Improved rapid thinning method of gallium arsenide substrate

A gallium arsenide and substrate technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of GaAs metal pollution, easy introduction of pollutants, performance loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

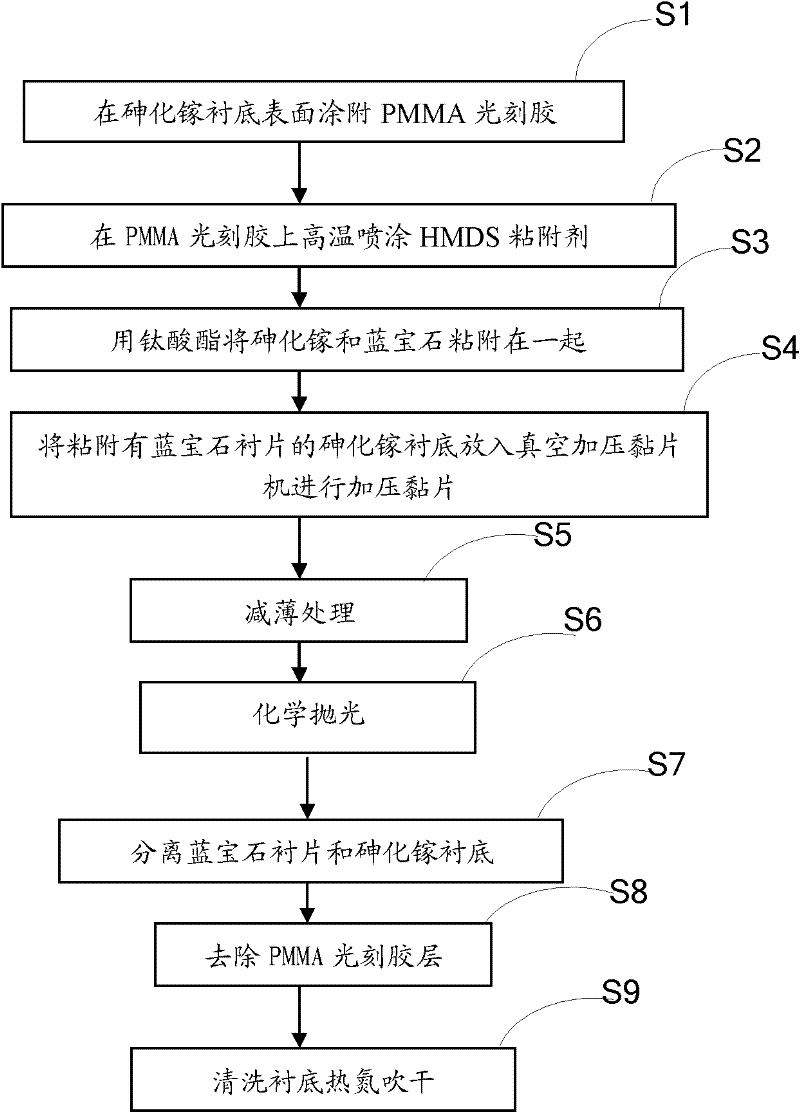

[0025] Such as figure 1 As shown, the technical process provided by the embodiment of the present invention specifically follows the steps:

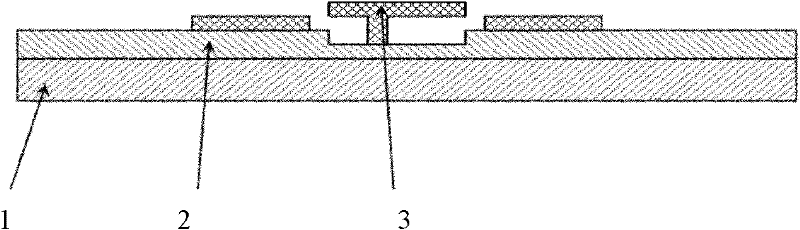

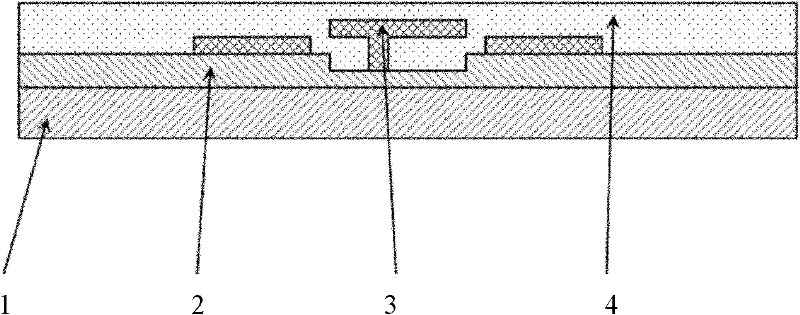

[0026] Step S1, the gallium arsenide substrate 1 with epitaxial layer 2 and circuit metal 3 (see figure 2 ) is coated with a PMMA (polymethyl methacrylate) photoresist layer 4 (see image 3 ),stand-by;

[0027] Step S2, spraying the HMDS (hexamethyldisilamine) 5 adhesive on the PMMA photoresist layer 4 at a high temperature of 120 to 150°C (actually, 90°C, 120°C, 135°C can also be selected) (see Figure 4 ), the thickness of the HMDS layer formed by spraying the HMDS adhesive on the PMMA photoresist layer is 0.1-1 μm (for example, 0.5 μm, 0.8 μm).

[0028] Step S3, place the gallium arsenide substrate adhered with HMDS on a hot plate at 130-150°C (for example, 120°C, 140°C) and pass titanate adhesive 6 (see Figure 5 ) attach the sapphire backing 7 to it (see Figure 6 ), the titanate adhesive is a titanate adhesive whose main comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com