Unfavorable geologic body grouting method under pressure-bearing seepage conditions

A kind of geological body and bad technology, applied in the direction of soil protection, construction, infrastructure engineering, etc., can solve the problems of complicated process, high cost of epoxy grouting, and difficult to achieve the reinforcement effect of conventional cement grouting, so as to improve the mechanical properties and anti-corrosion Permeability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A mixed slurry is a cement-epoxy mixed slurry formed by adding a certain amount of epoxy slurry to an ordinary cement slurry. The ordinary cement slurry is a stable slurry configured with a strength grade of not less than 42.5MP ordinary Portland cement or other grouting cements with a water-cement ratio of 0.6:1-0.8:1. The epoxy grout is a high-permeability epoxy grout used for underwater grouting reinforcement, and the amount of the epoxy grout can be 10%-100% of the water content in the cement stabilization grout.

[0044] The water-cement ratio of cement-stabilized slurry and the mixing amount of epoxy slurry in the mixed slurry are mainly determined through field tests according to the formation conditions and engineering requirements. The following are the two preferred ratios.

[0045] Proportion and main performance of two kinds of mixed slurry adopted in the present invention

[0046]

[0047] Note: 1. The cement adopts high sulfate-resistant cement with a ...

Embodiment 2

[0050] The specific requirements of a grouting method for unfavorable geological bodies under the condition of confined water seepage of the present invention are as follows:

[0051] 1) The basic configuration of the main equipment and implements used in the present invention is as follows:

[0052] Basic configuration table of main equipment and tools used in the present invention

[0053]

[0054] 2) A grouting method for unfavorable geological bodies under pressure seepage conditions. First, according to the integrated drilling and irrigation process requirements, the grouting hole orifice is inlaid with a Φ89mm orifice pipe, and the orifice pipe passes through the contact surface between the concrete and the bedrock and enters the bedrock for 2.0m ;The drilling structure of the grouting hole is a small diameter of Φ75mm and one diameter to the end;

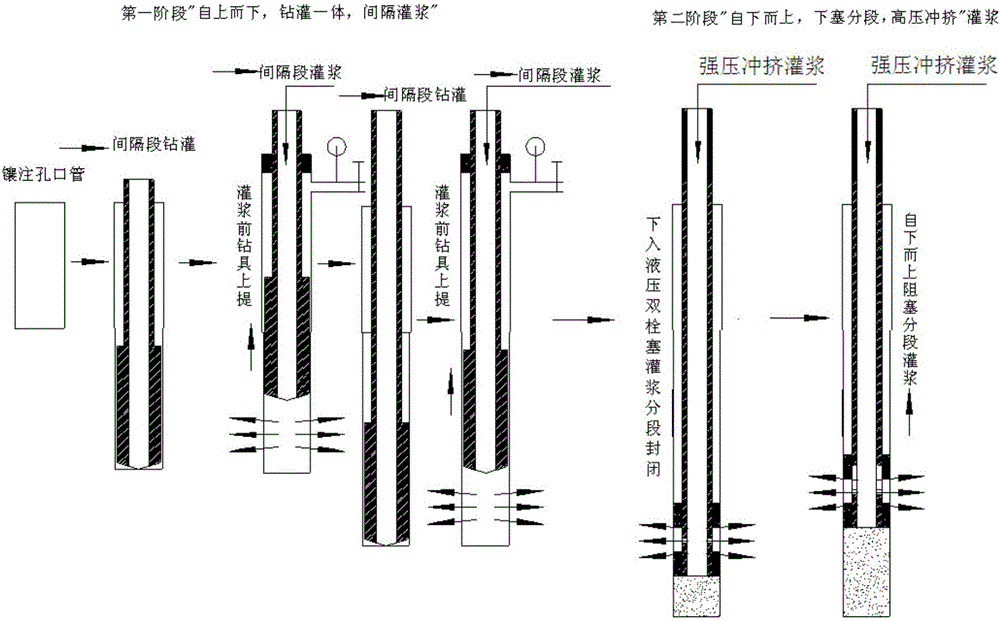

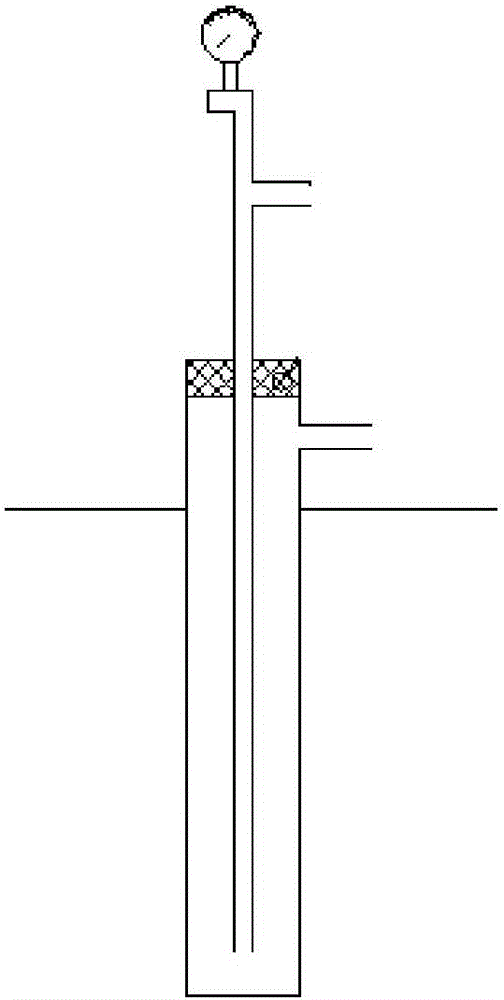

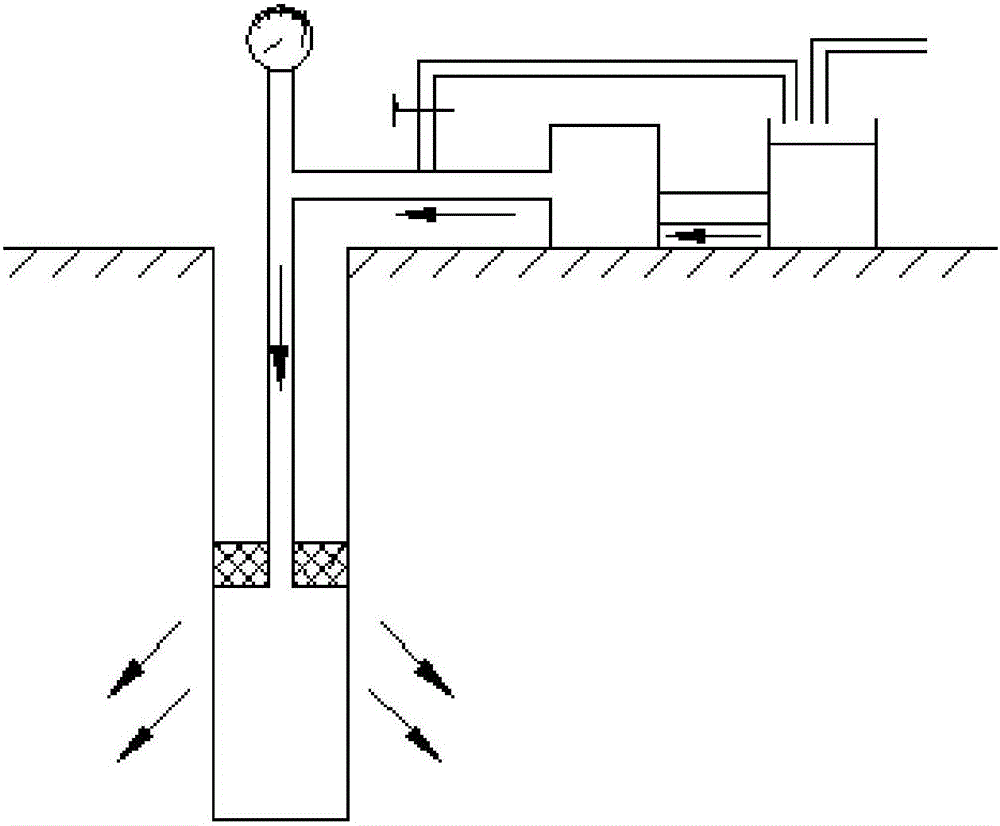

[0055] 3) In the first stage, the stable grout "drilling and filling together, top-down, high-pressure extrusion" grout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com