Thermal processing molding process of a carbon fiber material head-mounted audio-visual and communication equipment shell

A technology of carbon fiber materials and communication equipment, which is applied in the field of communication and audio-visual equipment, can solve the problems of failure to realize audio-visual industry applications, high surface polishing requirements, and failure to obtain compliance, etc., to achieve good low-frequency noise attenuation, good visual sense, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

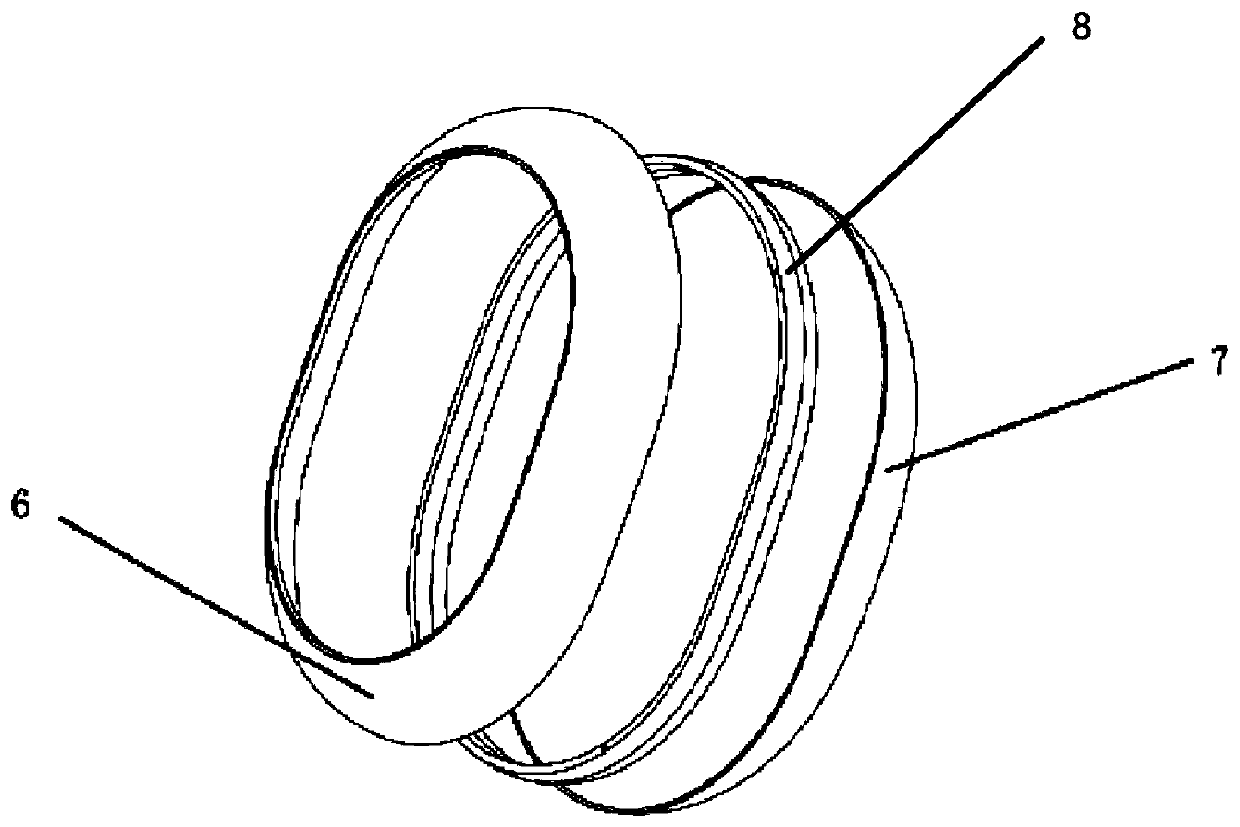

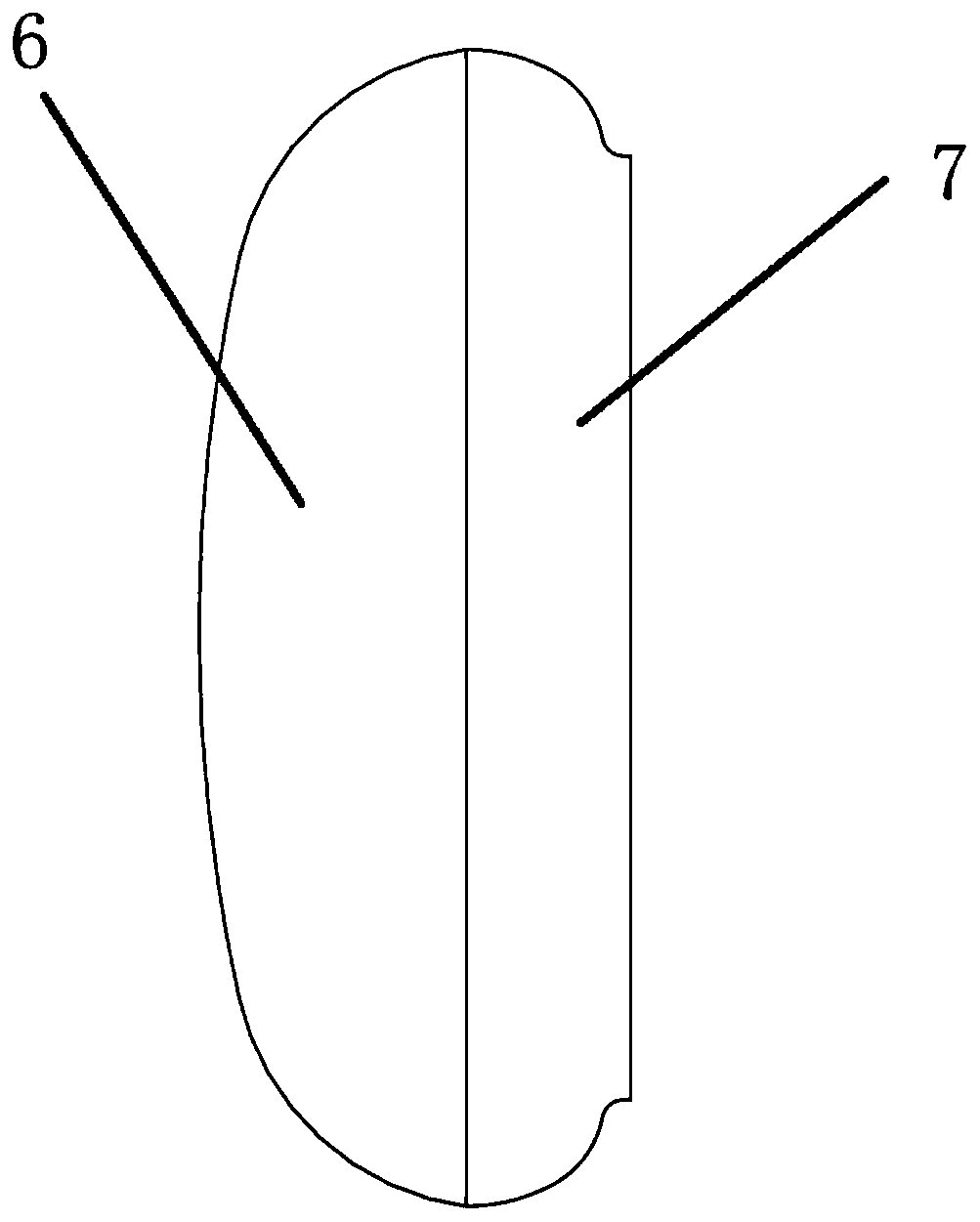

[0040] This embodiment is a process for preparing the shell of a basic outsourcing earphone used in audiovisual equipment. The shell is as figure 2 Shown.

[0041] In this embodiment, a carbon fiber cloth woven with carbon fiber filaments with a diameter of 6.9 μm is selected. First, the carbon fiber cloth is immersed in a modified thermoplastic epoxy resin, and the thickness is about 0.65 mm after the impregnation is completed. Then it is coated with PC customized special film, the thickness of the upper and lower layers is about 0.045mm respectively. The above-mentioned impregnation and coating process can use the existing mature process.

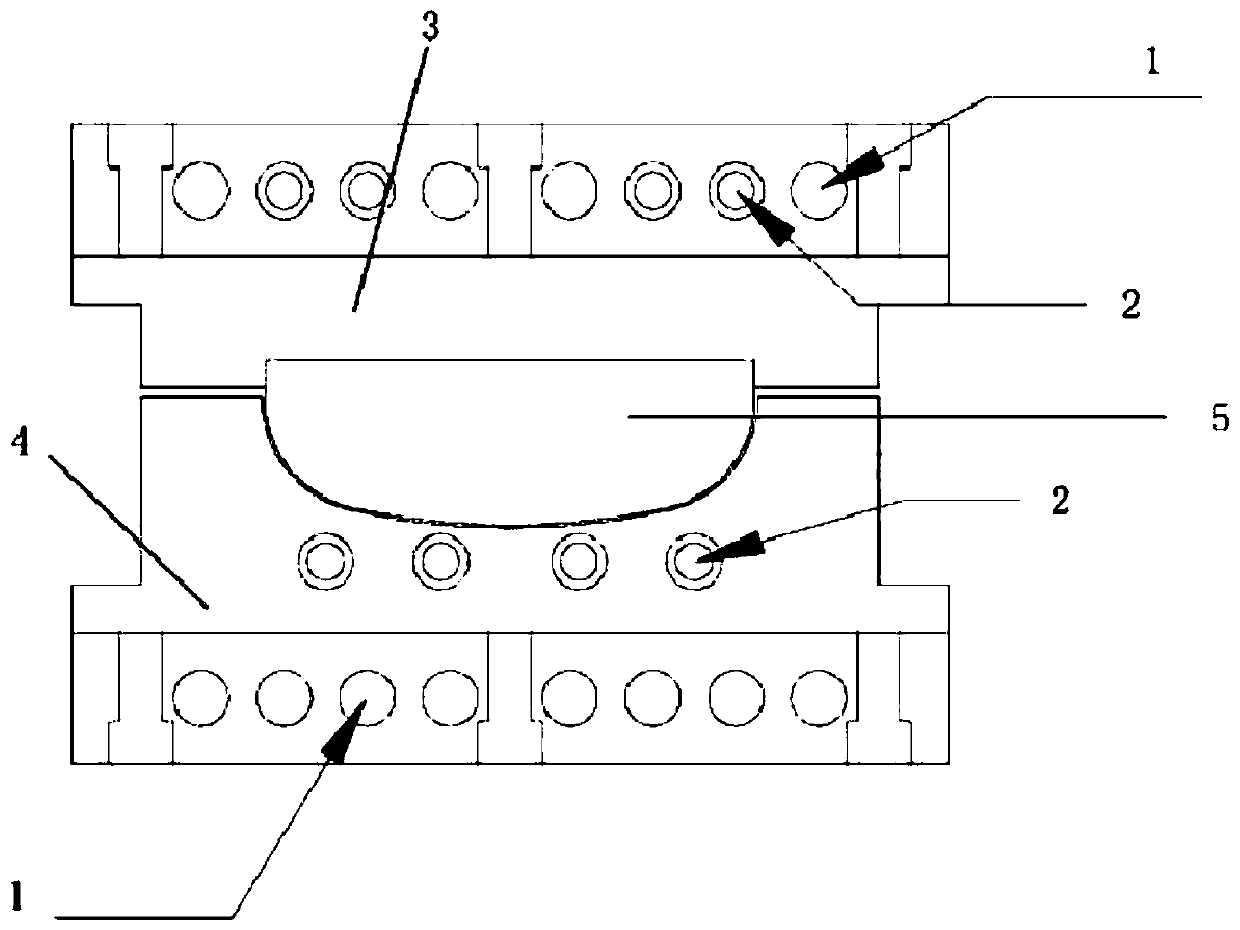

[0042] The customized carbon fiber sheet obtained above is formed in the mold:

[0043] ① Preheat the mold for 3 minutes, and then put the processed customized carbon fiber sheet above the lower mold.

[0044] ②Heat the upper and lower molds so that the upper and lower molds reach about 160 degrees Celsius. At the same time, infrared devices ar...

Embodiment 2

[0049] This embodiment is the manufacturing process of the shell of the earphone with antenna, and the shell part is as Figure 4 Shown.

[0050] In this embodiment, a carbon fiber cloth woven with carbon fiber filaments with a diameter of 7.2 μm is selected, and the carbon fiber cloth is first impregnated in PC resin, and the thickness after the impregnation is completed is about 0.75 mm. Then cover the PMMA customized special film, the thickness of the upper and lower layers is about 0.050mm respectively. The above-mentioned impregnation and coating process can use the existing mature process.

[0051] Shape the customized carbon fiber sheet obtained above:

[0052] ① Preheat the mold for 3 minutes, and then put the processed customized carbon fiber sheet above the lower mold.

[0053] ②Heat the upper and lower molds so that the upper and lower molds reach about 160 degrees Celsius. At the same time, infrared devices are used for heating. The infrared heating conditions are 16CM fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com