A forging method for preventing cracks in hot forging of mn18cr18n steel retaining ring

A technology of hot forging and cracking, which is applied in the field of forging to prevent cracks from hot forging of Mn18Cr18N steel retaining rings. Forming force, effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

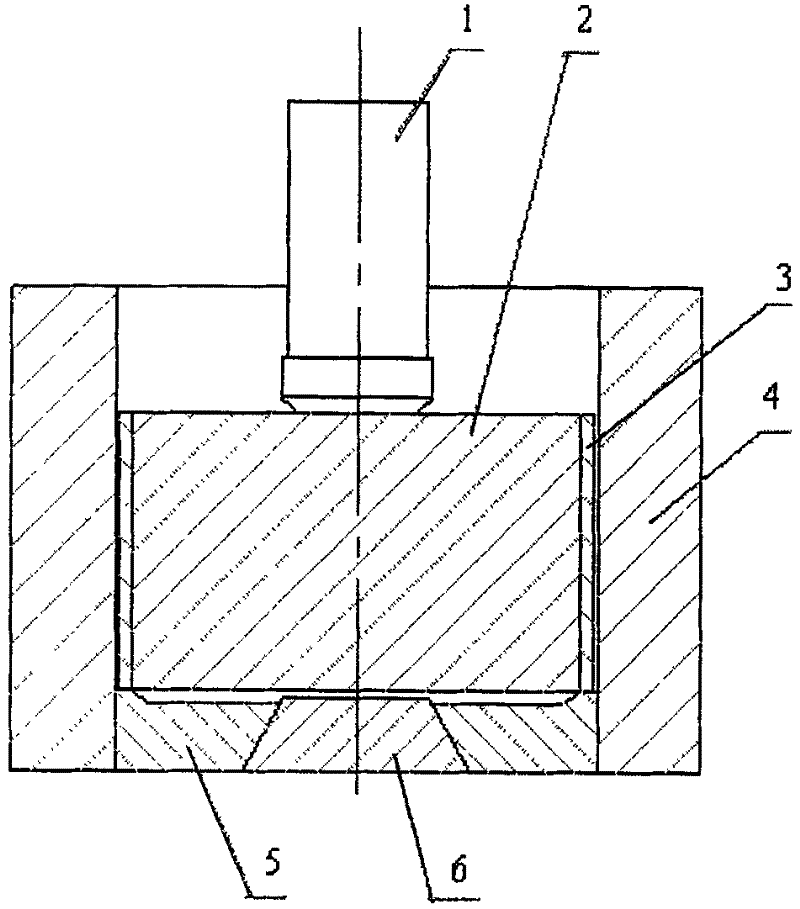

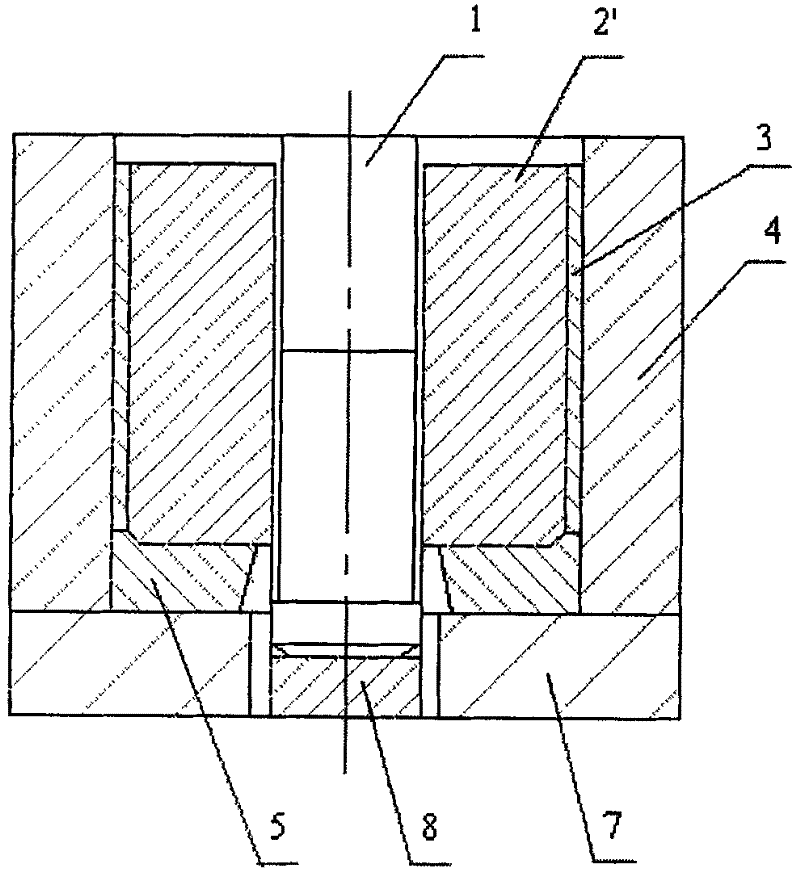

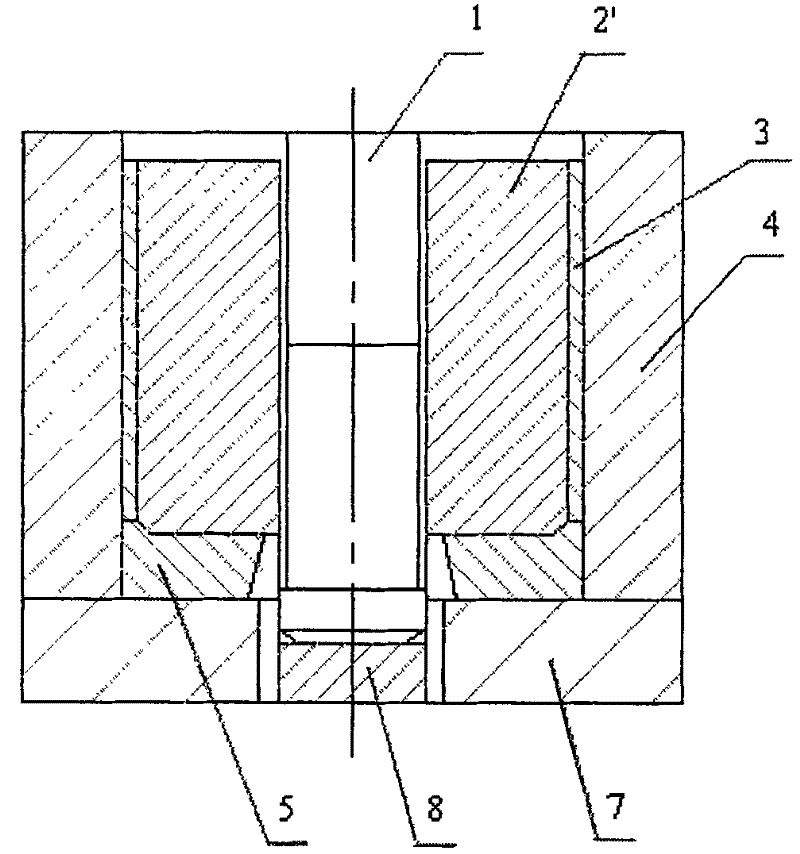

[0017] Now take the production of a forging of a retaining ring whose material is Mn18Cr18N steel and whose size is φ990×φ640×990mm as an example, the diameter of the punch is set to d=430mm, and the diameter of the small end of the 5 taper holes at the bottom of the mold is d 1 =460mm, leakage disk 7 hole diameter d 2 =460mm, billet diameter D=1030mm, the forging process method is:

[0018] (1) Boss 6 is placed in the conical hole in the bottom mold 5 middle part, and it is placed together in a tubular barrel mold 4 inner bottom;

[0019] (2) A tubular sheath 3 made of 20 steel is tightly placed on the outside of the billet 2 with a diameter of D=1030mm, and heated together to 1150°C, the wall thickness of the sheath 3 is 36mm;

[0020] (3) Place the heated blank 2 and the sheath 3 together in the barrel mold 4, the gap δ=50mm between the outer surface of the sheath 3 and the inner surface of the barrel mold 4, use a punch equipped with a locator 1 Punch the blank 2 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com