A weighing and clamping mechanism

A weighing and rack technology, used in the fields of medicine, food, and cosmetic packaging equipment, can solve the problems of difficult cleaning and disinfection, complex structure of the weighing and clamping mechanism, and difficult adjustment, etc., and achieves sensitive operation, easy cleaning and sterilization. , Improve the effect of motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

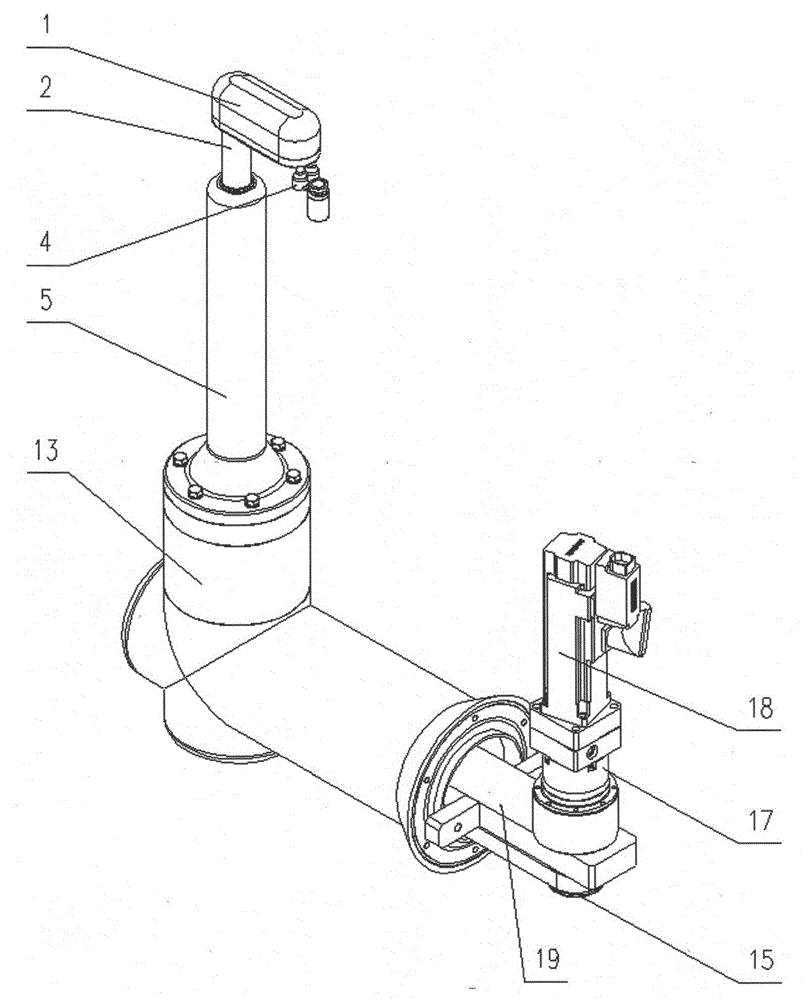

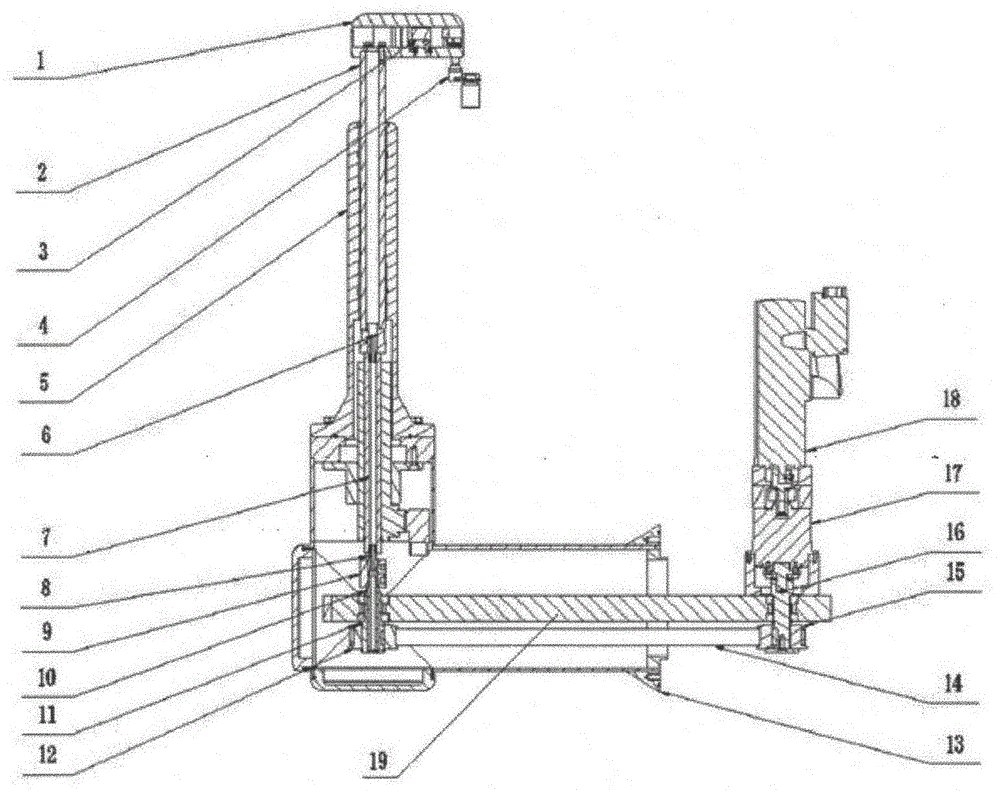

[0024] Such as Figure 1-2 As shown, it is a structural schematic diagram of the weighing and clamping mechanism provided by the present invention. A weighing and clamping mechanism includes a frame 13, and the frame 13 is in the shape of a hollow cross cylinder. Horizontally insert a positioning rod 19 in the frame 13, the left and right ends of positioning rod 19 are respectively provided with synchronous belt pulley one 12, synchronous belt pulley two 15, and synchronous belt pulley one 12, synchronous belt pulley two 15 overcoat one Timing belt 14. The right end of positioning rod 19 is exposed from the right side of frame 13 . Guide seat 5 is installed above the vertical direction cylinder on the left side of frame 13. A linear motor 7 is installed on the synchronous pulley 12, and the bottom end of the linear motor 7 is connected with the synchronous pulley 12 through a shaft assembly. One end is connected with the outer spline hollow shaft 10 through the coupling two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com