Smoking article

a technology of smoking article and cigarette, which is applied in the field of smoking article, can solve the problems of reducing the production efficiency of cigarette products, affecting the quality of cigarette products, and affecting the quality of cigarette products, and achieves the effects of improving the laser power, not increasing the cost of machines, and being easy to process during manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

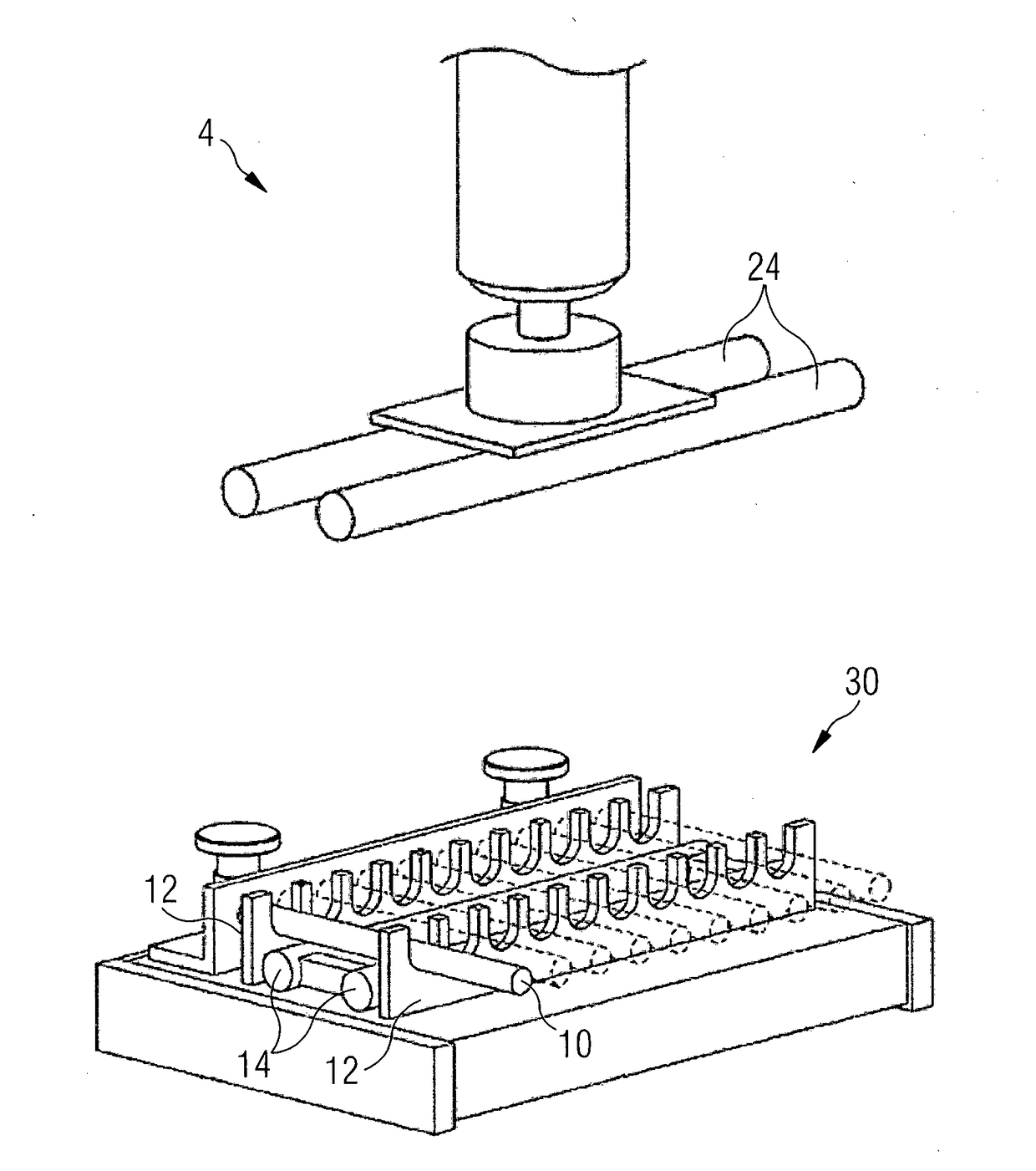

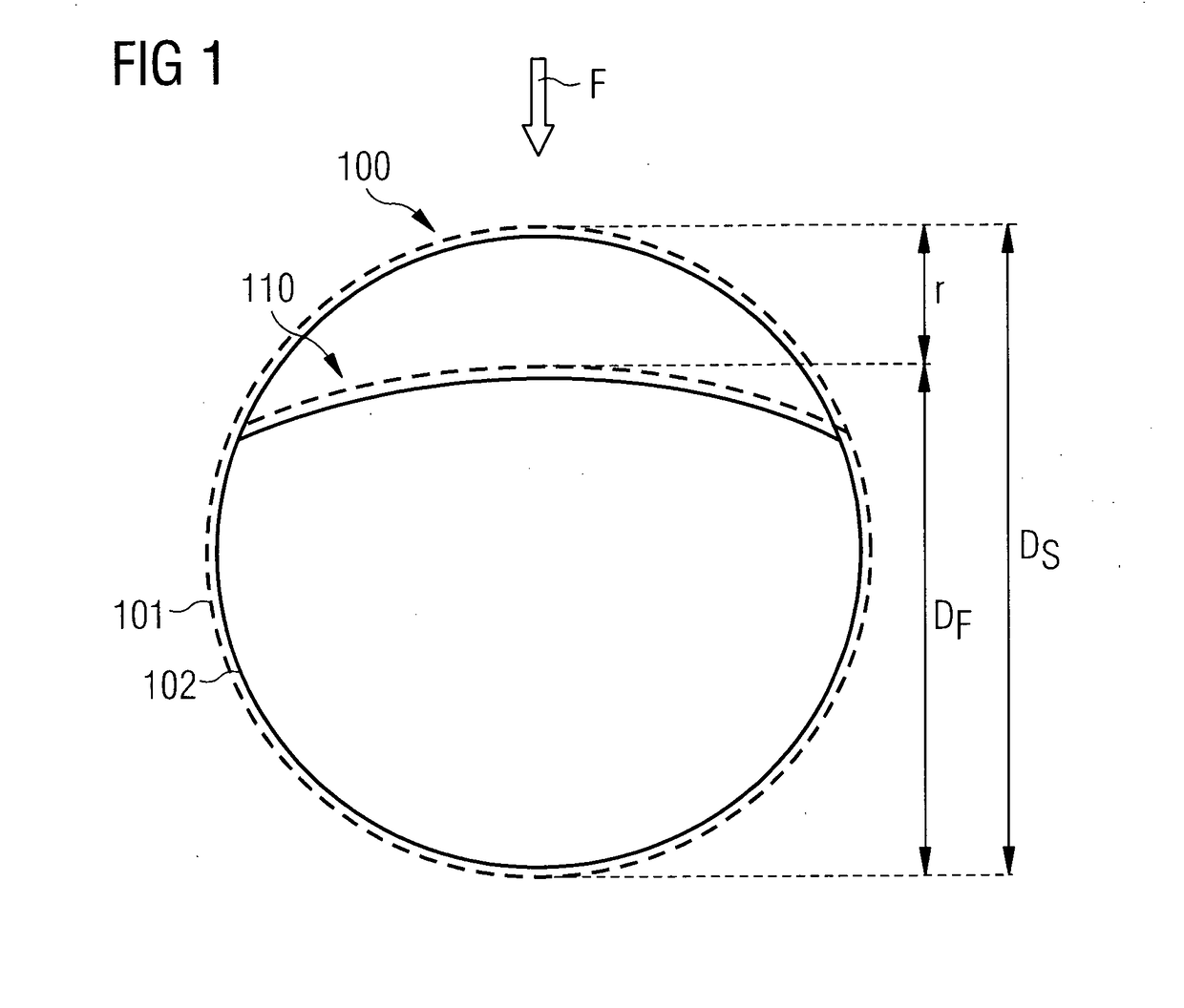

Image

Examples

example 1

[0076]A filter cigarette with a monoacetate filter having 3.80 denier per filament and 30,000 total denier, comprising 8.0 wt % triacetin as plasticizer and having a cellulose acetate tow weight of 137.25 mg. The filtration material is wrapped with a non-porous filter wrapper, having a basis weight of 27 g / m2 and a thickness of 43 micron.

[0077]The filter is attached in end-to-end relationship with a tobacco rod by tipping paper having a basis weight of 50 g / m2.

[0078]The filter has a length of 27 mm and a circumference (Laser) of 24.2 mm.

[0079]The filter shows pressure drop of 70 mmWC.

[0080]The filter cigarette was tested using the above described method and apparatus, and a hardness value of 89% was measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com