Surface mirror treatment technique for aluminum alloy

A technology of mirror surface treatment and aluminum alloy, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of low yield rate, poor polishing heat dissipation, and limiting the application of electronic products, etc., and achieve high yield rate and surface treatment good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

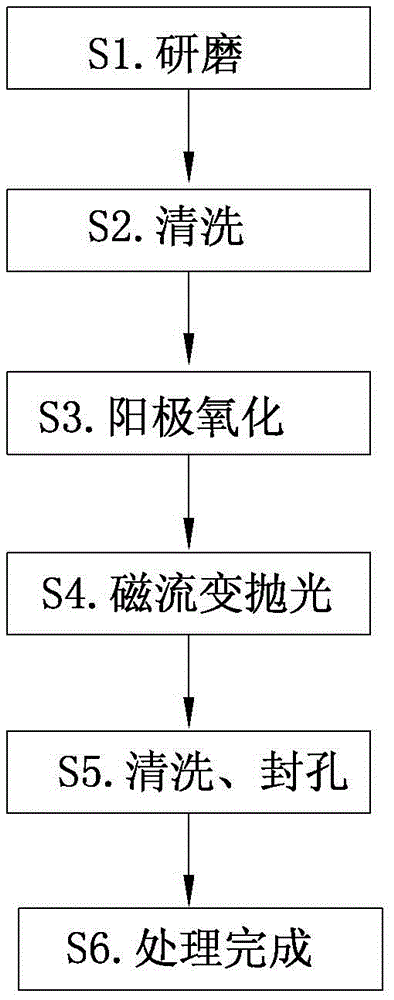

[0025] A surface mirror treatment process of aluminum alloy, comprising the following process steps:

[0026] S1. Grinding the surface of the aluminum alloy product to remove the material texture on the surface of the product to achieve a mirror finish;

[0027] S2. Cleaning the aluminum alloy products;

[0028] S3. Carrying out anodic oxidation treatment to the aluminum alloy product; after the anodic oxidation treatment, a layer of anodic oxidation film is formed on the surface of the aluminum alloy, and the anodic oxidation film can be a transparent or translucent film according to the needs of the product. It is best to seal the aluminum alloy products for the first time. The first hole sealing is processed by cold sealing, which is beneficial to quickly send the sealed aluminum alloy product to the next processing procedure.

[0029] In order to improve the transparent smoothness of the anodized film, in this step S4, the aluminum alloy product is sent to the magnetorhe...

Embodiment 2

[0035] A surface mirror treatment process of aluminum alloy, comprising the following process steps:

[0036] S1. Grinding the surface of the aluminum alloy product to remove the material texture on the surface of the product to achieve a mirror finish;

[0037] S2. Cleaning the aluminum alloy products;

[0038] S3. Perform anodic oxidation treatment on the aluminum alloy product; after the anodic oxidation treatment, perform first sealing on the aluminum alloy product. The first hole sealing is processed by cold sealing, which is beneficial to quickly send the sealed aluminum alloy product to the next processing procedure.

[0039] S4. Send the aluminum alloy product to the magnetorheological polishing equipment for magnetorheological polishing treatment to obtain a high-brightness transparent oxide film; specifically, in this step, in the step of S4, the magnetorheological polishing equipment The magnetic field strength is controlled at 165KA / m, the rotational speed of the...

Embodiment 3

[0045] A surface mirror treatment process of aluminum alloy, comprising the following process steps:

[0046] S1. Grinding the surface of the aluminum alloy product to remove the material texture on the surface of the product to achieve a mirror finish;

[0047] S2. Cleaning the aluminum alloy products;

[0048] S3. Perform anodic oxidation treatment on the aluminum alloy product; after the anodic oxidation treatment, perform first sealing on the aluminum alloy product. The first hole sealing is processed by cold sealing, which is beneficial to quickly send the sealed aluminum alloy product to the next processing procedure.

[0049] S4. Send the aluminum alloy product to the magnetorheological polishing equipment for magnetorheological polishing treatment to obtain a high-brightness transparent oxide film; specifically, in this step, in the step of S4, the magnetorheological polishing equipment The magnetic field strength is controlled at 180KA / m, the rotation speed of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com