Patents

Literature

55results about How to "Meet the requirements of GMP" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

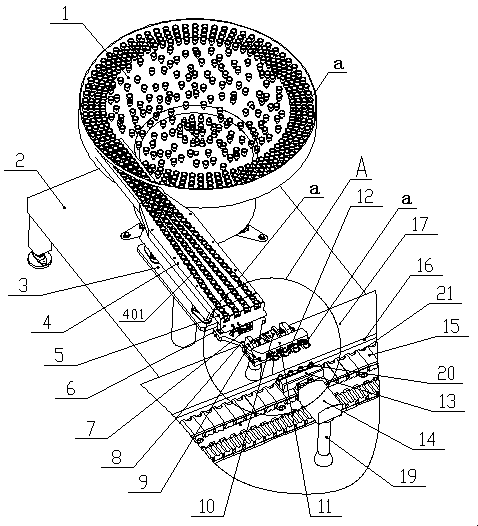

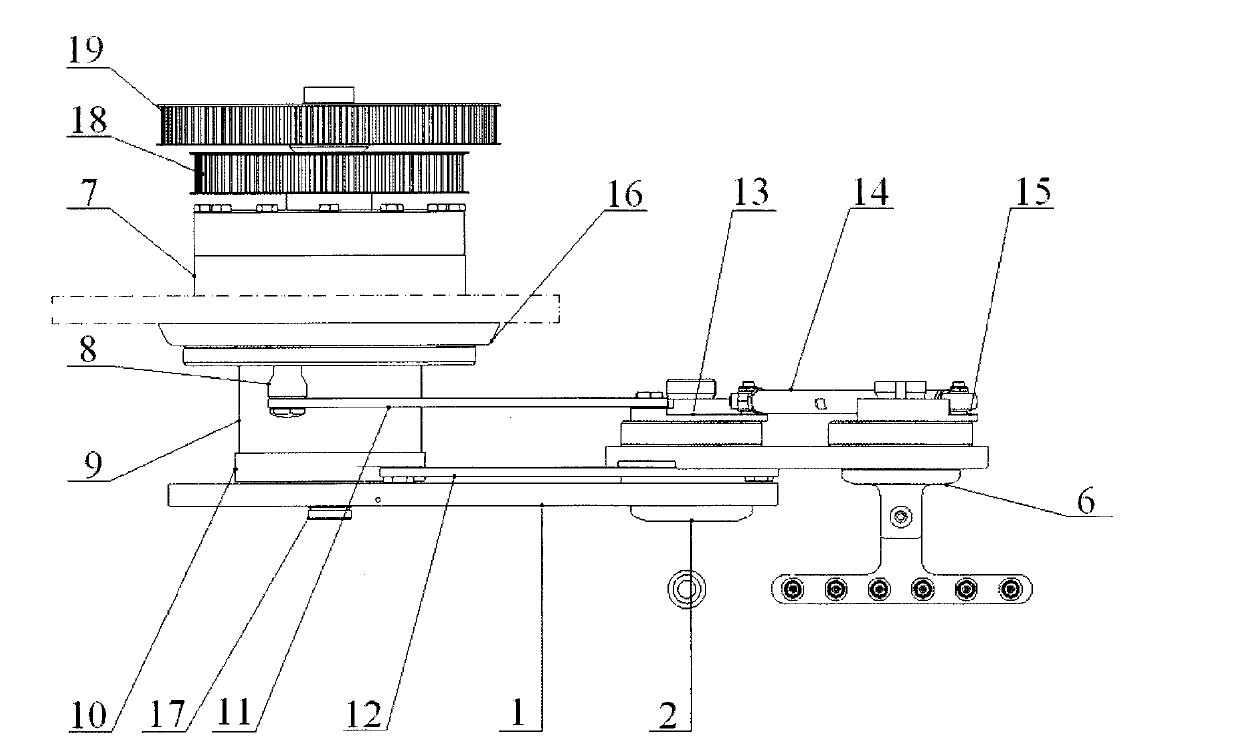

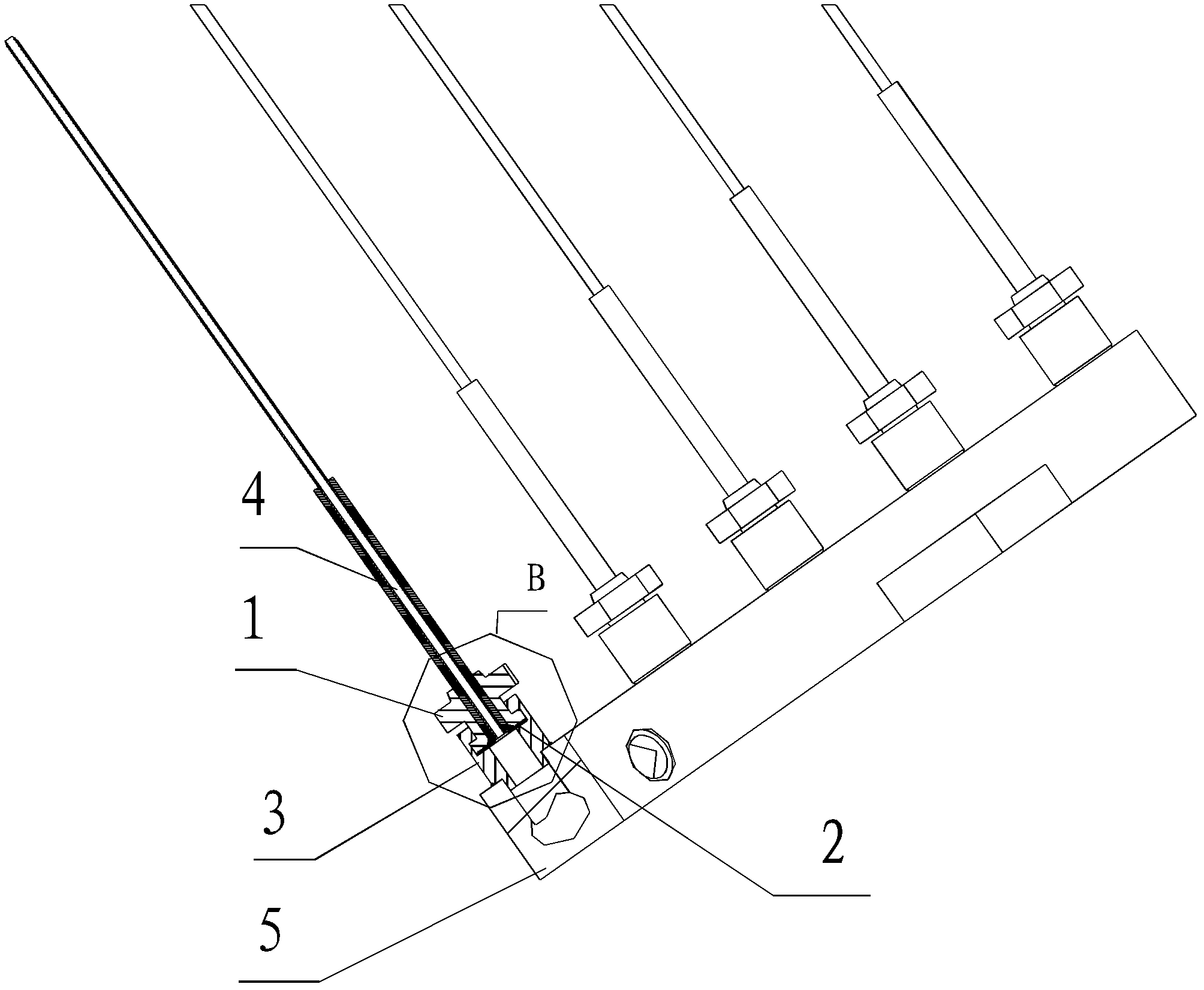

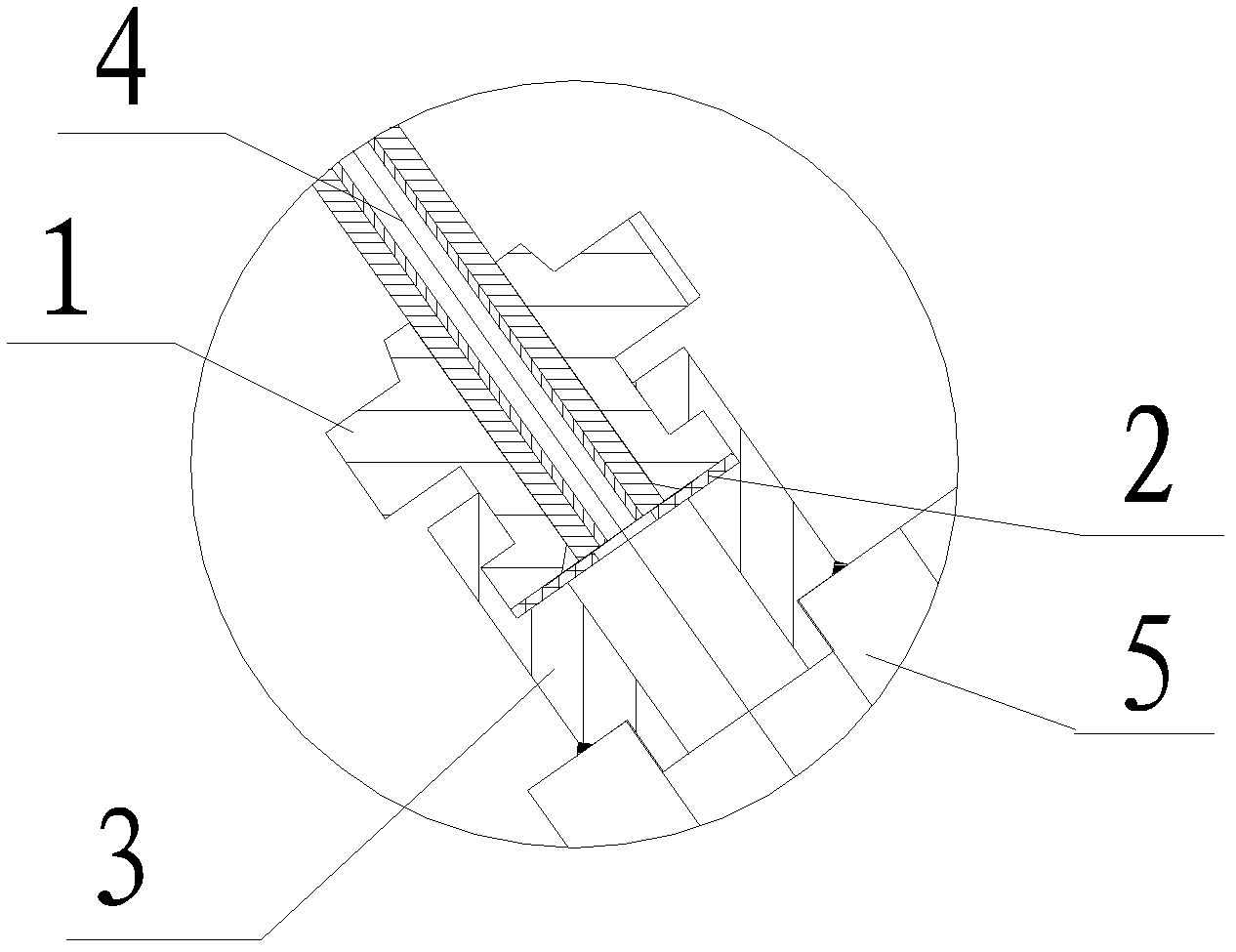

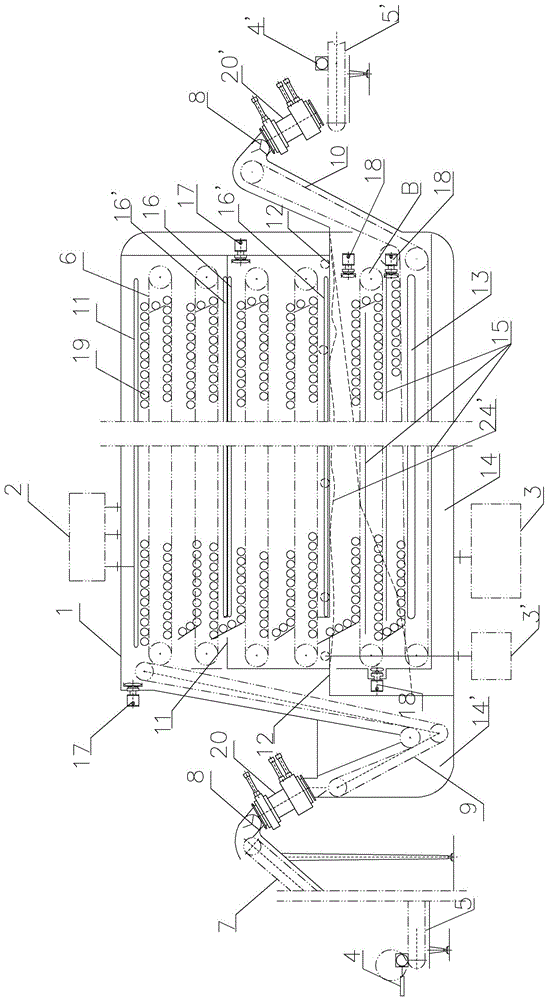

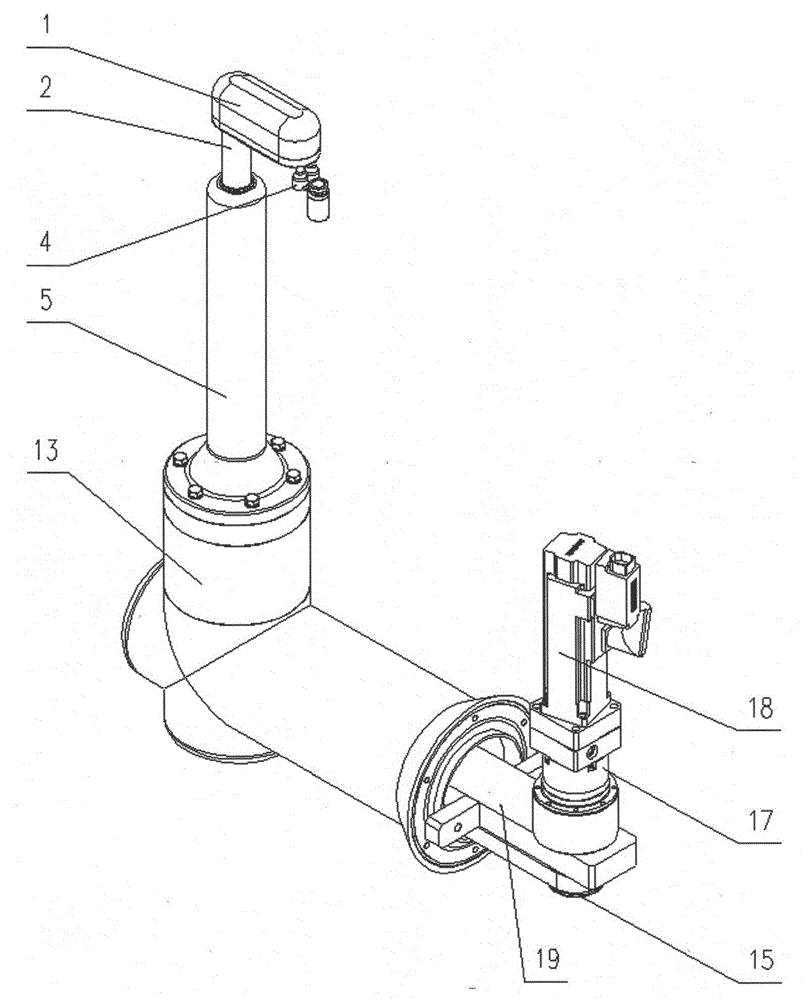

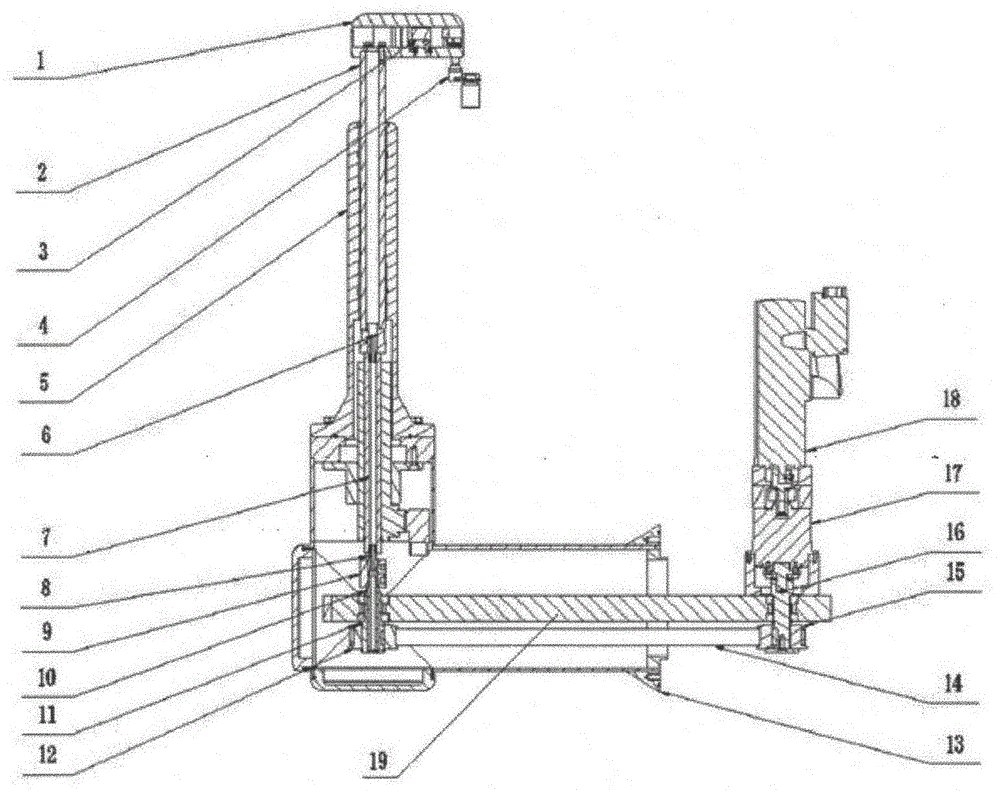

Overturning stopper adding and capping device for linear plastic bottle filling sealing machine

InactiveCN103832953AImprove general performanceCompact structureCapsClosure using stoppersReciprocating motionButt joint

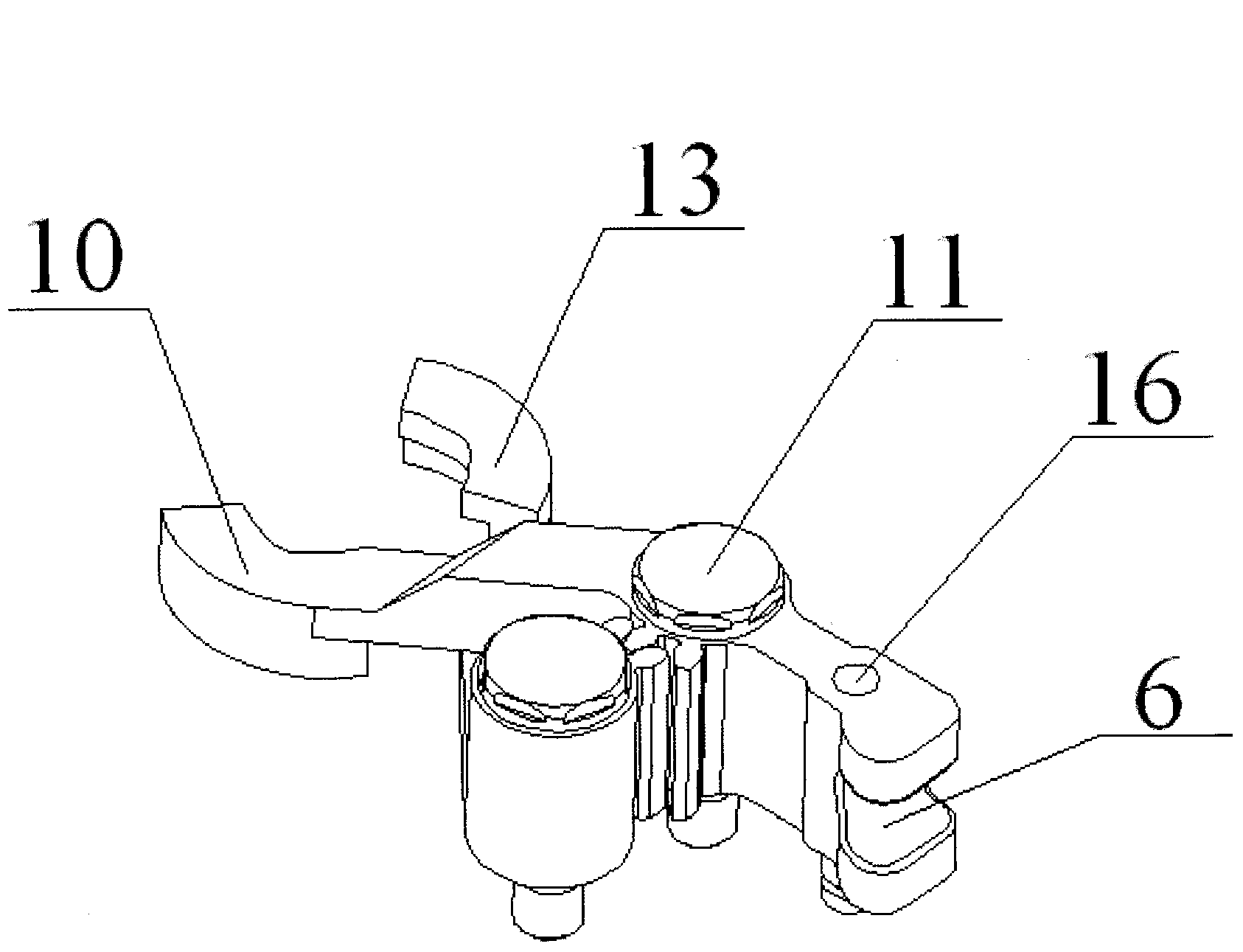

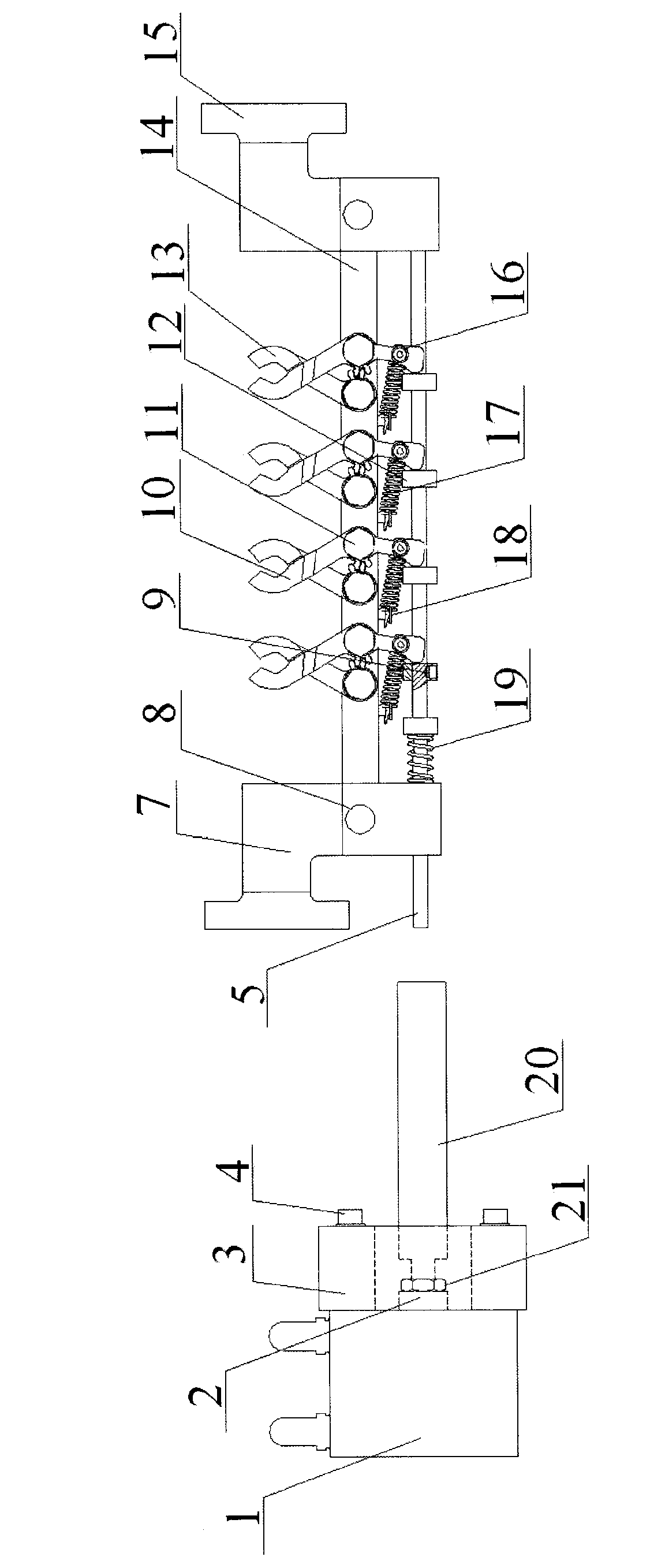

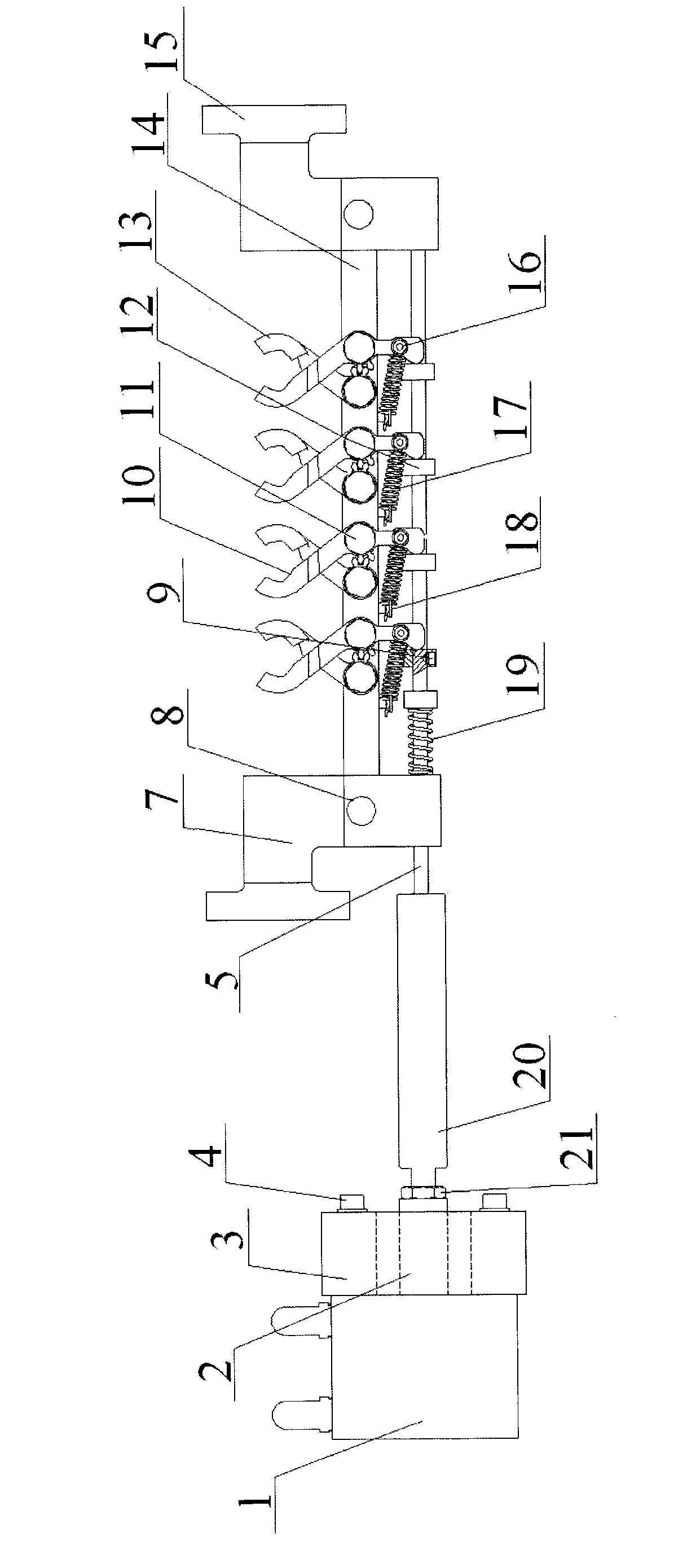

The invention discloses an overturning stopper adding and capping device for a linear plastic bottle filling sealing machine. The overturning stopper adding and capping device comprises a feeding mechanism provided with a feeding groove, a material dividing mechanism in butt joint with the feeding mechanism, a clamping mechanism in butt joint with the material dividing mechanism, and a positioning mechanism corresponding to the clamping mechanism. The material dividing mechanism comprises a separation baffle movably arranged at the end of the feeding groove and moving in a reciprocating mode relative to the feeding groove. The separation baffle is provided with a notch corresponding to the feeding groove. The clamping mechanism comprises an overturning arm and a mechanical arm arranged on the overturning arm and corresponding to the end of the feeding groove. The overturning stopper adding and capping device is simple and compact in structure, easy to maintain, accurate and reliable in stopper adding and capping, high in production efficiency, high in universality of packaging materials, more clean in packaging process and capable of meeting the requirement for the new-edition GMP of pharmacy, and a relative friction movement component which may generate fine particles is not arranged above an opening of a packaging bottle in the stopper adding and capping process.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

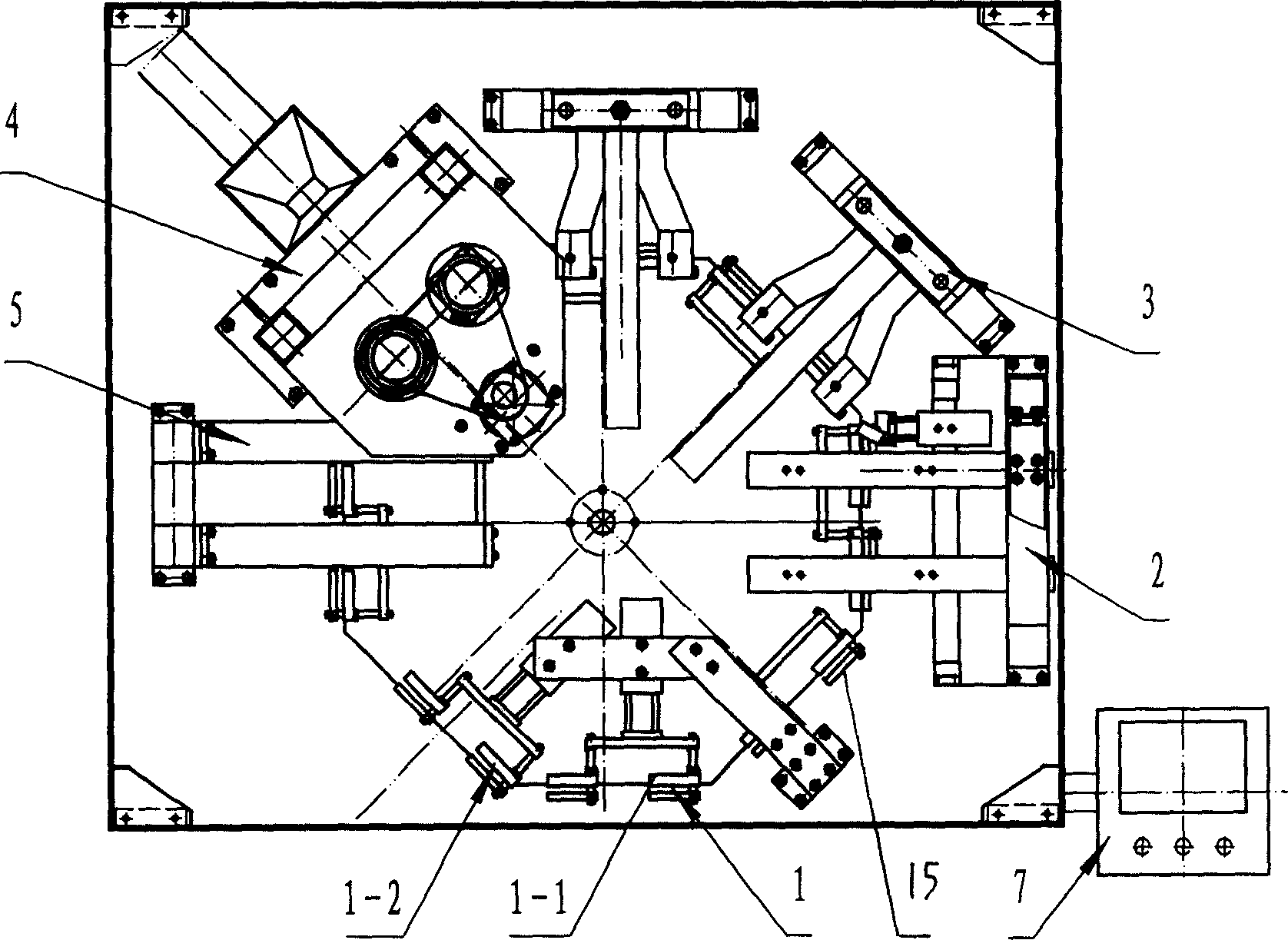

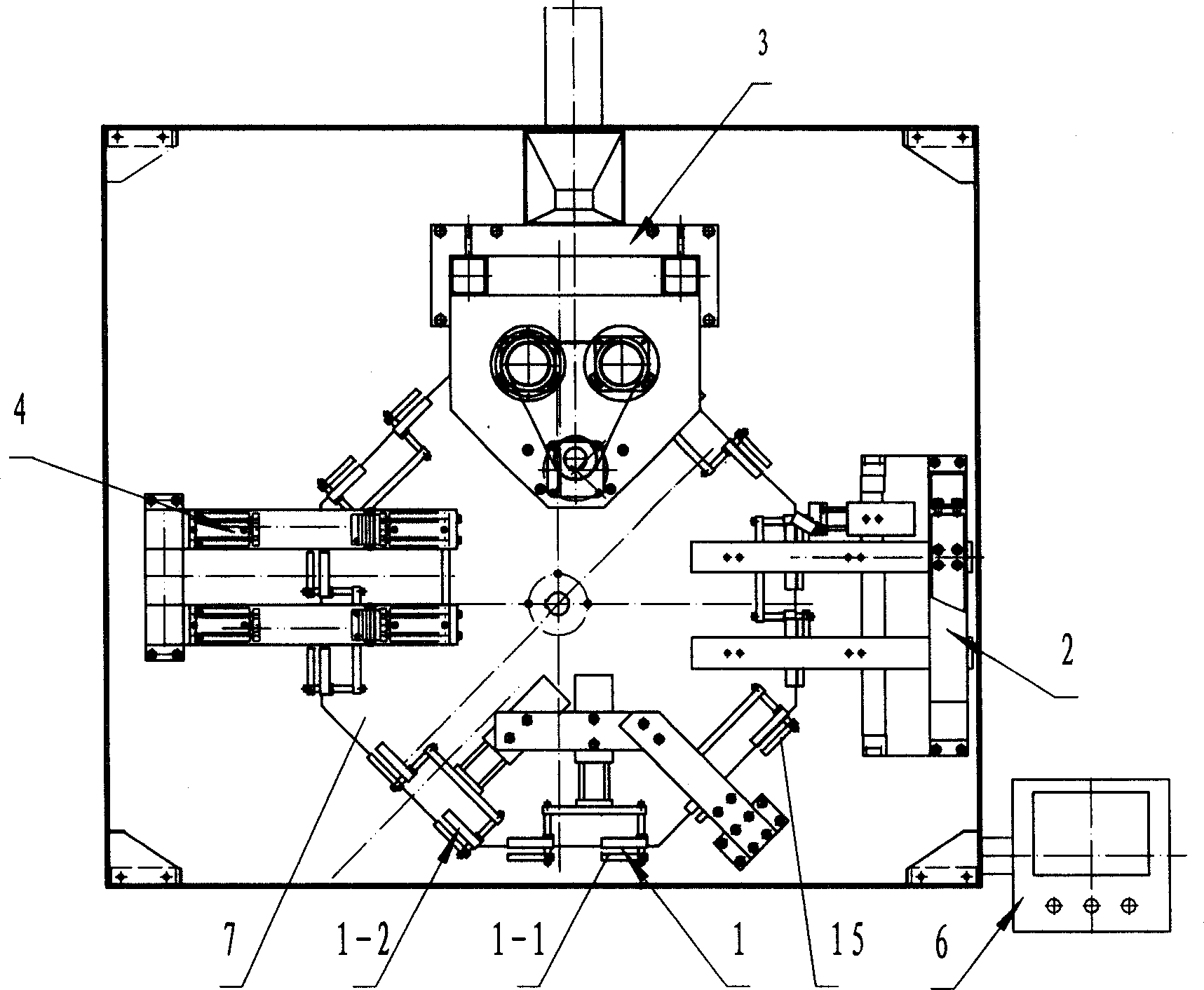

Intermittent rotary non-PVC large infusion soft-bag solid drug filling machine

ActiveCN1743232AChange the way the medicine is dispensedChange middle linkPharmaceutical product form changeWrapper supporting apparatusNitrogenEngineering

The solid medicine filling machine comprises power drive component, central dial, take-in and take-out component, bag-cutting part, part for filling clean air, part for filling nitrogen, thermal sealing part, rack and electric control cabinet. The parts above are set on the side of the center dial that connects with the power drive component and are supported by the rack to layout in turn. Around the central dial is fitted with a bag holder for hanging infusion bag.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

Intermittent rotary solid-drug-chargeable non-PVC infusion bag solid-drug filling machine

ActiveCN1743233AChange the way the medicine is dispensedChange middle linkPharmaceutical product form changeWrapper supporting apparatusEngineeringElectric control

The solid medicine-filling machine comprises power drive component, central dial, take-in and take-out component, bag-cutting part, thermal-sealing part, rack and electric control cabinet. The parts above are set on the side of the center dial that connects with the power drive component and are supported by the rack to layout in turn. Around the central dial is fitted with a bag holder for hanging infusion bag. On the filling part can be provided with a protective gas inlet.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

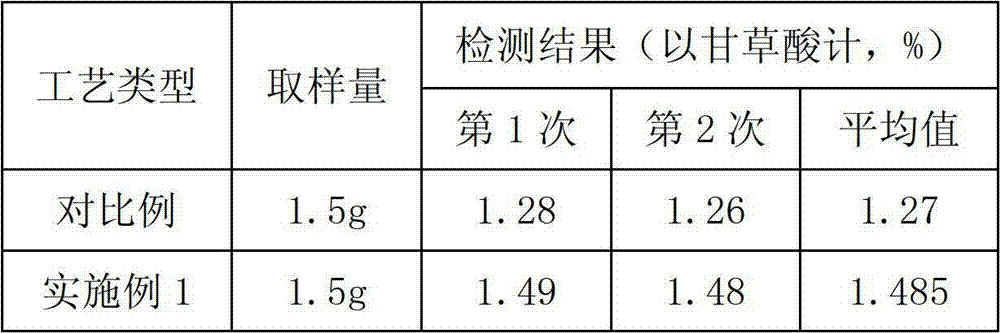

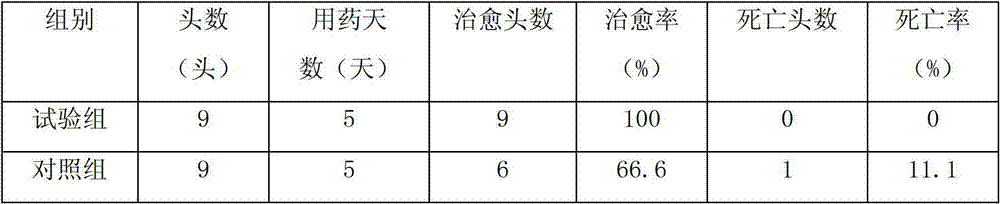

Preparation method of licorice particles for livestock and poultry

ActiveCN102727569AChanging the high temperature decoction processPromote leachingAntibacterial agentsDigestive systemCyclodextrinSolvent

The invention discloses a preparation method of licorice particles for livestock and poultry, comprising the following steps of: firstly taking licorice, placing it into an extraction pot to form a medicinal material layer, adding water and immersing, adjusting the operating temperature of the extraction pot to 60-80 DEG C for extraction, leading out parts of an extract from the bottom of the extraction pot during the extraction process and carrying out vacuum concentration while the concentration temperature is 50-70 DEG C, condensing steam generated by the concentration, returning the stream used as a new solvent into the extraction pot for permeating extraction of the medicinal material layer, continuously repeating for 2-3 hours, condensing to finally obtain a fluid extract, adding anhydrous glucose and maltodextrin or cyclodextrin and the fluid extract into a spray drying granulator, and carrying out granulation so as to obtain the licorice particles for livestock and poultry. According to the preparation method of the licorice particles for livestock and poultry, the two processes of licorice extraction and condensation are synchronously carried out so as to change a high-temperature decocting technology of a traditional extraction pot under pressure and at normal pressure. Therefore, energy can be saved by 0.3-0.5 time; the amount of a hydrosolvent is minimized by 0.5-1 time; the feeding amount is increased by 30-60%; extract yielding rate is raised by more than 10%; the storage process is minimized; and electric power energy is saved by more than 30%.

Owner:ZHENGZHOU BARY ANIMAL PHARMA

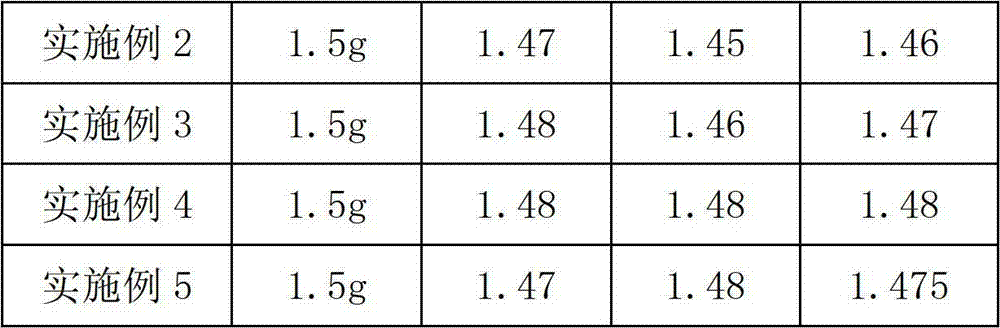

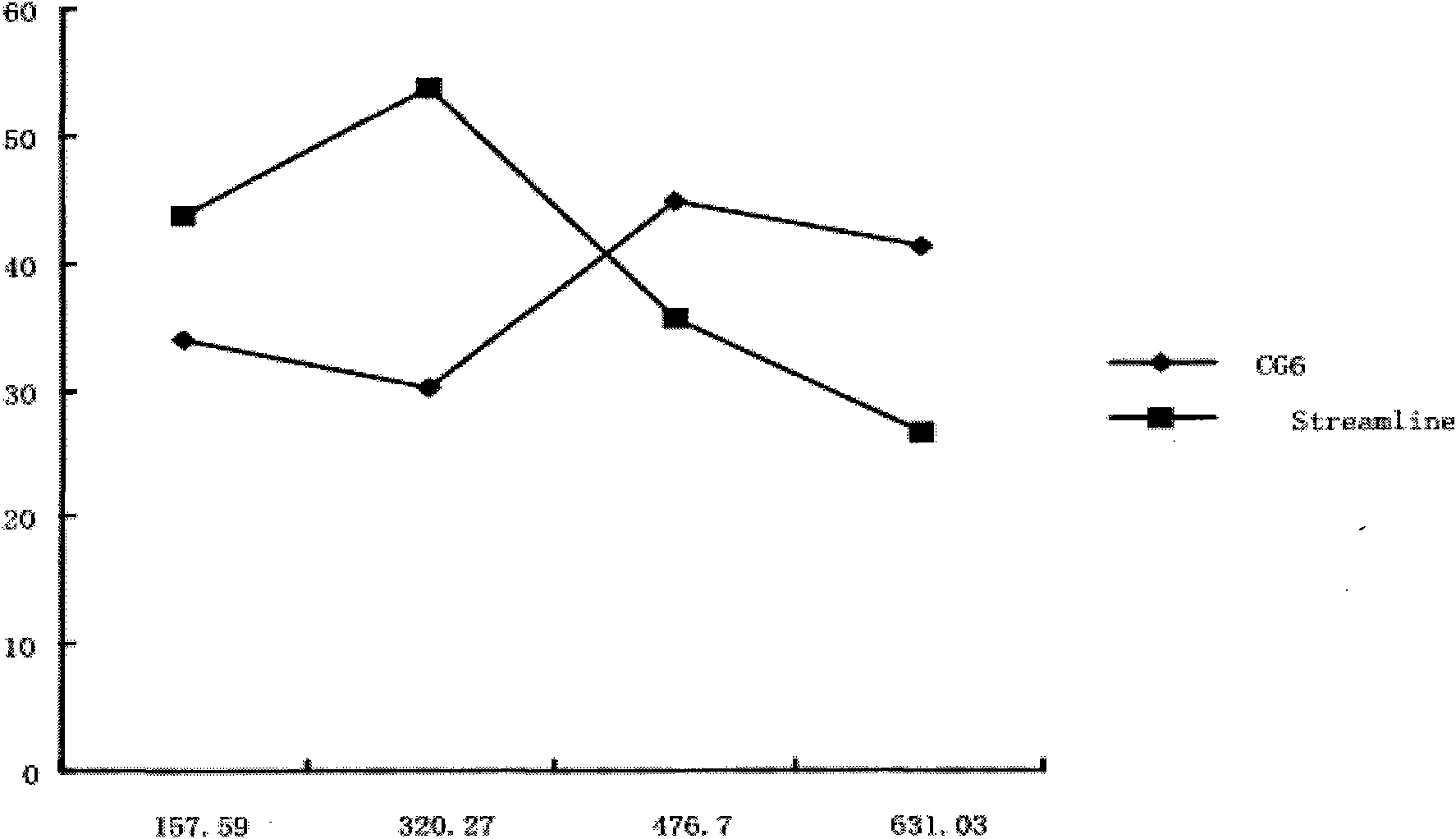

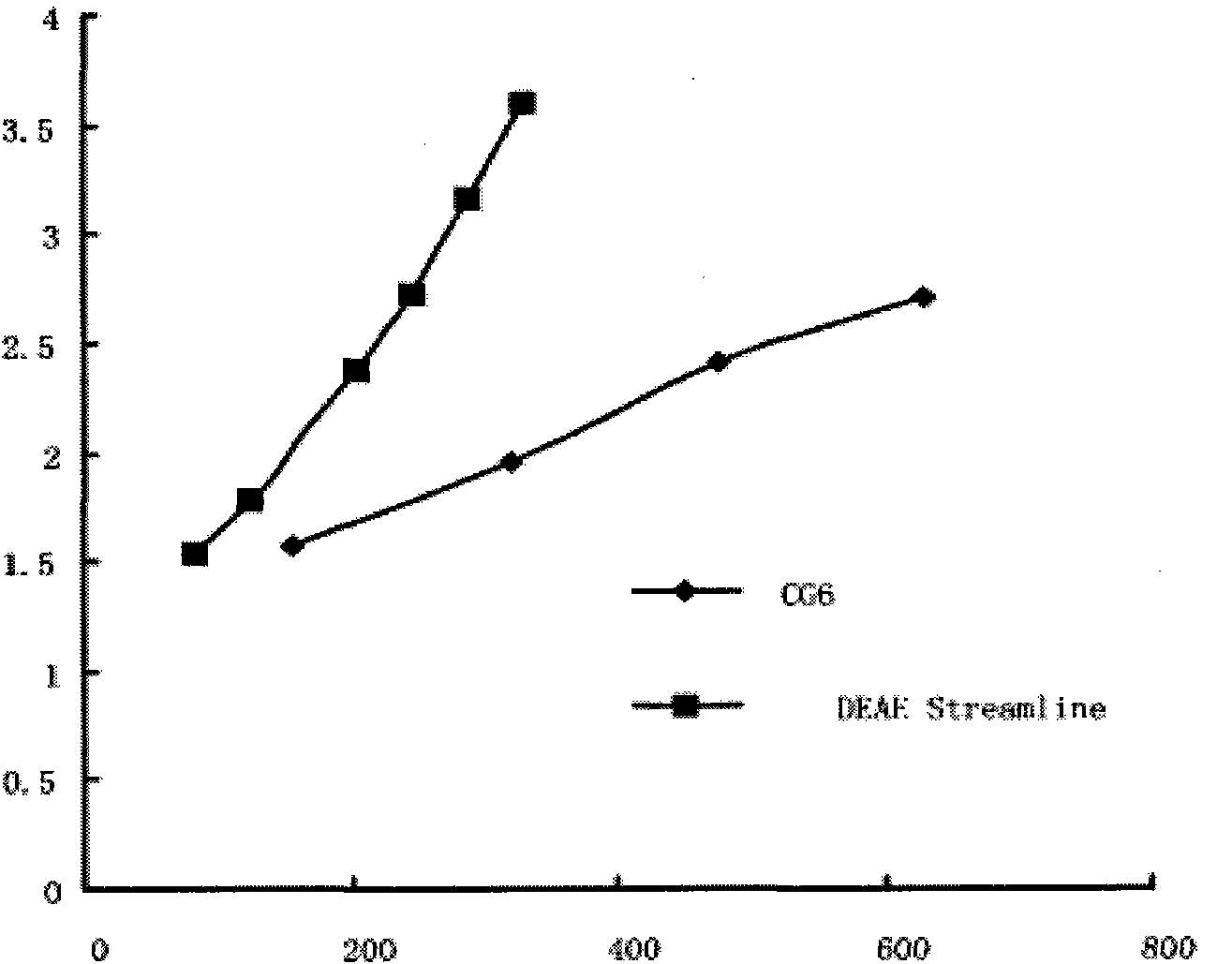

Method for absorbing and separating human prothrombin complex by utilizing expansion bed

InactiveCN101838304AAdsorption separation stabilityEfficient Adsorption SeparationPeptide preparation methodsContinuous flow centrifugationPROTHROMBIN COMPLEX

The invention relates to a method for absorbing and separating a human prothrombin complex by utilizing an expansion bed, comprising the following steps: (a) separating cryoprecitation from melted refrigerated plasma by using a refrigeration type continuous flow centrifuge, and collecting supernate as a raw material; (b) carrying out stable expansion on an expansion bed by using a buffer solution A, wherein the buffer solution A is 0.05mol / L1tris-citric acid with the PH value of 7.0; (c) rapidly switching into a feed solution after the expansion bed is in stable balance, stopping feeding and rapidly switching into the buffer solution A when breakthrough points reaches 5-10%, and washing in an expanded mode; and (d) switching into buffer solutions of 0.4mol / L NaCl and 1.6mol / L NaCl after washing, carrying out gradient elution in a stationary bed mode, and collecting the protein elution peak of the buffer solution of 1.6mol / L NaCl to obtain a prothrombin complex crude product.

Owner:成都英德生物工程有限公司

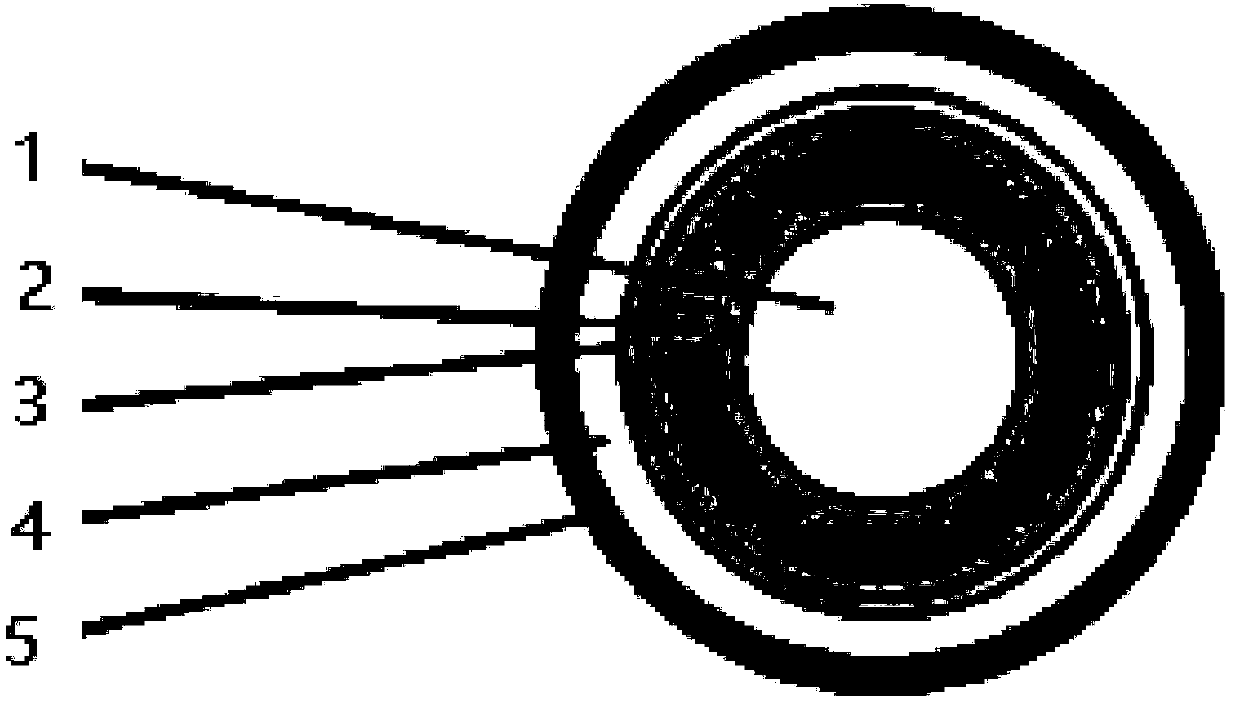

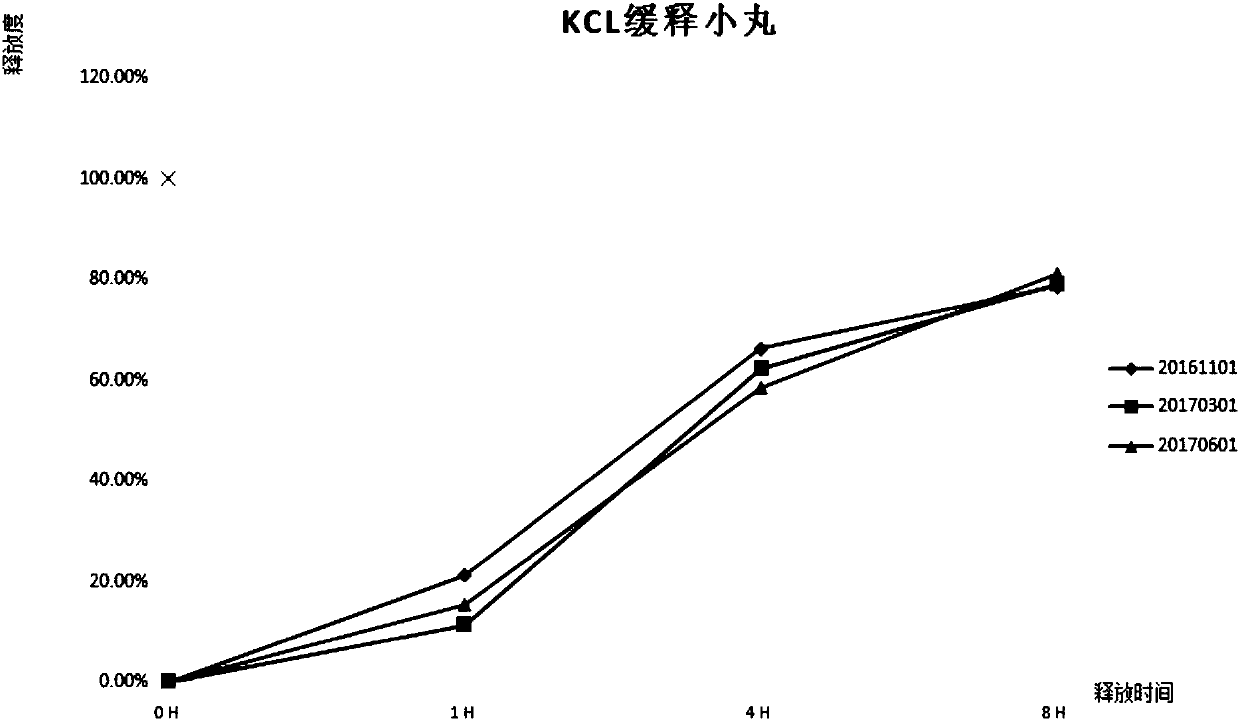

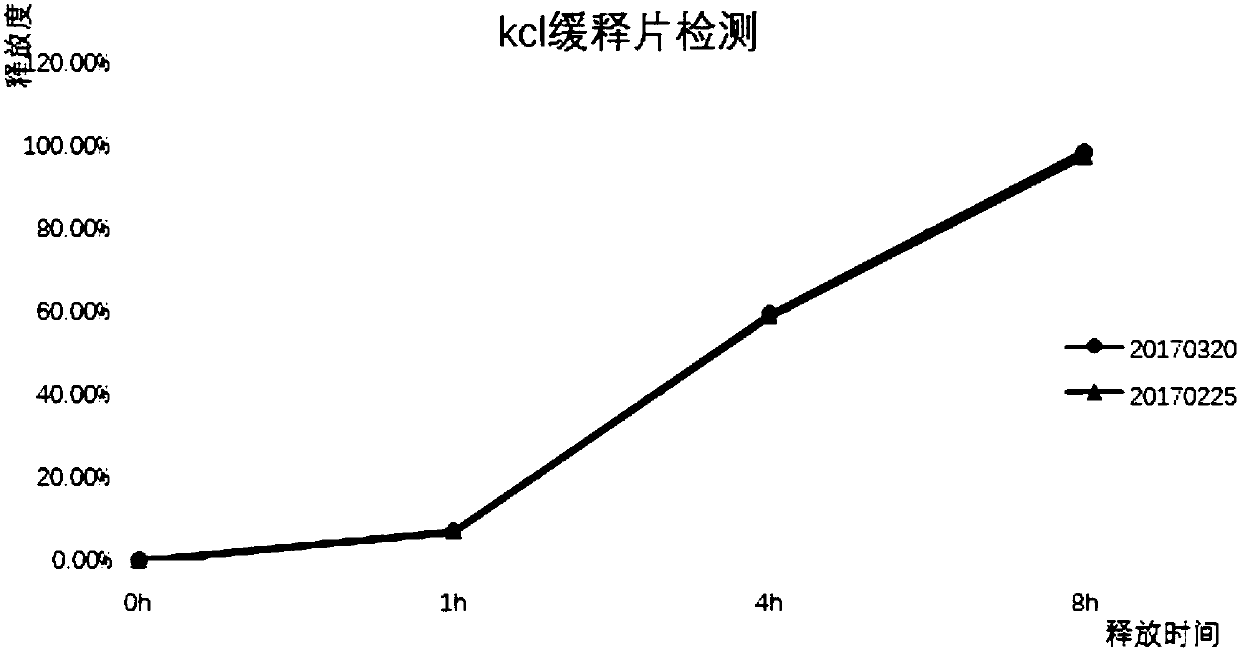

Potassium chloride sustained-release pellet and preparation method and application thereof

ActiveCN107823189AHigh yieldMeet the requirements of GMPMetabolism disorderPharmaceutical non-active ingredientsSustained release pelletsBlood concentration

The invention relates to a potassium chloride sustained-release pellet and a preparation method and application thereof. The potassium chloride sustained-release pellet provided by the invention comprises a pellet core, a potassium chloride main drug layer, an isolated layer, a sustained-release coating layer and a colored coating layer. According to the potassium chloride sustained-release pelletprepared in the invention, the release amount within 1 hour is smaller than or equal to 25%, the release amount within 4 hours is smaller than or equal to 70%, and the release amount of the potassiumchloride sustained-release pellet within 8 hours is smaller than or equal to 85%. By using the sustained-release coating material, the drug is released stably by accurately controlling the sustained-release speed of potassium chloride inside the potassium chloride sustained-release pellet, an expected blood concentration is obtained, relatively long action time can be maintained, the phenomenon of sudden release does not exist, and adverse reactions such as stimulation for gastric mucosa can be avoided.

Owner:杭州高成生物营养技术有限公司 +1

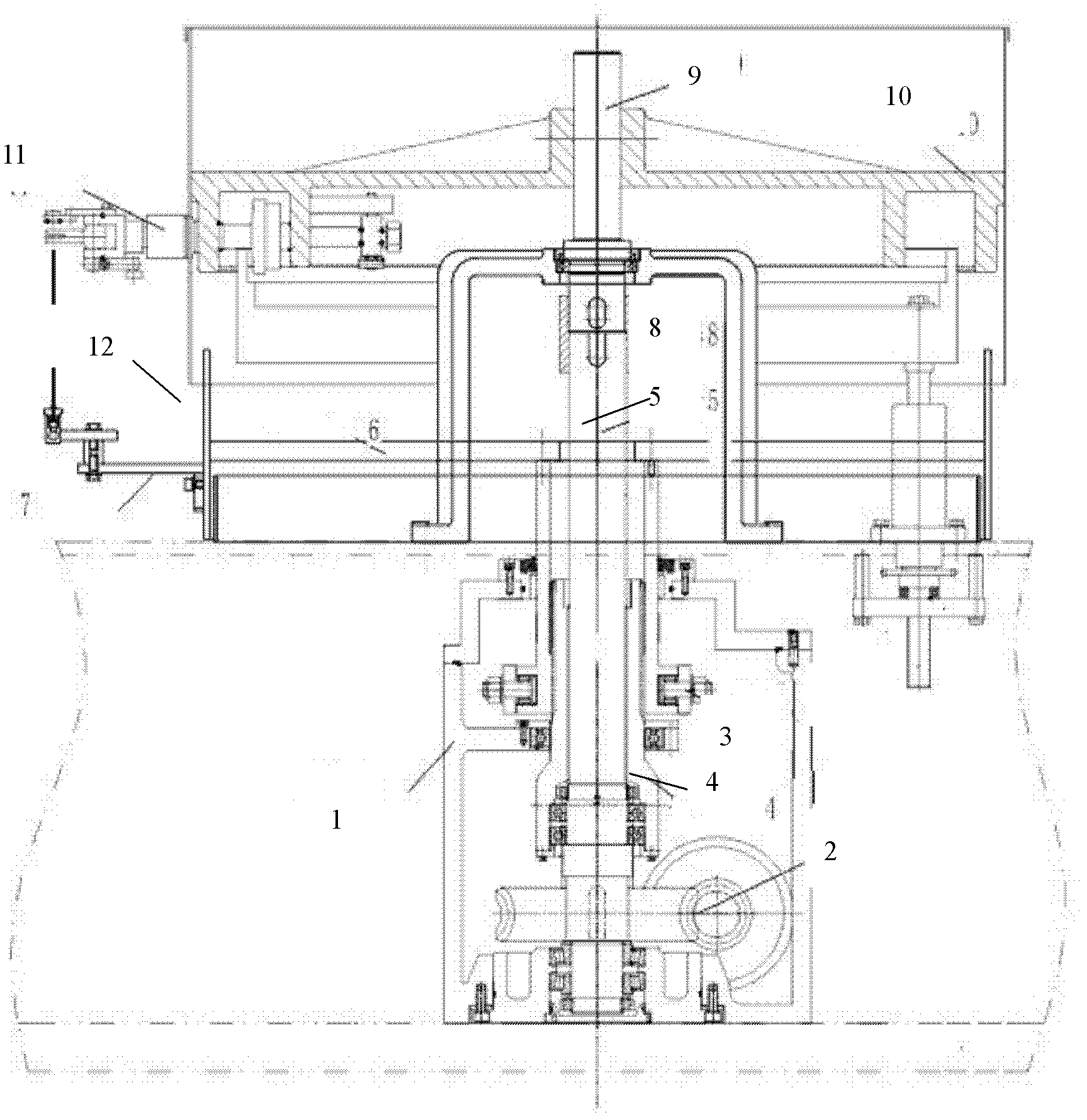

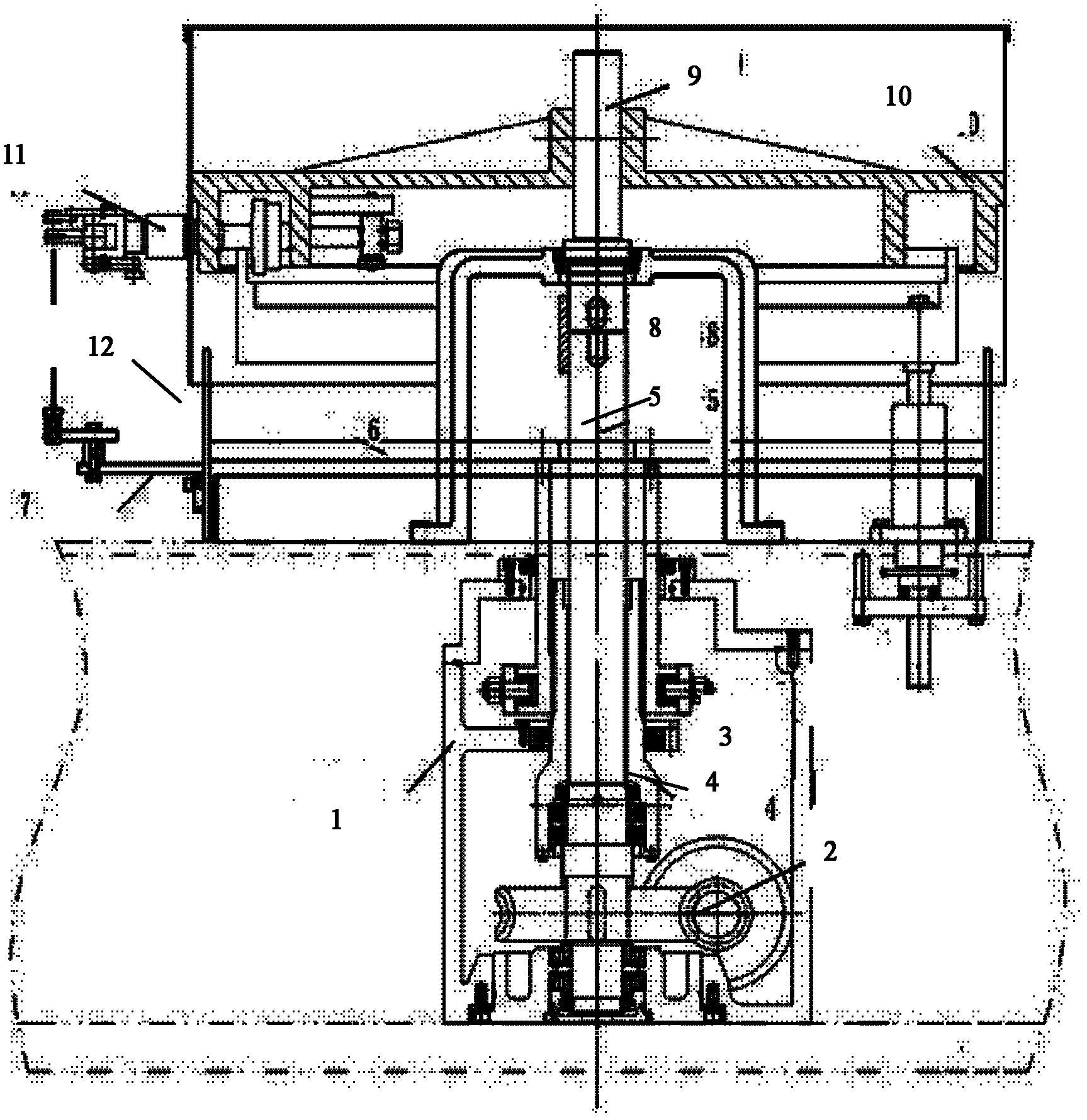

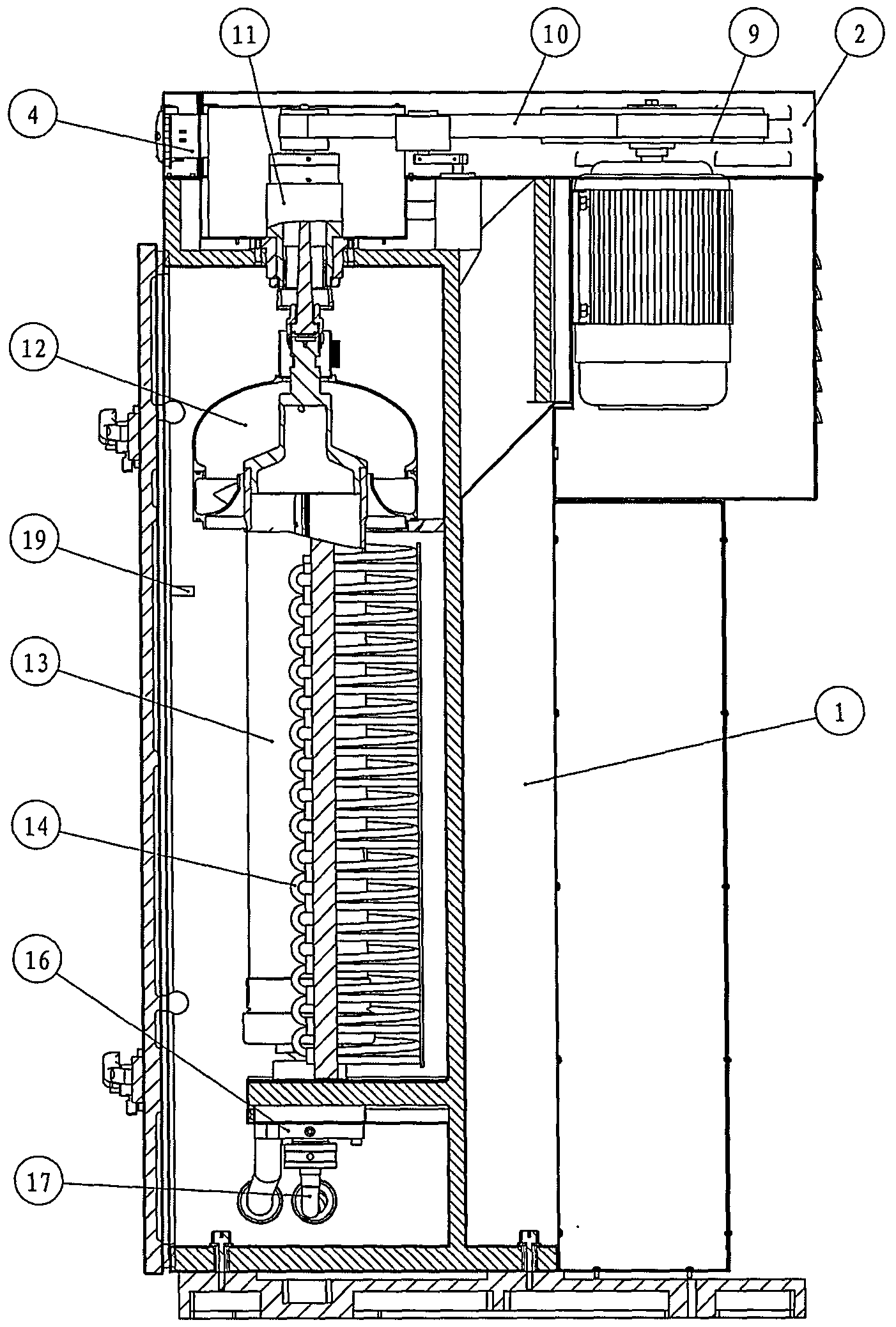

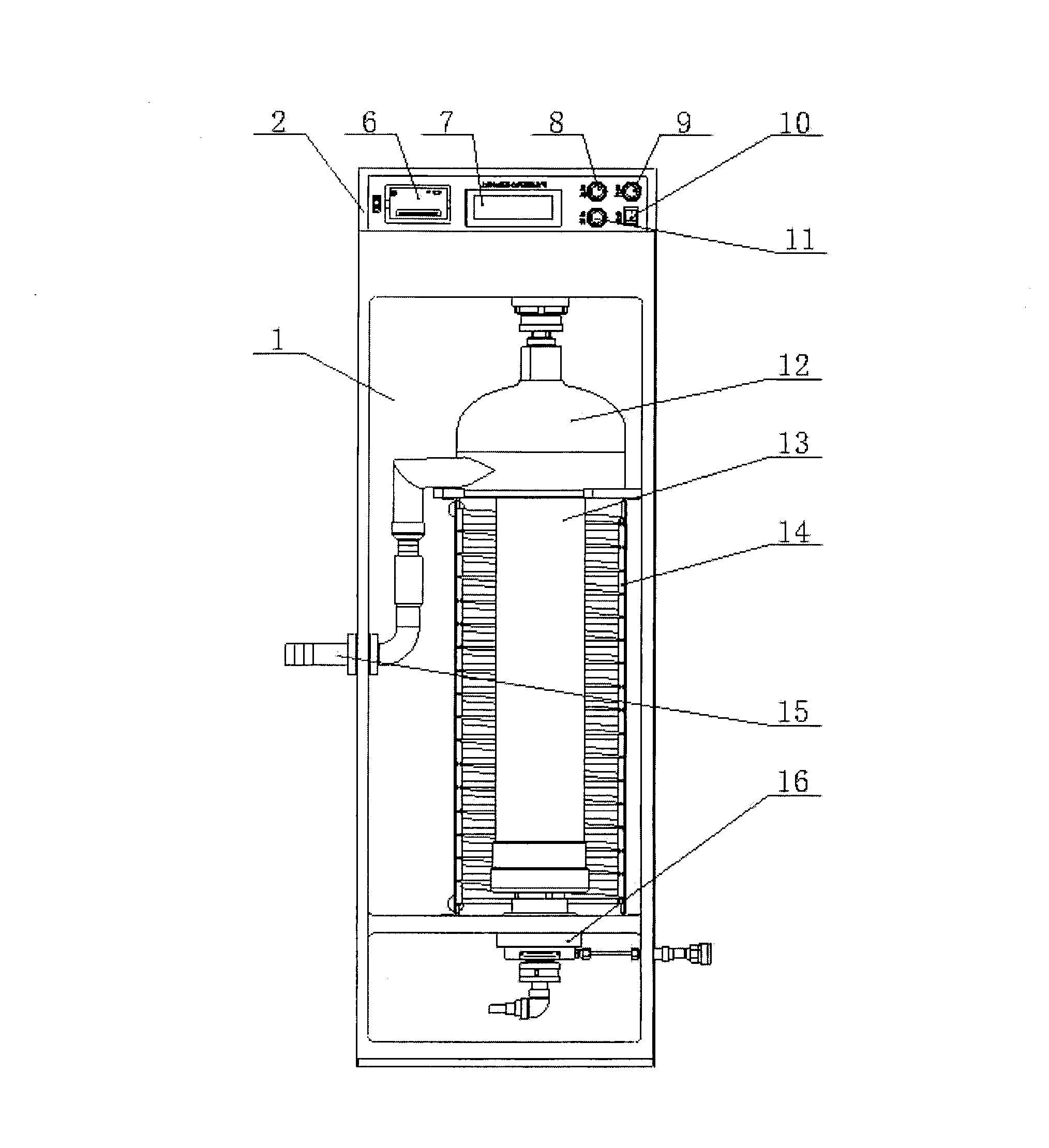

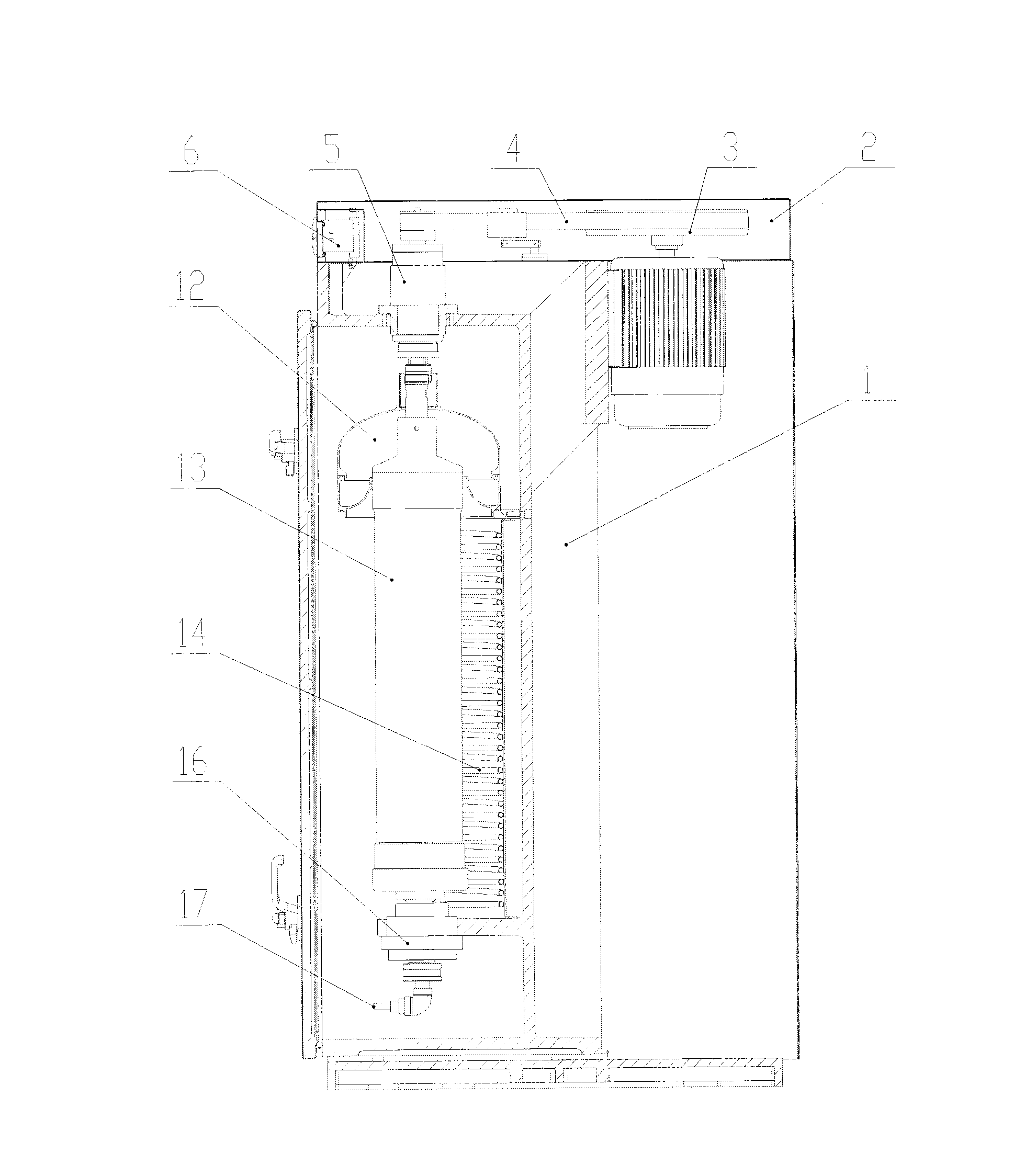

Upright bottle cleaning machine

The invention discloses an upright bottle cleaning machine, which comprises a work station box including a worm gear transmission assembly, a lifting swinging combined cam transmission assembly, a swinging hollow shaft and a central rotation shaft. The worm gear of the worm gear transmission assembly is connected to the central rotation shaft, the lifting swinging combined cam transmission assembly is connected to the swinging hollow shaft, the central rotation shaft is fixedly connected to an extension central shaft via a coupling, the extension central shaft is connected with a central rotary disc, the central rotary disc is provided with at least one group of pincers, the swinging hollow shaft is connected with a swinging cross which is connected with a swinging needle holder through a swinging ring, the swinging hollow shaft is fitted outside the central rotation shaft, lifting and swinging of the swinging needle holder are realized by one set of the lifting swinging combined cam transmission assembly in the work station box, rotation of the pincers rotary disc is realized by one set of the worm gear transmission assembly in the work station box, and the work station box is soaked below lubricating oil and sealed both at the end face and in the axial direction to ensure that main transmission causes no contamination to cleaning water and gas of the bottle cleaning machine.

Owner:上海千山远东制药机械有限公司

Preparation method of indigowoad root and indigowoad leaf particles used for livestock and poultry

ActiveCN102727545AChanging the high temperature decoction processPromote leachingAntibacterial agentsAntiviralsBoiling processWorking temperature

The invention discloses a preparation method of indigowoad root and indigowoad leaf particles used for livestock and poultry. First, indigowoad root and indigowoad leaf are placed in an extraction tank, such that a medicine material layer is formed; the materials are soaked by using water; the working temperature of the extraction tank is regulated to 60-80 DEG C, and extraction is carried out; during the extraction process, a part of the extraction solution is fetched from the bottom of the extraction tank, and is subjected to vacuum concentration, wherein the concentration temperature is 50-70 DEG C; vapor generated by concentration is condensed and adopted as a novel solvent, and is delivered back to the extraction tank for carrying out percolation extraction upon the medicine material layer; the steps are repeated for 2-3h, and a fluid extract is obtained by concentration; anhydrous dextrose, maltodextrin or cyclodextrin, and the fluid extract are added into a spray-drying granulator for granulation, such that the indigowoad root and indigowoad leaf particles used for livestock and poultry are obtained. According to the preparation method of the indigowoad root and indigowoad leaf particles used for livestock and poultry, two processes which are the extraction and concentration of the indigowoad root and indigowoad leaf are carried out simultaneously, a pressurized and normal-pressure boiling process in a traditional extraction tank is changed, such that energy can be saved by 0.3-0.5 times, the dosage of a water solvent can be reduced by 0.5-1 time, a feeding amount is increased by 30-60%, an extract yield is increased by more than 10%, a storage process is reduced, and electric energy is saved by more than 30%.

Owner:ZHENGZHOU BARY ANIMAL PHARMA

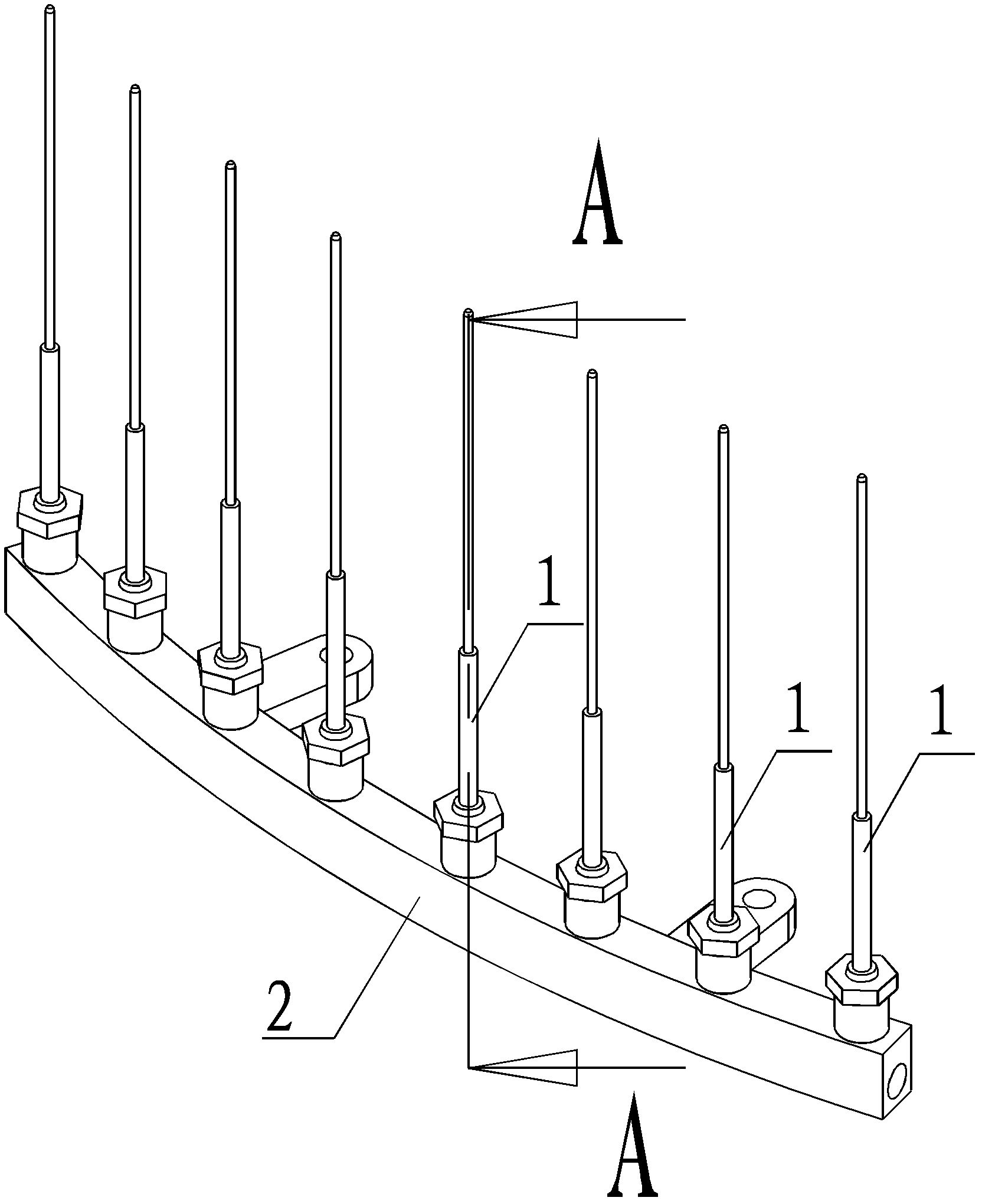

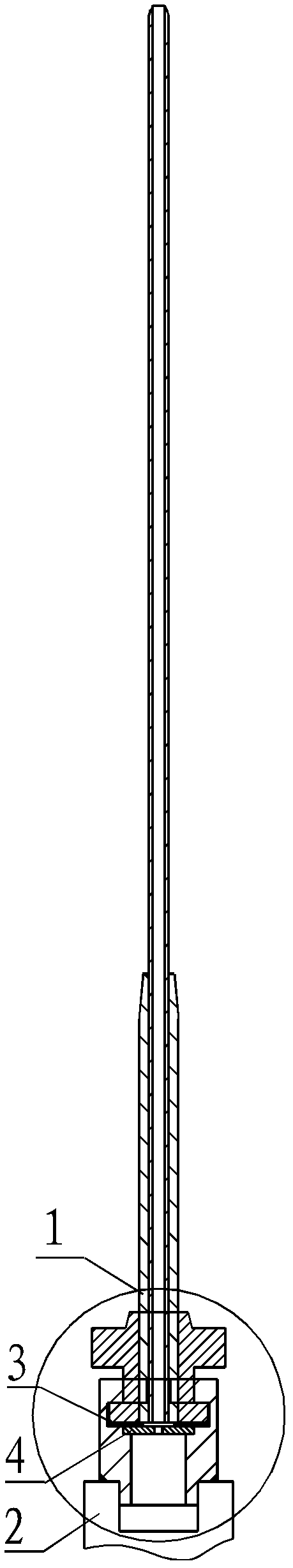

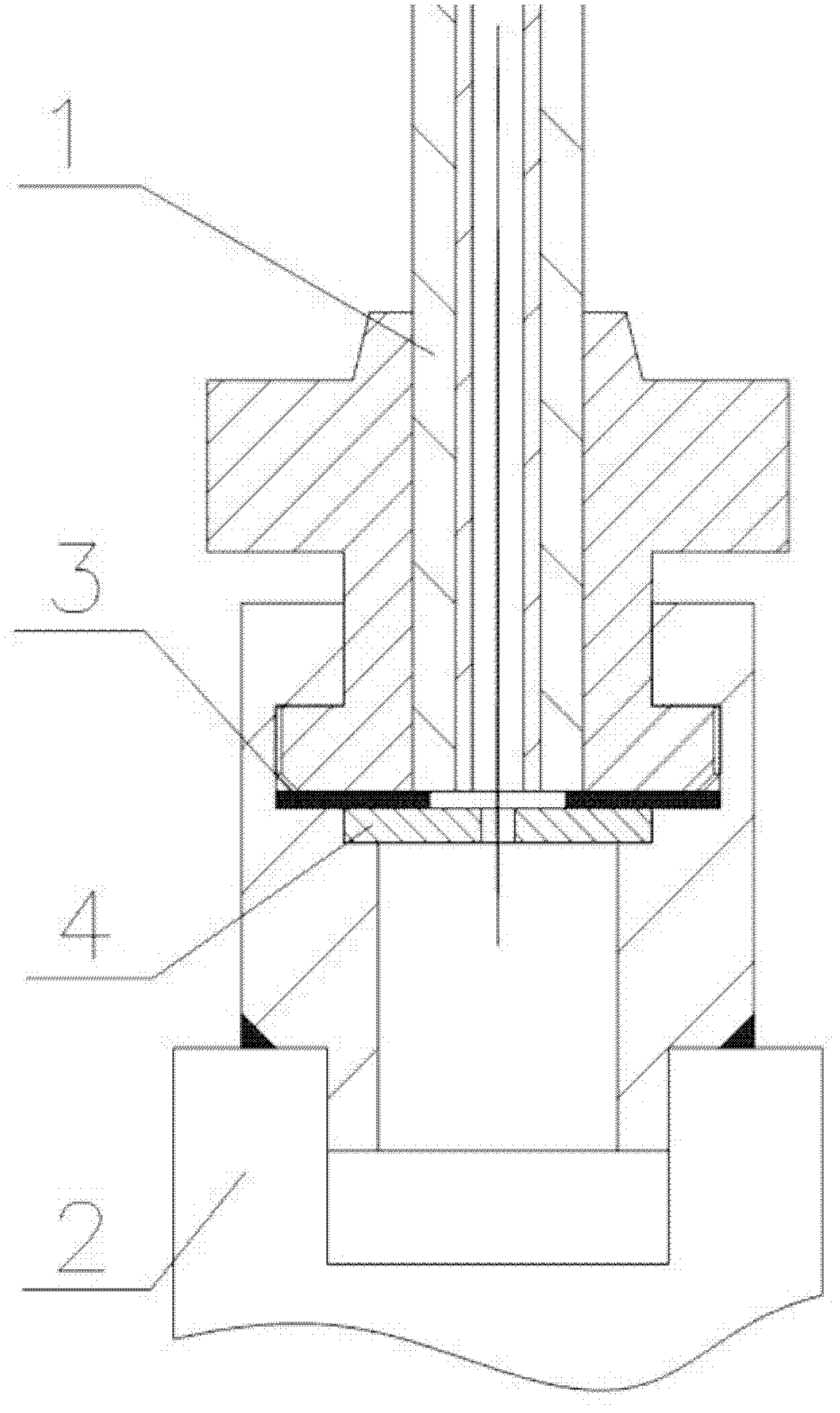

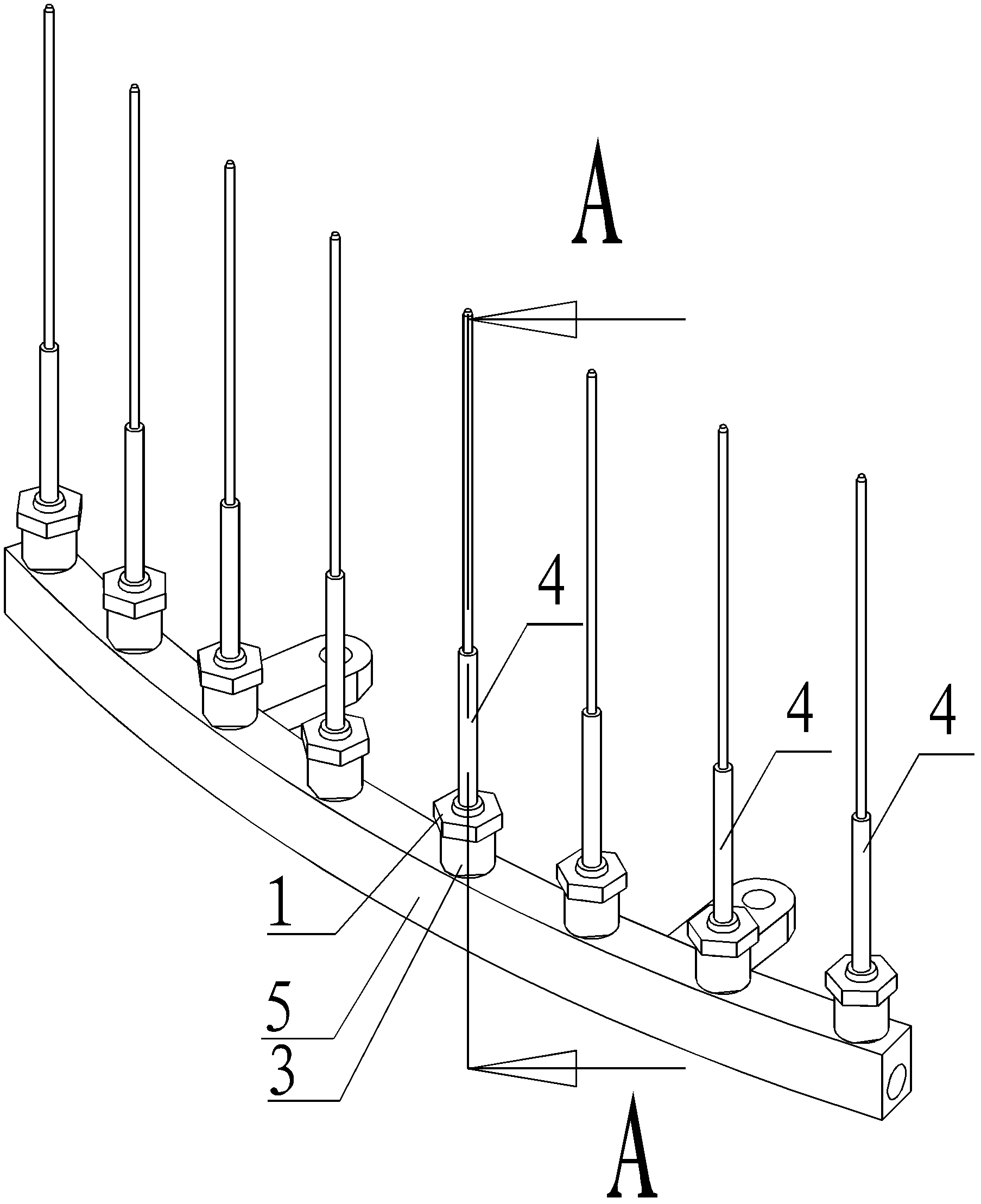

Bottle washer spray needle frame with spray needles having adjustable hydraulic pressure balance

The invention relates to a bottle washer spray needle frame with spray needles having adjustable hydraulic pressure balance. The bottle washer spray needle frame comprises the spray needles, a needle frame, sealing gaskets and throttling orifices with different bore diameters. The throttling orifices are mounted between connecting surfaces of the spray needles and the needle frame, the sealing gaskets are mounted on the throttling orifices, an outer convex surface of each spray needle is a V-shaped outer conical surface, two symmetric support lugs are arranged at ends of each spray needle, an inner concave surface of the needle frame is a V-shaped inner conical surface, a groove provided with two symmetric notches is arranged at an end of the needle frame, and the convex surface support lugs on the spray needles are aligned to the notches at the upper end of the concave surface of the needle frame and are embedded into the groove on the needle frame. By means of connection of a fastened rapid connector, the spray needles and a support are connected together, the throttling orifices and the sealing gaskets capable of adjusting water pressure are added between the spray needles and the support, spray pressures of the spray needles of a bottle washer are ensured to be approximately equal by adjusting diameters of the throttling orifices, and each bottle can be sufficiently cleaned.

Owner:上海千山远东制药机械有限公司

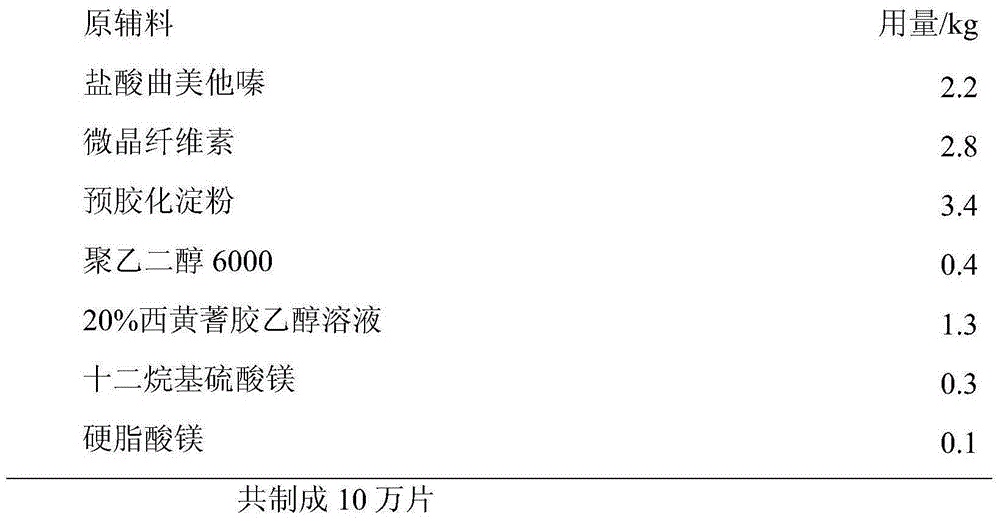

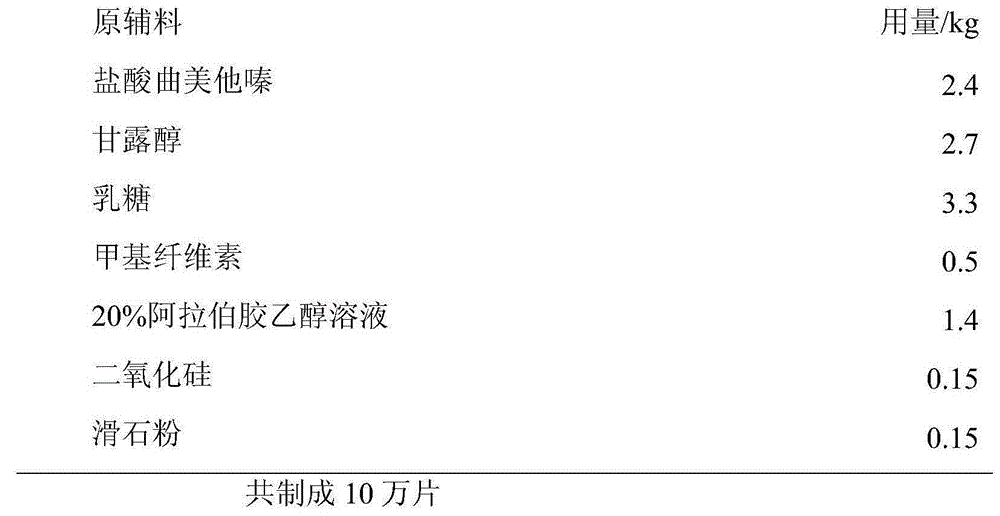

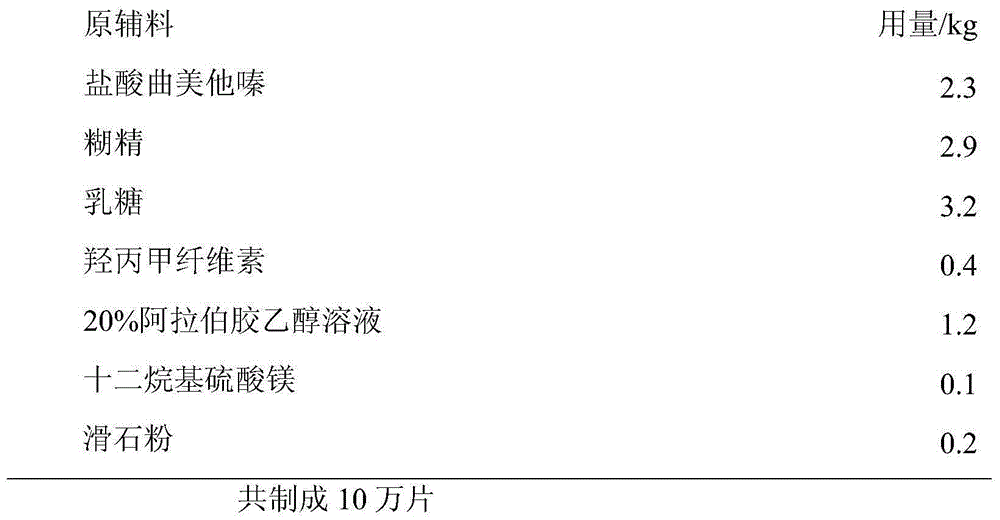

Trimetazidine hydrochloride tablets and preparation method thereof

InactiveCN105055352AImprove liquidityGood compressibilityOrganic active ingredientsSenses disorderLubricantTrimetazidine hydrochloride

The invention belongs to the technical field of medicine and particularly relates to trimetazidine hydrochloride tablets and a preparation method thereof. The trimetazidine hydrochloride tablets are prepared from raw materials as follows: trimetazidine hydrochloride, filler, a binder, a lubricant and a wetting agent. The trimetazidine hydrochloride tablets solve the problems of poor compressibility and difficulty in forming of the trimetazidine hydrochloride as the raw material. The invention further provides the preparation method of the trimetazidine hydrochloride tablets. The compressibility of the prepared trimetazidine hydrochloride tablets is improved, the trimetazidine hydrochloride tablets are formed easily, the use value of the trimetazidine hydrochloride tablets can be increased better, trimetazidine hydrochloride is prepared into tablets to facilitate taking of a patient, pain of the patient can be relieved timely, the process is simple, the quality is stable, a production process meets the requirement of GMP (Good Manufacture Practice of Drugs), and the trimetazidine hydrochloride tablets and the preparation method are applicable to industrial mass production.

Owner:REYOUNG PHARMA

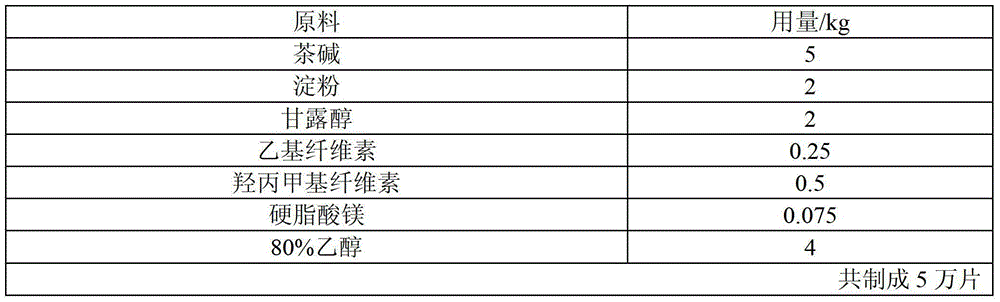

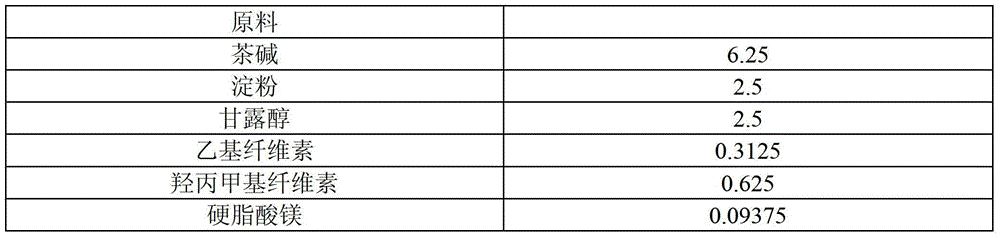

The preparation method of theophylline sustained-release tablet

ActiveCN103239419BQuality improvementImprove use valuePharmaceutical delivery mechanismRespiratory disorderSustained Release TabletFluidized bed

Owner:REYOUNG PHARMA

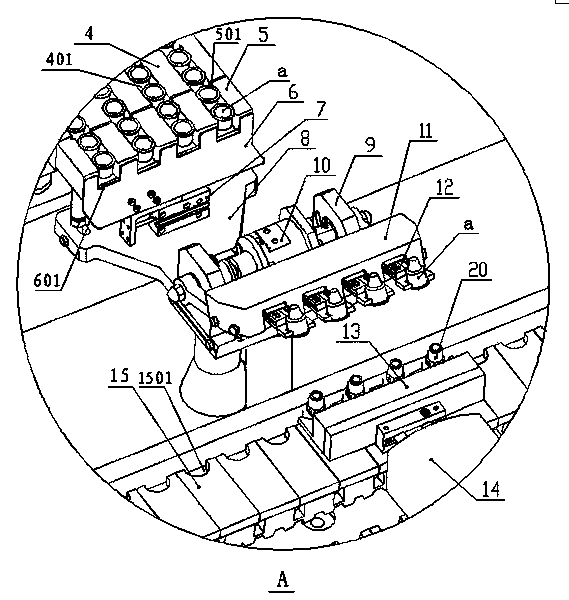

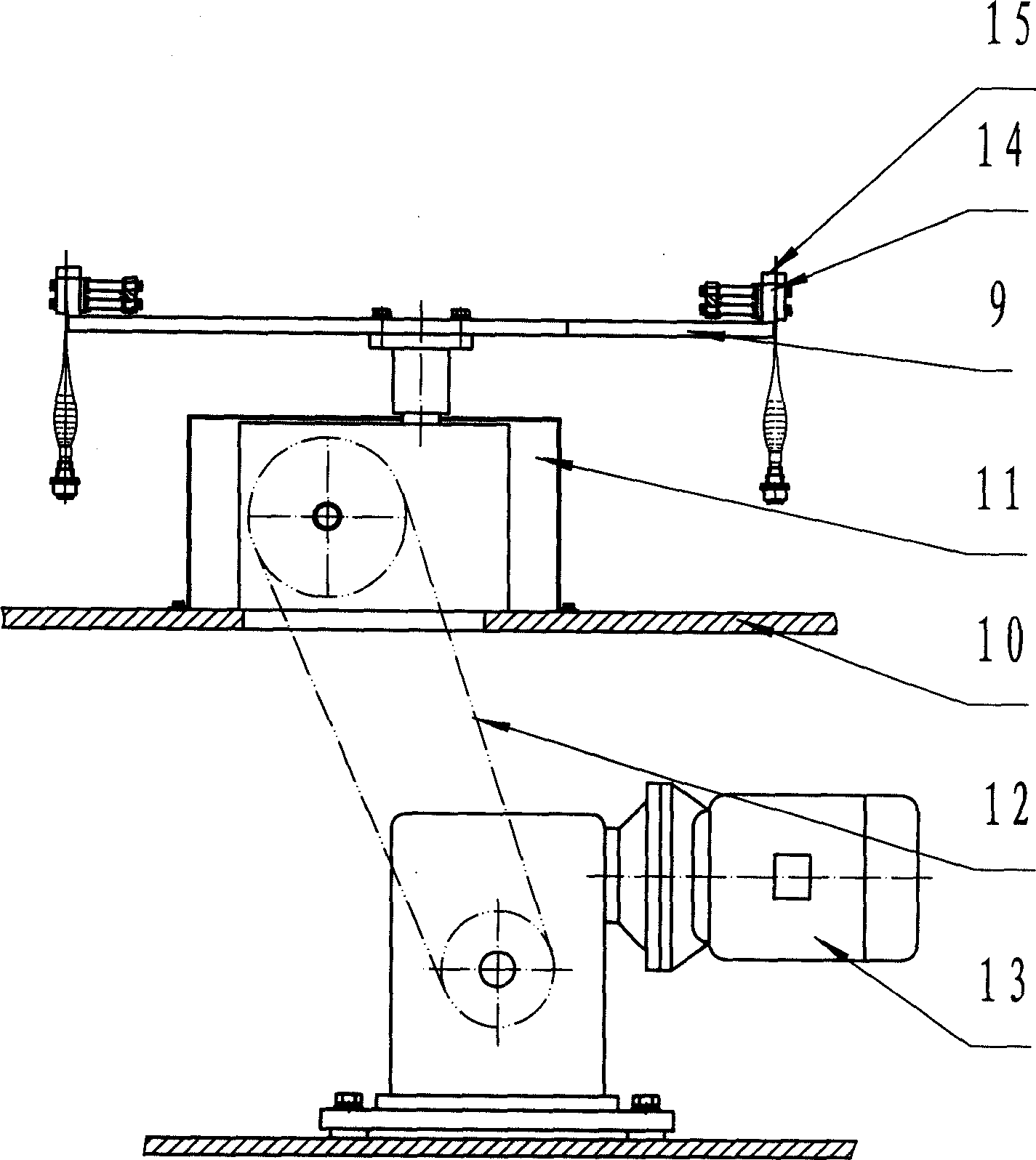

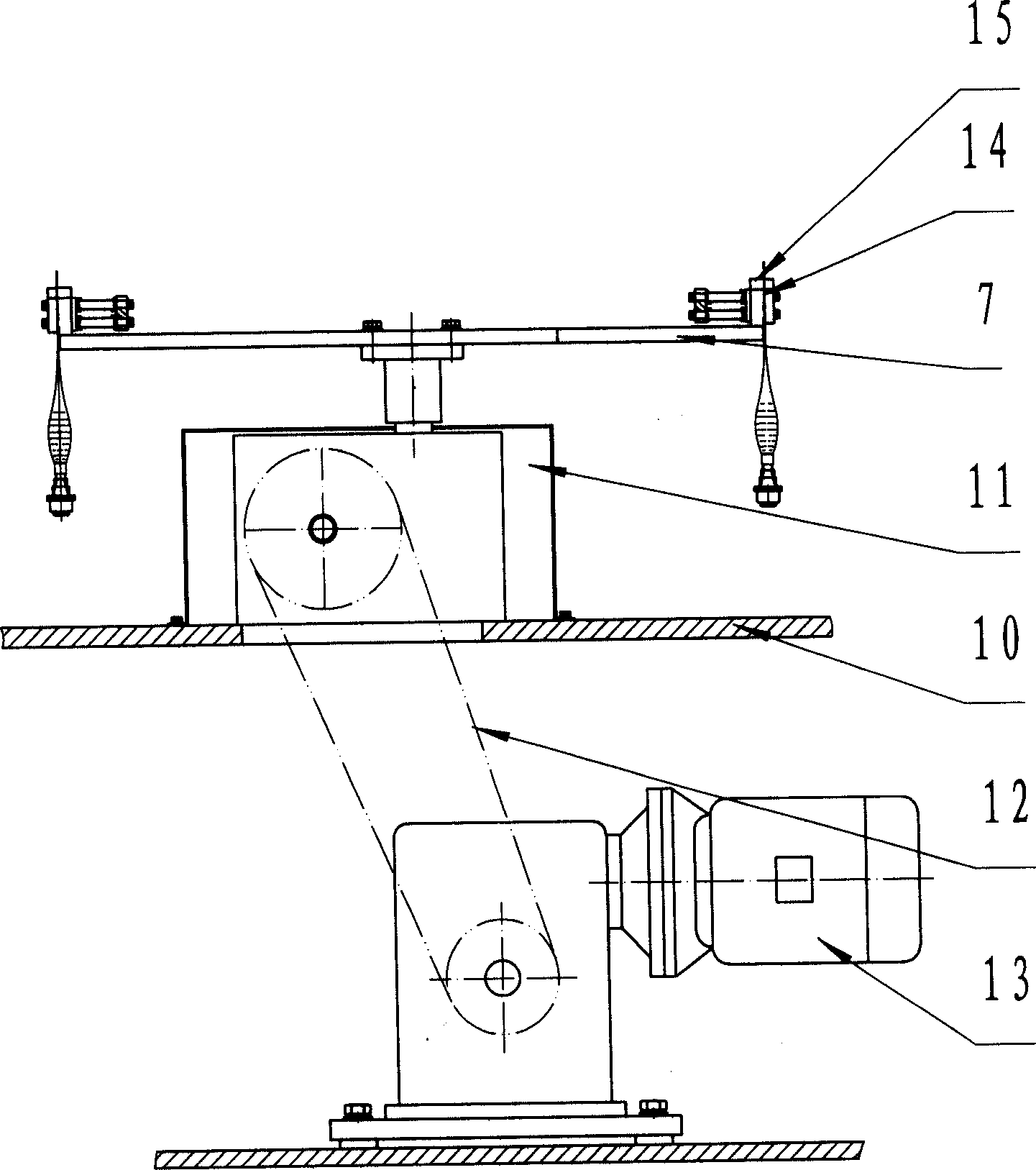

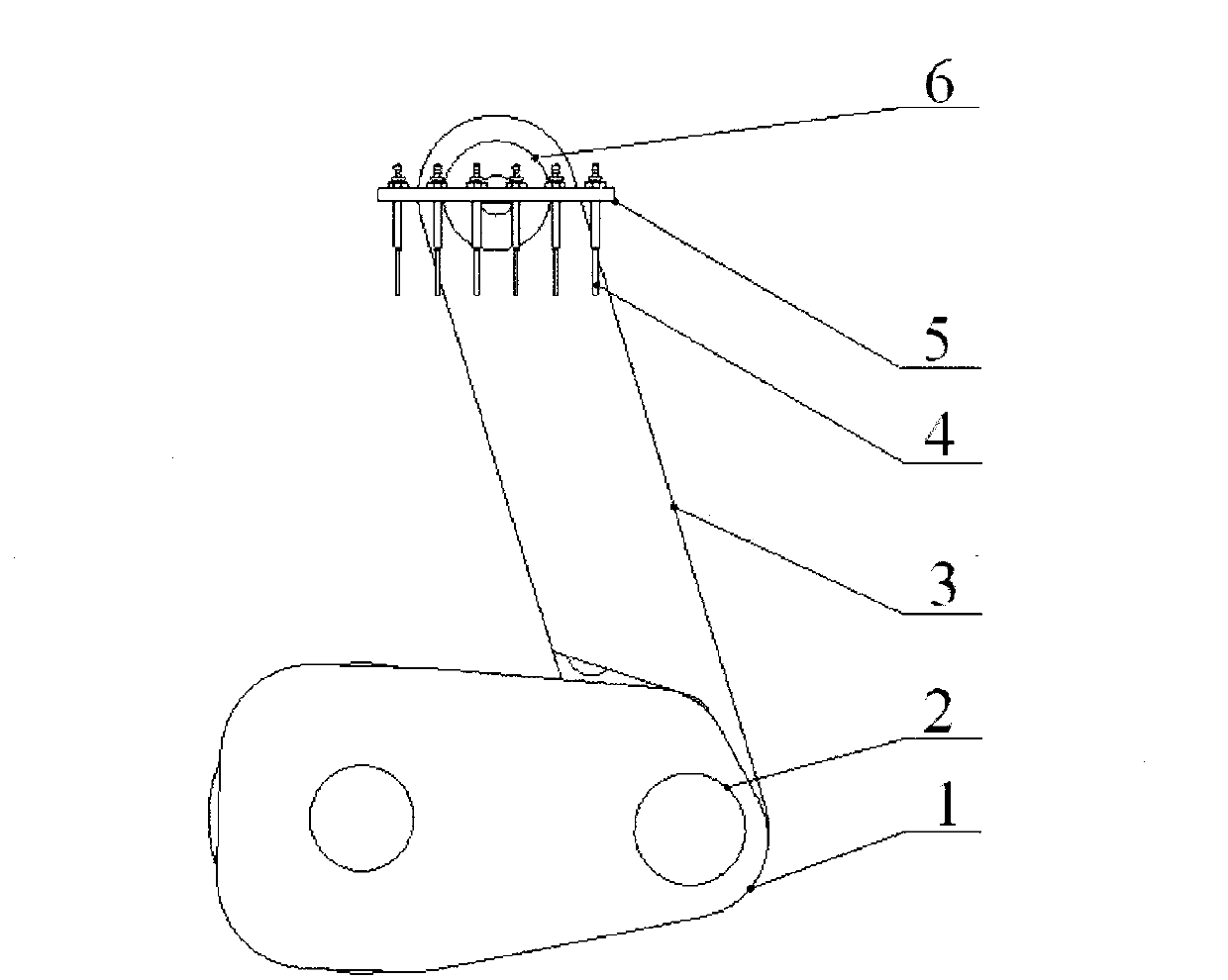

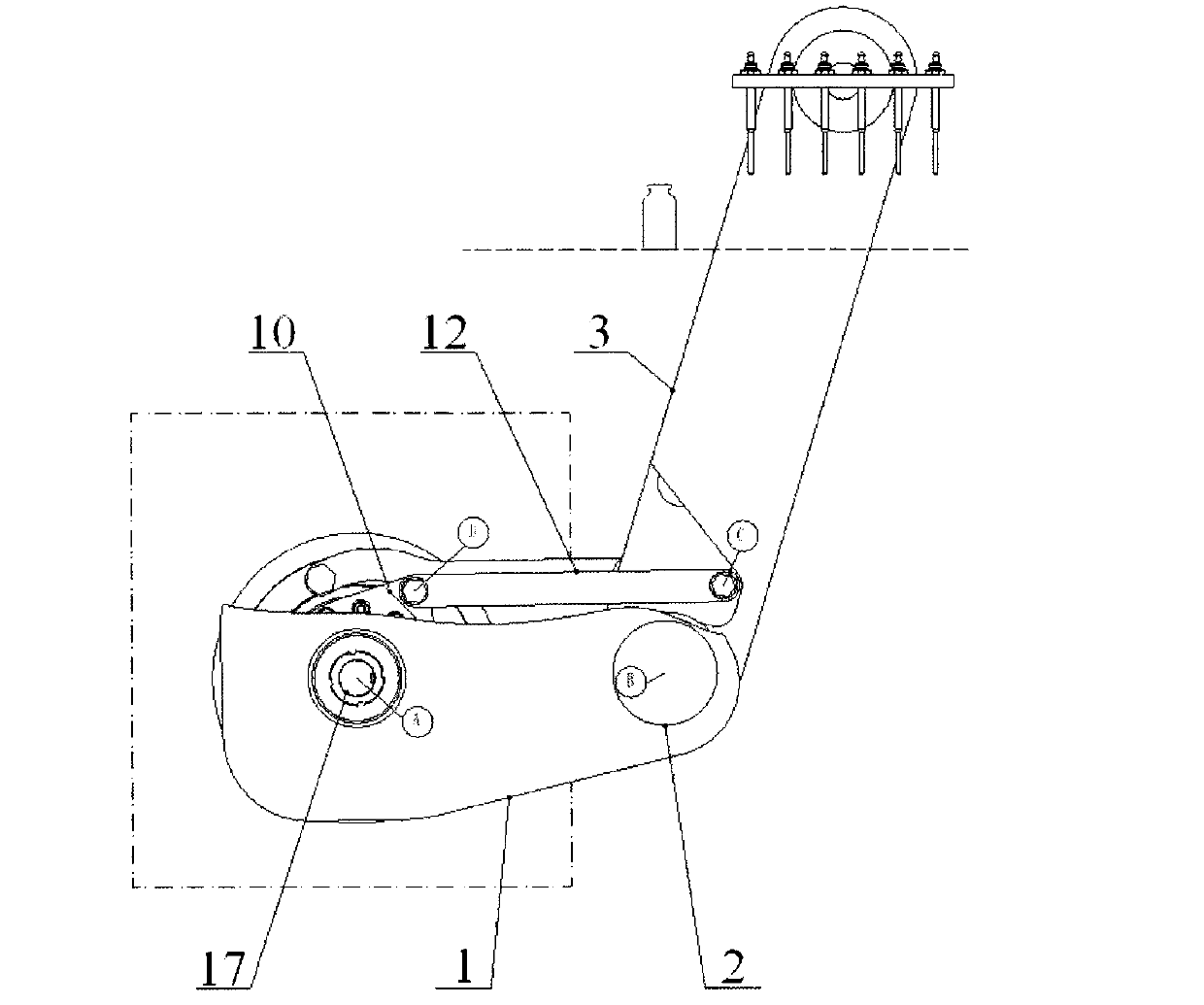

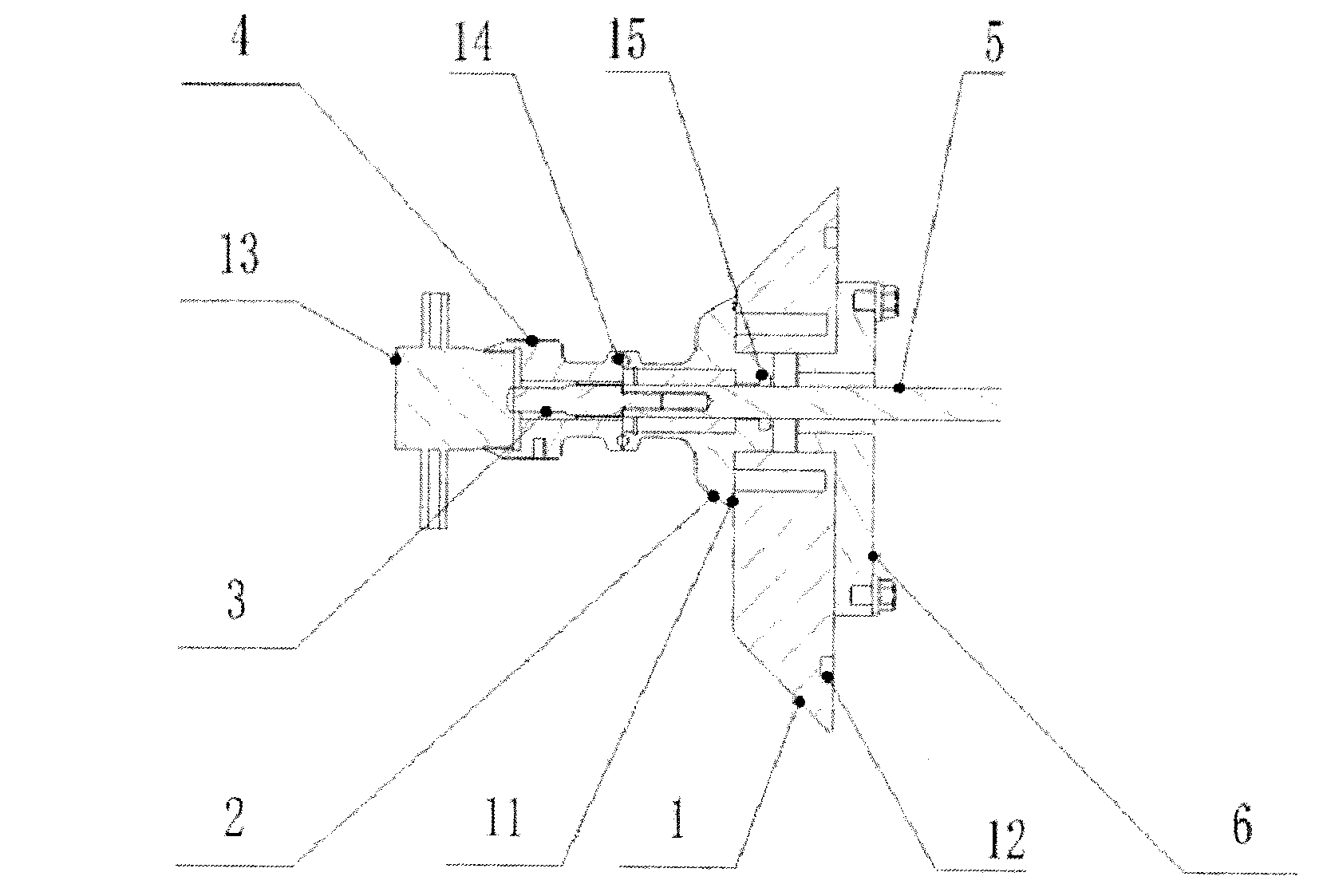

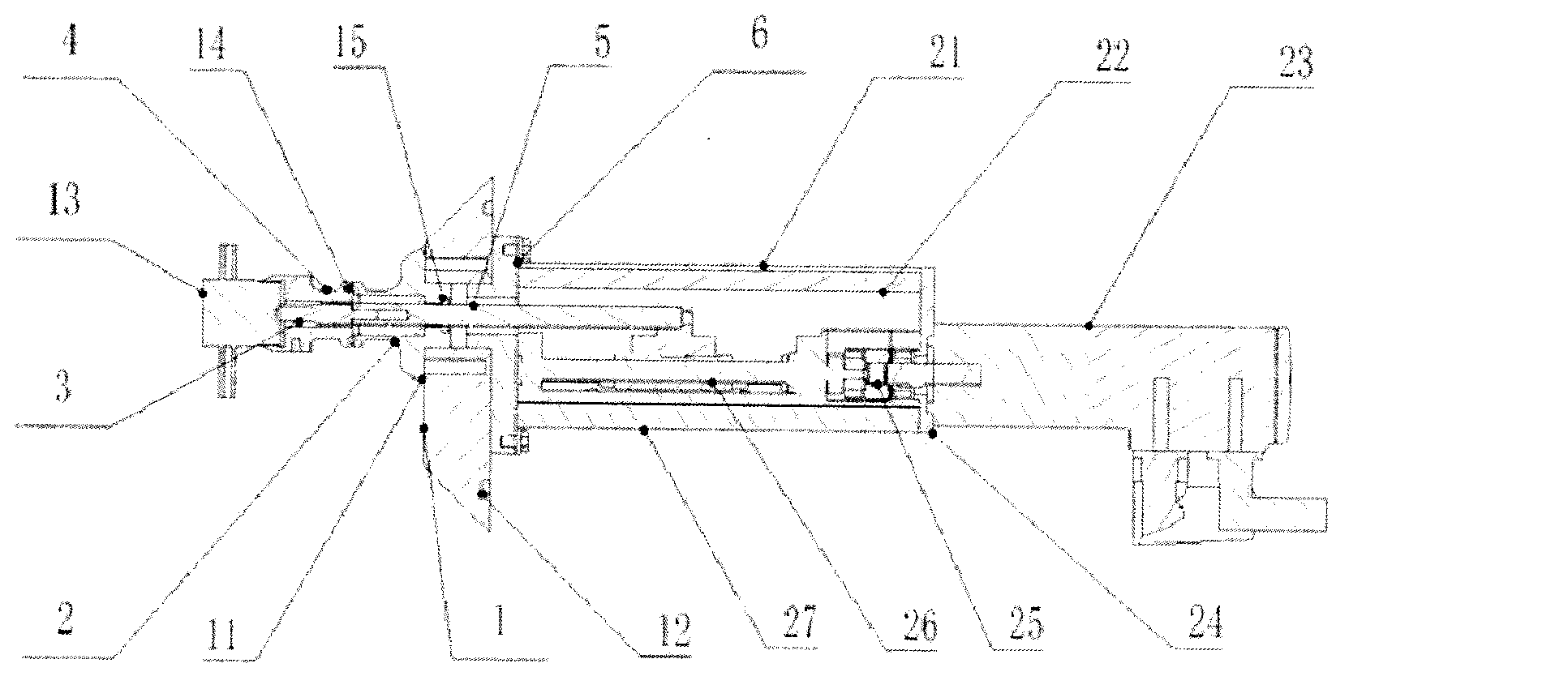

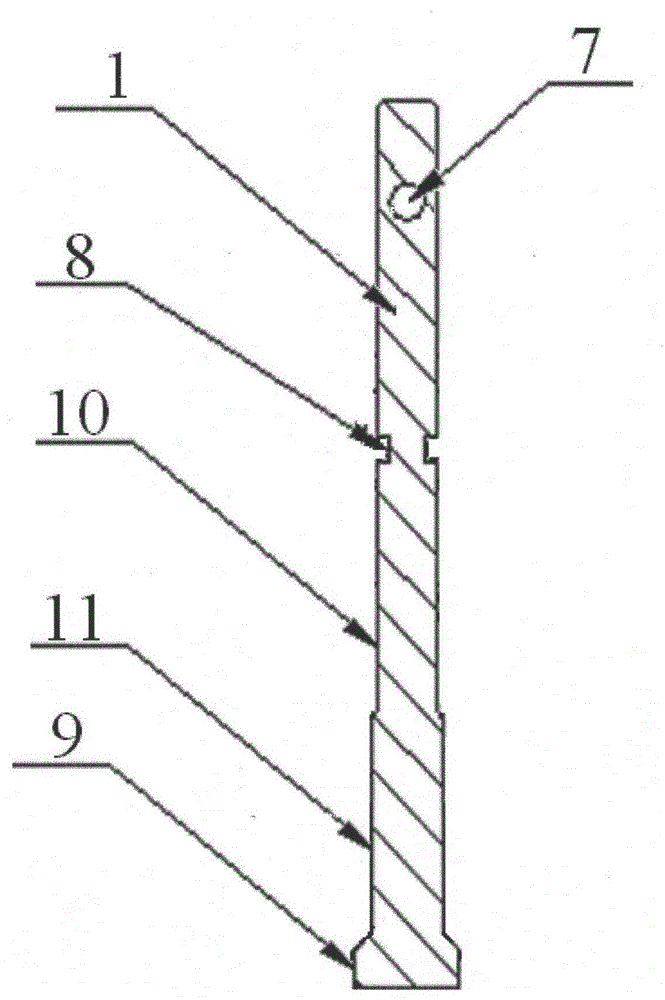

Filling tracking manipulator

ActiveCN103448931ARealize online tracking fillingStable trackingLiquid materialDrive shaftEngineering

The invention discloses a filling tracking manipulator comprising an upper servo motor (3), a lower servo motor (4), a lower swing arm transmission shaft (5), a lower swing arm (6), a link holder (7), an upper swing arm assist rod (8), a middle link (9), a filling needle rack (10), an upper swing arm transmission shaft (11), a middle shaft (12), an upper swing arm (13), an assist support (14), and a lower swing arm assist rod (15). The link holder (7), the upper swing arm assist rod (8), the middle link (9) and the upper swing arm (13) form an upper parallelogram link mechanism. The lower swing arm (6), the link holder (7), the lower swing arm assist rod (15) and the assist support (14) form a lower parallelogram link mechanism. The servo motors drive the upper swing arm transmission shaft and the lower swing arm transmission shaft to rotate at certain angles respectively, so that the filling needle rack is horizontal constantly; tracking is fast and stable and production efficiency is high.

Owner:南京固延制药设备有限公司

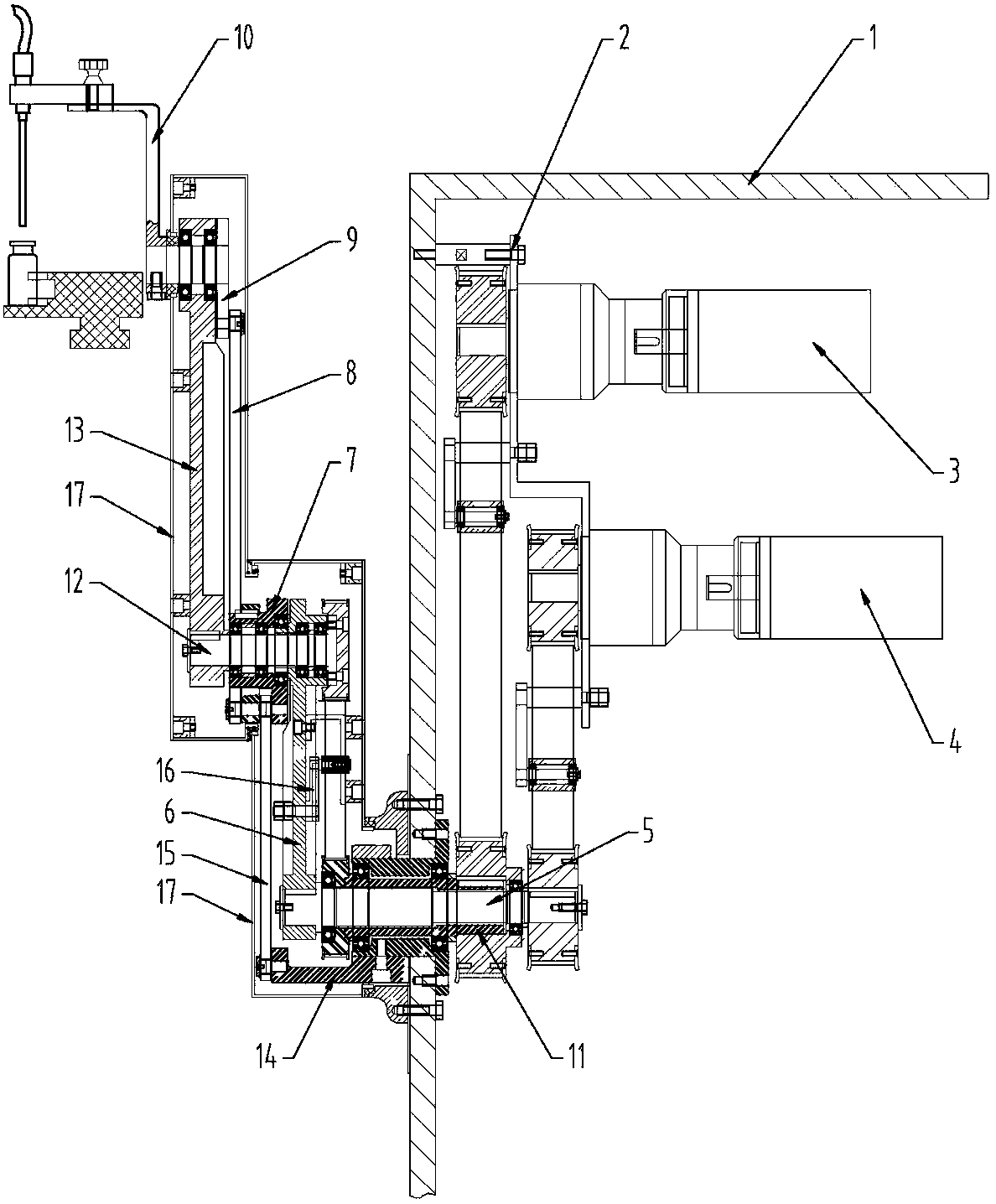

Filling action mechanism of filling machine

The invention discloses a filling action mechanism of a filling machine. The filling action mechanism is characterized by comprising a mechanical arm main shaft, wherein one end of the mechanical arm main shaft penetrates through a hollow speed reducer and is connected with one end of a large mechanical hand arm; the other end of the large mechanical hand arm is connected with one end of a small mechanical hand arm through a mechanical hand countershaft; the output end of the hollow speed reducer is connected with the small mechanical hand arm through a connecting joint, a first movable joint and a second connecting rod; the other end of the small mechanical hand arm is provided with a needle rack fixing shaft; the needle rack fixing shaft is provided with a needle rack; and the needle rack is always horizontal to the ground surface through the effect of movable devices and is provided with a filling needle. The filling action mechanism has the characteristics of being high in integration level, being capable of realizing modularized installation and disassembling, being more convenient to maintain, and the like.

Owner:上海东富龙生物试剂有限公司

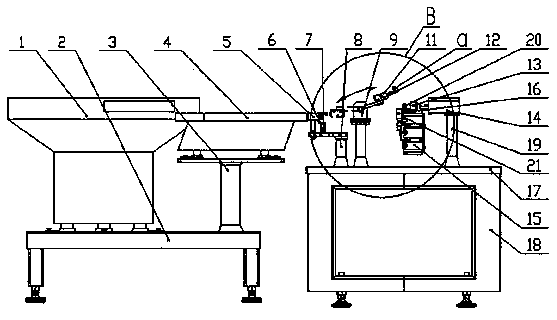

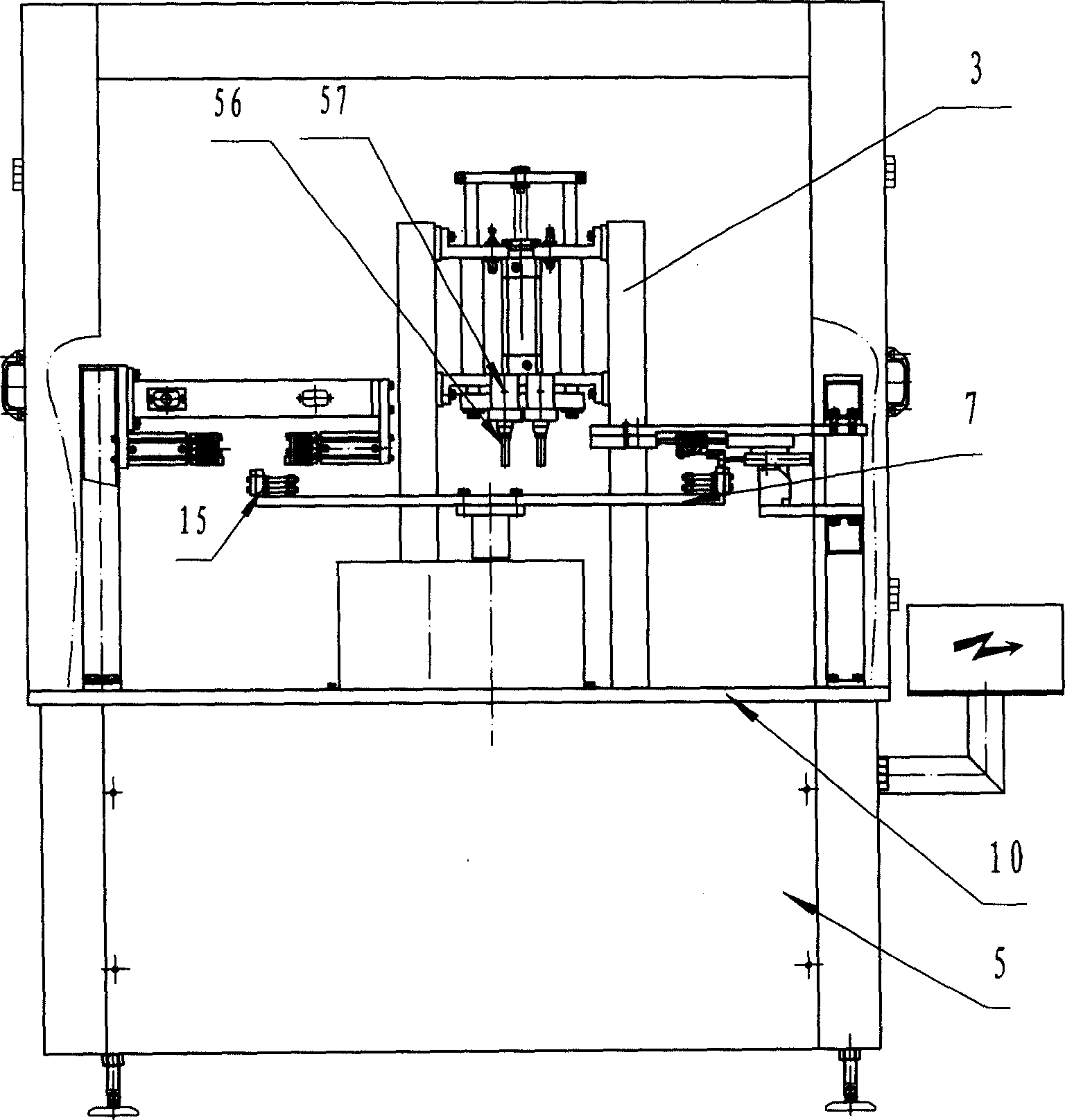

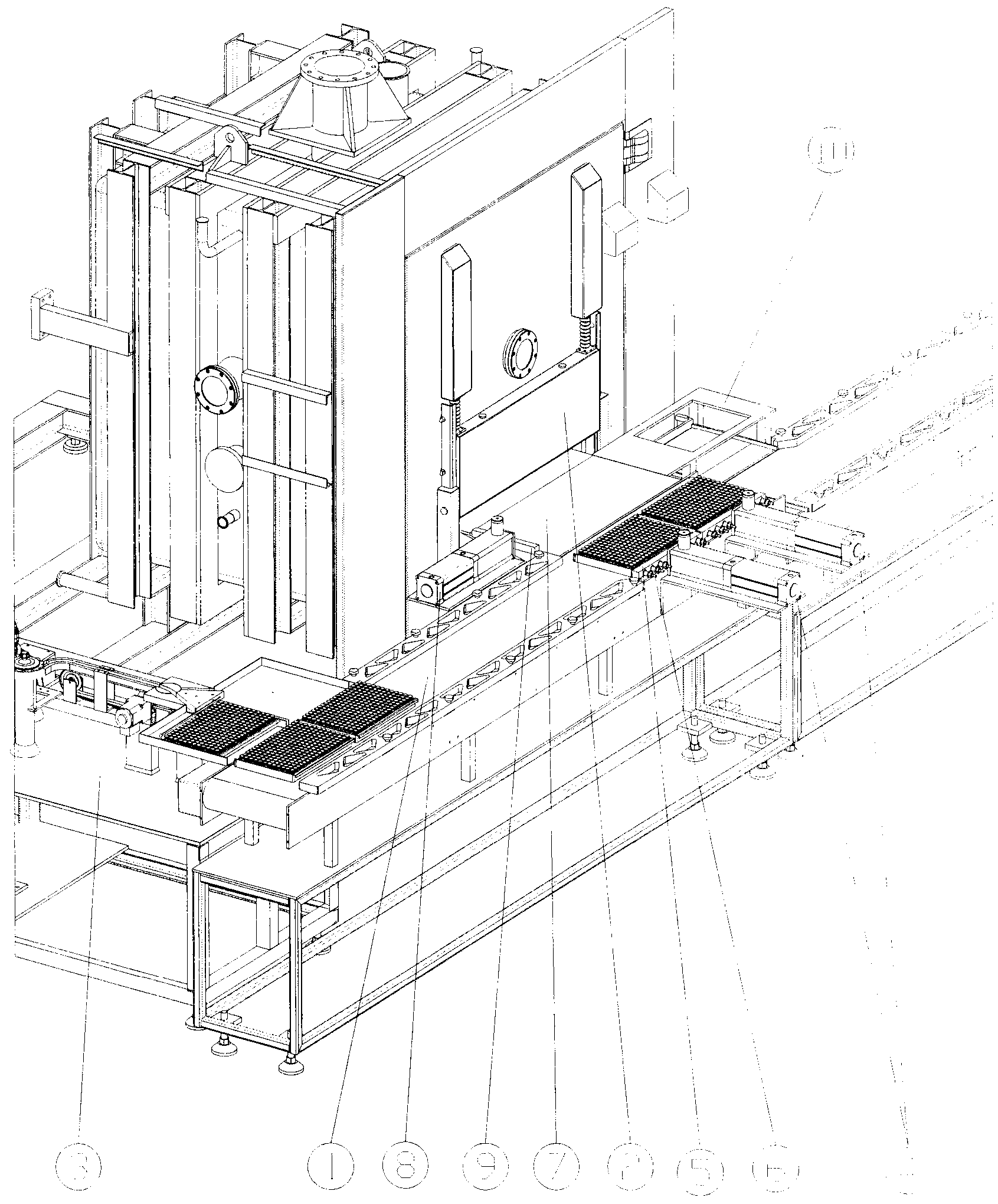

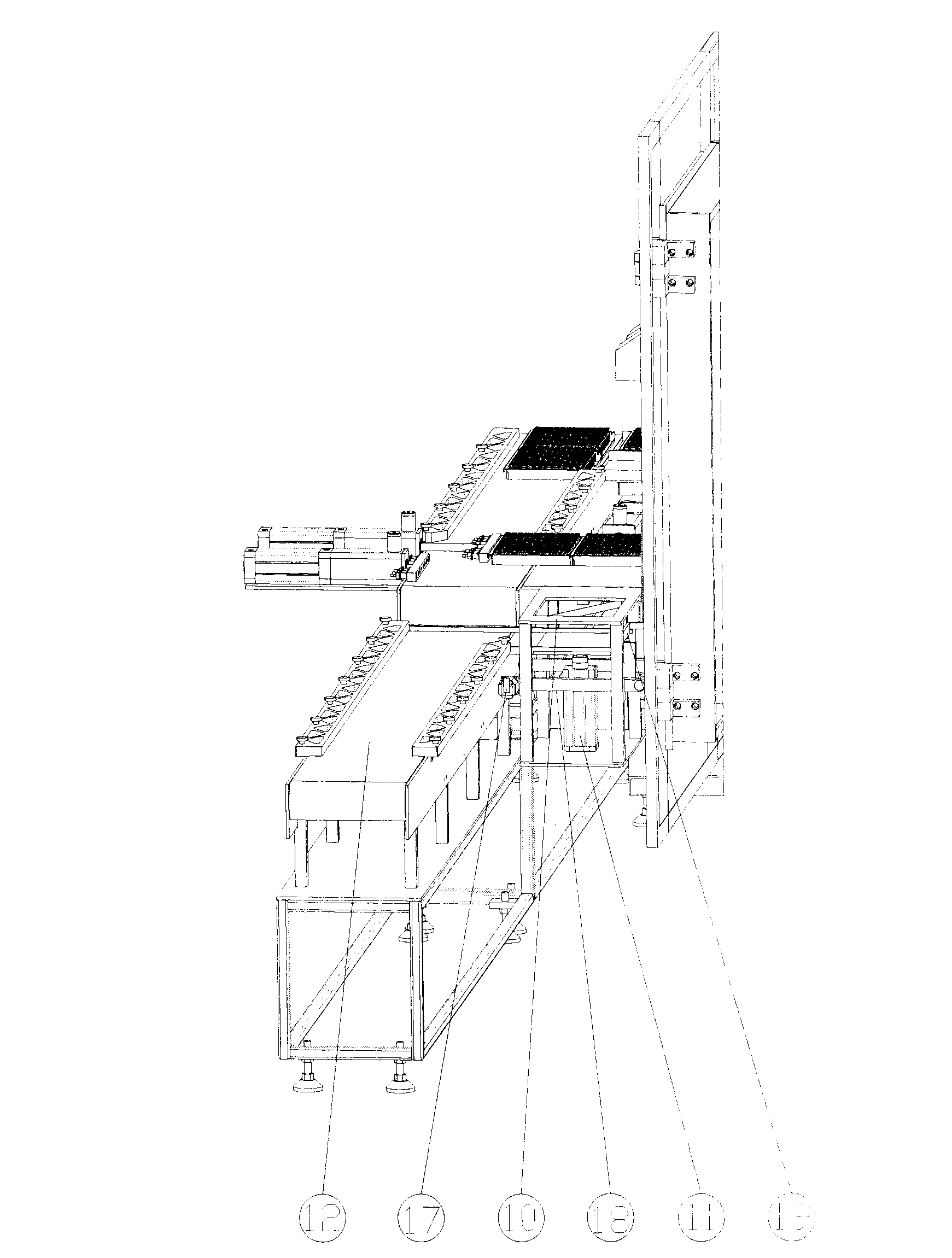

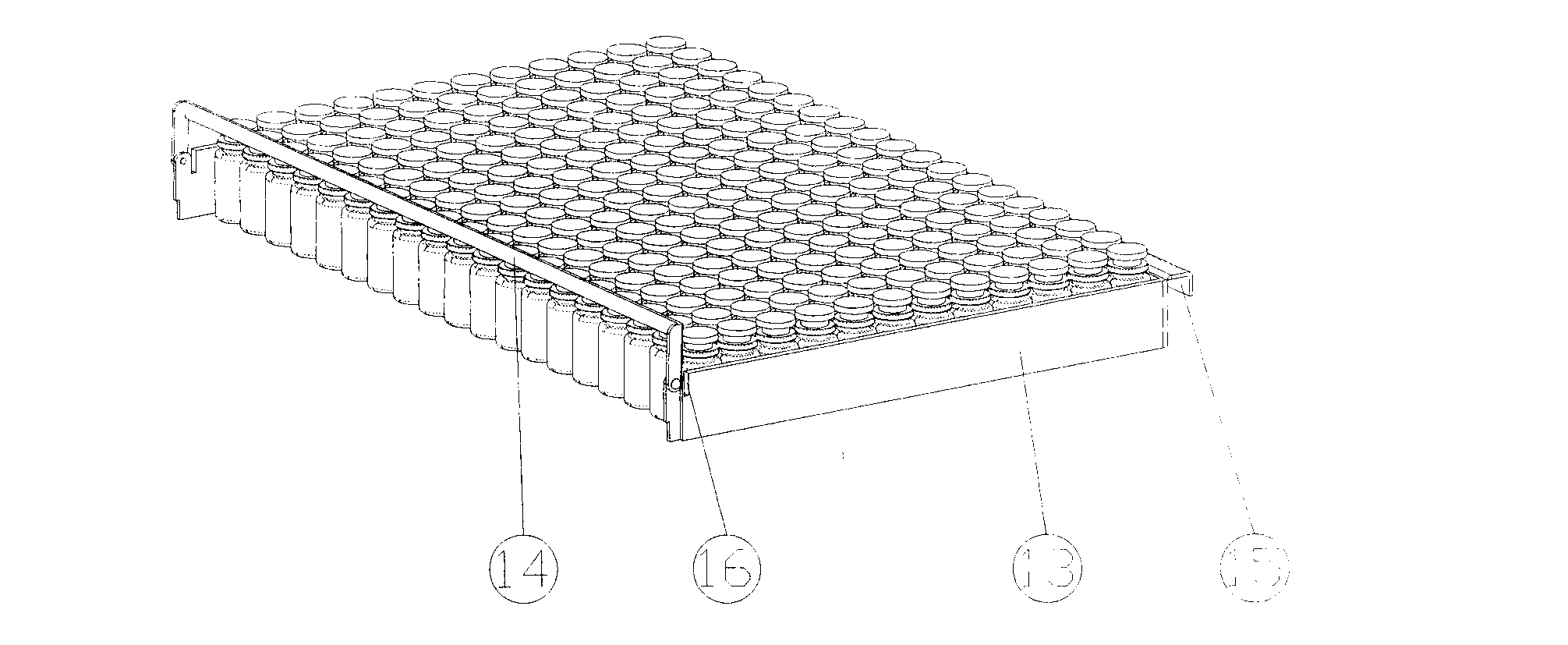

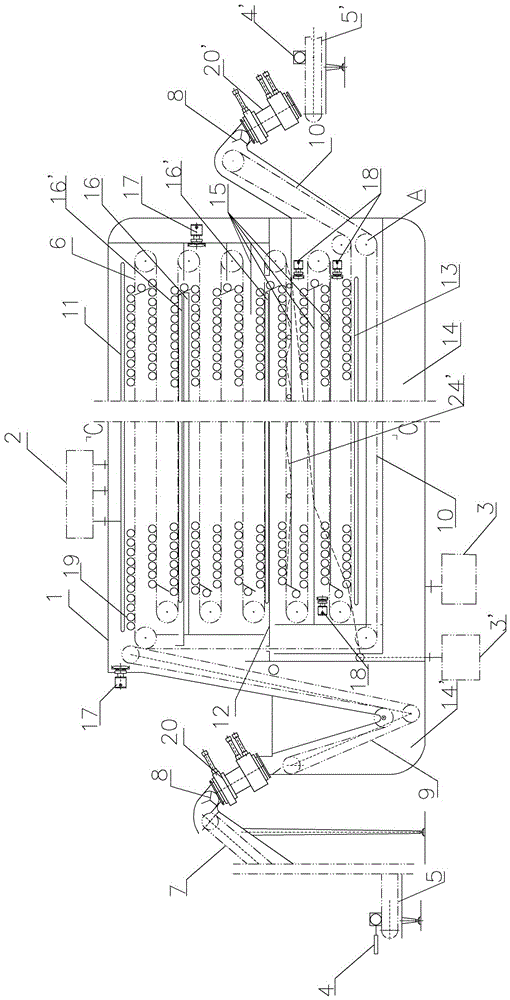

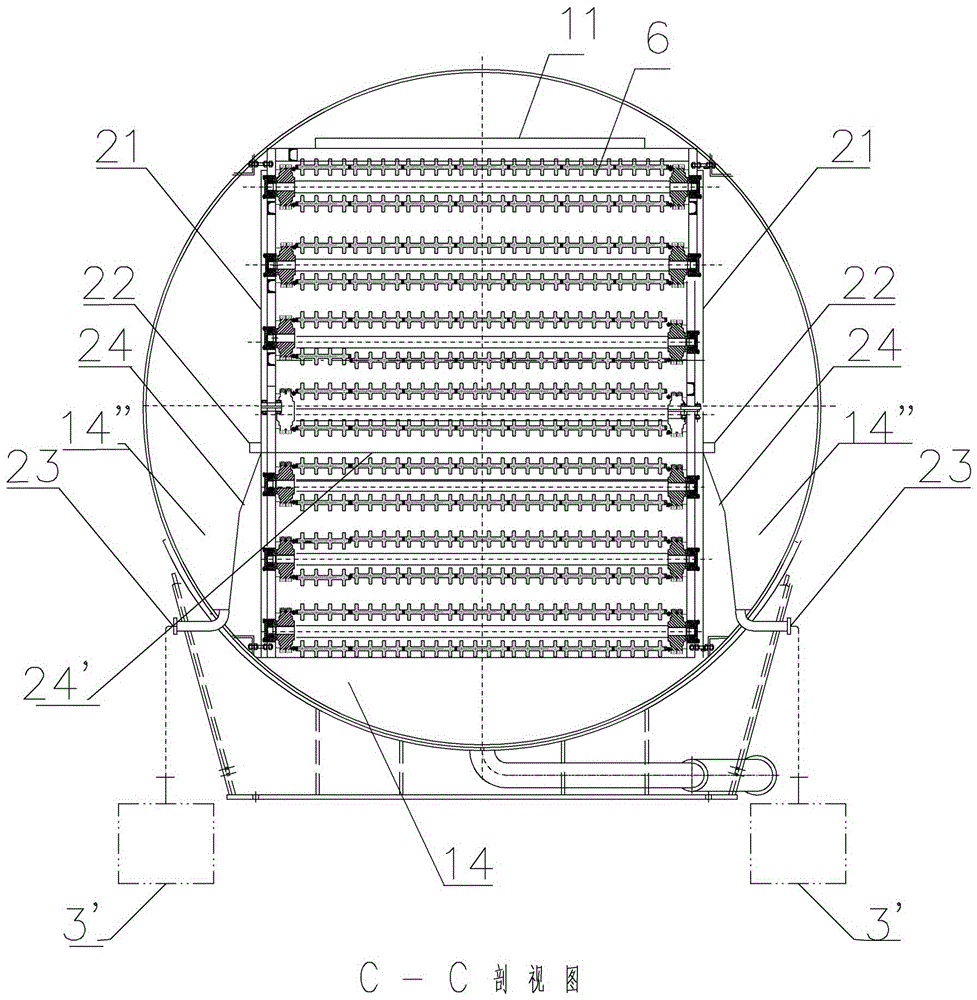

Automatic frame-type penicillin bottle preparation feeding and discharging device of freeze dryer

ActiveCN103256802ARealize automatic loading and unloadingImprove work efficiencyDrying solid materialsPenicillinBiochemical engineering

Disclosed is an automatic frame-type penicillin bottle preparation feeding and discharging device of a freeze dryer. The integral automatic frame-type penicillin bottle preparation feeding and discharging device is fixed on the front side of the freeze dryer via a rack, two feeding linear guide rails are fixed on the outer side, right facing a small feeding gate, of a feeding conveyor belt, feeding push rods are mounted on the front portions of the feeding linear guide rails, vacuum suction discs are mounted inside the feeding push rods, a discharging linear guide rail is mounted on the left side of a bridging platform, a bottle push rod is mounted on the front portion of the discharging linear guide rail, a frame-off platform is mounted on the right side of the bridging platform, a discharging conveyor belt is mounted right in front of the frame-separating platform, a frame-separating air cylinder is mounted below the frame-separating platform, and a scraper plate is arranged on the frame-separating platform. By the automatic frame-type penicillin bottle preparation feeding and discharging device of the freeze dryer, automatic feeding and discharging of penicillin bottle preparation to the freeze dryer are realized, working efficiency is greatly improved, operation is safe, bottles are prevented from falling off, and in the whole process, no operators are involved in operation, so that manufactured products cannot contaminated by the operators, percentage of pass of the products is effectively guaranteed to reach 100%, the products meet GMP (good manufacturing practice) requirements, and guarantee of health of people is facilitated.

Owner:SHANGHAI SUPARMIN ELECTROMECHANICAL SCI & TECH CO LTD

Bottle clamp mechanism

The invention discloses a bottle clamp mechanism which is characterized by comprising a cylinder. The cylinder is arranged on a cylinder fixing base, a cylinder piston rod on the cylinder is connected with one end of a push rod, a bottle clamp driving shaft is arranged on one side of the other end of the push rod, the bottle clamp driving shaft penetrates through a tail through hole of a bottle clamp installation left fixed block and a tail through hole of a bottle clamp installation right fixed block, the bottle clamp installation left fixed block and the bottle clamp installation right fixed block are connected through a bottle clamp installation plate, the bottle clamp installation plate is connected with a primary bottle clamp and a secondary bottle clamp through bottle clamp rotating pins, teeth of the primary bottle clamp and teeth of the secondary bottle clamp are meshed with each other, and the tail of the primary bottle clamp is contacted with the bottle clamp driving shaft. The bottle clamp mechanism has the advantages of being simple in structure, stable to operate, adjustable in bottle clamp opening, capable of performing overload protection, wide in application range and the like.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

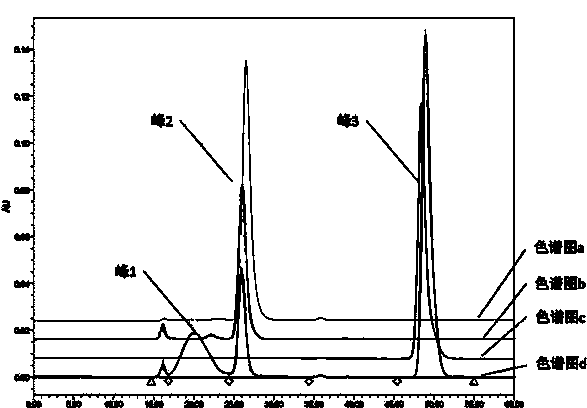

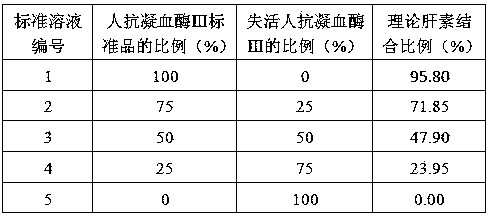

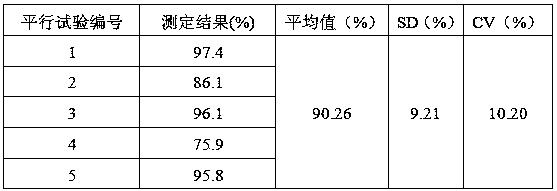

Human anti-thrombin III heparin combination ratio detection method

ActiveCN103743837ASimple methodEliminate immunoassay workComponent separationPhosphoric acidBuffer solution

The invention discloses a human anti-thrombin III heparin combination ratio detection method. The detection method comprises the steps of using an efficient size exclusion chromatography column and a sodium salt buffer solution with mobile phases comprising isopropanol and phosphoric acid at pH of 6.0-7.5 to calculate a combination ratio between the human anti-thrombin III and the heparin through a ratio of an area of characteristic peak and a corresponding standard curve; adding inactivated human anti-thrombin III into a standard product of the human anti-thrombin III according to a ratio, and manufacturing a standard curve according to change of the ratio of the area of characteristic peak. According to the method, the human factors are excluded; the accuracy and the precision of results are high, the experiment operation steps are simple, the detection time can be shortened, the experiment cost is reduced and the working efficiency of detectors is greatly improved.

Owner:SHANDONG TAIBANG BIOLOGICAL PROD CO LTD

Preparation method of ziprasidone or its salt inclusion

InactiveCN1839839AImprove stabilityShort timePowder deliveryOrganic active ingredientsZiprasidoneInclusion compound

The invention relates to a process for preparing Ziprasidone or its salt inclusion compound, which comprises the steps of, (1) providing a solution of Ziprasidone or its salts, heating the solution at 78+-1.5 deg C to dissolve Ziprasidone or its salts, (2) filtering non-soluble substance in the solution, then drying the dissolvent.

Owner:SHANGHAI INST OF PHARMA IND

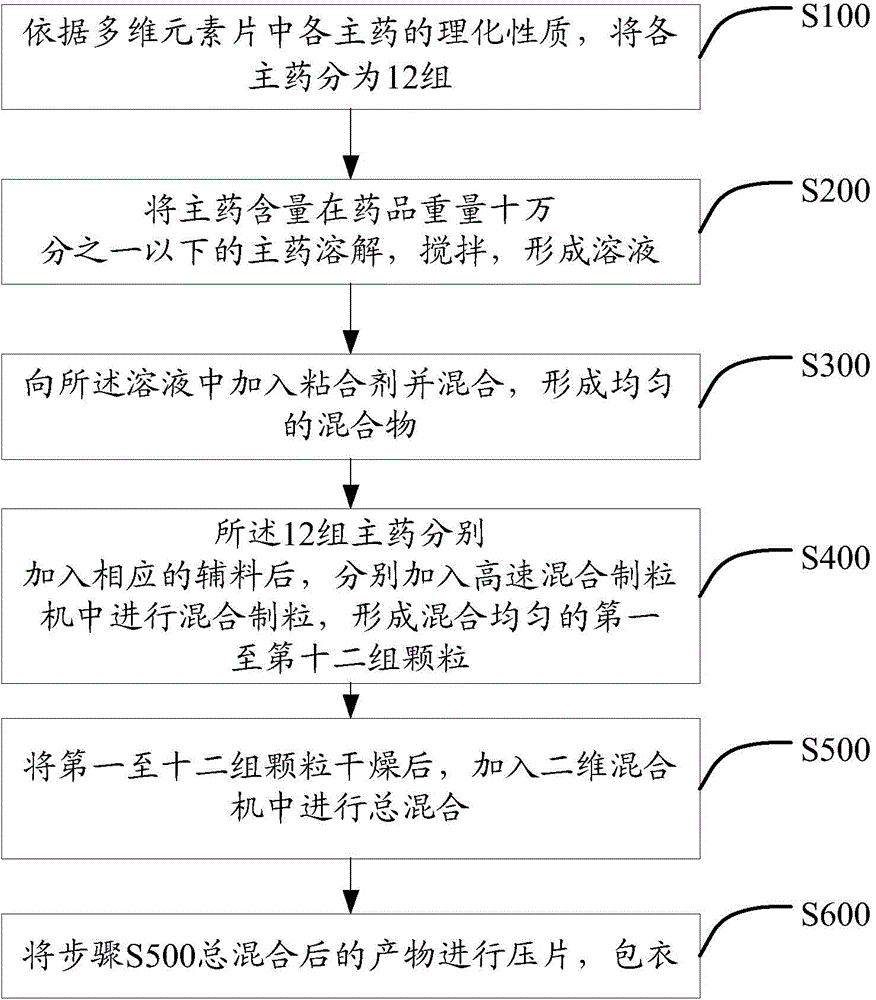

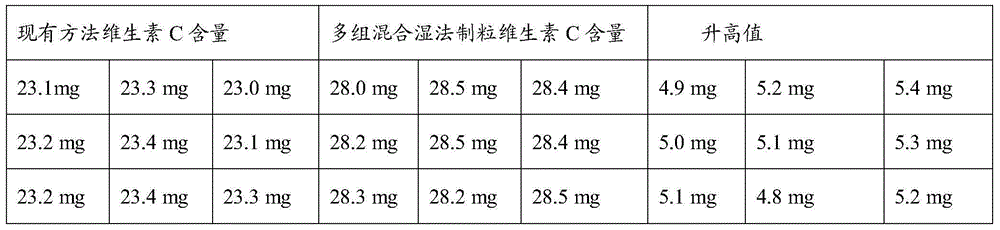

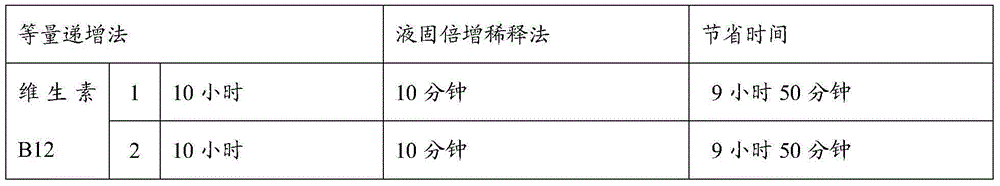

Multivitamin and mineral tablet and mixing granulation technology thereof

InactiveCN104666341AImprove product qualityLow costHeavy metal active ingredientsHydroxy compound active ingredientsAdhesiveMultivitamin

The invention provides a multivitamin and mineral tablet and a mixing granulation technology thereof. The mixing granulation technology comprises the following steps: A dividing main medicines into 12 groups according to the physicochemical properties of the main medicines in the multivitamin and mineral tablet; B dissolving and stirring the main medicines of which the content is smaller than one-hundred-thousandth of weight of the medicines to form a solution; C adding an adhesive to the solution, mixing and forming a uniform mixture; D operating the 12 groups of main medicines according to the methods in the steps A, B and C, respectively adding corresponding auxiliary materials to each group of mixture, respectively adding to a high-speed mixing granulator, and carrying out mixing granulation, so as to form 1-12 groups of uniform particles; and E drying the 1-12 groups of particles, adding to a two-dimensional mixing machine, carrying out total mixing, tabletting and coating. According to the method, raw materials are effectively saved; the mixing frequency is reduced; the pollution risk is reduced; and the requirements of GMP (good manufacturing practice) are met.

Owner:SHANGHAI WORLDBEST ANHUI JINHUI PHARMA CO LTD

Filling structure

ActiveCN103303507APrecisely adjust the openingImprove compatibilityFilling without pressureLiquid materialDrive shaftEngineering

The invention relates to a filling structure which comprises a diaphragm valve with a metal diaphragm sheet, an adapter joint which can be rapidly detached, a top rod, a driving shaft, a mounting board, a fixing base and a fixed joint. The filling structure is characterized in that the diaphragm valve is detachably fixed on the adapter joint; the adapter joint is in detachable connection with the fixed joint; the top rod is arranged inside the adapter joint and the fixed joint; the end part of the driving shaft extends into the fixed joint to be connected with the top rod; the driving shaft drives the top rod to move forwards or backwards under the driving of a driving mechanism; when the top rod moves forwards in place, the end part of the top rod is propped against the metal diaphragm sheet of the diaphragm valve so as to close the diaphragm valve; when the top rod retreats, the metal diaphragm sheet of the diaphragm valve is reset under the action of the self elasticity, then the diaphragm valve is opened. The filling structure is simple in structure, convenient to assemble and disassemble, high in filling precision and capable of realizing SOP (Standard Operation Process) / SIP (Standard Inspection Process) compatibility, no other equipment needs to be changed for a dosage of 0.1-20 ml, and the complete isolation of a filling area from a driving part is realized.

Owner:上海东富龙生物试剂有限公司

Spray-needle buckled type quick connector for bottle washing machine

InactiveCN102615078AQuality assuranceChange the thread seal connection methodCleaning processes and apparatusEngineeringBottle

The invention relates to a spray-needle buckled type quick connector for a bottle washing machine, which comprises a spray needle, a spray needle frame and a sealing pad. The spray needle comprises a convex head spray needle seat and a needle tube which are welded together. The spray needle frame comprises a concave head spray needle seat and a support. The sealing pad with effect of sealing and shock absorption is arranged at the connection position between the spray needle and the spray needle frame. The buckled quick connector uses unique design of connection between the spray needle and the spray needle frame, changes an original threaded sealing connection method between the spray needle and the spray needle frame into quick buckled sealing connection, avoids secondary pollution, guarantees cleaning quality of bottles and meets requirements of new-edition good manufacturing practice (GMP).

Owner:上海千山远东制药机械有限公司

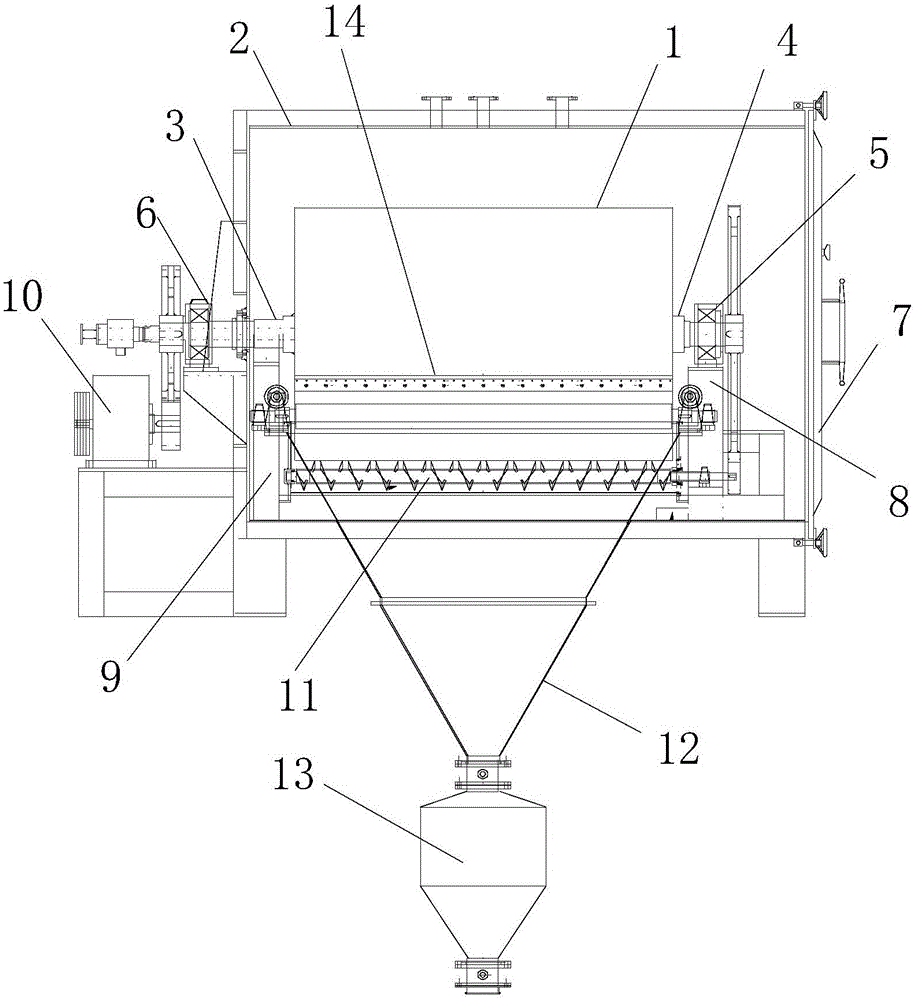

Vacuum type roller scraping plate drying machine

InactiveCN105020987AIncrease vacuumRealize acquisitionDrying solid materials without heatPulp and paper industryEnd face mechanical seal

The invention relates to a vacuum type roller scraping plate drying machine. The drying machine comprises a main cylinder body. A vacuum cylinder is arranged outside the main cylinder body. The main cylinder body is arranged in the vacuum cylinder in a rotating mode. The upper end of the vacuum cylinder is provided with at least one vacuumizing opening. One end of the main cylinder body is provided with a drive rotating shaft. The other end of the main cylinder body is provided with a driven rotating shaft. The drive rotating shaft of the main cylinder body stretches out of the vacuum cylinder. Mechanical end face sealing is formed between the drive rotating shaft and the vacuum cylinder. The driven rotating shaft of the main cylinder body is supported in the vacuum cylinder in a rotating mode. A material groove is formed below the main cylinder body. A rotatable stirring shaft is arranged in the material groove. The stirring shaft is in transmission fit with the driven rotating shaft. By means of the vacuum type roller scraping plate drying machine, the vacuum degree in the vacuum cylinder is increased, gas generated due to volatilization of material liquid in the vacuum cylinder is not prone to being mixed with impurities, and therefore the purpose that the high-purity gas formed through volatilization of raw materials is collected in the vacuumizing openings is achieved.

Owner:CHANGZHOU JINLING DRYING EQUIP

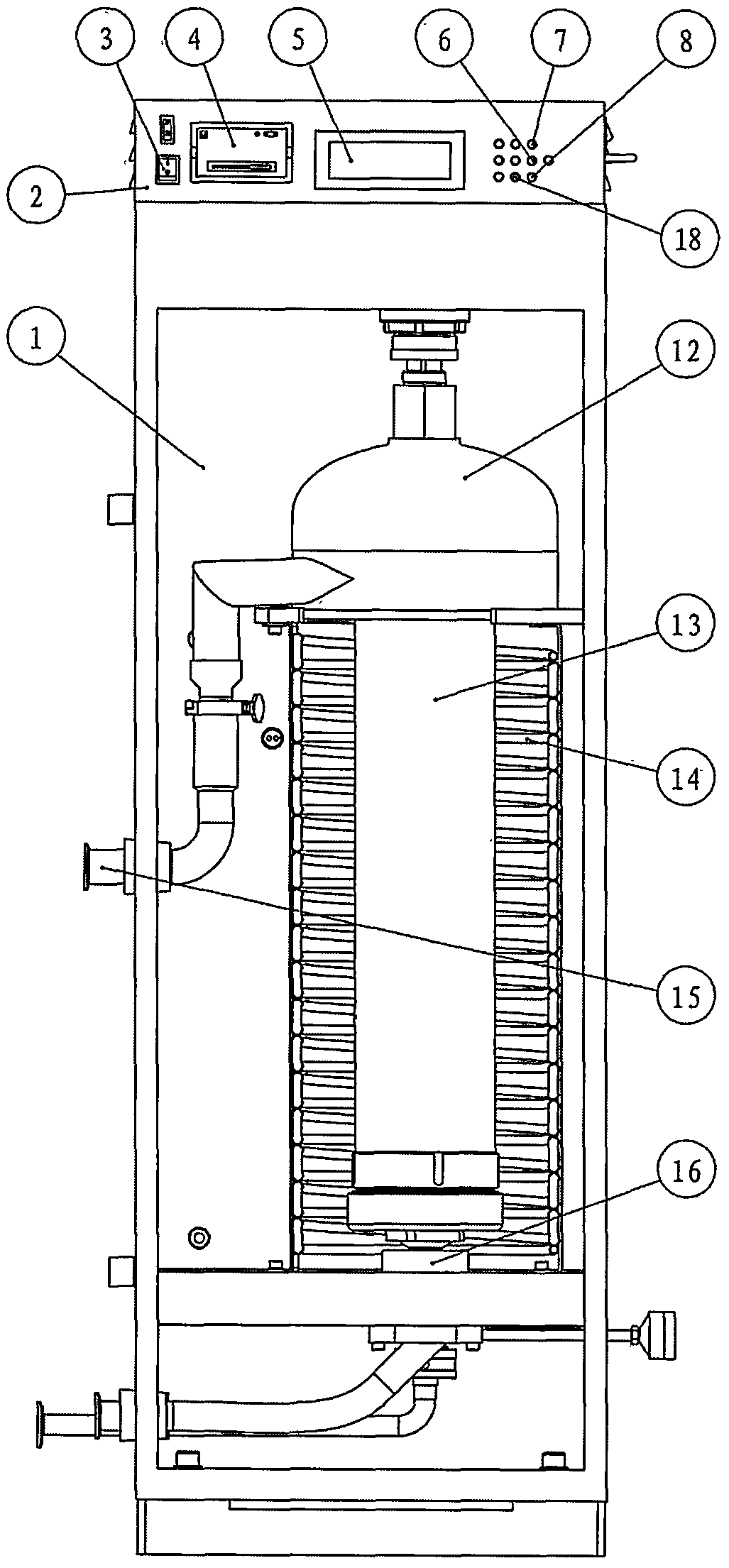

On-line monitoring type tube centrifuge and separation technology thereof

InactiveCN104338617AEasy to controlControl real-time controlRotary centrifugesAutomatic controlControl system

Disclosed are an on-line monitoring type tube centrifuge and a separation technology thereof. The separation technology includes adjusting various materials through a control system, then monitoring the surface of a rotor drum to send a signal to a control system with a microprocessor, leading to the separation under the stated temperature, and sending the separation simultaneously to the automatic control of a control display screen; during the separation, subjecting the materials to entering the rotor drum in the high-speed revolution through a feed pipe to perform the separation, causing liquid to return through a discharging outlet of a liquid accumulating plate, and solid to descend at the bottom of the rotor drum, and discharging the rotor drum to pour the solid. Compared with the prior art, the on-line monitoring type tube centrifuge and the separation technology thereof have the advantages that temperature is measured in the non-contact manner, the temperature is set before the separation, and parameters are adjusted during the separation to achieve timely control; automation degree is high, operation is convenient, the temperature of the materials in the centrifuge is timely controlled, and the like, and accordingly, the material quality is accurately controlled; the separation is displayed on the display screen and a printer through the microprocessor in the visual and convenient manner, and GMP (good manufacturing practice) requirements are met.

Owner:SHANGHAI ZHIZHENG CENTRIFUGE

Online monitoring tubular centrifugal machine and separation monitoring process thereof

InactiveCN103203290AReal-time display speedAccurate quality controlRotary centrifugesMicrocomputerPulp and paper industry

The invention relates to an online monitoring tubular centrifugal machine and a separation monitoring process thereof. The online monitoring tubular centrifugal machine is entirely arranged in a machine body, a lower damper is fixed in the inner lower part of the machine body, the upper part of the lower damper is connected with a rotary drum through a bearing, the rotary drum is provided with a liquid accumulation disc, a rotating shaft of a machine head penetrates through the liquid accumulation disc to be connected with the rotary drum through a bearing, the liquid accumulation disc is connected with a discharging pipe, a feeding pipe penetrates through the lower damper to stretch into a cavity of the rotary drum, and a monitoring system is arranged in a top housing. Compared with the prior art, the online monitoring tubular centrifugal machine has the advantages of being simple in structure, convenient to operate and high in automation degree, the rotation speed of the centrifugal machine, the temperature of in / out materials and the separation time can be displayed in real time, and the quality of the materials can be more precisely controlled and displayed on a display screen and a printer after being processed by a microcomputer, therefore, intuition and simplicity can be realized, and the requirements of GMP (Good Manufacturing Practice) can be met.

Owner:SHANGHAI ZHIZHENG CENTRIFUGE

Preparation method of common andrographis herb bitter granules

InactiveCN109106783AStrengthen the function of clearing heat and detoxifyingChange to high heat decoctionAntiviralsGranular deliveryMedicinal herbsSucrose

The invention discloses a preparation method of common andrographis herb bitter granules. The method comprises the steps of placing common andrographis herb, radix astragali seu hedysari, fructus evodiae, radix et rhizoma rhei, radix angelicae dahuricae, radix sophorae flavescentis, herba taraxaci, radix pulsatillae chinensis and liquorice root into an extraction tank to form a medicine layer, adding water for soaking, and then adjusting the operating temperature of the extraction tank to be 70-80 DEG C; leading out extract from the bottom of the extraction tank in an extracting process and concentrating under the reduced pressure, wherein the concentration temperature is 60-70 DEG C; condensing steam, produced by concentration, as a new solvent, and returning to the extraction tank for carrying out percolation extracting on the medicine layer; repeating the operations for 2-4h, and finally concentrating to obtain fluid extract; taking saccharose and cyclodextrin and then adding into aspray drying granulating machine together with the fluid extract for granulating so as to obtain the common andrographis herb bitter granules. According to the preparation method, the two processes,i.e., extraction and concentration of raw medicine materials are performed synchronously, and changes the process of high-temperature boiling, concentration and fractionation in the traditional extraction tank with pressure and under the atmospheric pressure, thus saving the energy by 0.2-0.4 time, reducing the consumption of a water solvent by 0.3-1 time, and saving labor time by 1-2h; furthermore, after the preparation method is adopted, the extract yield is increased by about 12%, and the product cost is lowered.

Owner:ZHENGZHOU HOUYI PHARMA

Continuous high temperature sterilization and water bath cooling integrated processing equipment

InactiveCN103508011BChange physical indicatorsShort time intervalPackage sterilisationWater bathsWarm water

Owner:浙江智宝婴童用品有限公司

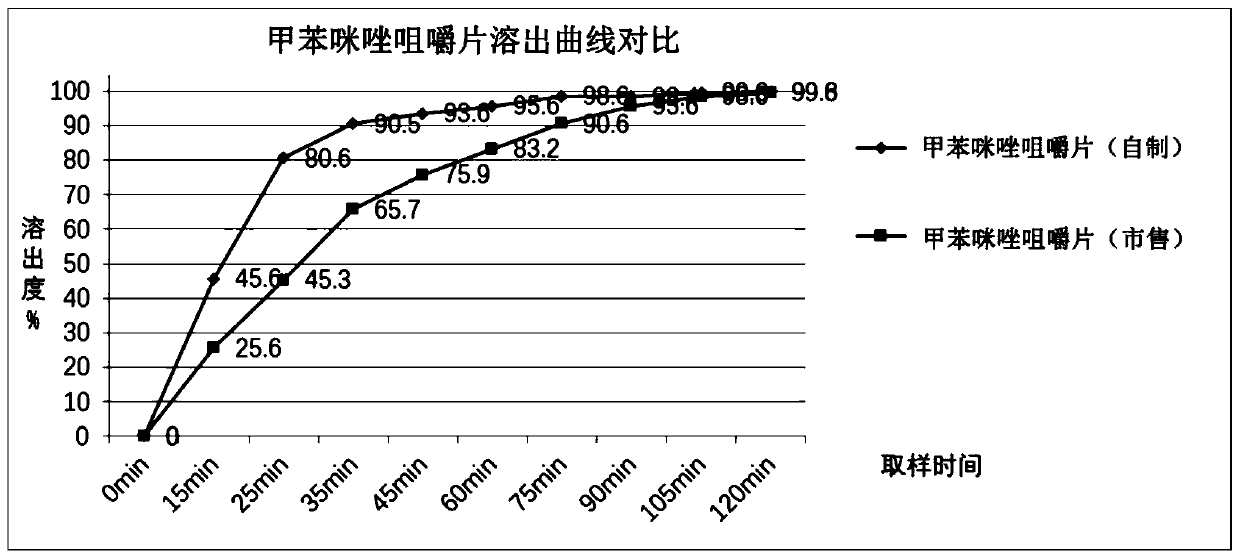

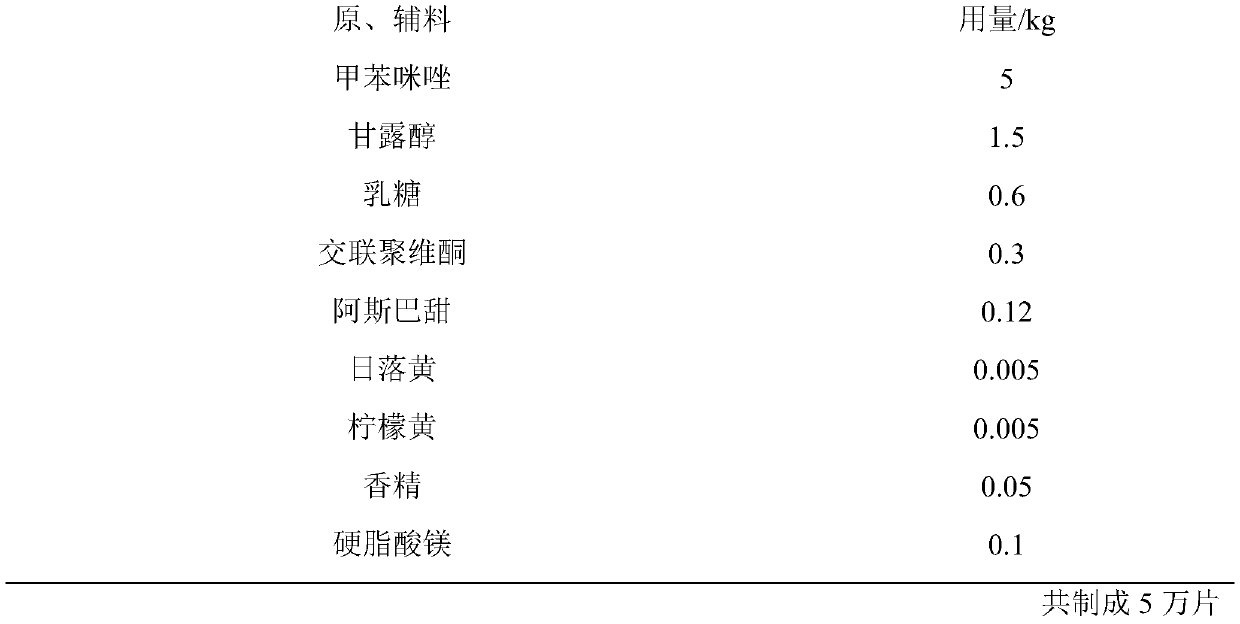

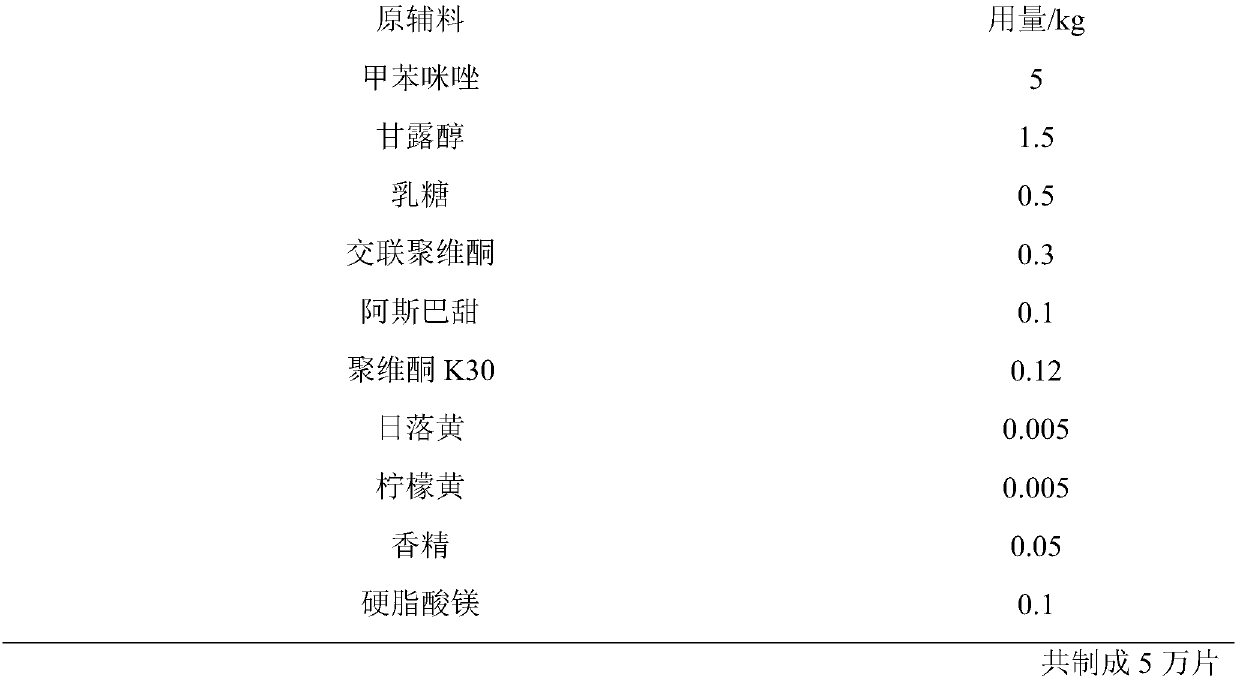

Preparation method of mebendazole chewable tablets

ActiveCN111494327AGreat tasteAvoid side effectsOrganic active ingredientsPill deliveryFluidized bedMebendazole

The invention belongs to the technical field of medicines, and particularly relates to a preparation method of mebendazole chewable tablets. The preparation method comprises the following steps: (1) adding mebendazole and auxiliary materials into a wet granulator according to a prescription amount, and premixing the components; (2) adding a prescription amount of adhesive, sunset yellow and lemonyellow to prepare a soft material; (3) granulating the prepared soft material by using a wet granulating machine; (4) pumping the wet granules into a fluidized bed for drying by using vacuum, and straightening the granules by using a crushing and straightening machine; and (5) adding essence and a lubricant into the granulated granules, mixing all the components, and tabletting the mixture to obtain the mebendazole chewable tablet. The preparation method disclosed by the invention is simple in process and good in batch-to-batch reproducibility, the production process meets the requirements ofGMP, and the preparation method is suitable for industrial large-scale production; the chewable tablet prepared by the method is stable in quality and good in taste.

Owner:REYOUNG PHARMA

Pharmaceutical pellet cores and preparation method thereof

ActiveCN102600475BRound shapeUniform particle size distributionPharmaceutical product form changePharmaceutical non-active ingredientsFluidized bedDrug carrier

Owner:珠海润都制药股份有限公司

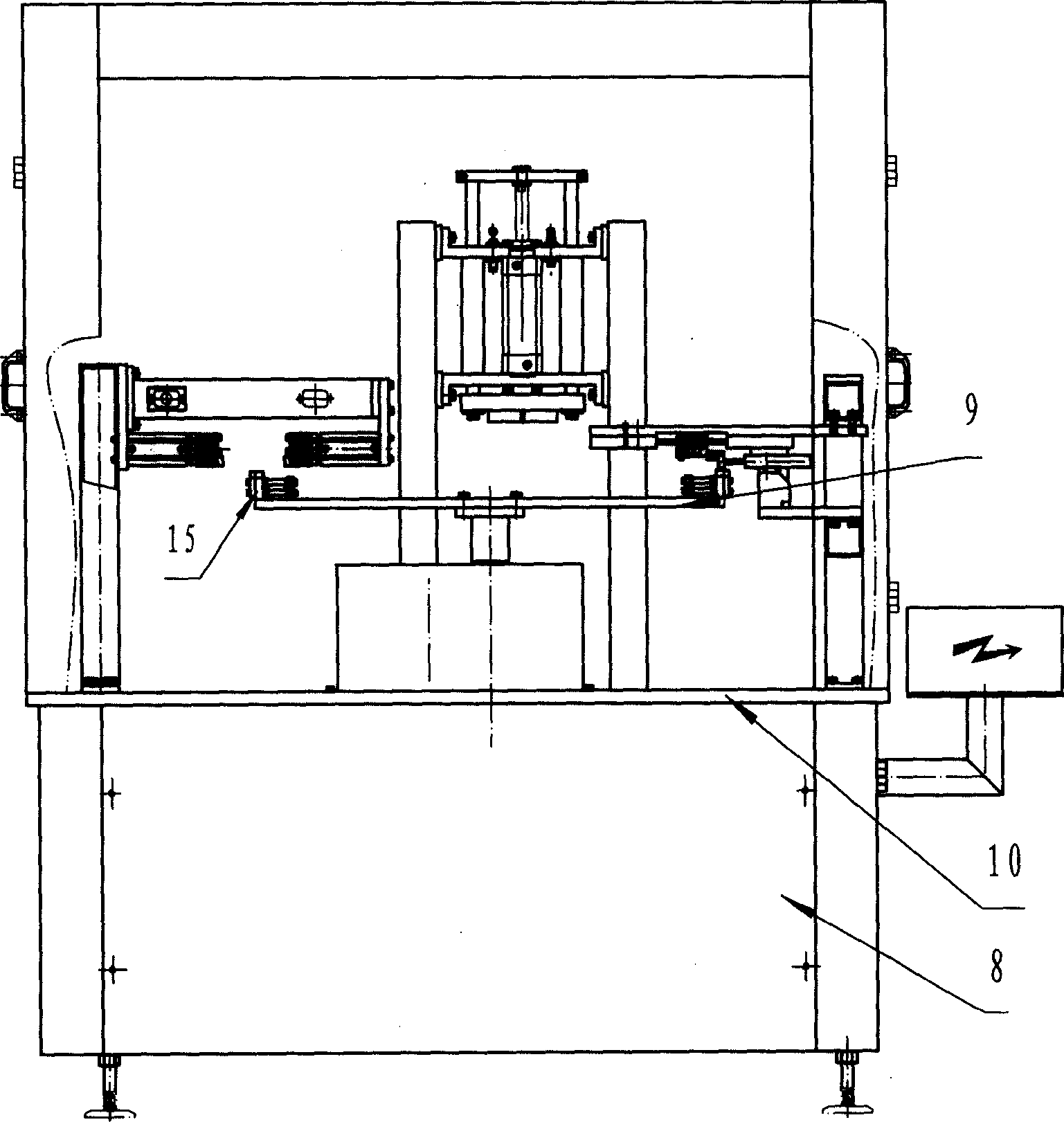

A weighing and clamping mechanism

ActiveCN103252775BHigh movement precisionSmooth accelerationProgramme-controlled manipulatorDrive shaftCoupling

The invention discloses a weighing clamping mechanism which comprises a rack. The weighing clamping mechanism is characterized in that a positioning rod is arranged in the rack, the left end of the positioning rod and the right end of the positioning rod are provided with a first synchronous belt wheel and a second belt synchronous wheel respectively, the first synchronous belt wheel and the second belt synchronous wheel are connected through synchronous belts, and the right end of the positioning rod is exposed out of the right side of the rack. A guide holder is arranged at the upper portion of the left side of the rack, a linear motor is arranged on each synchronous belt wheel, the bottom end of the linear motor is connected with each synchronous belt wheel through a shaft assembly, the top end of the linear motor is connected with the bottom end of a guide rod through a coupler, the top end of the guide rod is exposed out of the guide holder, and a clamping assembly is arranged on the top end of the guide rod. A speed reducer is arranged on each second synchronous belt wheel, the speed reducer is connected with the synchronous belt wheel through transmission shafts, and a servo motor is arranged on the speed reducer. The servo motor passes through the speed reducer, and drives the clamping assembly to rotate through a synchronous belt transmission mechanism. The linear motor drives the clamping assembly to move in a lifting mode through the guide rod. An air cylinder drives a bottle clamp to achieve opening or closing of the bottle clamp, and three kinds of motion are combined in order to achieve the functions of clamping, transporting and releasing.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

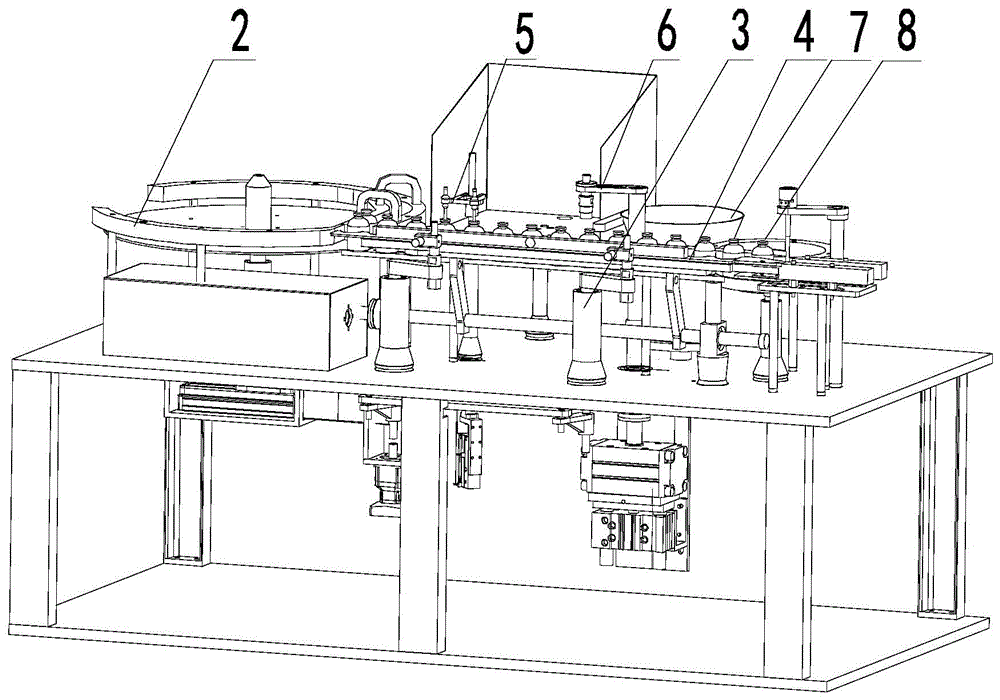

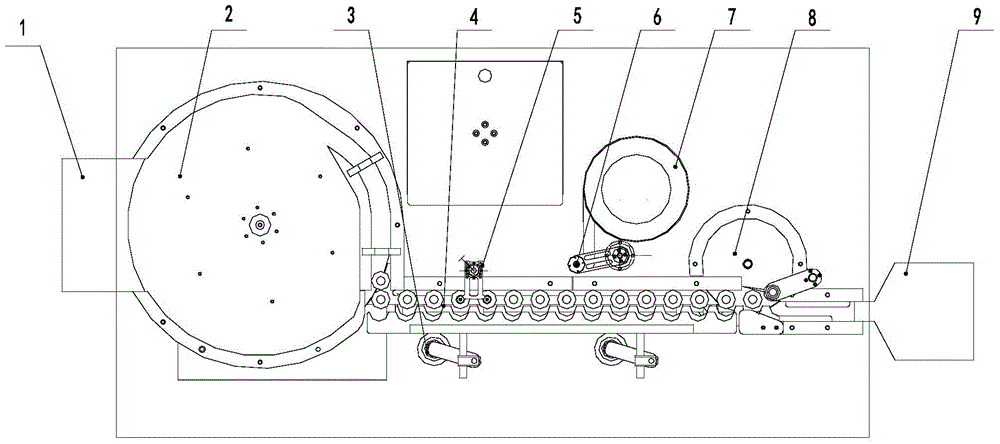

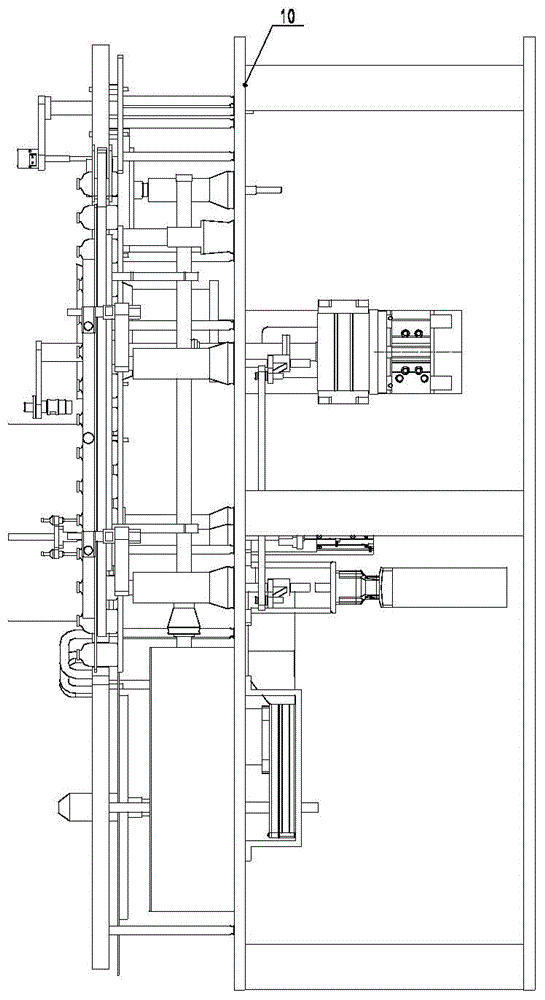

Single-head filling and capping machine

InactiveCN105129707ASimple structureReduce volumeBottle-handling machinesButt jointGood manufacturing practice

A single-head filling and capping machine comprises a rack and a bottle feeding disc; the bottle feeding disc is connected with a bottle arranging part; a bottle conveying part is located below the bottle arranging part and connected with the bottle arranging part; a medicine bottle locating part is arranged at the side, close to the bottle arranging part, of the bottle conveying part; a filling part is arranged at the other side of the bottle conveying part; the filling part, a capping part, a waste removing part and a bottle discharging part are arranged in sequence in the medicine bottle conveying direction; a cap arranging part is in butt joint with the capping part. The single-head filling and capping machine is simple in structure, small in size and low in cost, the problem that in the prior art, the sanitation of manual filling is substandard is overcome, meanwhile, a high-speed filling machine does not need to be occupied, and the single-head filling and capping machine is particularly suitable for the requirement for low-speed operation in the processes such as scientific research; transmission assemblies of the filling machine are all located below a table top of the rack, and the overall arrangement fully meets the requirements of new good manufacturing practice (GMP).

Owner:SHINVA MEDICAL INSTR CO LTD

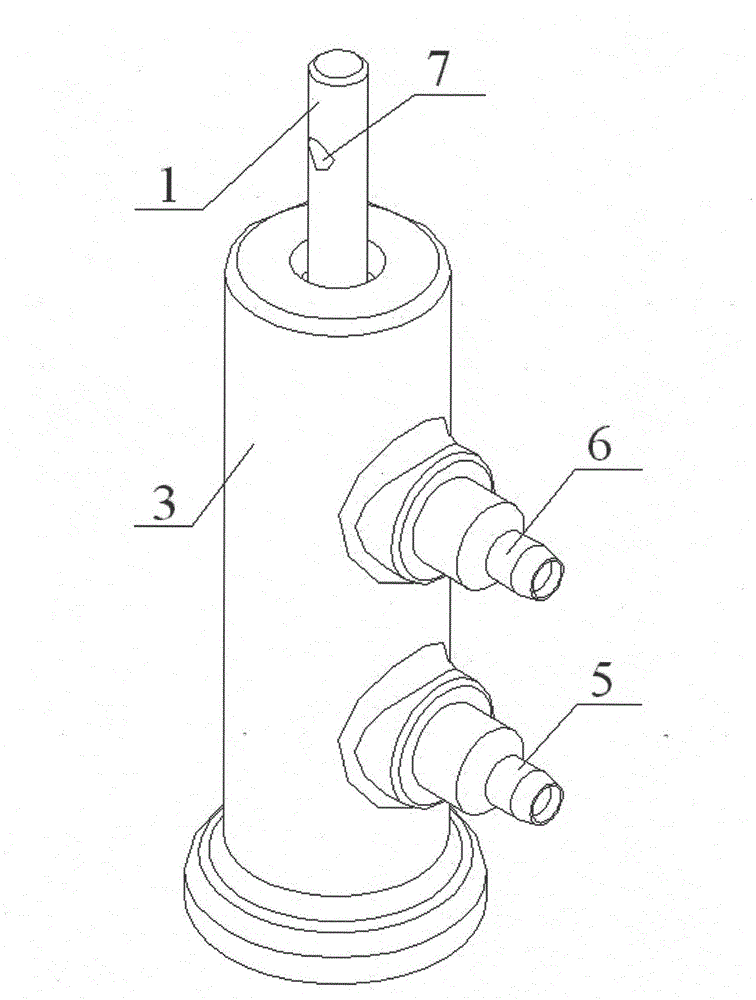

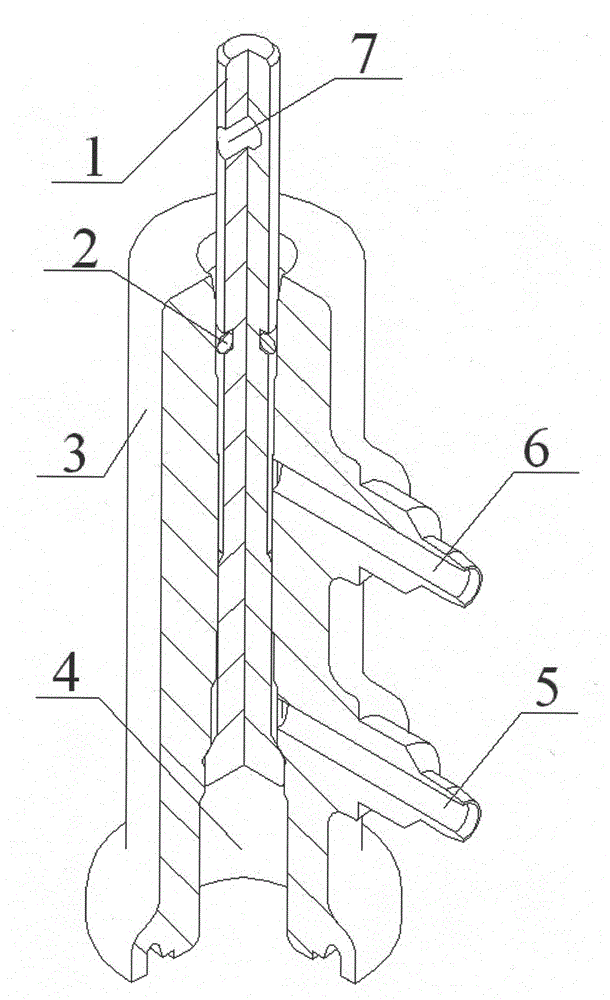

On-off valve used for time pressure method split charging and cip-sip

ActiveCN103256403BImprove machining accuracySolve the deformationMultiple way valvesAeration devicesMechanical engineeringTime pressure

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com