Gasket capping device

A tablet pressing device and gasket technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of gaskets being difficult to place, affecting the sealing effect, and low work efficiency, so as to achieve simple structure and improve work efficiency. The effect of the effect of the efficiency, the improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

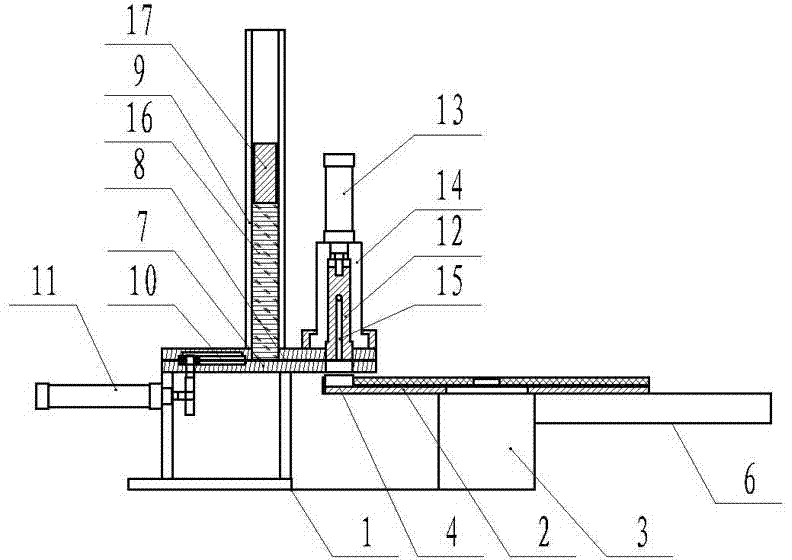

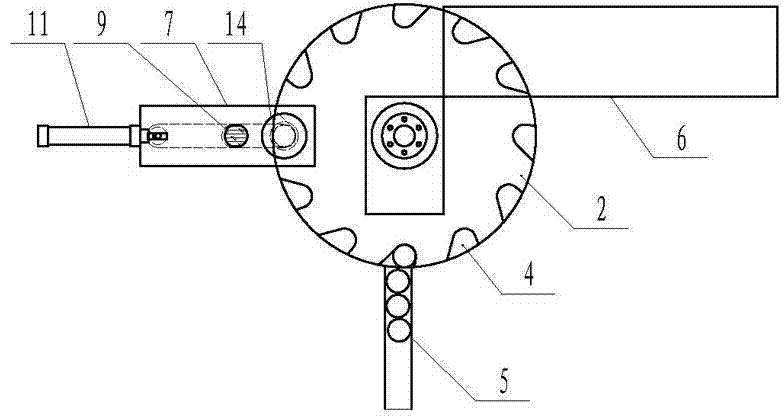

[0012] The gasket inserting device of the present invention will be further described in detail through specific embodiments below.

[0013] like figure 1 , figure 2 As shown, the gasket inserting device includes a frame 1, and the frame 1 is provided with a workbench 2 and a driving motor 3 that can drive the workbench 2 to rotate. In the workbench 2, there are several setters evenly arranged along the ring direction. The cover groove 4, the side of the workbench 2 are sequentially provided with a cover entry track 5, a tablet pressing device and a conveyor belt 6 along the direction of rotation of the workbench 2. The push piece track 7 on the push piece track 7 is provided with a gasket groove 8, the top of the push piece track 7 is provided with a gasket storehouse 9, the lower part of the gasket storehouse 9 communicates with the gasket groove 8, and the push piece track 7 A push rod 10 and a push rod cylinder 11 for driving the push rod 10 to move are arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com