Low-expansion heat-resistant ceramic plate

A ceramic plate and low-expansion technology, applied in the field of ceramics, can solve the problems of large expansion coefficient, polishing, and low strength, and achieve the effects of low expansion coefficient, good visual effect and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

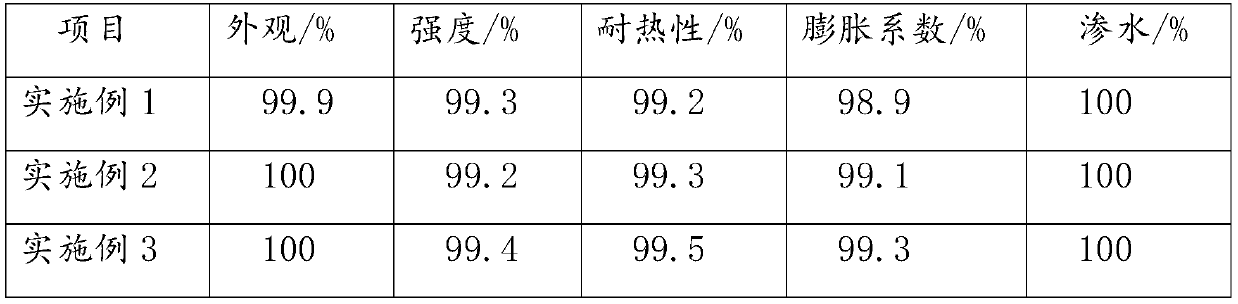

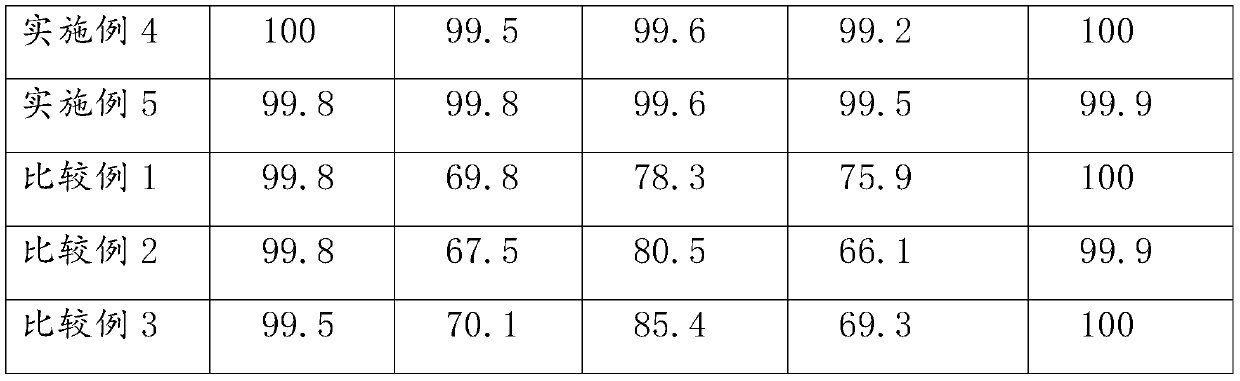

Examples

Embodiment 1

[0028] Take 10 parts of kaolin, 12 parts of talcum powder, 0.5 parts of polyvinyl alcohol, 0.4 parts of citric acid, 25 parts of cordierite, 3 parts of barium sulfate, and 1 part of titanium dioxide, add an appropriate amount of water, and use a ball mill for ball milling for 16 hours to obtain The fineness is 0.5% on a 250 mesh sieve. After removing iron, adjust the moisture content of the slurry to 38%, and then spray granulate to obtain particles with a particle size of 2-2.5mm, with a moisture content of 1%, and pass through the silo for 24 hours; then use an automatic brick pressing mechanism The billet has a thickness of 5.5mm and a length and width of 250mm. It is fired in a roller kiln at 1200°C, and the firing cycle is 35 to 45 minutes.

[0029] Take 75 parts of lithium feldspar, 5 parts of potassium feldspar, 6 parts of zinc oxide, 4 parts of kaolin, 8 parts of calcined talc, 2 parts of lithium carbonate, 3 parts of zinc carbonate, 1 part of dolomite, add appropriate...

Embodiment 2

[0031] Take 20 parts of kaolin, 8 parts of talcum powder, 1 part of polyvinyl alcohol, 0.2 parts of citric acid, 35 parts of cordierite, 1 part of barium sulfate, and 3 parts of titanium dioxide, add an appropriate amount of water, and use a ball mill for ball milling for 18 hours to obtain The fineness is 1.0% on a 250-mesh sieve. After removing iron, adjust the moisture content of the slurry to 42%, and then spray granulate to obtain particles with a particle size of 2-2.5mm, with a moisture content of 1%, and pass through the silo for 24 hours; then use an automatic brick pressing mechanism The billet has a thickness of 6.5mm and a length and width of 250mm. It is fired in a roller kiln at 1300°C, and the firing cycle is 35 to 45 minutes.

[0032] Take 65 parts of lithium feldspar, 15 parts of potassium feldspar, 4 parts of zinc oxide, 6 parts of kaolin, 6 parts of burnt talc, 4 parts of lithium carbonate, 1 part of zinc carbonate, 3 parts of dolomite, add appropriate amoun...

Embodiment 3

[0034] Take 15 parts of kaolin, 10 parts of talcum powder tailings, 0.8 parts of polyvinyl alcohol, 0.3 parts of citric acid, 30 parts of cordierite, 2 parts of barium sulfate, 2 parts of titanium dioxide, 1 part of polyurethane, and 3 parts of di-tert-butyl-p-cresol , add an appropriate amount of water, and use a ball mill to carry out ball milling for 18 hours to obtain a fineness of 250 mesh sieve remaining 0.8%. After removing iron, adjust the moisture content of the slurry to 40%, and then spray granulate to obtain particles with a particle size of 2-2.5mm, with a moisture content of 1%, and pass through the silo for 24 hours; then use an automatic brick pressing mechanism The billet has a thickness of 6mm and a length and width of 250mm. It is fired in a roller kiln at 1280°C, and the firing cycle is 35 to 45 minutes.

[0035] Take 70 parts of petalite, 10 parts of potassium feldspar, 5 parts of zinc oxide, 5 parts of kaolin, 7 parts of calcined talc, 3 parts of lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com