Equipment for thermoplastic continuous fiber pre-impregnated belt pipe production and use method thereof

A continuous fiber and prepreg tape technology, which is applied in the field of equipment for the production of thermoplastic continuous fiber prepreg tape pipes, can solve problems such as difficult to eliminate interlayer air bubbles, low interlayer compactness, process or product quality problems, etc. The effect of temperature balance, smooth appearance and reduced heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

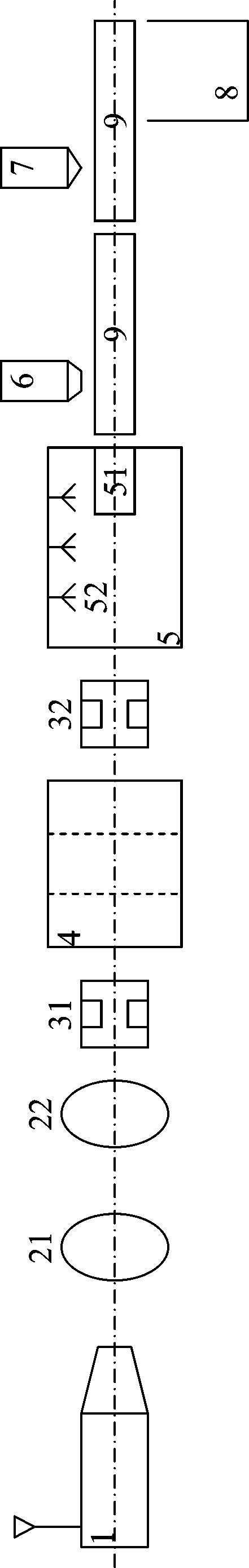

[0037] A kind of equipment for the production of thermoplastic continuous fiber prepreg tape pipe, comprising extruder 1, tape winding machine 21, film winding machine 22, first tractor 31, second tractor 32, oven 4, vacuum box 5, Labeling machine 6, cutting machine 7 and receiving table 8, such as figure 1 As shown, the specific structure is:

[0038] The tape winding machine 21, the film winding machine 22, the oven 4 and the vacuum box 5 are sequentially arranged in front of the head of the extruder 1, the first tractor 31 is arranged between the film winding machine 22 and the feed port of the oven 4, and the second Two tractors 32 are located between the discharge port of the oven 4 and the feed port of the vacuum box 5, the marking machine 6 and the cutting machine 7 are successively arranged in front of the discharge port of the vacuum box 5, and the receiving platform 8 is located at the cutting machine 7 The bottom of the blanking port;

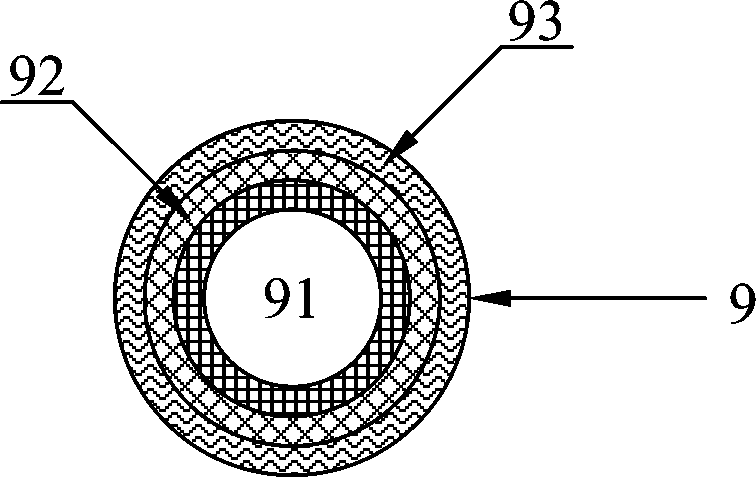

[0039] The central axes of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com