Glazed brick manufacturing method and product

A manufacturing method and technology for polishing glazed tiles, which are applied in the field of ceramic tile manufacturing, can solve problems such as the wavy surface of polished glazed tiles, and achieve the effects of solving pinhole concave glaze on the glazed surface, reducing the moisture content of the body, and reducing the concave glaze of the glaze layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

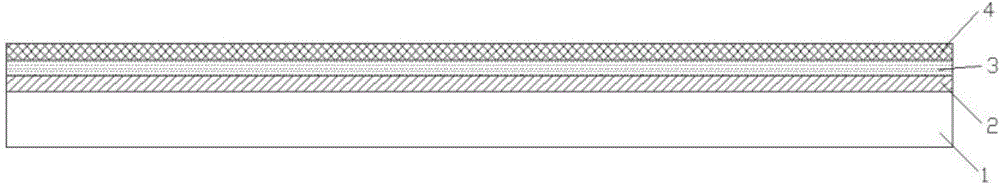

[0025] like figure 1 As shown, a glazed glazed tile of this embodiment includes a base layer 1, a printing layer 2, a protective glaze layer 3 and a transparent glaze layer 4 from bottom to top, wherein the thickness of the base layer 1 is 8.5mm, and the printing layer The thickness of the layer is 0.05mm, the thickness of the protective glaze layer is 0.2mm, and the thickness of the transparent glaze layer is 0.8mm.

[0026] The above-mentioned manufacturing method of polished glazed tiles with a specification of 1000*1000mm, the steps include in sequence:

[0027] A. Press the ceramic powder to form adobe, control the temperature of the adobe at 65°C after drying, and apply 380g of bottom glaze on the adobe to form the bottom adobe layer 1;

[0028] B. On the bottom base layer 1 after the step A, pass screen printing and dry to form a printing layer 2, control the temperature of the brick body at 55°C, apply protective glaze 350g to form a protective glaze layer 3, and the ...

Embodiment 2

[0034] like figure 1 As shown, a kind of polished glazed tile of the present embodiment comprises a bottom base layer 1, a printing layer 2, a protective glaze layer 3 and a transparent glaze layer 4 from bottom to top, wherein the thickness of the bottom base layer 1 is 6mm, and the printing layer The thickness is 0.08mm, the thickness of the protective glaze layer is 0.1mm, and the thickness of the transparent glaze layer is 1.0mm.

[0035] The above-mentioned manufacturing method of polished glazed tiles with a specification of 1000*1000mm, the steps include in sequence:

[0036] A. Spray and granulate the raw material ingredients by ball milling and then press to form adobe. After drying, control the temperature of the adobe at 75°C and apply 300g of bottom glaze on the adobe to form the bottom adobe layer 1;

[0037] B. On the bottom base layer 1 after the step A, the printing layer 2 is formed by inkjet printing and drying, the temperature of the brick body is controlle...

Embodiment 3

[0043] like figure 1 As shown, a kind of polished glazed tile of the present embodiment comprises a bottom base layer 1, a printing layer 2, a protective glaze layer 3 and a transparent glaze layer 4 from bottom to top, wherein the thickness of the base base layer 1 is 9mm, and the printing layer The thickness is 0.06mm, the thickness of the protective glaze layer is 0.15mm, and the thickness of the transparent glaze layer is 0.9mm.

[0044] The above-mentioned manufacturing method of polished glazed tiles with a specification of 1000*1000mm, the steps include in sequence:

[0045]A. Spray and granulate the raw materials by ball milling and then press to form adobe. After drying, control the temperature of the adobe at 70°C and apply 400g of bottom glaze on the adobe to form the bottom adobe layer 1;

[0046] B. On the bottom base layer 1 after the step A, the printing layer 2 is formed after roller printing and drying, the temperature of the brick body is controlled at 55° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com