Fixing method and structure for columnar mould

A fixing method and technology for fixing structures, which are applied in building construction, formwork/template/work frame, and on-site preparation of building components, etc. The effect of less warping deformation, less seams, and high turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

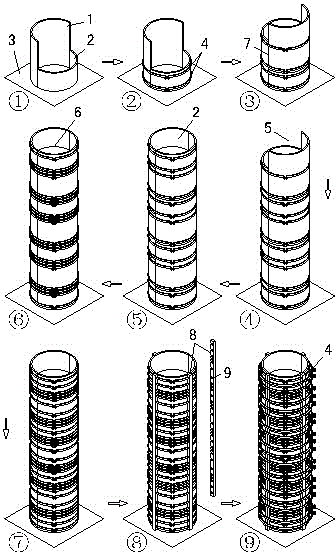

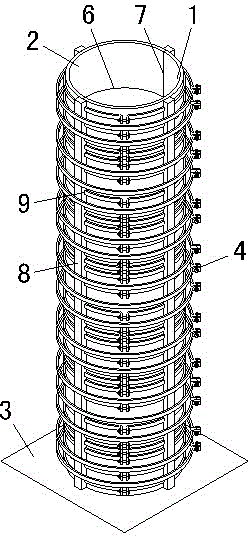

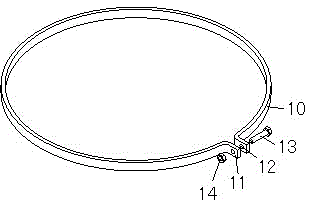

[0043] When the semicircular wood formwork or fiberglass formwork is assembled, the left and right formworks are assembled alternately and formed into a cylindrical formwork through steel bands. The steel hoops are arranged longitudinally along the cylindrical mold, the bottom steel hoop is set at a distance of 100mm from the ground, and a steel hoop is set at the horizontal joint of each cylindrical mold and 100mm above and below the horizontal joint; the rest are arranged according to the spacing 200 ~ 250mm setting. The four directions of the cylindrical formwork are respectively vertically placed wooden strips 8, wherein two wooden strips are positioned at the vertical joints 7 of the left and right templates, and are fixed with a group of steel band hoops. Such as Figure 4 As shown, a notch 9 is sawed at the junction of the wooden strip 7 and the steel band hoop 4, so as to ensure that the arc surface of the wooden strip 9 and the vertical seam 7 of the cylindrical mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com