An anti-collapse high-fullness mirror gloss varnish and its preparation process

A fullness and bright technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of not meeting the needs of high-end market, poor fullness of bright varnishes, affecting the coating effect, etc., to achieve surface drying and curing speed. Fast, high construction efficiency, reducing curing shrinkage and internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

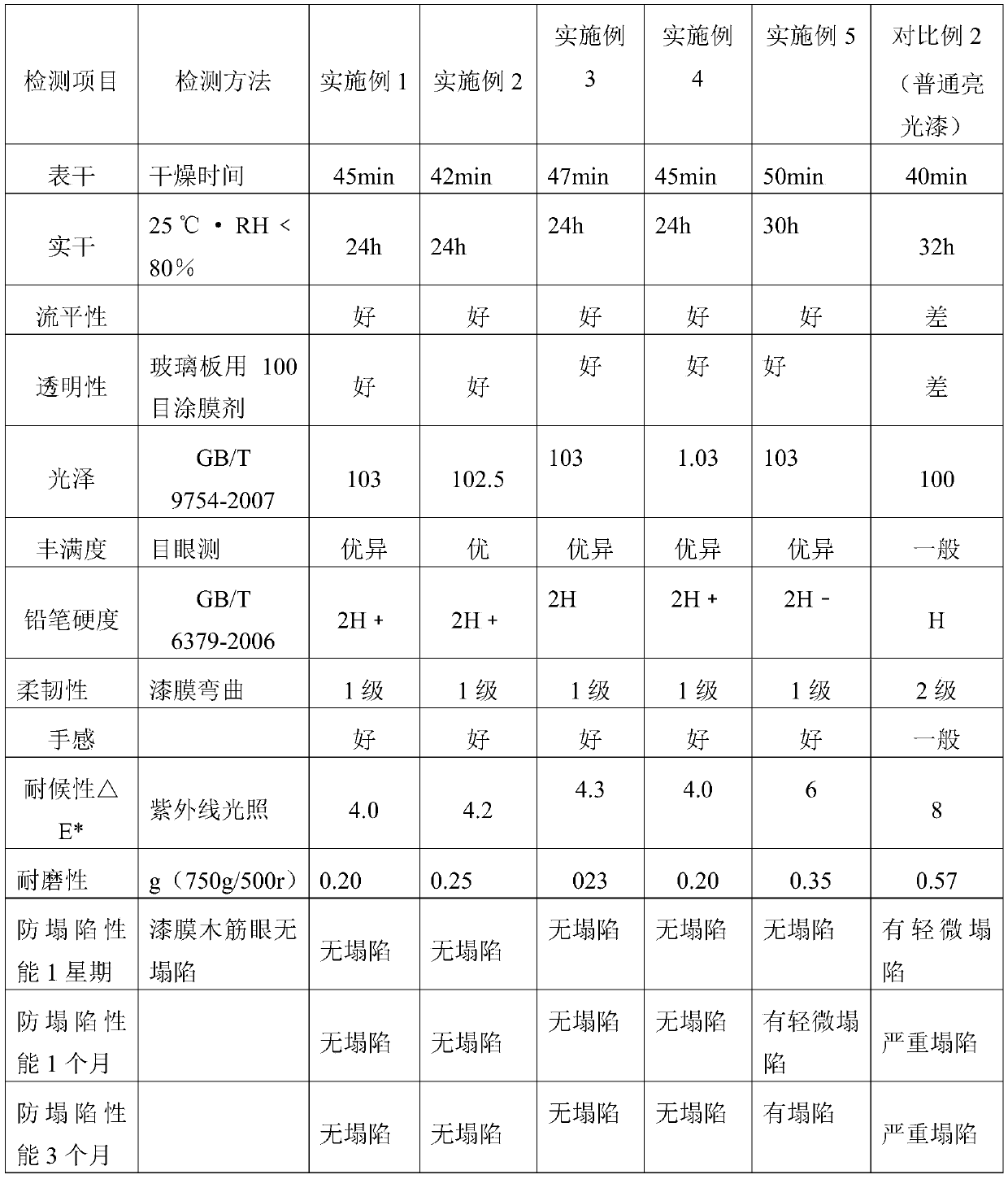

Examples

Embodiment 2

[0072] An anti-slump high-fullness specular gloss varnish, comprising three components A, B and C, wherein component A includes the following raw materials by weight percentage:

[0073] Coconut Fatty Acid Resin 45%,

[0074] Acrylic resin 10%,

[0075] Synthetic fatty acid alkyd resin 30%,

[0076] ZM-11 1%,

[0077] BYK306 0.4%,

[0078] EFKA3777 0.3%

[0079] Deqian 5300 0.3%,

[0080] Butyl acetate 1%,

[0081] PCE 2%;

[0082] Described B component comprises following raw material by weight percentage:

[0083] TDT / TMP adduct 50%,

[0084] HDI trimer 24%,

[0085] Dehydrated butyl acetate 26%;

[0086] Described C component comprises following raw material by weight percentage:

[0087] Xylene 35%,

[0088] Butyl acetate 30%,

[0089] MPS 30%,

[0090] EGDA 5%;

[0091] The weight ratio of the components A, B and C is 1:0.8:0.5.

[0092] The preparation method of the anti-slump high-fullness specular gloss varnish is the same as that in Example 1.

Embodiment 3

[0094] An anti-slump high-fullness specular gloss varnish, comprising three components A, B and C, wherein component A includes the following raw materials by weight percentage:

[0095] Coconut Fatty Acid Resin 20%,

[0096] Acrylic resin 35%,

[0097] Synthetic fatty acid alkyd resin 35%,

[0098] ZM-11 1%,

[0099] BYK306 0.4%,

[0100] EFKA3777 0.3%,

[0101] Deqian 5300 0.3%,

[0102] Butyl acetate 1%,

[0103] PCE 2%;

[0104] Described B component comprises following raw material by weight percentage:

[0105] TDT / TMP adduct 50%,

[0106] HDI trimer 24%,

[0107] Dehydrated butyl acetate 26%;

[0108] Described C component comprises following raw material by weight percentage:

[0109] Xylene 35%,

[0110] Butyl acetate 30%,

[0111] MPS 30%,

[0112] EGDA 5%;

[0113] The weight ratio of the components A, B and C is 1:0.8:0.5.

[0114] The preparation method of the anti-slump high-fullness specular gloss varnish is the same as that in Example 1.

Embodiment 4

[0116] An anti-slump high-fullness specular gloss varnish, comprising three components A, B and C, wherein component A includes the following raw materials by weight percentage:

[0117] Coconut Fatty Acid Resin 35%,

[0118] Acrylic resin 28%,

[0119] Synthetic fatty acid alkyd resin 32%,

[0120] ZM-11 1%,

[0121] BYK306 0.4%,

[0122] EFKA3777 0.3%,

[0123] Deqian 5300 0.3%,

[0124] Butyl acetate 1%,

[0125] PCE 2%;

[0126] Described B component comprises following raw material by weight percentage:

[0127] TDT / TMP adduct 30%,

[0128] HDI trimer 30%,

[0129] Dehydrated butyl acetate 40%;

[0130] Described C component comprises following raw material by weight percentage:

[0131] Xylene 35%,

[0132] Butyl acetate 30%,

[0133] MPS 30%,

[0134] EGDA 5%;

[0135] The weight ratio of the components A, B and C is 1:0.8:0.5.

[0136] The preparation method of the anti-slump high-fullness specular gloss varnish is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com