Semi-reflective and semi-transparent glass and preparation method thereof

A semi-transparent, glass technology, applied in chemical instruments and methods, glass/slag layered products, lamination devices, etc., can solve problems such as poor visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

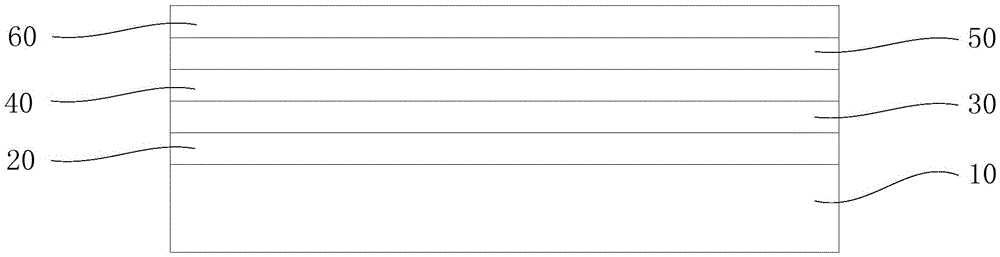

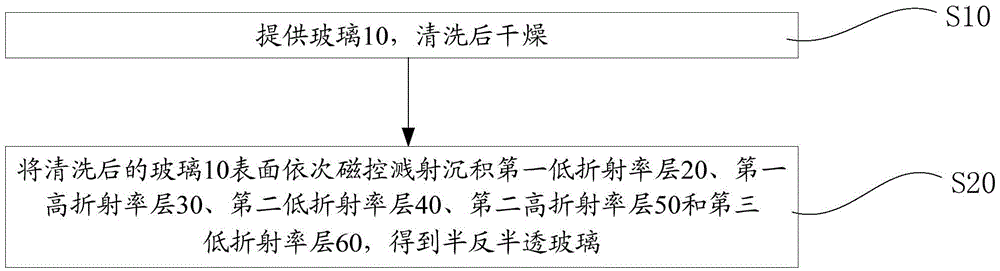

[0049] Such as figure 2 The preparation method of the above-mentioned transflective and translucent glass shown comprises the steps:

[0050] S10, providing the glass substrate 10, washing and drying.

[0051] The glass substrate 10 can be selected from float glass or other conventional glass in the field.

[0052] S20, deposit the first low refractive index layer 20, the first high refractive index layer 30, the second low refractive index layer 40, the second high refractive index layer 50, the third The low refractive index layer 60 and the ITO layer 70 are used to obtain a semi-reflective and semi-transparent glass.

[0053] The material of the first low refractive index layer 20 is SiO 2 or MgF 2 . SiO 2 The refractive index of 1.48, MgF 2 The refractive index of 1.38. Using SiO 2 or MgF 2 As the material of the first low refractive index layer 20 , the transmittance of the first low refractive index layer 20 is relatively high.

[0054] The thickness of the f...

Embodiment 1

[0069] The float glass is washed and dried.

[0070] The working pressure is 2×10 -3 Under the condition of mbar, on the surface of float glass, the thickness is sequentially deposited as SiO 2 layer, thickness is Nb 2 o 5 layer, thickness is SiO 2 layer, thickness is Nb 2 o 5 layers and thicknesses are SiO 2 layer to obtain the required transflective and semi-transparent glass with a reflectivity of 20%.

Embodiment 2

[0072] The float glass is washed and dried.

[0073] The working pressure is 3×10 -3 Under the condition of mbar, on the surface of float glass, the thickness is sequentially deposited as SiO 2 layer, thickness is Nb 2 o 5 layer, thickness is SiO 2 layer, thickness is Nb2 o 5 layers and thicknesses are SiO 2 layer to obtain a transflective glass with a reflectivity of 33%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com