An intelligent integrated device for catalytic denitrification, de-CO and waste heat utilization

A catalytic denitrification and intelligent technology, applied in the field of sintering flue gas pollution prevention and control in the iron and steel metallurgy industry, can solve the problems of CO catalytic reaction equipment unable to meet the denitration demand temperature, not considering the fluctuation of sintering flue gas load, and the large area of can not be implemented. , to achieve the effect of reducing gas consumption, small footprint and increasing equipment height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

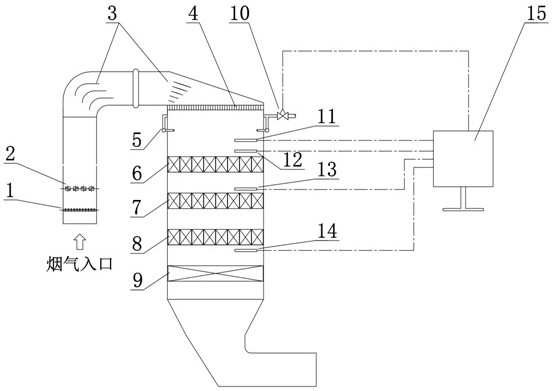

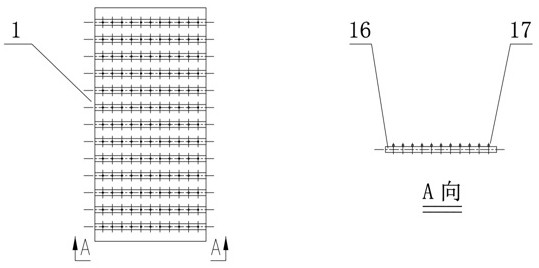

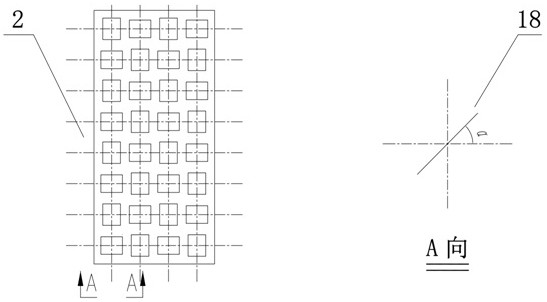

[0045] like figure 1 As shown in the figure, an intelligent integrated device for catalytic denitration, CO and waste heat utilization is provided. The inlet flue of the device is sequentially provided with an ammonia injection grill 1, a forced flue gas spoiler 2, a guide vane 3, and a rectifying grille. 4.

[0046] The device is provided with a built-in direct combustion furnace 5 , a de-CO catalyst layer 6 , a first-stage denitration catalyst layer 7 , a second-stage denitration catalyst layer 8 , and a backup catalyst layer 9 .

[0047] The device is provided with an intelligent control system, including intelligent control device 15, online CO concentration monitoring device 11, No. 1 online temperature monitoring device 12, No. 2 online temperature monitoring device 13, No. 3 online temperature monitoring device 14, supplemental combustion adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com