Plastic steel zipper mirror polishing machine

A technology of mirror polishing and zipper, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, automatic control devices, etc., can solve problems such as inability to produce, and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment is a preferred embodiment of the present invention, and other principles and basic structures that are the same as or similar to those of this embodiment fall within the protection scope of the present invention.

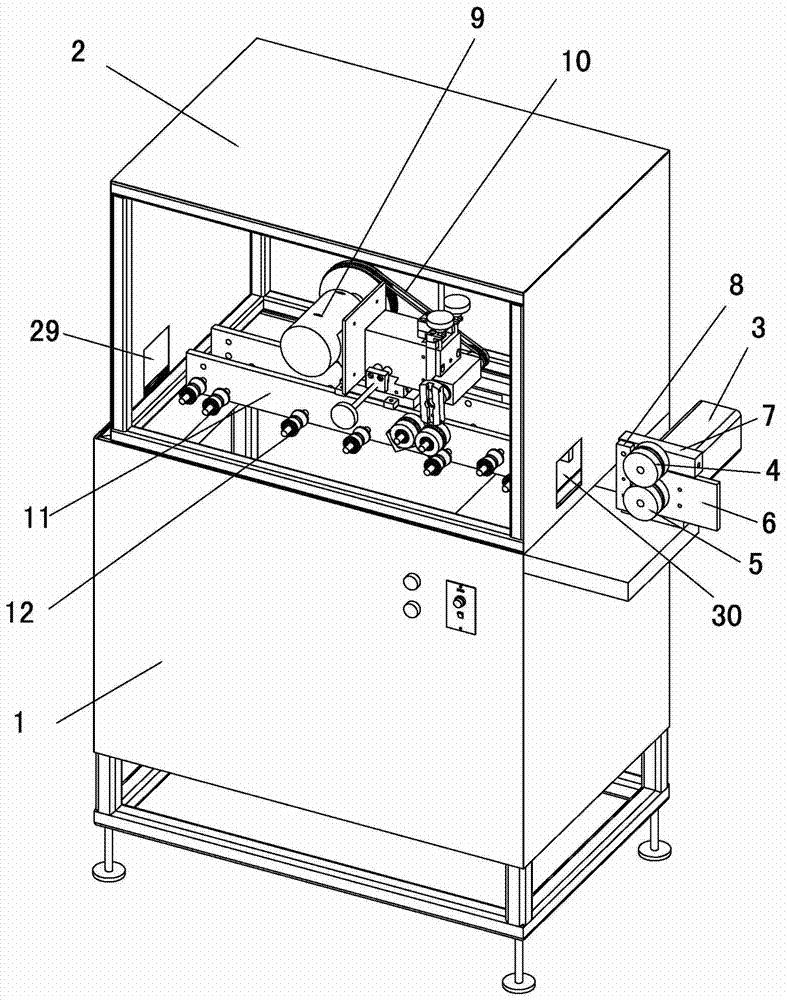

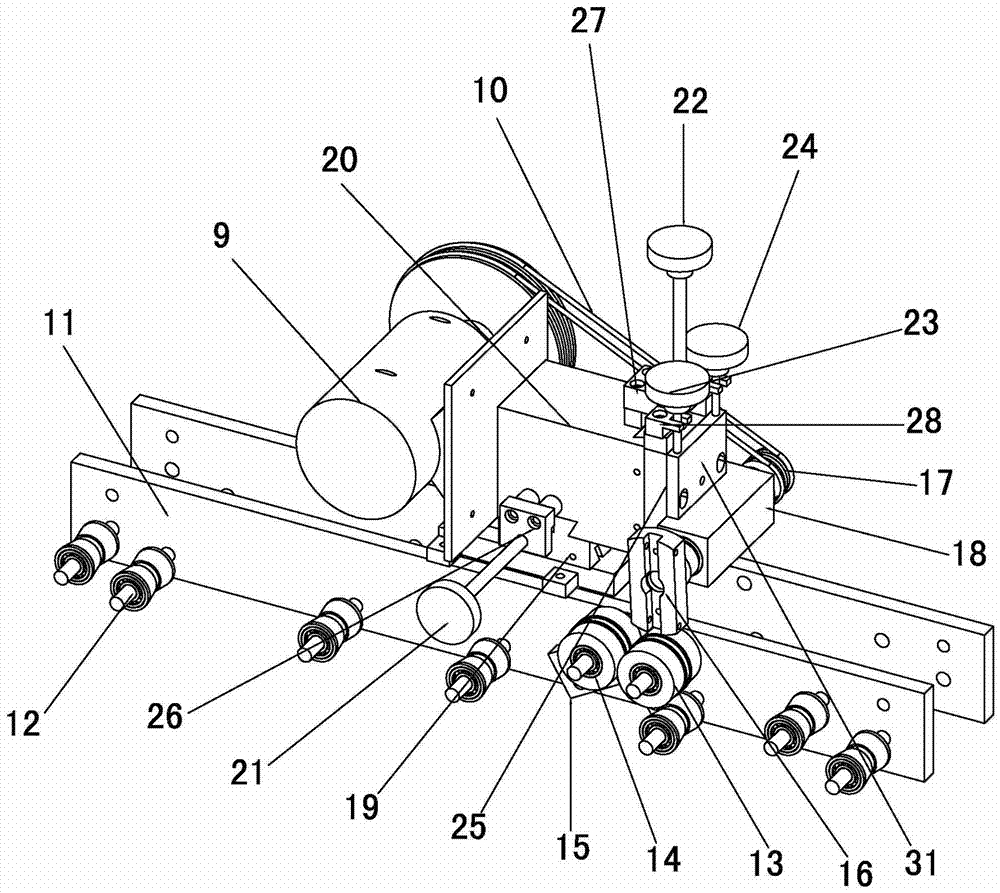

[0019] Please refer to the attached figure 1 And figure 2 , The present invention mainly includes a main frame 1, a protective cover 2, a tool setting mechanism, a cutting mechanism and a towing mechanism. The main frame 1 is the main support mechanism of the present invention. The protective cover 2, a knife setting mechanism, a cutting mechanism and a towing mechanism are respectively installed in On the main frame 1, the tool setting mechanism and the cutting mechanism are arranged in the protective cover, the tool setting mechanism and the cutting mechanism are correspondingly arranged, the protective cover 2 is provided with a feed port 29 and a material outlet 30, and the towing mechanism is set outside the protective cover 2. , Correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com