Filling structure

A filling and mounting board technology, which is applied in the fields of food, cosmetics packaging equipment, and medicine, can solve the problems that the filling structure cannot be cleaned off-line, cannot be cleaned in place, and the filling accuracy is low, so as to reduce cleaning risks and realize Versatility, the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

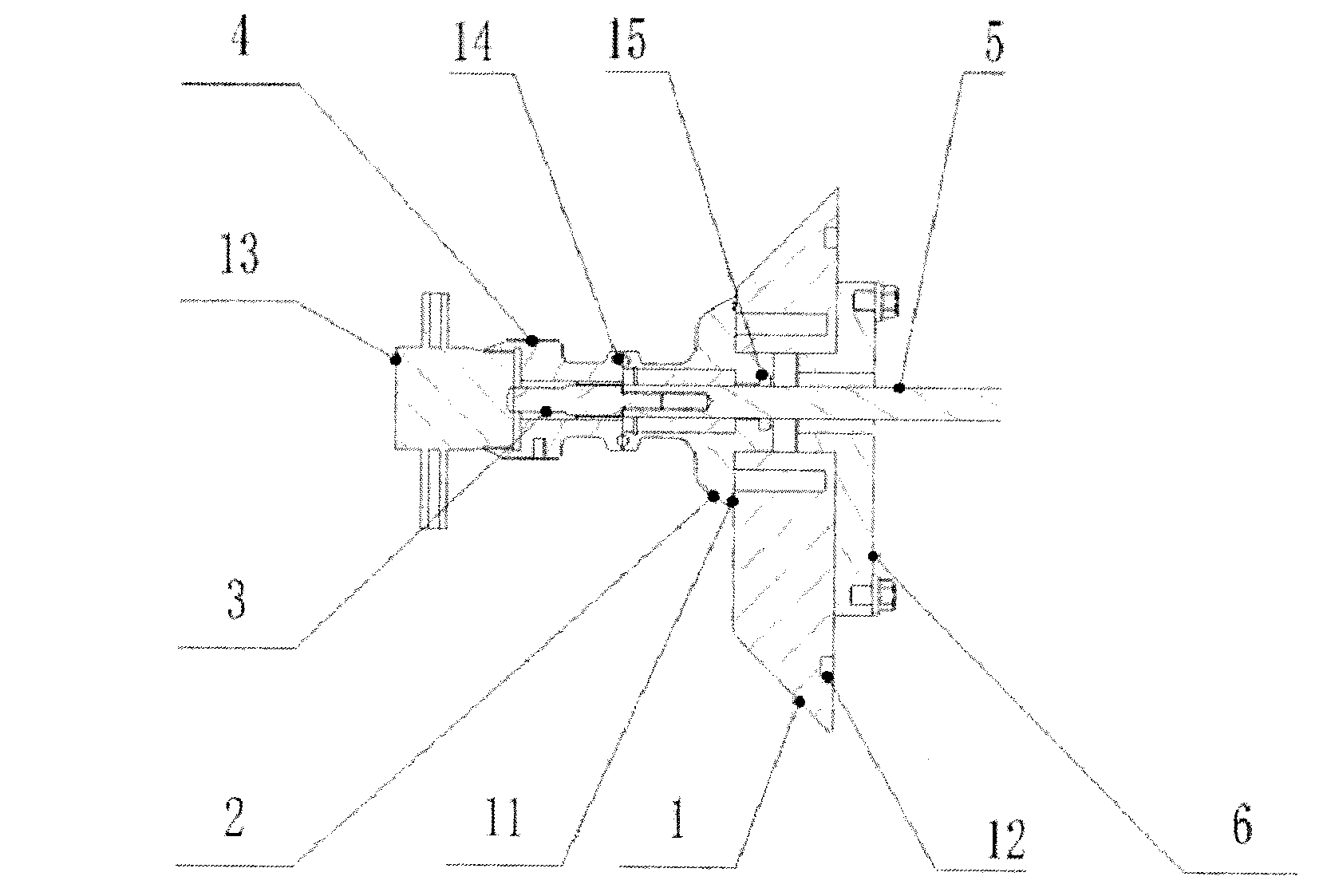

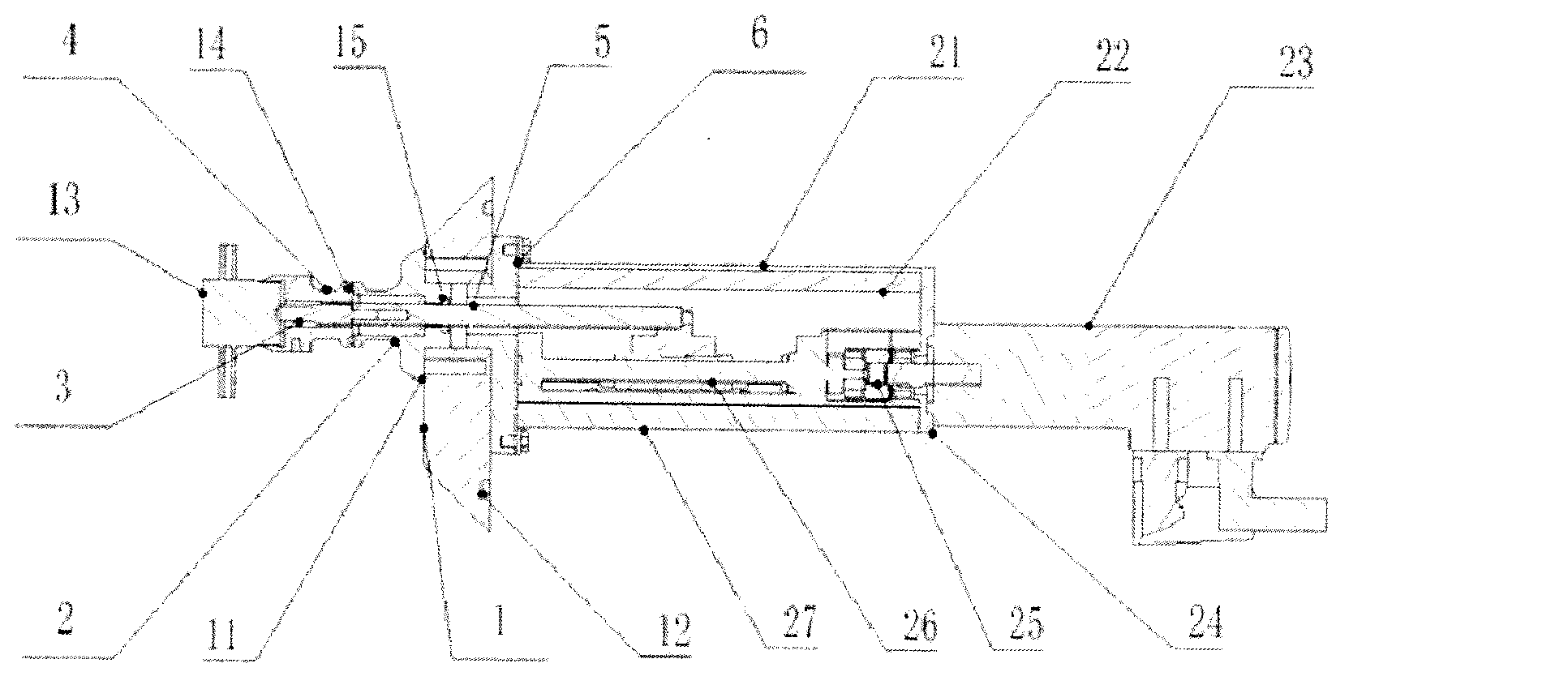

[0019] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0020] combine figure 1 and figure 2 , a filling structure disclosed in this embodiment includes a diaphragm valve 13 with a metal diaphragm. In this embodiment, the diaphragm valve 13 is a diaphragm valve with a temperature resistance of 150°C, which fully meets the requirements of SIP. The metal diaphragm has high durability and elasticity, and also includes an adapter joint 4, a push rod 3, a drive shaft 5, a mounting plate 6, a fixed base 1 and a fixed joint 2.

[0021] Mounting plate 6 is fixed on the lower support plate 27, there is a dust cover 21 above the lower support plate 27, a lead screw 26 is installed between the lower support plate 27 and the dust cover 21, and the output shaft of the servo motor 23 is connected through a high-precision coupling. The shaft device 25 is connected with the lead screw 26, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com