Coating with mirror surface effect and preparation method thereof

A paint and emulsion technology, which is applied in the field of paint with mirror effect and its preparation, can solve the problems of short time for smoothing out light, poor mirror effect of the coating, and unfavorable production of large-area coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1: the preparation of coating

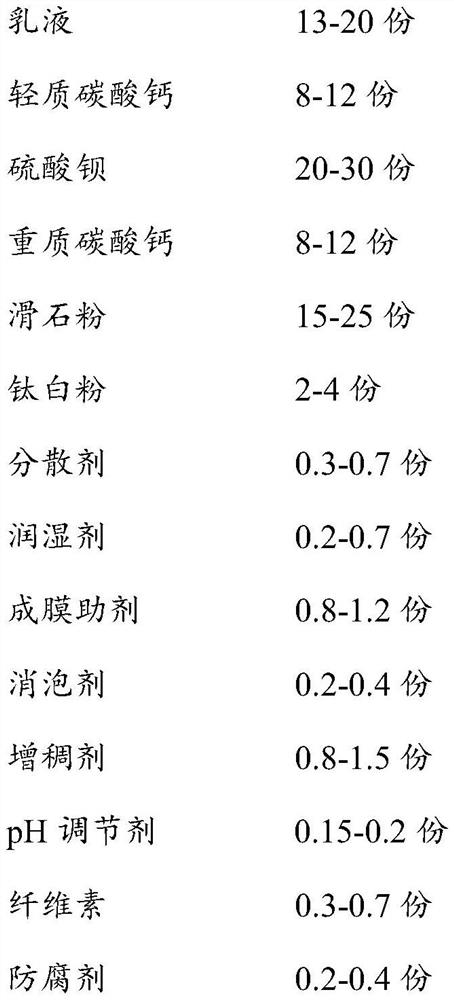

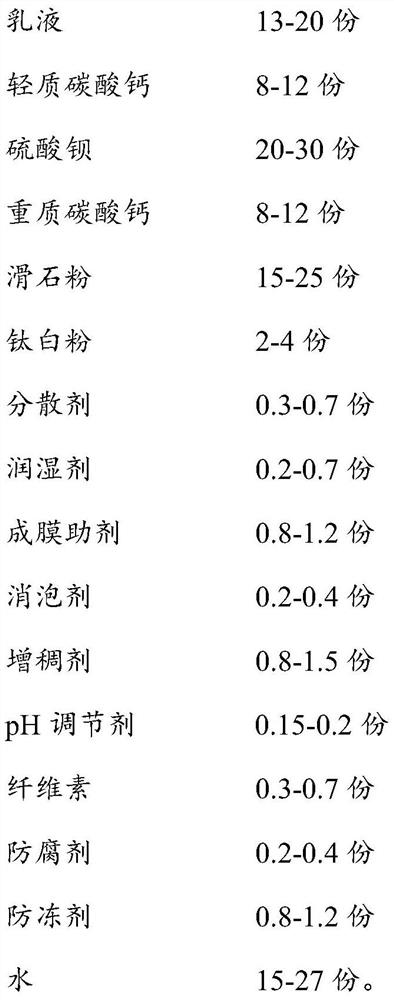

[0073] A kind of coating with specular effect, by weight, comprises the following components:

[0074]

[0075]

[0076] Emulsion is the EZ3010 emulsion of Wacker Company of Germany;

[0077] The dispersant is ECODIS P30 from France Gaotai Company;

[0078] The wetting agent is Clariant's EMUL SOGEN LCN 407;

[0079] The film-forming aid is OE300 from Eastman Company of the United States;

[0080] The defoaming agent is polysiloxane;

[0081] The thickener is bentonite;

[0082] The pH regulator is AMP-95 from American Dow;

[0083] Antifreeze is propylene glycol;

[0084] Preservatives are 0.15 parts of EG CONC preservative provided by British Thor Chemical Company and 0.15 part of MBS 5050 preservative provided by British Thor Chemical Company;

[0085] The mesh number of light calcium carbonate, barium sulfate, heavy calcium carbonate, talcum powder and titanium dioxide is 1250 mesh.

[0086] A method for prepa...

Embodiment 2

[0090] Embodiment 2: the preparation of coating

[0091] A kind of coating with specular effect, by weight, comprises the following components:

[0092]

[0093]

[0094] Emulsion is the EZ3010 emulsion of Wacker Company of Germany;

[0095] The dispersant is ECODIS P30 from France Gaotai Company;

[0096] The wetting agent is Clariant's EMUL SOGEN LCN 407;

[0097] The film-forming aid is OE300 from Eastman Company of the United States;

[0098] The defoamer is polyether modified silicone oil;

[0099] The thickener is bentonite;

[0100] The pH regulator is AMP-95 from American Dow;

[0101] Antifreeze is propylene glycol;

[0102] The preservatives are 0.1 part of EG CONC preservative provided by Thor Chemical Company of the United Kingdom and 0.2 part of MBS 5050 preservative provided by Thor Chemical Company of the United Kingdom.

[0103] A method for preparing a coating with a mirror effect, comprising the following steps:

[0104] (1) Premixing: Stir and ...

Embodiment 3

[0107] Embodiment 3: the preparation of coating

[0108] A kind of coating with specular effect, by weight, comprises the following components:

[0109]

[0110]

[0111] Emulsion is the EZ3010 emulsion of Wacker Company of Germany;

[0112] The dispersant is vinyl bis stearamide;

[0113] The wetting agent is Clariant's EMUL SOGEN LCN 407;

[0114] The film-forming aid is OE300 from Eastman Company of the United States;

[0115] The defoamer is polyether modified silicone oil;

[0116] The thickener is bentonite;

[0117] The pH regulator is AMP-95 from American Dow;

[0118] Antifreeze is propylene glycol;

[0119] The preservative is Dovihill-75.

[0120] A method for preparing a coating with a mirror effect, comprising the following steps:

[0121] (1) Premixing: Stir and mix 23 parts of water and cellulose, the stirring speed is 550 rpm, and the stirring time is 4 minutes, then add dispersant, wetting agent, 0.2 part of defoamer, film-forming agent Auxiliar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com