Drilling and grouting integrated top-down high-pressure impact extrusion grouting method

A top-down drilling irrigation technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as splitting, unstable drilling hole walls, and prominent problems of ineffective irrigation, and achieves a simple process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

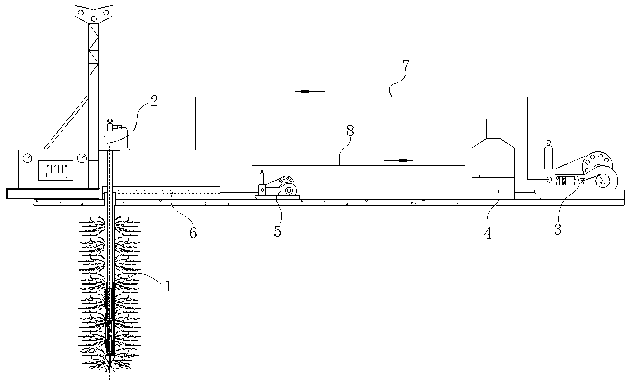

[0042] A method that adopts the above-mentioned integrated drilling and irrigation, top-down, high-pressure flushing grouting, such as figure 1 As shown, the specific steps are:

[0043] (1) According to the stratum conditions and engineering design requirements, determine the drilling and irrigation holes and row spacing through field tests.

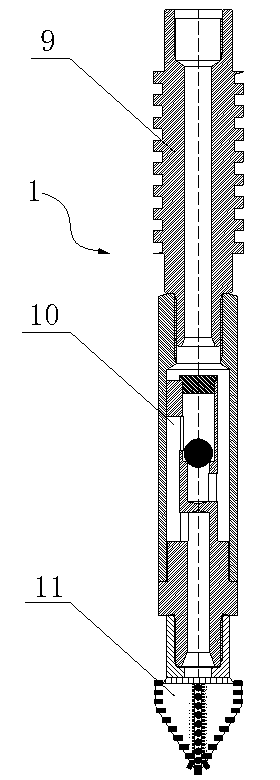

[0044](2) The equipment and layout of drilling and grouting integration, top-down, high-pressure punching and extrusion grouting are shown in the appendix figure 2 : Schematic diagram of drilling and grouting integration, top-down, high-pressure extrusion grouting.

[0045] (3) Drilling and grouting construction should use a power head drilling rig or an ordinary mechanical transmission geological drilling rig 2; the grouting pump should use a single-cylinder single-action reciprocating plunger grouting pump 3, the working pressure of the grouting pump should be greater than 5.0MPa, and the single pulse volume It should be greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com