A method for quickly acquiring high-speed impact extrusion resistance of a projectile

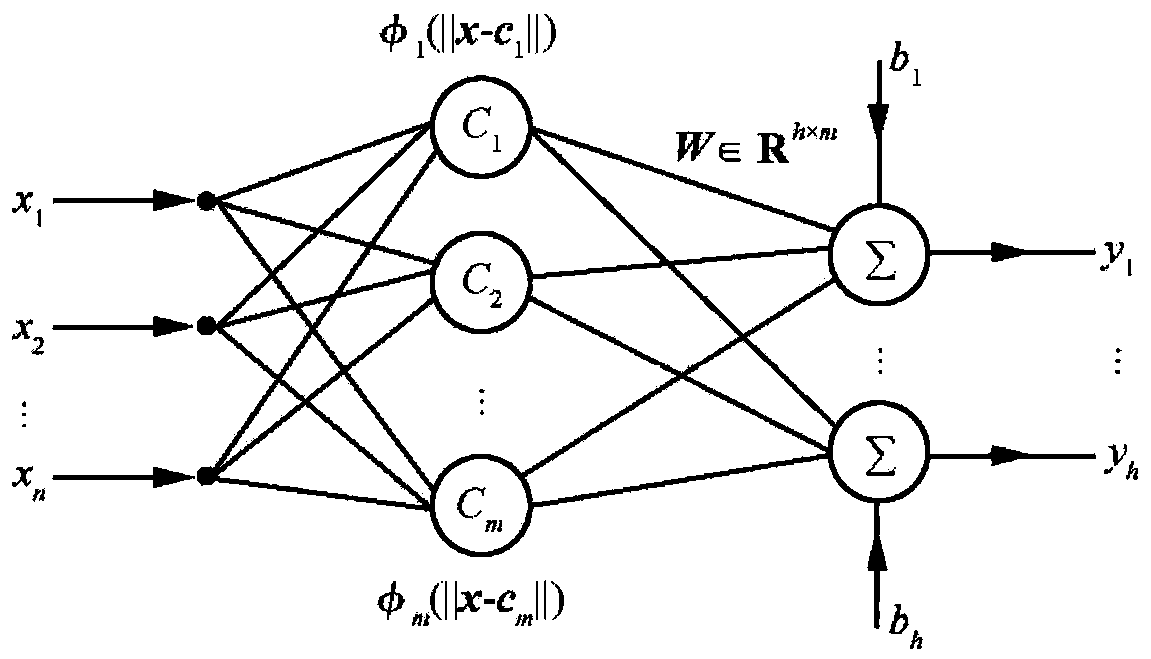

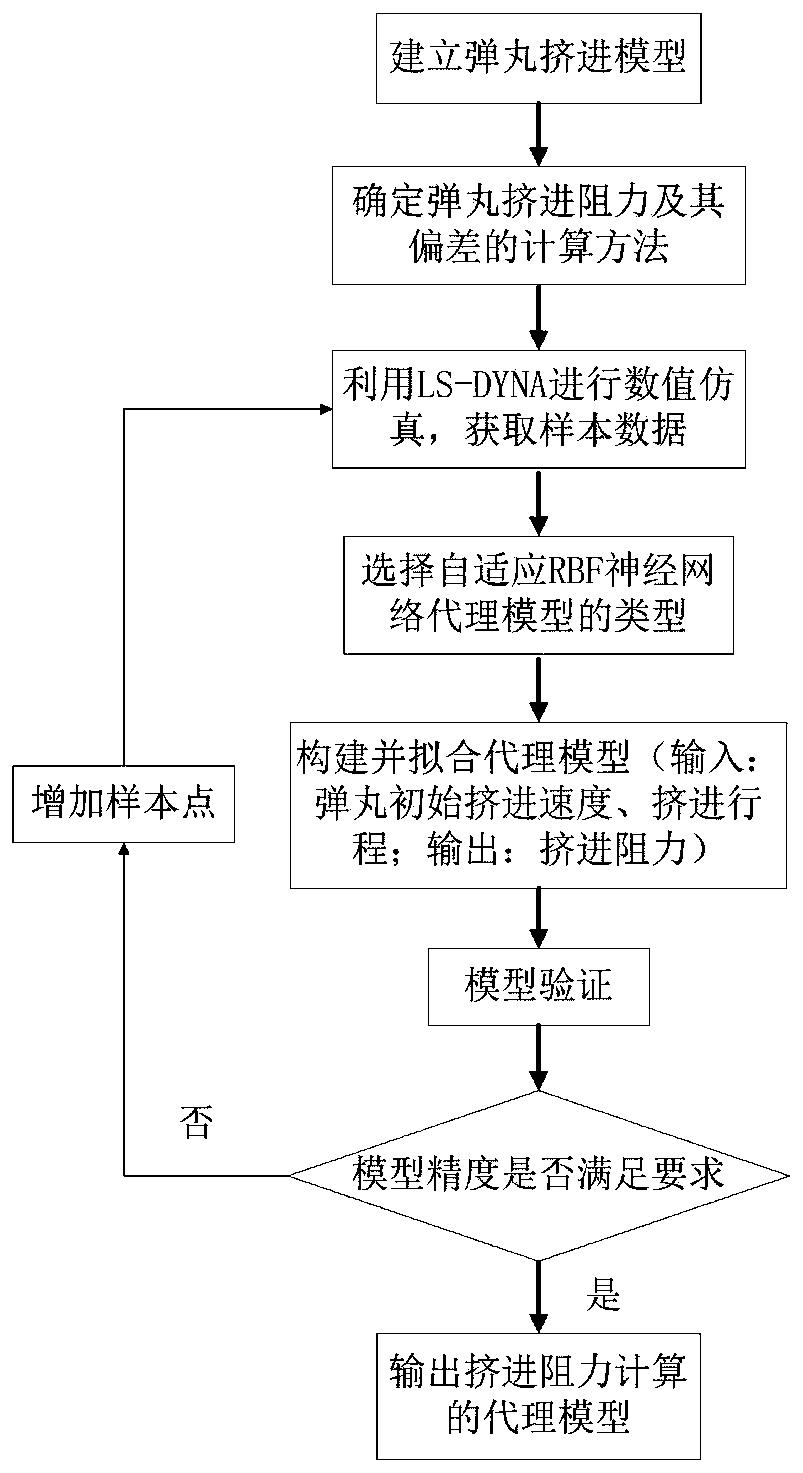

A technology of high-speed impact and acquisition methods, applied in instruments, biological neural network models, design optimization/simulation, etc., can solve problems such as time-consuming numerical simulation, shorten the overall solution time, preserve integrity and calculation accuracy, and improve scientific Research Efficiency and Scientific Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

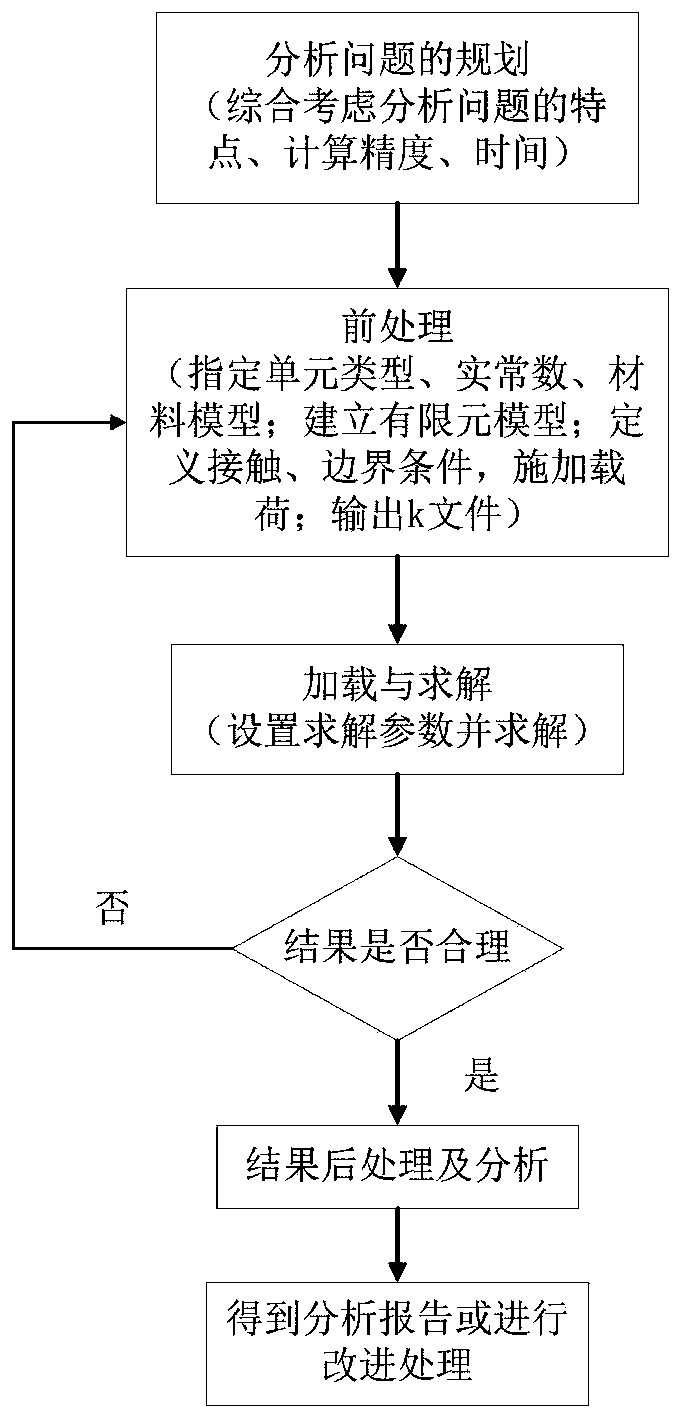

[0041] The projectile extrusion process is a process in which the projectile gradually moves along the barrel and squeezes into the slope and the rifle. This process involves three nonlinear problems, including material nonlinear problems such as large deformation and large strain of the projectile material and damage failure. Geometric nonlinear problems such as large displacement and rotation during the movement of the projectile, and boundary condition nonlinear problems such as the contact between the projectile and the sloped rifling of the barrel. To solve and study the above problems, it is necessary to combine theory, cooperate with finite element numerical simulation method, and use nonlinear dynamics software L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com