Vacuum type roller scraping plate drying machine

A drum scraper drying and vacuum-type technology, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of low vacuum degree and inability to collect high-purity gas, and achieve improved vacuum degree and vacuum Guaranteed and reduced leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

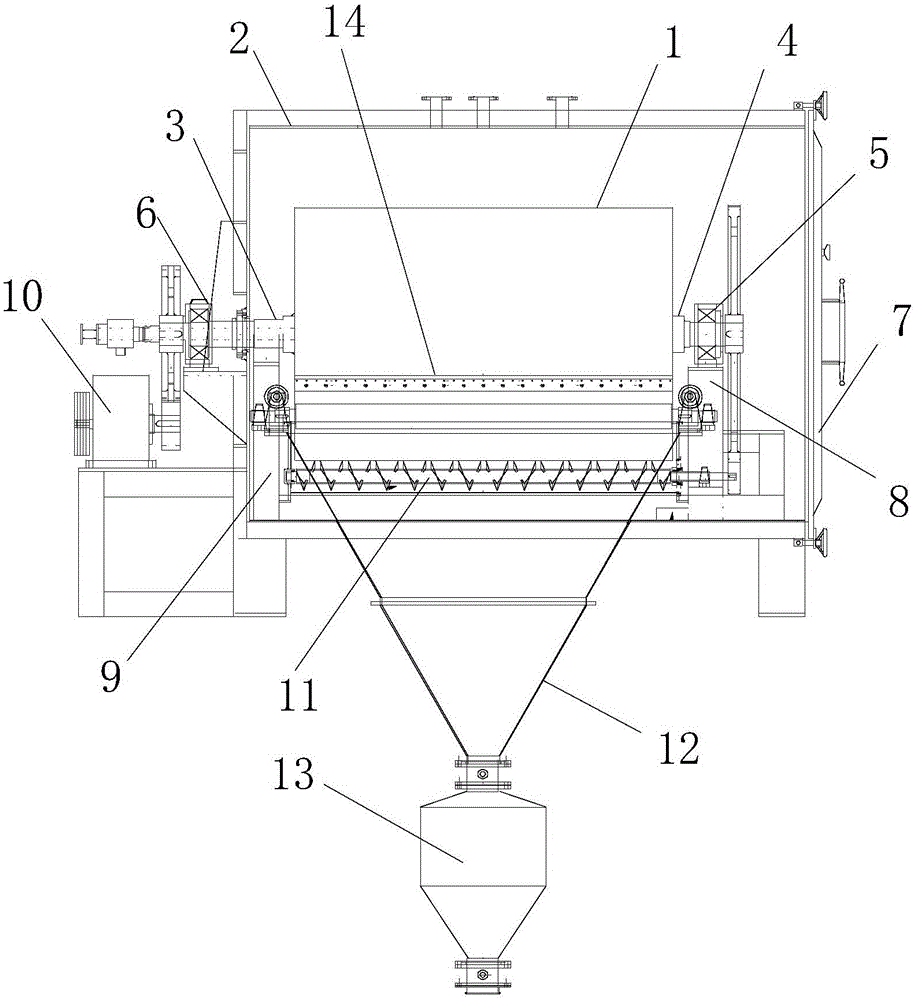

[0025] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0026] Such as figure 1 As shown, a vacuum drum scraper dryer includes a main cylinder body 1, a vacuum cylinder 2 is arranged on the outside of the main cylinder body 1, the main cylinder body 1 is rotated and installed in the vacuum cylinder 2, and the upper end of the vacuum cylinder 2 is provided with a At least one vacuum port; preferably three vacuum ports, one of which is used as a spare port.

[0027] One end of the main cylinder 1 is provided with a driving shaft 3, and the other end of the main cylinder 1 is provided with a driven shaft 4; For sealing, the driven rotating shaft 4 of the main cylinder body 1 is rotationally supported and arranged in the vacuum cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com