Ultra-precise rapid circularity measuring tool

An ultra-precision and tooling technology, applied in the field of optical instruments, can solve the problems of large vibration of the device, difficult to determine the center of the ball to be measured, lack of a reliable ball fixing device, etc., and achieve the effect of reducing vibration and fast and accurate roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

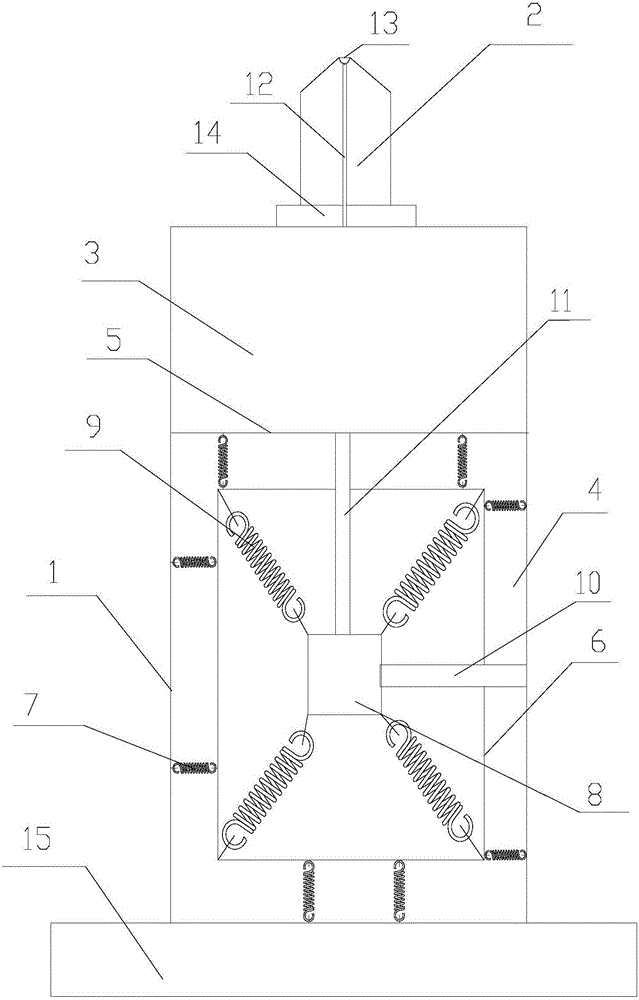

[0019] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

[0020] see figure 1 As shown, an ultra-precise roundness tooling quick test, including tooling body 1 and ball fixing device 2; tooling body 1 is a cylindrical hollow structure, the upper part is a vacuum chamber 3, the lower part is a buffer chamber 4, the vacuum chamber 3 and The buffer compartment 4 is separated by a partition 5; the vacuum compartment 3 is provided with a cylindrical vacuum pump accommodation compartment 6, and the vacuum pump accommodation compartment 6 is fixed in the vacuum compartment 3 by sixteen damping springs 7; the vacuum pump accommodation compartment 6 is provided with a vacuum pump 8. The vacuum pump 8 is fixed in the vacuum pump storage compartment 6 through eight tension springs 9; the exhaust port of the vacuum pump 8 is connected with an exhaust pipeline 10, and the exhaust pipeline 10 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com