Method for machining reduced copper capillary tube used in air conditioner

A copper capillary and air-conditioning device technology, which is applied in the field of copper capillary variable diameter processing, can solve the problems of easy welding and plugging capillary, high cost, increased material cost, etc., and achieve smooth and round inner and outer surfaces, low production cost, and excellent straightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

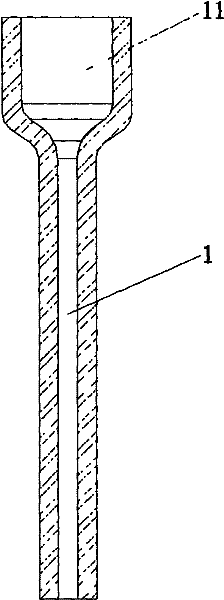

[0025] The copper capillary blank is: the outer diameter is 4mm, the inner diameter is 3mm, and the length is L;

[0026] Processing requirements: the length of the big end is 8mm, and the outer diameter is 6.35mm.

[0027] The specific processing steps are as follows:

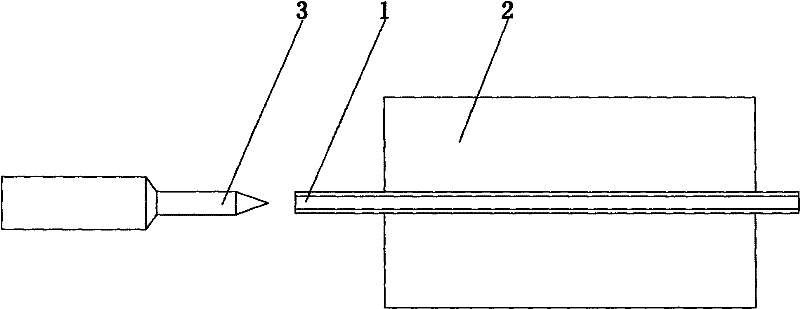

[0028] Such as figure 1 as shown, The first step: place the copper capillary blank 1 in the tightening tooling 2 of the hydraulic clamping device, use a punch 3 with an outer diameter of 4.2mm to squeeze the end of the capillary, and perform the first expansion (about 15mm in length). The inner diameter of the tube 11 at the rear end of the mouth is 4.2mm; the outer diameter is 5.3mm. Before flaring, lubricating oil should be applied to the end 11 of the expanded end. The lubricating oil used in this example is: Idemitsu series products from Japan, and the product model is Idemitsu 560. During this process, the oil pressure in the hydraulic clamping device is 8Mpa.

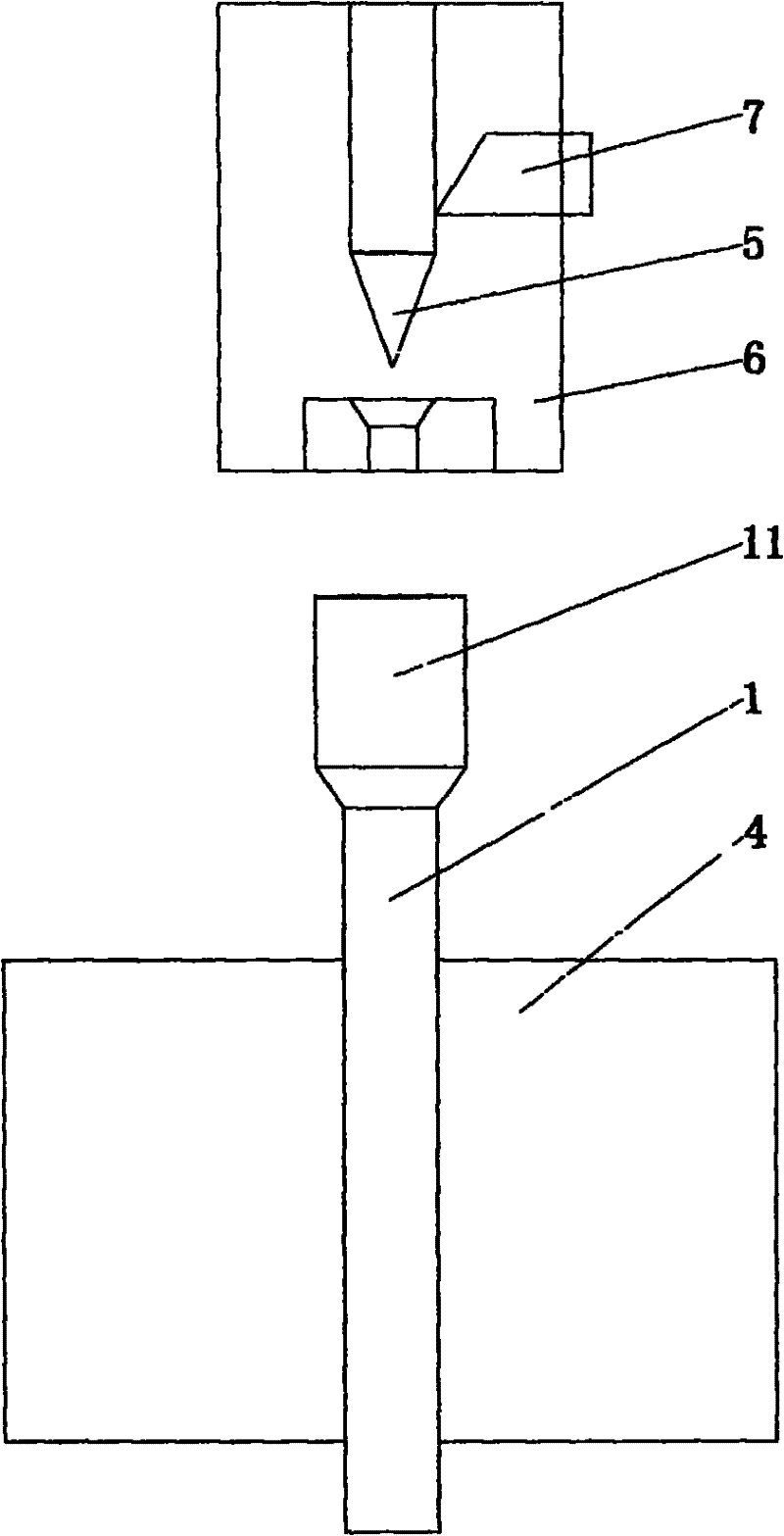

[0029] Such as figure 2 as shown,...

Embodiment 2

[0031] The copper capillary blank is: the outer diameter is 4.5mm, the inner diameter is 3mm, and the length is L;

[0032] Processing requirements: the length of the big end is 8mm, and the outer diameter is 7.0mm.

[0033] The specific processing steps are as follows:

[0034] Such as figure 1 as shown, The first step: place the copper capillary blank 1 in the tightening tooling 2 of the hydraulic clamping device, punch the end of the capillary with a punch 3 with an outer diameter of 4.5mm, and perform the first expansion (about 15mm in length). The inner diameter of the 11 tubes at the rear end of the mouth is 4.5 mm; the outer diameter is 6.0 mm. Before flaring, lubricating oil should be applied to the end 11 of the expanded end. The lubricating oil used in this example is: Idemitsu series products from Japan, and the product model is Idemitsu 560. During this process, the oil pressure in the hydraulic clamping device is 8Mpa.

[0035] Such as figure 2 as shown,...

Embodiment 3

[0037] The copper capillary blank is: the outer diameter is 6.35mm, the wall thickness is 0.7mm, and the length is L;

[0038] Processing requirements: the length of the big end is 7mm, and the outer diameter is 9.52mm.

[0039] The specific processing steps are as follows:

[0040] Such as figure 1 as shown, The first step: place the copper capillary blank 1 in the tightening tooling 2 of the hydraulic clamping device, use a punch 3 with an outer diameter of 6.5mm to squeeze the end of the capillary, and perform the first flaring (length about 15mm). The inner diameter of the 11 tubes at the rear end of the mouth is 6.5 mm; the outer diameter is 8.1 mm. Before flaring, lubricating oil should be applied to the end 11 of the expanded end. The lubricating oil used in this example is: Idemitsu series products from Japan, and the product model is Idemitsu 560. During this process, the oil pressure in the hydraulic clamping device is 9Mpa.

[0041] Such as figure 2 as sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com