Filling system adopting time pressure method

A filling system and time pressure technology, used in the fields of medicine, food, and cosmetic packaging equipment, can solve the problems of the large influence of the filling volume stability, the low precision of small dose filling, and the inability to achieve in-situ sterilization. Cleaning risks, avoidance of contamination and cross-contamination, achieving universal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

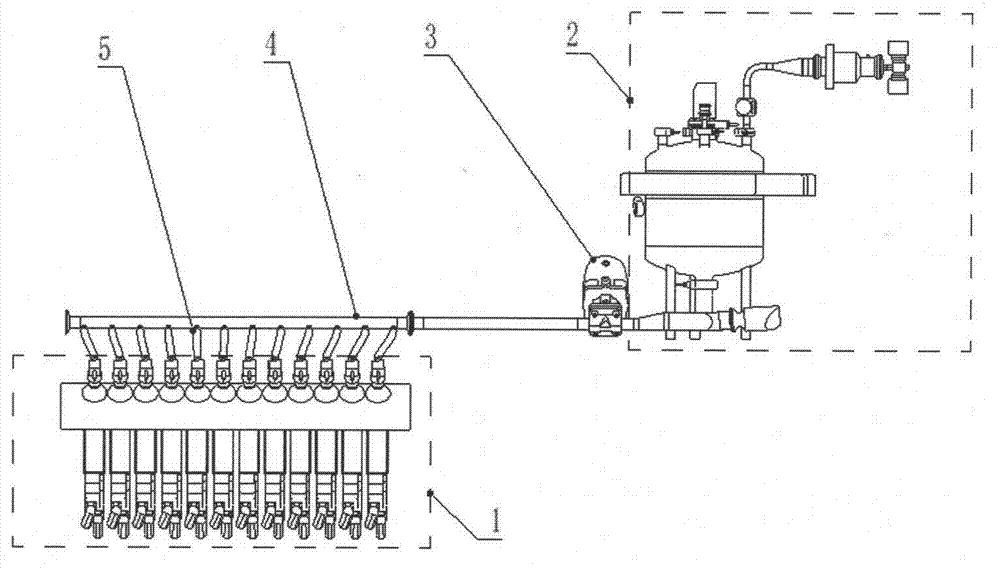

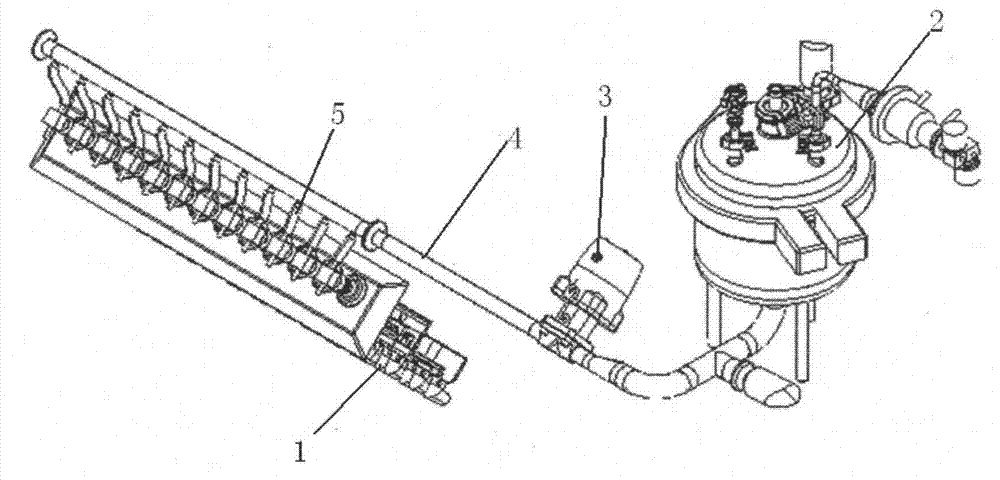

[0037] Such as figure 1 As shown, a filling system provided by the present invention includes a filling structure 1, a constant pressure device 2, a control valve 3, a distribution pipe 4 and a hose 5, the constant pressure device 2 is connected to the distribution pipe 4, and on the distribution pipe 4 A control valve 3 is provided, and the distribution pipe 4 is connected to different diaphragm valves 2-13 with metal diaphragms on the filling structure 1 through different hoses 5 . When the working conditions in the constant pressure device 2 meet the filling requirements, the control valve 3 is automatically opened to start filling.

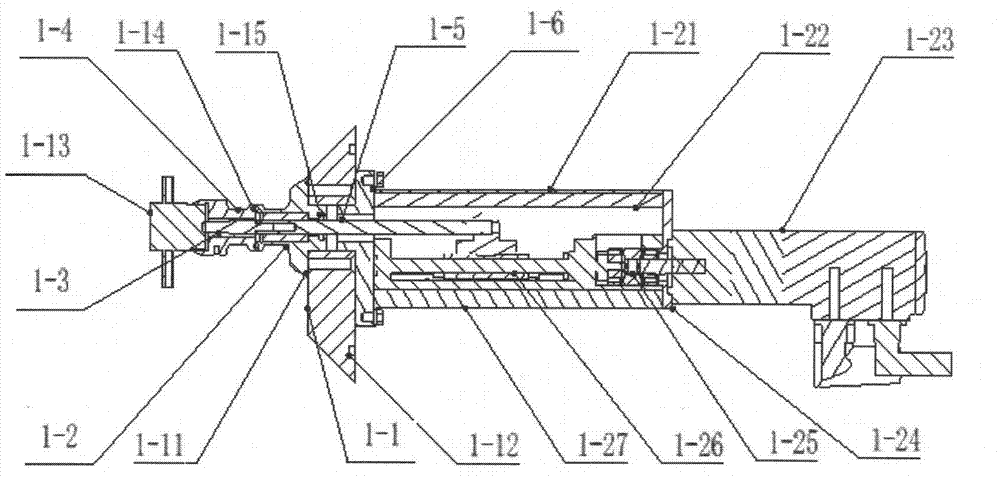

[0038] Such as image 3 As shown, in this embodiment, the filling structure includes a diaphragm valve 1-13 with a metal diaphragm. In this embodiment, the diaphragm valve 1-13 is a diaphragm va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com