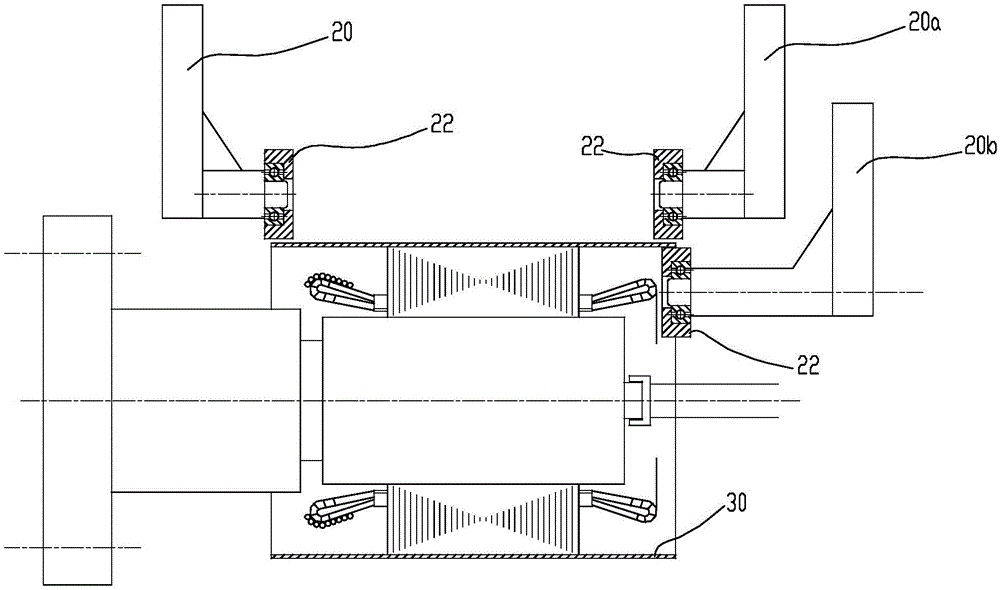

[0009] A shaping device for a thin-walled rotary part, comprising a rotating shaft 10 for fixing and driving a thin-walled rotary part 30 to rotate. Unit 20, the shaping unit 20 includes a bracket 21 and a shaping ring 22 fixed on the bracket 21, the axis of the shaping ring 22 is parallel to the axis of the rotating shaft 10, and the distance between the shaping ring 22 and the axis of the rotating shaft 10 is equal to the thin-walled The theoretical turning radius of the rotating member 30 and the sum of the radii of the shaping ring 22 or the difference of half of the radii. Specifically means: the distance between the shaping ring 22 and the axis of the rotating shaft 10=theoretical turning radius of the thin-walled rotary part 30+the radius of the shaping ring 22, in this case the shaping unit 20 is used to trim the outer circle of the thin-walled rotary part 30 or the distance between the shaping ring 22 and the axis of the rotating shaft 10=theoretical turning radius of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com