Solvent type intaglio mirror ink for transparent plastic thin film

A technology of plastic film and mirror ink, which is applied in the field of ink, can solve the problems of insufficient mirror effect, low production efficiency, unsmooth construction, etc., achieve excellent mirror paint film effect, simple production operation, and reduce production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

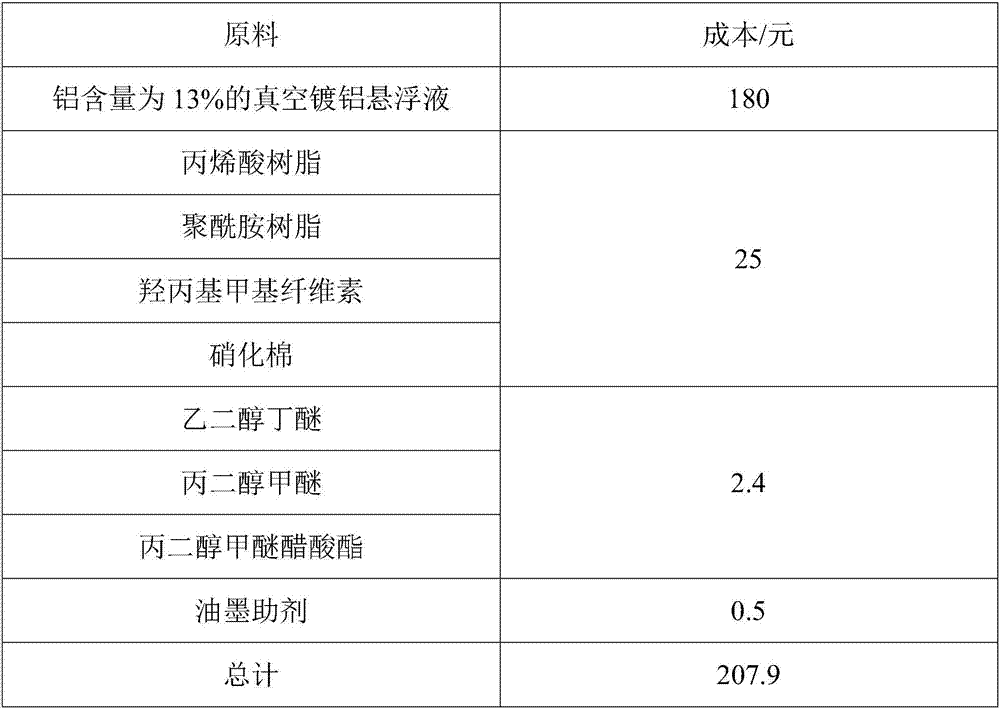

[0027] The invention proposes a solvent-based gravure mirror ink for transparent plastic films, the raw materials of which include 35% of vacuum aluminum plating suspension, 55% of resin and 10% of solvent.

Embodiment 2

[0029] A solvent-based gravure mirror ink for transparent plastic films proposed by the present invention, its raw materials include by weight percentage: 50% of vacuum aluminized n-propyl acetate suspension with an aluminum content of 10%, 40% of alcohol-soluble resin, n-propyl acetate Esters 10%.

[0030] The thickness of the aluminum sheet is 10-100nm, and the particle size of the aluminum sheet is D 50 4-8μm.

Embodiment 3

[0032] A solvent-based gravure mirror ink for transparent plastic films proposed by the present invention, its raw materials include by weight percentage: 20% of vacuum aluminized ethylene glycol butyl ether suspension with an aluminum content of 15%, 70% of cellulose acetate, ethylene glycol Alcohol Butyl Ether 10%.

[0033] In the vacuum aluminized ethylene glycol butyl ether suspension, the thickness of the aluminum flakes is 10-100nm, and the particle size of the aluminum flakes is D 50 4-8μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com