Overturning stopper adding and capping device for linear plastic bottle filling sealing machine

A filling and sealing, plastic bottle technology, applied in the directions of sealing stopper, bottle filling, bottle/container cap, etc., can solve the problem that the clamping and positioning device is difficult to achieve accurate multi-head positioning, can not fully meet the requirements of the new pharmaceutical GMP, reliable accuracy It is difficult to guarantee and other problems, to achieve the effect of simple and compact device structure, clean packaging process, accurate and reliable capping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

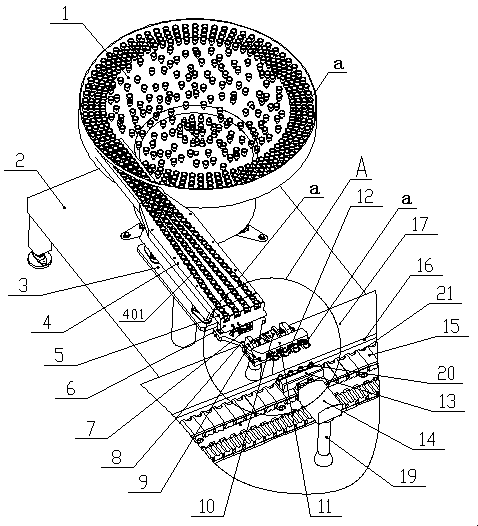

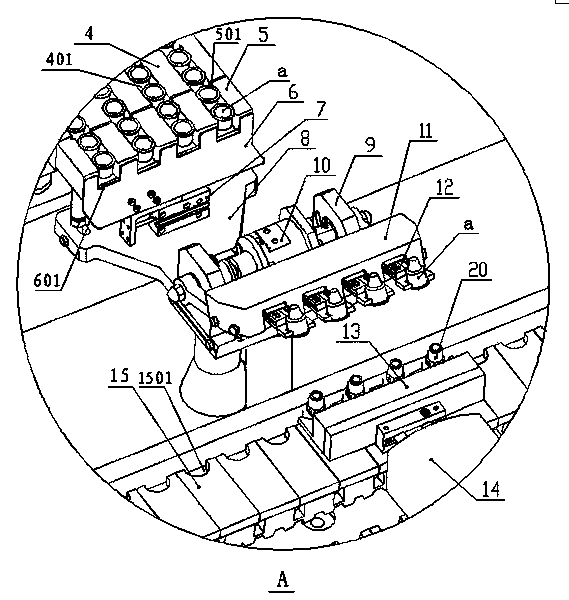

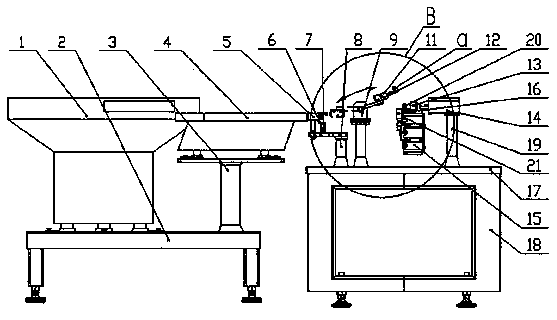

[0024] See figure 1 —7, the flipping plugging and capping device of the linear plastic bottle filling and sealing machine provided by the present invention includes a feeding mechanism, a feeding mechanism docked with the feeding mechanism, a clamping mechanism docked with the feeding mechanism, and a clamping mechanism Corresponding positioning mechanism; the feeding mechanism includes a spiral electromagnetic oscillation feeding part 1 and a linear electromagnetic oscillation feeding part 4 arranged on one side of the frame 18, the spiral electromagnetic oscillation feeding part 1 is located on the vibration mounting seat 2, and the linear electromagnetic oscillation feeding part 4 The component 4 is arranged on the vibration mounting base 2 through the linear electromagnetic oscillation support frame 3, the spiral electromagnetic oscillation feeding part 1 is connected with the linear electromagnetic oscillation feeding part 4, and the linear electromagnetic oscillation feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com