Integral drilling and filling top-bottom high-pressure impact extrusion grouting system

A top-down, high-pressure technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as splitting, unstable drilling hole walls, and prominent problems of ineffective perfusion, and achieve the effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

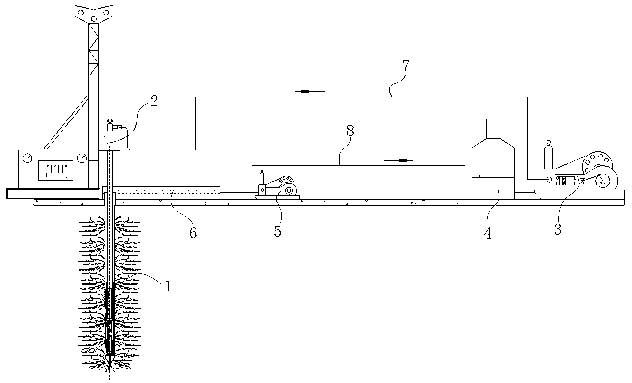

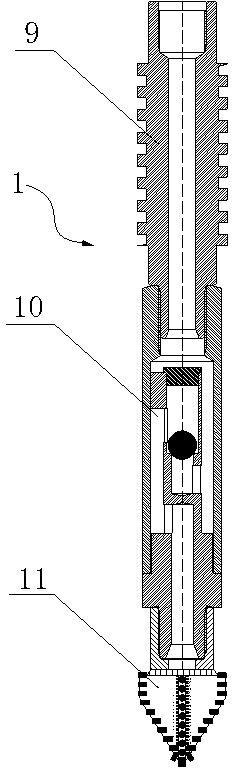

[0030] A drilling-filling integrated, top-down, high-pressure flushing grouting system, such as figure 1 As shown, it includes a drilling rig 2. The lower end of the drill pipe connected to the vertical shaft drill pipe of the drilling rig 2 is used for drilling and grouting from top to bottom. The screw-sealed high-pressure punching grouting head 1 passes through The vertical shaft drill pipe is driven to rotate or move up and down, and several drill pipes are connected to the upper part of the screw-sealed high-pressure punching grouting head. The drilling rig 2 is connected to a grouting pump 3 through a grouting pipe 7 for drilling and grouting. The grouting pump 3 is preferably a horizontal bar single-action reciprocating plunger grouting pump; Device 6, the orifice return slurry is collected, and the return slurry after sedimentation treatment in the settling device 6 is sent to the grouting storage tank 4 through the drilling and grouting return pipe 8 by the mud pump 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com